How to Implement Ferrofluid in Reducing Power Consumption in Electronics?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel manipulation in zero gravity, ferrofluids have found diverse applications across various industries. The journey of ferrofluid technology in electronics began with its use in sealing and cooling systems for hard disk drives, demonstrating its potential for thermal management.

The progression of ferrofluid technology has been marked by advancements in nanoparticle synthesis, carrier fluid optimization, and surface modification techniques. These improvements have led to enhanced stability, magnetic responsiveness, and thermal conductivity of ferrofluids. The miniaturization trend in electronics has further propelled research into ferrofluid applications for efficient heat dissipation in compact devices.

Recent years have witnessed a growing interest in leveraging ferrofluids for power consumption reduction in electronic systems. This shift in focus aligns with the global push for energy-efficient technologies and sustainable computing. Researchers are exploring novel ways to integrate ferrofluids into cooling systems, aiming to minimize energy requirements for thermal management in electronic devices.

The primary objective of implementing ferrofluid technology in electronics is to achieve significant reductions in power consumption without compromising performance. This goal encompasses several key aspects, including enhancing heat transfer efficiency, developing adaptive cooling mechanisms, and creating self-regulating thermal management systems. By harnessing the unique properties of ferrofluids, such as their responsiveness to magnetic fields and high thermal conductivity, researchers aim to design innovative cooling solutions that can dynamically adjust to varying heat loads.

Another crucial objective is to overcome the limitations of conventional cooling methods, particularly in high-performance computing and data center environments. Ferrofluid-based cooling systems have the potential to address hotspot issues more effectively, leading to more uniform temperature distribution and reduced overall power consumption for cooling.

The long-term vision for ferrofluid technology in electronics extends beyond mere cooling applications. Researchers are exploring the possibility of integrating ferrofluids into electronic components themselves, potentially revolutionizing circuit design and power management at the nanoscale. This ambitious goal could pave the way for a new generation of energy-efficient electronic devices with built-in, dynamically responsive thermal management capabilities.

As the technology continues to evolve, interdisciplinary collaboration between materials scientists, electrical engineers, and thermal management experts will be crucial. The objectives for future development include improving the long-term stability of ferrofluids in electronic environments, enhancing their compatibility with existing manufacturing processes, and developing standardized methods for integrating ferrofluid-based cooling systems into electronic devices.

The progression of ferrofluid technology has been marked by advancements in nanoparticle synthesis, carrier fluid optimization, and surface modification techniques. These improvements have led to enhanced stability, magnetic responsiveness, and thermal conductivity of ferrofluids. The miniaturization trend in electronics has further propelled research into ferrofluid applications for efficient heat dissipation in compact devices.

Recent years have witnessed a growing interest in leveraging ferrofluids for power consumption reduction in electronic systems. This shift in focus aligns with the global push for energy-efficient technologies and sustainable computing. Researchers are exploring novel ways to integrate ferrofluids into cooling systems, aiming to minimize energy requirements for thermal management in electronic devices.

The primary objective of implementing ferrofluid technology in electronics is to achieve significant reductions in power consumption without compromising performance. This goal encompasses several key aspects, including enhancing heat transfer efficiency, developing adaptive cooling mechanisms, and creating self-regulating thermal management systems. By harnessing the unique properties of ferrofluids, such as their responsiveness to magnetic fields and high thermal conductivity, researchers aim to design innovative cooling solutions that can dynamically adjust to varying heat loads.

Another crucial objective is to overcome the limitations of conventional cooling methods, particularly in high-performance computing and data center environments. Ferrofluid-based cooling systems have the potential to address hotspot issues more effectively, leading to more uniform temperature distribution and reduced overall power consumption for cooling.

The long-term vision for ferrofluid technology in electronics extends beyond mere cooling applications. Researchers are exploring the possibility of integrating ferrofluids into electronic components themselves, potentially revolutionizing circuit design and power management at the nanoscale. This ambitious goal could pave the way for a new generation of energy-efficient electronic devices with built-in, dynamically responsive thermal management capabilities.

As the technology continues to evolve, interdisciplinary collaboration between materials scientists, electrical engineers, and thermal management experts will be crucial. The objectives for future development include improving the long-term stability of ferrofluids in electronic environments, enhancing their compatibility with existing manufacturing processes, and developing standardized methods for integrating ferrofluid-based cooling systems into electronic devices.

Market Demand for Energy-Efficient Electronics

The demand for energy-efficient electronics has been steadily increasing in recent years, driven by several key factors. Consumers are becoming more environmentally conscious and seeking products that minimize their carbon footprint. This shift in consumer behavior has led to a growing market for electronics that consume less power while maintaining or improving performance. Additionally, the proliferation of portable devices and the Internet of Things (IoT) has created a need for longer battery life and reduced energy consumption in a wide range of electronic products.

In the industrial sector, companies are increasingly focused on reducing operational costs and meeting stringent environmental regulations. This has resulted in a surge in demand for energy-efficient electronics in manufacturing processes, data centers, and industrial automation systems. The adoption of smart building technologies and energy management systems has further fueled the market for low-power electronic components and systems.

Government initiatives and regulations aimed at reducing energy consumption and greenhouse gas emissions have also played a significant role in shaping market demand. Many countries have implemented energy efficiency standards and labeling programs for electronic products, incentivizing manufacturers to develop and market more energy-efficient solutions.

The global market for energy-efficient electronics is experiencing robust growth. This trend is expected to continue as technological advancements enable further improvements in power efficiency. The market encompasses a wide range of products, including energy-efficient processors, power management integrated circuits, LED lighting, and smart home devices.

In the context of implementing ferrofluid technology to reduce power consumption in electronics, there is a potential market opportunity. Ferrofluids could be utilized in cooling systems for electronic devices, potentially offering more efficient heat dissipation compared to traditional methods. This could lead to reduced power consumption in cooling systems and improved overall energy efficiency of electronic devices.

However, the market demand for ferrofluid-based solutions in electronics is still emerging. While there is a clear need for more energy-efficient cooling solutions, the adoption of ferrofluid technology will depend on factors such as cost-effectiveness, reliability, and compatibility with existing electronic designs. As research and development in this area progress, it is likely that market demand will grow, particularly in high-performance computing, data centers, and other applications where thermal management is critical.

To capitalize on this potential market, companies developing ferrofluid-based solutions for electronics will need to demonstrate clear energy savings and performance improvements over existing technologies. They will also need to address any concerns regarding the long-term stability and safety of ferrofluids in electronic applications. As awareness of this technology grows and its benefits become more apparent, it is expected that market demand will increase, particularly among early adopters and industries with high energy consumption in their electronic systems.

In the industrial sector, companies are increasingly focused on reducing operational costs and meeting stringent environmental regulations. This has resulted in a surge in demand for energy-efficient electronics in manufacturing processes, data centers, and industrial automation systems. The adoption of smart building technologies and energy management systems has further fueled the market for low-power electronic components and systems.

Government initiatives and regulations aimed at reducing energy consumption and greenhouse gas emissions have also played a significant role in shaping market demand. Many countries have implemented energy efficiency standards and labeling programs for electronic products, incentivizing manufacturers to develop and market more energy-efficient solutions.

The global market for energy-efficient electronics is experiencing robust growth. This trend is expected to continue as technological advancements enable further improvements in power efficiency. The market encompasses a wide range of products, including energy-efficient processors, power management integrated circuits, LED lighting, and smart home devices.

In the context of implementing ferrofluid technology to reduce power consumption in electronics, there is a potential market opportunity. Ferrofluids could be utilized in cooling systems for electronic devices, potentially offering more efficient heat dissipation compared to traditional methods. This could lead to reduced power consumption in cooling systems and improved overall energy efficiency of electronic devices.

However, the market demand for ferrofluid-based solutions in electronics is still emerging. While there is a clear need for more energy-efficient cooling solutions, the adoption of ferrofluid technology will depend on factors such as cost-effectiveness, reliability, and compatibility with existing electronic designs. As research and development in this area progress, it is likely that market demand will grow, particularly in high-performance computing, data centers, and other applications where thermal management is critical.

To capitalize on this potential market, companies developing ferrofluid-based solutions for electronics will need to demonstrate clear energy savings and performance improvements over existing technologies. They will also need to address any concerns regarding the long-term stability and safety of ferrofluids in electronic applications. As awareness of this technology grows and its benefits become more apparent, it is expected that market demand will increase, particularly among early adopters and industries with high energy consumption in their electronic systems.

Current Challenges in Ferrofluid-Based Cooling

The implementation of ferrofluid-based cooling systems in electronics faces several significant challenges that hinder widespread adoption. One of the primary obstacles is the complexity of designing and manufacturing suitable containment systems for ferrofluids. These magnetic liquids require specialized enclosures that can withstand their unique properties while allowing for efficient heat transfer. The development of such containment systems often involves intricate engineering and costly materials, making large-scale production challenging.

Another major hurdle is the long-term stability of ferrofluids in electronic cooling applications. Over time, ferrofluids may experience degradation due to exposure to heat, magnetic fields, and other environmental factors. This degradation can lead to reduced cooling efficiency and potential system failures. Researchers are still working on developing more stable ferrofluid formulations that can maintain their properties over extended periods under various operating conditions.

The integration of ferrofluid-based cooling systems with existing electronic components presents another significant challenge. Many current electronic designs are not optimized for ferrofluid cooling, requiring substantial redesigns of circuit boards, heat sinks, and other components. This integration process can be time-consuming and expensive, potentially offsetting the energy-saving benefits of ferrofluid cooling in the short term.

Controlling the behavior of ferrofluids in complex electronic systems is also a considerable challenge. The magnetic properties of ferrofluids can be affected by the electromagnetic fields generated by electronic components, potentially leading to unpredictable fluid dynamics and reduced cooling efficiency. Developing robust control systems that can manage these interactions and maintain optimal cooling performance is an ongoing area of research.

Furthermore, the scalability of ferrofluid-based cooling solutions remains a significant concern. While promising results have been demonstrated in laboratory settings and small-scale applications, scaling up these systems for use in larger electronic devices or data centers presents numerous engineering challenges. Issues such as uniform heat distribution, magnetic field management, and system reliability become more complex as the scale of implementation increases.

Lastly, there are environmental and safety concerns associated with the use of ferrofluids in electronic cooling. The potential for leaks or spills of these magnetic liquids raises questions about their impact on the environment and human health. Addressing these concerns through the development of safer ferrofluid formulations and improved containment systems is crucial for the widespread adoption of this technology in consumer electronics and industrial applications.

Another major hurdle is the long-term stability of ferrofluids in electronic cooling applications. Over time, ferrofluids may experience degradation due to exposure to heat, magnetic fields, and other environmental factors. This degradation can lead to reduced cooling efficiency and potential system failures. Researchers are still working on developing more stable ferrofluid formulations that can maintain their properties over extended periods under various operating conditions.

The integration of ferrofluid-based cooling systems with existing electronic components presents another significant challenge. Many current electronic designs are not optimized for ferrofluid cooling, requiring substantial redesigns of circuit boards, heat sinks, and other components. This integration process can be time-consuming and expensive, potentially offsetting the energy-saving benefits of ferrofluid cooling in the short term.

Controlling the behavior of ferrofluids in complex electronic systems is also a considerable challenge. The magnetic properties of ferrofluids can be affected by the electromagnetic fields generated by electronic components, potentially leading to unpredictable fluid dynamics and reduced cooling efficiency. Developing robust control systems that can manage these interactions and maintain optimal cooling performance is an ongoing area of research.

Furthermore, the scalability of ferrofluid-based cooling solutions remains a significant concern. While promising results have been demonstrated in laboratory settings and small-scale applications, scaling up these systems for use in larger electronic devices or data centers presents numerous engineering challenges. Issues such as uniform heat distribution, magnetic field management, and system reliability become more complex as the scale of implementation increases.

Lastly, there are environmental and safety concerns associated with the use of ferrofluids in electronic cooling. The potential for leaks or spills of these magnetic liquids raises questions about their impact on the environment and human health. Addressing these concerns through the development of safer ferrofluid formulations and improved containment systems is crucial for the widespread adoption of this technology in consumer electronics and industrial applications.

Existing Ferrofluid Cooling Implementations

01 Ferrofluid-based power generation systems

Ferrofluids can be used in power generation systems, utilizing their unique magnetic properties to convert mechanical energy into electrical energy. These systems often involve the movement of ferrofluid in response to magnetic fields, which can be harnessed to generate power. This approach can be applied in various applications, including renewable energy and small-scale power generation.- Ferrofluid-based power generation systems: Ferrofluids can be used in power generation systems, utilizing their unique magnetic properties to convert mechanical energy into electrical energy. These systems often involve the movement of ferrofluid in response to magnetic fields, which can be harnessed to generate power. This approach can be applied in various applications, including renewable energy and small-scale power generation.

- Ferrofluid cooling and heat dissipation in electronic devices: Ferrofluids can be employed in cooling systems for electronic devices, improving heat dissipation and potentially reducing power consumption. By using magnetic fields to control the flow of ferrofluid, these systems can efficiently transfer heat away from critical components, allowing for better thermal management and potentially improved energy efficiency in electronic devices.

- Ferrofluid-based sealing and lubrication systems: Ferrofluids can be used in sealing and lubrication systems, potentially reducing friction and improving energy efficiency in various mechanical applications. These systems utilize the magnetic properties of ferrofluids to create dynamic seals or provide controlled lubrication, which can lead to reduced power consumption in rotating machinery and other mechanical systems.

- Ferrofluid-based sensors and control systems: Ferrofluids can be incorporated into sensors and control systems, potentially improving the efficiency and accuracy of various processes. These systems may use the magnetic properties of ferrofluids to detect changes in position, pressure, or other parameters, allowing for more precise control and potentially reducing power consumption in industrial and automotive applications.

- Ferrofluid-based energy harvesting devices: Ferrofluids can be used in energy harvesting devices that capture and convert ambient energy into usable electrical power. These devices may utilize the movement of ferrofluid in response to external vibrations or magnetic fields to generate small amounts of electricity, potentially providing power for low-energy applications or supplementing existing power sources.

02 Ferrofluid sealing and lubrication in power systems

Ferrofluids are employed in sealing and lubrication applications within power systems to reduce friction and improve efficiency. By using magnetic fields to control the ferrofluid, these systems can create dynamic seals and provide adaptive lubrication, potentially reducing power consumption and wear in rotating machinery and other mechanical components.Expand Specific Solutions03 Ferrofluid-based cooling and heat transfer systems

Ferrofluids can be utilized in cooling and heat transfer systems to improve thermal management in power-consuming devices. By manipulating the ferrofluid with magnetic fields, these systems can enhance heat dissipation and temperature control, potentially reducing overall power consumption in electronic devices and other heat-generating equipment.Expand Specific Solutions04 Ferrofluid-enhanced energy storage and power management

Ferrofluids can be incorporated into energy storage and power management systems to improve efficiency and performance. These applications may include ferrofluid-based capacitors, magnetic field energy storage, or adaptive power distribution systems that utilize the unique properties of ferrofluids to optimize energy use and reduce power consumption.Expand Specific Solutions05 Ferrofluid-based sensors and control systems for power optimization

Ferrofluids can be used in sensors and control systems to monitor and optimize power consumption in various applications. These systems may leverage the magnetic and fluid properties of ferrofluids to detect changes in pressure, temperature, or other parameters, allowing for more precise control and improved energy efficiency in power-consuming devices and processes.Expand Specific Solutions

Key Players in Ferrofluid Cooling Solutions

The implementation of ferrofluid in reducing power consumption in electronics is an emerging field with significant potential. The market is in its early growth stage, with increasing interest from both research institutions and industry players. While the market size is still relatively small, it is expected to expand rapidly as the technology matures and finds wider applications. Companies like Samsung Electronics, Apple, and IBM are investing in research and development, leveraging their expertise in electronics and nanotechnology. Smaller specialized firms such as Semiconductor Energy Laboratory and TDK Corp. are also making strides in ferrofluid applications. The technology is progressing from laboratory experiments to practical implementations, with several patents filed in recent years, indicating a growing technological maturity.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a ferrofluid-based cooling system for electronic devices, particularly smartphones and tablets. The system utilizes a ferrofluid composed of nanoparticles suspended in a carrier fluid, which can be manipulated by magnetic fields. When heat is generated by the device's components, the ferrofluid is directed to the hotspots through microchannels, efficiently dissipating heat and reducing power consumption. This technology allows for more effective thermal management, enabling devices to operate at higher performance levels without overheating[1][3]. Samsung's implementation includes a network of electromagnets strategically placed within the device to guide the ferrofluid flow, optimizing heat distribution and minimizing energy loss[2].

Strengths: Highly efficient heat dissipation, allows for thinner device designs, and enables higher performance without increased power consumption. Weaknesses: Complexity of implementation, potential for magnetic interference with other components, and higher manufacturing costs.

Apple, Inc.

Technical Solution: Apple has explored the use of ferrofluids in their electronic devices to enhance thermal management and reduce power consumption. Their approach involves integrating ferrofluid-filled heat pipes into the chassis of devices such as MacBooks and iPhones. The ferrofluid acts as a highly efficient heat transfer medium, rapidly moving heat away from critical components like processors and batteries. Apple's implementation uses a combination of passive and active magnetic fields to control the ferrofluid flow, adapting to varying thermal loads in real-time[4]. This system allows for more aggressive thermal throttling, reducing the need for energy-intensive cooling fans and enabling longer battery life[5]. Additionally, Apple has investigated the use of ferrofluid-based nanogenerators to harvest waste heat and convert it back into usable electricity, further improving overall energy efficiency[6].

Strengths: Adaptive thermal management, potential for energy harvesting, and improved device longevity. Weaknesses: Increased production complexity, potential for long-term reliability issues with ferrofluid degradation, and challenges in scaling for larger devices.

Innovative Ferrofluid Cooling Techniques

Cooling composition for powertrain of electric vehicles

PatentWO2025061695A1

Innovation

- A ferrofluid comprising a liquid carrier, ferromagnetic particles, and a dispersant is used for direct contact cooling of powertrain elements in electric vehicles, enhancing heat extraction through the application of a magnetic field.

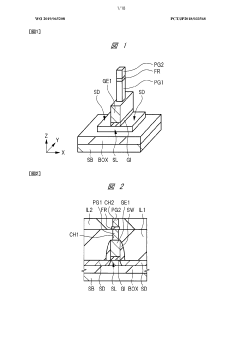

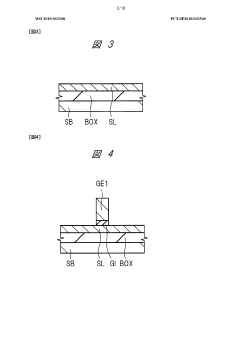

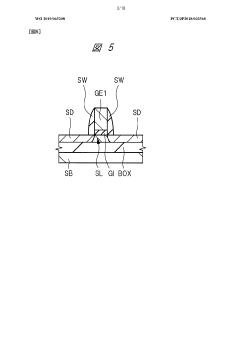

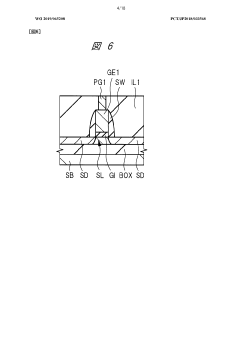

Semiconductor device

PatentWO2019065208A1

Innovation

- A semiconductor device design that incorporates a ferroelectric film interposed between plugs constituting the gate plug, allowing for a reduced effective residual polarization value and a negative capacitance state, thereby reducing the S factor below 60 mV/decade and enhancing the steepness of the drain current rise.

Environmental Impact of Ferrofluid Cooling

The implementation of ferrofluid cooling in electronics presents a promising avenue for reducing power consumption while also considering environmental impacts. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique thermal management properties that can significantly enhance heat dissipation in electronic devices. This improved cooling efficiency directly translates to reduced power consumption, as less energy is wasted as heat.

From an environmental perspective, the use of ferrofluid cooling systems can lead to several positive outcomes. Firstly, the increased efficiency in heat dissipation allows for the development of more compact electronic devices, potentially reducing the overall material usage in manufacturing. This reduction in material consumption can lead to decreased resource extraction and associated environmental impacts.

Furthermore, the improved thermal management capabilities of ferrofluids may extend the lifespan of electronic components. By maintaining optimal operating temperatures, the degradation of sensitive electronic parts is slowed, potentially reducing electronic waste generation. This longevity factor aligns well with sustainability goals and circular economy principles.

However, it is crucial to consider the potential environmental risks associated with ferrofluids. The nanoparticles used in ferrofluids, typically iron oxides, must be carefully managed to prevent their release into the environment. Proper containment and disposal protocols are essential to mitigate any potential ecological impacts. Additionally, the production of ferrofluids involves the synthesis of nanoparticles, which may have energy-intensive processes. It is important to assess the overall life cycle impact of ferrofluid production and use to ensure a net positive environmental outcome.

The recyclability of ferrofluid cooling systems is another important environmental consideration. While the magnetic properties of ferrofluids may facilitate their recovery and reuse, the separation of nanoparticles from the carrier fluid presents technical challenges. Developing efficient recycling methods for ferrofluids is crucial for minimizing waste and promoting a closed-loop system in electronic cooling applications.

In terms of energy savings, the implementation of ferrofluid cooling can lead to significant reductions in the power consumption of data centers and high-performance computing systems. These facilities are major contributors to global energy consumption, and any improvements in their cooling efficiency can have substantial environmental benefits. By reducing the energy demand for cooling, ferrofluid systems can indirectly lower greenhouse gas emissions associated with electricity generation.

From an environmental perspective, the use of ferrofluid cooling systems can lead to several positive outcomes. Firstly, the increased efficiency in heat dissipation allows for the development of more compact electronic devices, potentially reducing the overall material usage in manufacturing. This reduction in material consumption can lead to decreased resource extraction and associated environmental impacts.

Furthermore, the improved thermal management capabilities of ferrofluids may extend the lifespan of electronic components. By maintaining optimal operating temperatures, the degradation of sensitive electronic parts is slowed, potentially reducing electronic waste generation. This longevity factor aligns well with sustainability goals and circular economy principles.

However, it is crucial to consider the potential environmental risks associated with ferrofluids. The nanoparticles used in ferrofluids, typically iron oxides, must be carefully managed to prevent their release into the environment. Proper containment and disposal protocols are essential to mitigate any potential ecological impacts. Additionally, the production of ferrofluids involves the synthesis of nanoparticles, which may have energy-intensive processes. It is important to assess the overall life cycle impact of ferrofluid production and use to ensure a net positive environmental outcome.

The recyclability of ferrofluid cooling systems is another important environmental consideration. While the magnetic properties of ferrofluids may facilitate their recovery and reuse, the separation of nanoparticles from the carrier fluid presents technical challenges. Developing efficient recycling methods for ferrofluids is crucial for minimizing waste and promoting a closed-loop system in electronic cooling applications.

In terms of energy savings, the implementation of ferrofluid cooling can lead to significant reductions in the power consumption of data centers and high-performance computing systems. These facilities are major contributors to global energy consumption, and any improvements in their cooling efficiency can have substantial environmental benefits. By reducing the energy demand for cooling, ferrofluid systems can indirectly lower greenhouse gas emissions associated with electricity generation.

Thermal Management Standards and Regulations

The implementation of ferrofluid in reducing power consumption in electronics must adhere to various thermal management standards and regulations. These guidelines ensure the safety, reliability, and efficiency of electronic devices while promoting energy conservation. The International Electrotechnical Commission (IEC) has established several standards relevant to thermal management in electronics, including IEC 60068-2-14 for temperature cycling tests and IEC 60068-2-1 for cold temperature tests. These standards provide a framework for evaluating the thermal performance of electronic components and systems.

In the United States, the Environmental Protection Agency (EPA) has implemented the ENERGY STAR program, which sets energy efficiency standards for various electronic products. While not directly related to ferrofluid implementation, these standards drive the need for innovative thermal management solutions to reduce power consumption. The European Union's Ecodesign Directive (2009/125/EC) also plays a crucial role in setting energy efficiency requirements for electronic products, indirectly influencing thermal management strategies.

The Institute of Electrical and Electronics Engineers (IEEE) has developed standards specifically addressing thermal management in electronics. IEEE 1149.6 provides guidelines for testing and verifying the thermal characteristics of integrated circuits, while IEEE 1101.2 focuses on thermal management for modular electronic systems. These standards are essential for ensuring that ferrofluid-based cooling solutions meet industry requirements and can be effectively integrated into existing electronic designs.

The Telecommunications Industry Association (TIA) has established standards such as TIA-942, which includes thermal management guidelines for data centers. As ferrofluid technology may find applications in cooling data center equipment, compliance with these standards is crucial for widespread adoption. Similarly, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides thermal guidelines for data processing environments, which may influence the implementation of ferrofluid-based cooling systems in large-scale computing facilities.

Regulatory bodies such as the Federal Communications Commission (FCC) in the United States and the European Telecommunications Standards Institute (ETSI) in Europe have set electromagnetic compatibility (EMC) standards that indirectly impact thermal management solutions. Ferrofluid implementations must not interfere with the electronic device's EMC performance while effectively reducing power consumption through improved thermal management.

As the technology evolves, it is likely that new standards and regulations specific to ferrofluid-based thermal management solutions will emerge. Industry organizations and regulatory bodies will need to collaborate to develop guidelines that address the unique properties and applications of ferrofluids in electronic cooling. These future standards may cover aspects such as ferrofluid composition, long-term stability, and compatibility with various electronic materials and components.

In the United States, the Environmental Protection Agency (EPA) has implemented the ENERGY STAR program, which sets energy efficiency standards for various electronic products. While not directly related to ferrofluid implementation, these standards drive the need for innovative thermal management solutions to reduce power consumption. The European Union's Ecodesign Directive (2009/125/EC) also plays a crucial role in setting energy efficiency requirements for electronic products, indirectly influencing thermal management strategies.

The Institute of Electrical and Electronics Engineers (IEEE) has developed standards specifically addressing thermal management in electronics. IEEE 1149.6 provides guidelines for testing and verifying the thermal characteristics of integrated circuits, while IEEE 1101.2 focuses on thermal management for modular electronic systems. These standards are essential for ensuring that ferrofluid-based cooling solutions meet industry requirements and can be effectively integrated into existing electronic designs.

The Telecommunications Industry Association (TIA) has established standards such as TIA-942, which includes thermal management guidelines for data centers. As ferrofluid technology may find applications in cooling data center equipment, compliance with these standards is crucial for widespread adoption. Similarly, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides thermal guidelines for data processing environments, which may influence the implementation of ferrofluid-based cooling systems in large-scale computing facilities.

Regulatory bodies such as the Federal Communications Commission (FCC) in the United States and the European Telecommunications Standards Institute (ETSI) in Europe have set electromagnetic compatibility (EMC) standards that indirectly impact thermal management solutions. Ferrofluid implementations must not interfere with the electronic device's EMC performance while effectively reducing power consumption through improved thermal management.

As the technology evolves, it is likely that new standards and regulations specific to ferrofluid-based thermal management solutions will emerge. Industry organizations and regulatory bodies will need to collaborate to develop guidelines that address the unique properties and applications of ferrofluids in electronic cooling. These future standards may cover aspects such as ferrofluid composition, long-term stability, and compatibility with various electronic materials and components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!