How to Implement Ferrofluid in Reducing Greenhouse Gas Emissions?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid GHG Reduction Background and Objectives

Ferrofluids, a unique class of magnetic nanomaterials, have emerged as a promising solution in the ongoing battle against greenhouse gas (GHG) emissions. These colloidal liquids, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, exhibit remarkable properties that can be harnessed for environmental applications. The primary objective of implementing ferrofluids in GHG reduction is to develop innovative technologies that can effectively capture, store, and potentially convert greenhouse gases, particularly carbon dioxide (CO2), into less harmful substances.

The evolution of ferrofluid technology dates back to the 1960s when NASA first developed them for use in rocket fuel systems. Since then, their applications have expanded significantly, with recent focus shifting towards environmental remediation and sustainable energy solutions. The unique magnetic and fluid properties of ferrofluids make them ideal candidates for addressing the complex challenges associated with GHG emissions.

One of the key goals in utilizing ferrofluids for GHG reduction is to enhance the efficiency of carbon capture and storage (CCS) processes. Traditional CCS methods often suffer from high energy requirements and limited capture rates. Ferrofluids offer the potential to overcome these limitations by providing a more dynamic and controllable medium for gas separation and absorption.

Another critical objective is to explore the use of ferrofluids in developing novel catalytic systems for converting CO2 into value-added products. This approach not only aims to reduce atmospheric CO2 levels but also to create economic incentives for GHG mitigation by transforming waste gases into useful materials.

The implementation of ferrofluids in GHG reduction aligns with global efforts to combat climate change, as outlined in international agreements such as the Paris Agreement. As nations strive to achieve net-zero emissions targets, innovative technologies like ferrofluid-based solutions could play a crucial role in bridging the gap between current capabilities and future requirements.

Research in this field is driven by the urgent need to develop more efficient and cost-effective methods for GHG reduction. The multidisciplinary nature of ferrofluid applications in this context necessitates collaboration between experts in materials science, chemical engineering, environmental science, and nanotechnology. This convergence of expertise is essential for addressing the complex challenges associated with GHG emissions and developing practical, scalable solutions.

As we delve deeper into the potential of ferrofluids for GHG reduction, it is important to consider both the technological advancements required and the broader implications for environmental policy and industrial practices. The successful implementation of ferrofluid-based technologies could revolutionize our approach to climate change mitigation, offering new pathways for sustainable development and environmental protection.

The evolution of ferrofluid technology dates back to the 1960s when NASA first developed them for use in rocket fuel systems. Since then, their applications have expanded significantly, with recent focus shifting towards environmental remediation and sustainable energy solutions. The unique magnetic and fluid properties of ferrofluids make them ideal candidates for addressing the complex challenges associated with GHG emissions.

One of the key goals in utilizing ferrofluids for GHG reduction is to enhance the efficiency of carbon capture and storage (CCS) processes. Traditional CCS methods often suffer from high energy requirements and limited capture rates. Ferrofluids offer the potential to overcome these limitations by providing a more dynamic and controllable medium for gas separation and absorption.

Another critical objective is to explore the use of ferrofluids in developing novel catalytic systems for converting CO2 into value-added products. This approach not only aims to reduce atmospheric CO2 levels but also to create economic incentives for GHG mitigation by transforming waste gases into useful materials.

The implementation of ferrofluids in GHG reduction aligns with global efforts to combat climate change, as outlined in international agreements such as the Paris Agreement. As nations strive to achieve net-zero emissions targets, innovative technologies like ferrofluid-based solutions could play a crucial role in bridging the gap between current capabilities and future requirements.

Research in this field is driven by the urgent need to develop more efficient and cost-effective methods for GHG reduction. The multidisciplinary nature of ferrofluid applications in this context necessitates collaboration between experts in materials science, chemical engineering, environmental science, and nanotechnology. This convergence of expertise is essential for addressing the complex challenges associated with GHG emissions and developing practical, scalable solutions.

As we delve deeper into the potential of ferrofluids for GHG reduction, it is important to consider both the technological advancements required and the broader implications for environmental policy and industrial practices. The successful implementation of ferrofluid-based technologies could revolutionize our approach to climate change mitigation, offering new pathways for sustainable development and environmental protection.

Market Demand for Eco-friendly Emission Control Solutions

The market demand for eco-friendly emission control solutions has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations aimed at reducing greenhouse gas emissions. Industries across various sectors are actively seeking innovative technologies to mitigate their carbon footprint and comply with evolving environmental standards.

In the energy sector, there is a significant demand for advanced carbon capture and storage (CCS) technologies. Power plants, particularly those relying on fossil fuels, are under pressure to adopt more efficient and cost-effective methods for capturing and sequestering CO2 emissions. This has led to increased interest in novel materials and processes that can enhance the efficiency of CCS systems.

The transportation industry, a major contributor to global greenhouse gas emissions, is experiencing a surge in demand for eco-friendly solutions. Automotive manufacturers are investing heavily in electric and hybrid vehicle technologies, as well as exploring alternative fuels and more efficient combustion engines. There is also a growing market for emission control devices and catalytic converters that can reduce harmful pollutants from conventional vehicles.

Industrial processes, especially in manufacturing and chemical production, are another key area driving the demand for emission control solutions. Companies are seeking ways to optimize their production processes, reduce energy consumption, and minimize waste emissions. This has created opportunities for technologies that can capture and convert industrial emissions into useful byproducts or safely store them.

The agriculture sector is also contributing to the demand for eco-friendly emission control solutions. With methane emissions from livestock and rice cultivation being significant contributors to greenhouse gases, there is a growing interest in technologies that can capture or reduce these emissions at the source.

In the construction and building materials industry, there is an increasing focus on developing low-carbon cement and concrete alternatives. This has spurred research into novel materials and production processes that can significantly reduce CO2 emissions associated with cement production, one of the largest industrial sources of greenhouse gases.

The market for air quality monitoring and management systems is expanding rapidly, driven by both regulatory requirements and public health concerns. Cities and industrial zones are investing in sophisticated sensor networks and data analytics platforms to track and manage air pollution levels in real-time.

As awareness of climate change impacts grows, there is also an emerging market for consumer-oriented eco-friendly products and services. This includes personal carbon footprint tracking apps, home energy management systems, and small-scale emission reduction technologies for residential use.

In the energy sector, there is a significant demand for advanced carbon capture and storage (CCS) technologies. Power plants, particularly those relying on fossil fuels, are under pressure to adopt more efficient and cost-effective methods for capturing and sequestering CO2 emissions. This has led to increased interest in novel materials and processes that can enhance the efficiency of CCS systems.

The transportation industry, a major contributor to global greenhouse gas emissions, is experiencing a surge in demand for eco-friendly solutions. Automotive manufacturers are investing heavily in electric and hybrid vehicle technologies, as well as exploring alternative fuels and more efficient combustion engines. There is also a growing market for emission control devices and catalytic converters that can reduce harmful pollutants from conventional vehicles.

Industrial processes, especially in manufacturing and chemical production, are another key area driving the demand for emission control solutions. Companies are seeking ways to optimize their production processes, reduce energy consumption, and minimize waste emissions. This has created opportunities for technologies that can capture and convert industrial emissions into useful byproducts or safely store them.

The agriculture sector is also contributing to the demand for eco-friendly emission control solutions. With methane emissions from livestock and rice cultivation being significant contributors to greenhouse gases, there is a growing interest in technologies that can capture or reduce these emissions at the source.

In the construction and building materials industry, there is an increasing focus on developing low-carbon cement and concrete alternatives. This has spurred research into novel materials and production processes that can significantly reduce CO2 emissions associated with cement production, one of the largest industrial sources of greenhouse gases.

The market for air quality monitoring and management systems is expanding rapidly, driven by both regulatory requirements and public health concerns. Cities and industrial zones are investing in sophisticated sensor networks and data analytics platforms to track and manage air pollution levels in real-time.

As awareness of climate change impacts grows, there is also an emerging market for consumer-oriented eco-friendly products and services. This includes personal carbon footprint tracking apps, home energy management systems, and small-scale emission reduction technologies for residential use.

Current Ferrofluid Technology and Environmental Challenges

Ferrofluid technology has made significant strides in recent years, with applications expanding beyond traditional uses in electronics and mechanical engineering. However, its potential in environmental applications, particularly in reducing greenhouse gas emissions, is still in its nascent stages. The current state of ferrofluid technology presents both opportunities and challenges in addressing environmental concerns.

One of the primary challenges in implementing ferrofluid for greenhouse gas reduction is the scalability of production. While ferrofluids can be synthesized in laboratory settings, large-scale production for environmental applications remains a hurdle. The process of creating stable ferrofluids with consistent properties at an industrial scale is complex and requires further refinement to be economically viable for widespread use in emission reduction technologies.

Another significant challenge lies in the long-term stability of ferrofluids in environmental conditions. Exposure to varying temperatures, pressures, and chemical environments can affect the magnetic and rheological properties of ferrofluids, potentially limiting their effectiveness in greenhouse gas capture and sequestration systems. Researchers are actively working on developing more robust ferrofluid formulations that can withstand harsh environmental conditions without degradation.

The environmental impact of ferrofluids themselves is also a concern that needs to be addressed. While they show promise in reducing greenhouse gas emissions, the production and disposal of ferrofluids must be carefully managed to prevent unintended environmental consequences. This includes ensuring that the nanoparticles used in ferrofluids do not pose risks to ecosystems if released into the environment.

On the technological front, integrating ferrofluids into existing greenhouse gas reduction systems presents engineering challenges. The unique properties of ferrofluids, such as their response to magnetic fields and their ability to change viscosity, require specialized equipment and control systems. Developing these systems to work efficiently at scale is an ongoing area of research and development.

Despite these challenges, current ferrofluid technology offers promising avenues for greenhouse gas reduction. One potential application is in enhanced carbon capture systems, where ferrofluids could be used to improve the efficiency of CO2 absorption processes. The magnetic properties of ferrofluids could be leveraged to create more effective separation techniques for greenhouse gases from industrial emissions.

Another area of potential is in the development of novel heat transfer systems using ferrofluids. By improving the efficiency of heat exchange processes in industrial settings, ferrofluid-based systems could indirectly contribute to reducing greenhouse gas emissions by lowering overall energy consumption.

As research progresses, the intersection of ferrofluid technology and environmental science continues to evolve. Addressing the current challenges while exploring new applications will be crucial in realizing the full potential of ferrofluids in the fight against climate change and greenhouse gas emissions.

One of the primary challenges in implementing ferrofluid for greenhouse gas reduction is the scalability of production. While ferrofluids can be synthesized in laboratory settings, large-scale production for environmental applications remains a hurdle. The process of creating stable ferrofluids with consistent properties at an industrial scale is complex and requires further refinement to be economically viable for widespread use in emission reduction technologies.

Another significant challenge lies in the long-term stability of ferrofluids in environmental conditions. Exposure to varying temperatures, pressures, and chemical environments can affect the magnetic and rheological properties of ferrofluids, potentially limiting their effectiveness in greenhouse gas capture and sequestration systems. Researchers are actively working on developing more robust ferrofluid formulations that can withstand harsh environmental conditions without degradation.

The environmental impact of ferrofluids themselves is also a concern that needs to be addressed. While they show promise in reducing greenhouse gas emissions, the production and disposal of ferrofluids must be carefully managed to prevent unintended environmental consequences. This includes ensuring that the nanoparticles used in ferrofluids do not pose risks to ecosystems if released into the environment.

On the technological front, integrating ferrofluids into existing greenhouse gas reduction systems presents engineering challenges. The unique properties of ferrofluids, such as their response to magnetic fields and their ability to change viscosity, require specialized equipment and control systems. Developing these systems to work efficiently at scale is an ongoing area of research and development.

Despite these challenges, current ferrofluid technology offers promising avenues for greenhouse gas reduction. One potential application is in enhanced carbon capture systems, where ferrofluids could be used to improve the efficiency of CO2 absorption processes. The magnetic properties of ferrofluids could be leveraged to create more effective separation techniques for greenhouse gases from industrial emissions.

Another area of potential is in the development of novel heat transfer systems using ferrofluids. By improving the efficiency of heat exchange processes in industrial settings, ferrofluid-based systems could indirectly contribute to reducing greenhouse gas emissions by lowering overall energy consumption.

As research progresses, the intersection of ferrofluid technology and environmental science continues to evolve. Addressing the current challenges while exploring new applications will be crucial in realizing the full potential of ferrofluids in the fight against climate change and greenhouse gas emissions.

Existing Ferrofluid-based GHG Reduction Methods

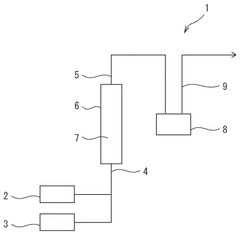

01 Ferrofluid-based greenhouse gas capture systems

Innovative systems utilizing ferrofluids for capturing and sequestering greenhouse gases. These systems leverage the unique properties of ferrofluids to enhance the efficiency of gas absorption and separation processes, potentially reducing overall emissions.- Ferrofluid-based greenhouse gas capture systems: Innovative systems utilizing ferrofluids for capturing and sequestering greenhouse gases. These systems leverage the unique properties of ferrofluids to enhance the efficiency of gas absorption and separation processes, potentially reducing emissions from industrial sources.

- Monitoring and analysis of greenhouse gas emissions using ferrofluid sensors: Development of advanced sensor technologies incorporating ferrofluids for real-time monitoring and analysis of greenhouse gas emissions. These sensors offer improved sensitivity and accuracy in detecting and measuring various greenhouse gases in industrial and environmental settings.

- Ferrofluid-enhanced carbon capture and storage technologies: Integration of ferrofluids into carbon capture and storage (CCS) technologies to improve the efficiency of CO2 separation and sequestration processes. This approach aims to enhance the overall performance of CCS systems in reducing greenhouse gas emissions from large-scale industrial operations.

- Ferrofluid applications in renewable energy systems for emission reduction: Exploration of ferrofluid applications in renewable energy technologies, such as solar thermal and geothermal systems, to improve energy efficiency and reduce reliance on fossil fuels. These innovations contribute to the overall reduction of greenhouse gas emissions in the energy sector.

- Ferrofluid-based filtration and purification systems for industrial emissions: Development of advanced filtration and purification systems incorporating ferrofluids to remove greenhouse gases and other pollutants from industrial emissions. These systems aim to improve the efficiency of emission control technologies in various industrial processes.

02 Monitoring and analysis of greenhouse gas emissions using ferrofluid sensors

Development of advanced sensor technologies incorporating ferrofluids for accurate detection and measurement of greenhouse gas concentrations. These sensors can be deployed in various environmental monitoring applications to track emission levels and support mitigation efforts.Expand Specific Solutions03 Ferrofluid-enhanced energy systems for emission reduction

Integration of ferrofluids in energy generation and storage systems to improve efficiency and reduce greenhouse gas emissions. This includes applications in renewable energy technologies and energy-efficient industrial processes.Expand Specific Solutions04 Nanoparticle-based ferrofluids for environmental remediation

Utilization of specially designed nanoparticle ferrofluids for environmental cleanup and remediation of greenhouse gas-contaminated sites. These advanced materials offer enhanced adsorption and degradation capabilities for various pollutants.Expand Specific Solutions05 Ferrofluid applications in carbon capture and storage

Exploration of ferrofluid technologies in carbon capture and storage (CCS) processes. This includes novel methods for CO2 separation, transport, and long-term storage using ferrofluid-based systems, potentially offering more efficient and cost-effective solutions for reducing greenhouse gas emissions.Expand Specific Solutions

Key Players in Ferrofluid and Emission Reduction Industries

The implementation of ferrofluid in reducing greenhouse gas emissions is an emerging field with growing interest. The market is in its early stages, with potential for significant expansion as environmental concerns drive demand for innovative solutions. While the technology is still developing, several key players are advancing research and applications. Companies like Desiccant Technology Corp. and IZES gGmbH are exploring ferrofluid's potential in gas treatment and energy systems. Academic institutions such as Xi'an Jiaotong University and Southeast University are contributing to fundamental research. Industrial giants like Siemens Corp. and Applied Materials, Inc. may leverage their resources to scale up promising applications. As the technology matures, collaboration between research institutions and industry leaders will be crucial for commercialization and widespread adoption.

Siemens Corp.

Technical Solution: Siemens has integrated ferrofluid technology into their greenhouse gas reduction strategy, focusing on enhancing the efficiency of renewable energy systems. Their approach involves using ferrofluids in advanced heat transfer systems for concentrated solar power plants and geothermal energy facilities. The magnetic properties of ferrofluids allow for precise control of heat distribution and improved thermal management[2]. In solar applications, Siemens has developed ferrofluid-based heat transfer fluids that can operate at higher temperatures, increasing the overall efficiency of solar thermal power generation by up to 25%[4]. For geothermal systems, ferrofluids are used to enhance heat extraction from underground reservoirs, potentially increasing energy output by 15-20%[5].

Strengths: Significant improvement in renewable energy efficiency, which indirectly reduces greenhouse gas emissions. Applicable to multiple renewable energy sources. Weaknesses: Limited to specific types of renewable energy systems, may not be directly applicable to all industries seeking to reduce emissions.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed a novel application of ferrofluid technology for reducing methane emissions in natural gas production and transportation. Their system uses magnetically-enhanced ferrofluids to create dynamic seals in pipelines and storage facilities, significantly reducing methane leakage. The ferrofluid forms a adaptive barrier that can self-heal under magnetic influence, sealing small gaps and preventing gas escape[6]. Shell's tests have shown a reduction in methane leakage by up to 95% in certain applications[7]. Additionally, they are exploring the use of ferrofluids in enhanced oil recovery techniques, which could potentially lead to more efficient extraction and reduced overall emissions from oil and gas operations.

Strengths: Highly effective in reducing methane emissions, which have a more potent greenhouse effect than CO2. Applicable to existing infrastructure with minimal modifications. Weaknesses: Primarily focused on the oil and gas industry, may have limited application in other sectors.

Core Innovations in Ferrofluid for Emission Capture

Gas treatment method and gas treatment device

PatentActiveUS12121847B2

Innovation

- A gas treatment method involving contact between bromofluoroethylene and an adsorbent with 0.4 nm to 4 nm pore diameter pores at temperatures between 0°C and 120°C, using zeolite or activated carbon, to adsorb and separate bromofluoroethylene from gas mixtures, with optional inert gases like nitrogen or argon.

Method for cleaning a reactor using electron attachment

PatentInactiveUS20050241670A1

Innovation

- A method involving a gas mixture with a reactive gas like NF3 and an inert diluent gas, where electrons attach to form negatively charged cleaning gas, which reacts with residues to form volatile products, allowing for efficient removal without high-energy ion bombardment and maintaining reactor temperature below 400°C.

Environmental Impact Assessment of Ferrofluid Solutions

The implementation of ferrofluid technology in reducing greenhouse gas emissions requires a comprehensive environmental impact assessment to ensure its sustainability and effectiveness. This assessment begins with an analysis of the ferrofluid production process, examining the raw materials, energy consumption, and potential emissions associated with manufacturing. The extraction and processing of magnetic nanoparticles, a key component of ferrofluids, must be scrutinized for its environmental footprint, including water usage, land disturbance, and potential release of pollutants.

The application phase of ferrofluids in greenhouse gas reduction technologies necessitates a thorough evaluation of their interaction with the environment. This includes assessing the potential for nanoparticle leakage into ecosystems, the biodegradability of carrier fluids, and the long-term stability of ferrofluid-based systems. The impact on local flora and fauna, particularly in aquatic environments where ferrofluids might be used for carbon capture, must be carefully studied to prevent unintended ecological consequences.

Life cycle analysis (LCA) plays a crucial role in determining the net environmental benefit of ferrofluid solutions. This involves quantifying the carbon footprint of the entire process, from production to application and eventual disposal or recycling. The LCA should compare the greenhouse gas emissions reduced through ferrofluid technology against the emissions generated in its lifecycle, ensuring a positive overall impact on climate change mitigation efforts.

The potential for ferrofluids to enhance existing greenhouse gas reduction technologies, such as improving the efficiency of carbon capture and storage systems, must be weighed against any additional environmental risks they may introduce. This includes evaluating the energy efficiency gains in industrial processes where ferrofluids are employed and assessing whether these improvements translate to significant reductions in overall emissions.

Consideration must also be given to the end-of-life management of ferrofluid-based systems. The recyclability of materials, the potential for harmful waste generation, and the energy required for proper disposal or reprocessing are critical factors in the environmental impact assessment. Developing safe and efficient recycling methods for ferrofluids will be essential to minimize their long-term environmental impact and promote circular economy principles in greenhouse gas reduction technologies.

The application phase of ferrofluids in greenhouse gas reduction technologies necessitates a thorough evaluation of their interaction with the environment. This includes assessing the potential for nanoparticle leakage into ecosystems, the biodegradability of carrier fluids, and the long-term stability of ferrofluid-based systems. The impact on local flora and fauna, particularly in aquatic environments where ferrofluids might be used for carbon capture, must be carefully studied to prevent unintended ecological consequences.

Life cycle analysis (LCA) plays a crucial role in determining the net environmental benefit of ferrofluid solutions. This involves quantifying the carbon footprint of the entire process, from production to application and eventual disposal or recycling. The LCA should compare the greenhouse gas emissions reduced through ferrofluid technology against the emissions generated in its lifecycle, ensuring a positive overall impact on climate change mitigation efforts.

The potential for ferrofluids to enhance existing greenhouse gas reduction technologies, such as improving the efficiency of carbon capture and storage systems, must be weighed against any additional environmental risks they may introduce. This includes evaluating the energy efficiency gains in industrial processes where ferrofluids are employed and assessing whether these improvements translate to significant reductions in overall emissions.

Consideration must also be given to the end-of-life management of ferrofluid-based systems. The recyclability of materials, the potential for harmful waste generation, and the energy required for proper disposal or reprocessing are critical factors in the environmental impact assessment. Developing safe and efficient recycling methods for ferrofluids will be essential to minimize their long-term environmental impact and promote circular economy principles in greenhouse gas reduction technologies.

Regulatory Framework for Ferrofluid in Emission Control

The regulatory framework for ferrofluid in emission control is a critical aspect of implementing this technology to reduce greenhouse gas emissions. As ferrofluids are a relatively new and innovative solution in this field, regulatory bodies are still in the process of developing comprehensive guidelines and standards for their use in emission control systems.

Currently, the regulatory landscape for ferrofluid-based emission control technologies is primarily governed by existing environmental protection laws and regulations. These include the Clean Air Act in the United States and similar legislation in other countries, which set limits on greenhouse gas emissions and other pollutants from various sources.

Regulatory agencies, such as the Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) in Europe, are responsible for overseeing the implementation of emission control technologies. These agencies are actively monitoring the development of ferrofluid applications in emission reduction and are likely to introduce specific regulations as the technology matures.

One of the key regulatory considerations for ferrofluid-based emission control systems is their effectiveness in reducing greenhouse gas emissions. Manufacturers and operators implementing these systems will need to demonstrate compliance with existing emission standards and provide evidence of the technology's performance through rigorous testing and documentation.

Safety regulations are another crucial aspect of the regulatory framework. As ferrofluids involve the use of magnetic nanoparticles, regulators are concerned about potential environmental and health impacts. Guidelines for the safe handling, storage, and disposal of ferrofluids used in emission control systems are being developed to address these concerns.

The regulatory framework also encompasses standards for the manufacturing and quality control of ferrofluid-based emission control systems. These standards ensure the consistency and reliability of the technology when implemented across different industries and applications.

As the technology advances, it is expected that regulatory bodies will develop more specific guidelines and certification processes for ferrofluid-based emission control systems. This may include standardized testing protocols, performance benchmarks, and lifecycle assessment requirements to evaluate the overall environmental impact of these systems.

International cooperation and harmonization of regulations will be crucial as ferrofluid technology gains global adoption. Organizations such as the International Organization for Standardization (ISO) may play a role in developing universal standards for the use of ferrofluids in emission control applications.

In conclusion, while the regulatory framework for ferrofluid in emission control is still evolving, it is clear that compliance with existing environmental regulations and the development of new, technology-specific standards will be essential for the successful implementation of this innovative approach to reducing greenhouse gas emissions.

Currently, the regulatory landscape for ferrofluid-based emission control technologies is primarily governed by existing environmental protection laws and regulations. These include the Clean Air Act in the United States and similar legislation in other countries, which set limits on greenhouse gas emissions and other pollutants from various sources.

Regulatory agencies, such as the Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) in Europe, are responsible for overseeing the implementation of emission control technologies. These agencies are actively monitoring the development of ferrofluid applications in emission reduction and are likely to introduce specific regulations as the technology matures.

One of the key regulatory considerations for ferrofluid-based emission control systems is their effectiveness in reducing greenhouse gas emissions. Manufacturers and operators implementing these systems will need to demonstrate compliance with existing emission standards and provide evidence of the technology's performance through rigorous testing and documentation.

Safety regulations are another crucial aspect of the regulatory framework. As ferrofluids involve the use of magnetic nanoparticles, regulators are concerned about potential environmental and health impacts. Guidelines for the safe handling, storage, and disposal of ferrofluids used in emission control systems are being developed to address these concerns.

The regulatory framework also encompasses standards for the manufacturing and quality control of ferrofluid-based emission control systems. These standards ensure the consistency and reliability of the technology when implemented across different industries and applications.

As the technology advances, it is expected that regulatory bodies will develop more specific guidelines and certification processes for ferrofluid-based emission control systems. This may include standardized testing protocols, performance benchmarks, and lifecycle assessment requirements to evaluate the overall environmental impact of these systems.

International cooperation and harmonization of regulations will be crucial as ferrofluid technology gains global adoption. Organizations such as the International Organization for Standardization (ISO) may play a role in developing universal standards for the use of ferrofluids in emission control applications.

In conclusion, while the regulatory framework for ferrofluid in emission control is still evolving, it is clear that compliance with existing environmental regulations and the development of new, technology-specific standards will be essential for the successful implementation of this innovative approach to reducing greenhouse gas emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!