How to Improve Vehicle Safety with Ferrofluid Technologies?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Safety Tech Evolution and Objectives

Ferrofluid technology has emerged as a promising avenue for enhancing vehicle safety, with its unique properties offering innovative solutions to longstanding challenges in automotive engineering. The evolution of ferrofluid applications in vehicle safety systems can be traced back to the early 2000s when researchers began exploring its potential for improving shock absorption and stability control.

The primary objective of integrating ferrofluid technologies into vehicle safety systems is to leverage its responsive nature to external magnetic fields and its ability to change viscosity rapidly. This adaptability allows for the development of more sophisticated and responsive safety mechanisms that can react in real-time to changing road conditions and potential hazards.

One of the key goals in this field is to create adaptive suspension systems that utilize ferrofluids to adjust damping characteristics instantaneously. This technology aims to enhance vehicle stability during sudden maneuvers, reduce body roll in corners, and improve overall ride comfort. The ability to fine-tune suspension performance on-the-fly represents a significant leap forward in vehicle dynamics and safety.

Another critical objective is the development of ferrofluid-based braking systems. These systems seek to improve braking efficiency and reduce stopping distances by utilizing the magnetorheological properties of ferrofluids. The vision is to create brake fluids that can change viscosity almost instantaneously when subjected to a magnetic field, allowing for more precise and responsive braking control.

Researchers are also exploring the potential of ferrofluids in impact absorption technologies. The goal is to design adaptive crumple zones that can alter their energy absorption properties based on the severity of an impending collision. This technology could revolutionize passive safety systems, providing tailored protection for occupants in various crash scenarios.

As the automotive industry moves towards autonomous vehicles, ferrofluid technologies are being investigated for their potential in enhancing the reliability and safety of self-driving systems. Objectives in this area include developing ferrofluid-based sensors for more accurate road condition assessment and improving the responsiveness of vehicle control systems in autonomous driving modes.

The evolution of ferrofluid safety technologies is closely tied to advancements in materials science and electromagnetic control systems. Future objectives include miniaturization of ferrofluid-based components, integration with AI-driven safety systems, and development of environmentally friendly ferrofluid formulations to align with sustainability goals in the automotive industry.

The primary objective of integrating ferrofluid technologies into vehicle safety systems is to leverage its responsive nature to external magnetic fields and its ability to change viscosity rapidly. This adaptability allows for the development of more sophisticated and responsive safety mechanisms that can react in real-time to changing road conditions and potential hazards.

One of the key goals in this field is to create adaptive suspension systems that utilize ferrofluids to adjust damping characteristics instantaneously. This technology aims to enhance vehicle stability during sudden maneuvers, reduce body roll in corners, and improve overall ride comfort. The ability to fine-tune suspension performance on-the-fly represents a significant leap forward in vehicle dynamics and safety.

Another critical objective is the development of ferrofluid-based braking systems. These systems seek to improve braking efficiency and reduce stopping distances by utilizing the magnetorheological properties of ferrofluids. The vision is to create brake fluids that can change viscosity almost instantaneously when subjected to a magnetic field, allowing for more precise and responsive braking control.

Researchers are also exploring the potential of ferrofluids in impact absorption technologies. The goal is to design adaptive crumple zones that can alter their energy absorption properties based on the severity of an impending collision. This technology could revolutionize passive safety systems, providing tailored protection for occupants in various crash scenarios.

As the automotive industry moves towards autonomous vehicles, ferrofluid technologies are being investigated for their potential in enhancing the reliability and safety of self-driving systems. Objectives in this area include developing ferrofluid-based sensors for more accurate road condition assessment and improving the responsiveness of vehicle control systems in autonomous driving modes.

The evolution of ferrofluid safety technologies is closely tied to advancements in materials science and electromagnetic control systems. Future objectives include miniaturization of ferrofluid-based components, integration with AI-driven safety systems, and development of environmentally friendly ferrofluid formulations to align with sustainability goals in the automotive industry.

Market Demand for Advanced Vehicle Safety Systems

The market demand for advanced vehicle safety systems has been steadily increasing in recent years, driven by a combination of regulatory pressures, consumer awareness, and technological advancements. As road safety remains a critical concern worldwide, automotive manufacturers and suppliers are continuously seeking innovative solutions to enhance vehicle safety features.

The global automotive safety system market is experiencing robust growth, with projections indicating significant expansion in the coming years. This growth is fueled by the rising adoption of advanced driver assistance systems (ADAS) and the increasing integration of safety technologies in mid-range and economy vehicles. Consumers are becoming more safety-conscious, prioritizing vehicles equipped with advanced safety features when making purchasing decisions.

One of the key drivers of market demand is the stringent safety regulations imposed by governments and regulatory bodies across the globe. These regulations mandate the incorporation of specific safety features in vehicles, such as airbags, anti-lock braking systems (ABS), and electronic stability control (ESC). As these regulations continue to evolve and become more stringent, the demand for advanced safety systems is expected to surge.

The automotive industry is witnessing a shift towards autonomous and connected vehicles, which is further propelling the demand for sophisticated safety systems. These vehicles require a complex array of sensors, cameras, and other safety technologies to ensure safe operation. As a result, there is a growing market for advanced safety features such as collision avoidance systems, lane departure warnings, and adaptive cruise control.

Emerging markets, particularly in Asia-Pacific and Latin America, are presenting significant opportunities for growth in the vehicle safety systems market. As disposable incomes rise and awareness of vehicle safety increases in these regions, there is a growing demand for vehicles equipped with advanced safety features.

The COVID-19 pandemic has had a mixed impact on the market for advanced vehicle safety systems. While it initially caused disruptions in the automotive supply chain and production, it has also heightened awareness of personal safety, potentially driving long-term demand for safer vehicles.

In the context of ferrofluid technologies, there is a growing interest in exploring their potential applications in vehicle safety systems. Ferrofluids, with their unique magnetic properties, could potentially be utilized in developing innovative safety solutions such as adaptive suspension systems, improved shock absorbers, or even in advanced sensor technologies for collision detection and avoidance.

As the automotive industry continues to evolve, the demand for advanced vehicle safety systems is expected to remain strong. Manufacturers and suppliers who can offer innovative, cost-effective safety solutions, potentially incorporating emerging technologies like ferrofluids, are likely to find significant market opportunities in this rapidly growing sector.

The global automotive safety system market is experiencing robust growth, with projections indicating significant expansion in the coming years. This growth is fueled by the rising adoption of advanced driver assistance systems (ADAS) and the increasing integration of safety technologies in mid-range and economy vehicles. Consumers are becoming more safety-conscious, prioritizing vehicles equipped with advanced safety features when making purchasing decisions.

One of the key drivers of market demand is the stringent safety regulations imposed by governments and regulatory bodies across the globe. These regulations mandate the incorporation of specific safety features in vehicles, such as airbags, anti-lock braking systems (ABS), and electronic stability control (ESC). As these regulations continue to evolve and become more stringent, the demand for advanced safety systems is expected to surge.

The automotive industry is witnessing a shift towards autonomous and connected vehicles, which is further propelling the demand for sophisticated safety systems. These vehicles require a complex array of sensors, cameras, and other safety technologies to ensure safe operation. As a result, there is a growing market for advanced safety features such as collision avoidance systems, lane departure warnings, and adaptive cruise control.

Emerging markets, particularly in Asia-Pacific and Latin America, are presenting significant opportunities for growth in the vehicle safety systems market. As disposable incomes rise and awareness of vehicle safety increases in these regions, there is a growing demand for vehicles equipped with advanced safety features.

The COVID-19 pandemic has had a mixed impact on the market for advanced vehicle safety systems. While it initially caused disruptions in the automotive supply chain and production, it has also heightened awareness of personal safety, potentially driving long-term demand for safer vehicles.

In the context of ferrofluid technologies, there is a growing interest in exploring their potential applications in vehicle safety systems. Ferrofluids, with their unique magnetic properties, could potentially be utilized in developing innovative safety solutions such as adaptive suspension systems, improved shock absorbers, or even in advanced sensor technologies for collision detection and avoidance.

As the automotive industry continues to evolve, the demand for advanced vehicle safety systems is expected to remain strong. Manufacturers and suppliers who can offer innovative, cost-effective safety solutions, potentially incorporating emerging technologies like ferrofluids, are likely to find significant market opportunities in this rapidly growing sector.

Current Ferrofluid Applications in Automotive Safety

Ferrofluids, a unique class of magnetic nanomaterials, have found their way into various automotive safety applications, showcasing their potential to enhance vehicle safety. One of the primary areas where ferrofluids are currently being utilized is in advanced shock absorber systems. These systems leverage the magnetic properties of ferrofluids to provide adaptive damping, allowing for real-time adjustments to road conditions and driving styles. By altering the viscosity of the ferrofluid in response to magnetic fields, these shock absorbers can offer improved vehicle stability, reduced body roll during cornering, and enhanced overall ride comfort.

Another significant application of ferrofluids in automotive safety is in brake systems. Ferrofluid-based brake fluids are being developed to improve braking performance and reliability. These fluids can change their viscosity rapidly when exposed to magnetic fields, potentially reducing brake fade and improving overall braking efficiency. This technology is particularly promising for high-performance vehicles and in extreme driving conditions where traditional brake fluids may fall short.

Ferrofluids are also being explored for use in tire pressure monitoring systems. By incorporating ferrofluid-based sensors within tires, it's possible to create more accurate and responsive pressure monitoring systems. These sensors can provide real-time data on tire pressure and temperature, allowing for early detection of potential issues and improving overall vehicle safety.

In the realm of occupant safety, ferrofluids are being investigated for use in advanced airbag systems. The rapid response of ferrofluids to magnetic fields could potentially be harnessed to create more precisely controlled airbag deployments, adapting to the specific characteristics of a crash and the occupant's position. This could lead to more effective protection in various collision scenarios.

Ferrofluid technology is also finding applications in vehicle sealing systems. Magnetic seals using ferrofluids can provide superior protection against dust, water, and other contaminants in critical vehicle components. This improved sealing can enhance the longevity and reliability of various vehicle systems, indirectly contributing to overall safety by reducing the risk of component failure.

Lastly, ferrofluids are being explored for use in energy-absorbing structures within vehicles. By incorporating ferrofluid-filled chambers into crumple zones, researchers are investigating ways to enhance energy dissipation during collisions. The unique properties of ferrofluids could potentially allow for more efficient and controlled energy absorption, leading to improved occupant protection in crash scenarios.

Another significant application of ferrofluids in automotive safety is in brake systems. Ferrofluid-based brake fluids are being developed to improve braking performance and reliability. These fluids can change their viscosity rapidly when exposed to magnetic fields, potentially reducing brake fade and improving overall braking efficiency. This technology is particularly promising for high-performance vehicles and in extreme driving conditions where traditional brake fluids may fall short.

Ferrofluids are also being explored for use in tire pressure monitoring systems. By incorporating ferrofluid-based sensors within tires, it's possible to create more accurate and responsive pressure monitoring systems. These sensors can provide real-time data on tire pressure and temperature, allowing for early detection of potential issues and improving overall vehicle safety.

In the realm of occupant safety, ferrofluids are being investigated for use in advanced airbag systems. The rapid response of ferrofluids to magnetic fields could potentially be harnessed to create more precisely controlled airbag deployments, adapting to the specific characteristics of a crash and the occupant's position. This could lead to more effective protection in various collision scenarios.

Ferrofluid technology is also finding applications in vehicle sealing systems. Magnetic seals using ferrofluids can provide superior protection against dust, water, and other contaminants in critical vehicle components. This improved sealing can enhance the longevity and reliability of various vehicle systems, indirectly contributing to overall safety by reducing the risk of component failure.

Lastly, ferrofluids are being explored for use in energy-absorbing structures within vehicles. By incorporating ferrofluid-filled chambers into crumple zones, researchers are investigating ways to enhance energy dissipation during collisions. The unique properties of ferrofluids could potentially allow for more efficient and controlled energy absorption, leading to improved occupant protection in crash scenarios.

Existing Ferrofluid Safety Implementations

01 Safety measures in ferrofluid sealing systems

Ferrofluid sealing systems are designed with safety features to prevent leakage and ensure proper containment of the ferrofluid. These systems often incorporate multiple sealing stages, pressure regulation mechanisms, and fail-safe designs to maintain integrity under various operating conditions. The safety measures aim to prevent contamination, minimize environmental risks, and protect equipment and personnel.- Safety measures in ferrofluid sealing systems: Ferrofluid sealing systems are designed with safety features to prevent leakage and ensure proper containment of the ferrofluid. These systems often incorporate multiple sealing stages, pressure regulation mechanisms, and backup seals to maintain integrity under various operating conditions. The design focuses on minimizing the risk of ferrofluid escape and contamination, ensuring safe operation in different applications.

- Environmental and health considerations in ferrofluid composition: The composition of ferrofluids is carefully formulated to minimize potential environmental and health risks. Manufacturers focus on using biocompatible and non-toxic materials for both the magnetic particles and carrier fluids. Research is ongoing to develop environmentally friendly ferrofluids that maintain performance while reducing potential hazards associated with their production, use, and disposal.

- Safety protocols in ferrofluid handling and storage: Proper handling and storage procedures are crucial for ensuring the safety of ferrofluid technologies. This includes guidelines for personal protective equipment, spill containment measures, and proper disposal methods. Training programs and safety protocols are implemented to educate personnel on the potential risks and appropriate handling techniques for ferrofluids in various industrial and research settings.

- Electromagnetic shielding and radiation safety: Ferrofluids are utilized in electromagnetic shielding applications to enhance safety in environments with high electromagnetic radiation. The magnetic properties of ferrofluids allow for effective absorption and redirection of electromagnetic waves, reducing potential health risks associated with exposure to high-frequency radiation in various industrial and medical settings.

- Thermal management and fire safety in ferrofluid applications: Ferrofluids play a role in enhancing thermal management and fire safety in various applications. Their unique properties allow for efficient heat transfer and dissipation, reducing the risk of overheating in electronic components and industrial machinery. Additionally, ferrofluid-based systems are being developed for fire suppression and containment, offering potential improvements in fire safety technologies.

02 Containment and handling of ferrofluids

Proper containment and handling procedures are crucial for ferrofluid safety. This includes using appropriate materials for storage containers, implementing spill prevention measures, and establishing protocols for safe transportation and disposal. Specialized equipment and training may be required for handling ferrofluids to minimize exposure risks and ensure environmental protection.Expand Specific Solutions03 Electromagnetic shielding and radiation safety

Ferrofluid technologies often involve electromagnetic fields, necessitating proper shielding and radiation safety measures. This includes designing systems to minimize electromagnetic emissions, implementing protective barriers, and monitoring exposure levels. Safety protocols may also involve regular equipment inspections and maintenance to ensure continued protection against potential radiation hazards.Expand Specific Solutions04 Thermal management and fire safety

Ferrofluid applications may involve high temperatures or heat generation, requiring effective thermal management strategies. This includes implementing cooling systems, using heat-resistant materials, and incorporating temperature monitoring devices. Fire safety measures, such as fire-resistant enclosures and automatic suppression systems, may also be necessary to mitigate potential risks associated with ferrofluid technologies.Expand Specific Solutions05 Environmental and health considerations

Ensuring the environmental and health safety of ferrofluid technologies involves assessing potential impacts on ecosystems and human health. This may include conducting toxicity studies, implementing filtration systems to prevent release of nanoparticles, and establishing guidelines for safe disposal. Regular monitoring and compliance with environmental regulations are essential to minimize potential risks associated with ferrofluid use and production.Expand Specific Solutions

Key Players in Ferrofluid-based Safety Solutions

The ferrofluid technologies for improving vehicle safety are in an early development stage, with a growing market potential as automotive safety becomes increasingly important. The technology's maturity is still evolving, with companies like NIPPON STEEL CORP., H-One Co., Ltd., and The Lubrizol Corp. leading research and development efforts. These firms are exploring applications in areas such as advanced shock absorption, adaptive suspension systems, and smart fluid-based safety mechanisms. As the technology progresses, it is expected to attract more attention from major automotive manufacturers and suppliers, potentially revolutionizing vehicle safety systems in the coming years.

West Virginia University Board of Governors

Technical Solution: Researchers at West Virginia University have developed an innovative ferrofluid-based technology aimed at improving vehicle safety through enhanced tire performance. Their system, called "MagnetoTread," incorporates ferrofluid-infused tire compounds that can be dynamically controlled by electromagnetic fields generated within the wheel assembly. This technology allows for real-time adjustment of tire characteristics such as tread stiffness and contact patch shape, optimizing traction and handling across various road conditions[13]. The MagnetoTread system uses an array of sensors to monitor road surface conditions, vehicle dynamics, and driver inputs, adjusting the ferrofluid properties accordingly. This results in improved grip during cornering, enhanced stability during emergency maneuvers, and potentially reduced stopping distances in adverse weather conditions[15]. Additionally, the researchers have explored the potential of this technology to reduce rolling resistance when high traction is not required, potentially improving fuel efficiency without compromising safety[17].

Strengths: Dynamic adaptation to road conditions, potential for significant improvements in vehicle handling and safety, and possible fuel efficiency benefits. Weaknesses: Complex integration with existing tire and wheel systems, potential durability concerns in long-term use.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed an innovative ferrofluid-based suspension system to enhance vehicle safety. This system utilizes magnetorheological fluids, which can change viscosity in response to magnetic fields. The suspension adapts in real-time to road conditions and driving dynamics, providing improved stability and handling[1]. BMW's system incorporates sensors that detect vehicle motion and road surface irregularities, adjusting the ferrofluid's viscosity within milliseconds to optimize damping characteristics. This results in reduced body roll during cornering, enhanced traction control, and improved overall ride comfort[3]. Additionally, BMW has integrated this technology with their active safety systems, allowing for more precise control in emergency maneuvers and potentially reducing the risk of accidents[5].

Strengths: Rapid response time, seamless integration with existing safety systems, and improved vehicle dynamics. Weaknesses: Potentially higher cost and complexity compared to traditional suspension systems, and the need for specialized maintenance.

Breakthrough Ferrofluid Safety Innovations

Fluids for enhanced gear protection

PatentInactiveUS8034754B2

Innovation

- A lubricant fluid composition comprising an acid phosphate as the primary antiwear component, a nitrogen-containing compound, and a sulfur-containing extreme pressure component, with a phosphorus to nitrogen weight ratio of greater than or equal to 1.0 and sulfur content of greater than or equal to 1.5 wt.%, specifically designed for driveline applications to reduce temperatures and enhance gear protection.

Composite Jacket System for Improved Safety

PatentPendingUS20250187299A1

Innovation

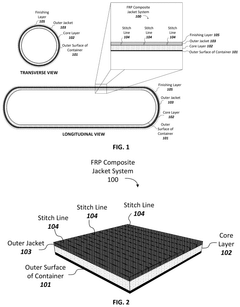

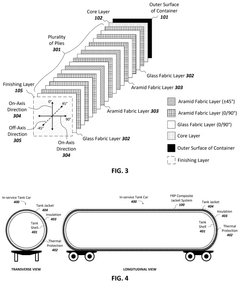

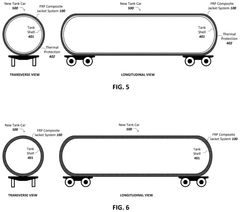

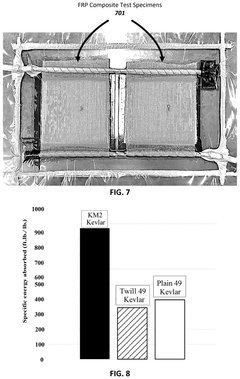

- A fiber-reinforced polymer (FRP) composite jacket system is applied to tank cars, comprising an outer surface, a core layer, and an outer jacket with aramid and glass fabric layers oriented in on-axis and off-axis directions, bonded with a thermosetting resin using vacuum-assisted resin transfer molding (VARTM).

Regulatory Framework for Automotive Safety Tech

The regulatory framework for automotive safety technology plays a crucial role in shaping the development and implementation of innovative safety solutions, including those involving ferrofluid technologies. In the United States, the National Highway Traffic Safety Administration (NHTSA) is the primary regulatory body responsible for establishing and enforcing vehicle safety standards. These standards, known as Federal Motor Vehicle Safety Standards (FMVSS), cover various aspects of vehicle design, performance, and equipment.

For ferrofluid technologies to be integrated into vehicle safety systems, they must comply with relevant FMVSS regulations. This includes standards related to crash avoidance, crashworthiness, and post-crash safety. The NHTSA also oversees the New Car Assessment Program (NCAP), which provides consumers with safety ratings for vehicles based on crash test performance and the presence of advanced safety technologies.

In the European Union, the regulatory landscape is governed by the European New Car Assessment Programme (Euro NCAP) and the United Nations Economic Commission for Europe (UNECE). These organizations set safety standards and conduct crash tests to evaluate vehicle safety performance. The EU also has specific regulations for type approval of vehicles, systems, and components, which would apply to any ferrofluid-based safety technologies.

Globally, the harmonization of vehicle safety regulations is an ongoing process through the World Forum for Harmonization of Vehicle Regulations (WP.29). This forum works to develop Global Technical Regulations (GTRs) that can be adopted by member countries, potentially streamlining the approval process for new safety technologies across different markets.

As ferrofluid technologies for vehicle safety are still emerging, regulatory bodies may need to develop new standards or adapt existing ones to accommodate these innovations. This process typically involves extensive testing, data collection, and collaboration between regulatory agencies, automotive manufacturers, and technology developers. The regulatory framework must balance the promotion of innovation with ensuring public safety and consumer protection.

Manufacturers and researchers working on ferrofluid-based safety systems must engage with regulatory bodies early in the development process to ensure compliance and to contribute to the evolution of safety standards. This proactive approach can help shape regulations that are both effective in improving vehicle safety and conducive to technological advancement.

For ferrofluid technologies to be integrated into vehicle safety systems, they must comply with relevant FMVSS regulations. This includes standards related to crash avoidance, crashworthiness, and post-crash safety. The NHTSA also oversees the New Car Assessment Program (NCAP), which provides consumers with safety ratings for vehicles based on crash test performance and the presence of advanced safety technologies.

In the European Union, the regulatory landscape is governed by the European New Car Assessment Programme (Euro NCAP) and the United Nations Economic Commission for Europe (UNECE). These organizations set safety standards and conduct crash tests to evaluate vehicle safety performance. The EU also has specific regulations for type approval of vehicles, systems, and components, which would apply to any ferrofluid-based safety technologies.

Globally, the harmonization of vehicle safety regulations is an ongoing process through the World Forum for Harmonization of Vehicle Regulations (WP.29). This forum works to develop Global Technical Regulations (GTRs) that can be adopted by member countries, potentially streamlining the approval process for new safety technologies across different markets.

As ferrofluid technologies for vehicle safety are still emerging, regulatory bodies may need to develop new standards or adapt existing ones to accommodate these innovations. This process typically involves extensive testing, data collection, and collaboration between regulatory agencies, automotive manufacturers, and technology developers. The regulatory framework must balance the promotion of innovation with ensuring public safety and consumer protection.

Manufacturers and researchers working on ferrofluid-based safety systems must engage with regulatory bodies early in the development process to ensure compliance and to contribute to the evolution of safety standards. This proactive approach can help shape regulations that are both effective in improving vehicle safety and conducive to technological advancement.

Environmental Impact of Ferrofluid Safety Systems

The implementation of ferrofluid technologies in vehicle safety systems presents both opportunities and challenges from an environmental perspective. While these innovative systems have the potential to enhance road safety significantly, their environmental impact must be carefully considered and mitigated.

Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, are generally considered to have low toxicity. However, the production and disposal of these materials require careful management to prevent potential environmental contamination. The manufacturing process of ferrofluids involves the use of various chemicals and energy-intensive procedures, which can contribute to carbon emissions and resource depletion if not properly managed.

One of the primary environmental concerns associated with ferrofluid safety systems is the potential for leakage or spillage during vehicle accidents or maintenance. While the quantities used in individual vehicles may be small, widespread adoption could lead to cumulative effects on soil and water ecosystems. To address this, manufacturers must focus on developing robust containment systems and implementing stringent quality control measures to minimize the risk of environmental release.

The use of rare earth elements in some ferrofluid formulations raises additional environmental considerations. The mining and processing of these materials can have significant ecological impacts, including habitat destruction and water pollution. As demand for ferrofluid-based safety systems grows, it is crucial to explore alternative formulations that reduce reliance on rare earth elements or develop more sustainable extraction methods.

On the positive side, ferrofluid safety systems have the potential to reduce the environmental impact of vehicle accidents. By improving overall vehicle safety and potentially reducing the severity of collisions, these systems could lead to fewer damaged vehicles and a decrease in the resources required for repairs and replacements. This indirect environmental benefit should be factored into the overall assessment of ferrofluid technology's ecological footprint.

Recycling and end-of-life management of ferrofluid-containing components present another environmental challenge. Developing efficient recycling processes for these materials is essential to minimize waste and recover valuable resources. Additionally, designing safety systems with easy disassembly and material separation in mind can facilitate more effective recycling and reduce the environmental burden at the end of the product lifecycle.

As the automotive industry moves towards more sustainable practices, the integration of ferrofluid safety systems must align with broader environmental goals. This includes considering the energy efficiency of these systems during operation and exploring synergies with other green technologies, such as electric powertrains or lightweight materials, to maximize the overall environmental benefits of next-generation vehicles.

Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, are generally considered to have low toxicity. However, the production and disposal of these materials require careful management to prevent potential environmental contamination. The manufacturing process of ferrofluids involves the use of various chemicals and energy-intensive procedures, which can contribute to carbon emissions and resource depletion if not properly managed.

One of the primary environmental concerns associated with ferrofluid safety systems is the potential for leakage or spillage during vehicle accidents or maintenance. While the quantities used in individual vehicles may be small, widespread adoption could lead to cumulative effects on soil and water ecosystems. To address this, manufacturers must focus on developing robust containment systems and implementing stringent quality control measures to minimize the risk of environmental release.

The use of rare earth elements in some ferrofluid formulations raises additional environmental considerations. The mining and processing of these materials can have significant ecological impacts, including habitat destruction and water pollution. As demand for ferrofluid-based safety systems grows, it is crucial to explore alternative formulations that reduce reliance on rare earth elements or develop more sustainable extraction methods.

On the positive side, ferrofluid safety systems have the potential to reduce the environmental impact of vehicle accidents. By improving overall vehicle safety and potentially reducing the severity of collisions, these systems could lead to fewer damaged vehicles and a decrease in the resources required for repairs and replacements. This indirect environmental benefit should be factored into the overall assessment of ferrofluid technology's ecological footprint.

Recycling and end-of-life management of ferrofluid-containing components present another environmental challenge. Developing efficient recycling processes for these materials is essential to minimize waste and recover valuable resources. Additionally, designing safety systems with easy disassembly and material separation in mind can facilitate more effective recycling and reduce the environmental burden at the end of the product lifecycle.

As the automotive industry moves towards more sustainable practices, the integration of ferrofluid safety systems must align with broader environmental goals. This includes considering the energy efficiency of these systems during operation and exploring synergies with other green technologies, such as electric powertrains or lightweight materials, to maximize the overall environmental benefits of next-generation vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!