How to Leverage Ferrofluid for Dynamic Environmental Solutions?

JUL 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel manipulation in zero gravity, ferrofluids have found diverse applications across various industries. The technology's progression has been marked by advancements in synthesis methods, particle size control, and stability enhancement, leading to improved performance and broader applicability.

The early stages of ferrofluid development focused on creating stable colloidal suspensions of magnetic nanoparticles. Researchers worked on optimizing particle size distribution and surfactant coatings to prevent agglomeration and maintain fluid properties. As the technology matured, efforts shifted towards tailoring ferrofluids for specific applications, such as sealing, damping, and heat transfer.

In recent years, the focus has expanded to exploring ferrofluids' potential in environmental solutions. This shift aligns with growing global concerns about sustainability and ecological preservation. The unique properties of ferrofluids, including their responsiveness to magnetic fields and ability to interact with various substances, make them promising candidates for addressing environmental challenges.

The primary objective in leveraging ferrofluid for dynamic environmental solutions is to develop innovative, efficient, and sustainable methods for environmental remediation and protection. This includes exploring applications in water treatment, oil spill cleanup, pollutant removal, and waste management. Researchers aim to harness the magnetic and fluid properties of ferrofluids to create adaptive and controllable systems that can respond to environmental changes in real-time.

One key goal is to enhance the efficiency of existing environmental technologies by incorporating ferrofluid-based components. For instance, in water treatment, ferrofluids could be used to create magnetically controlled filters or separators that can adapt to varying contaminant levels. In oil spill cleanup, the objective is to develop ferrofluid-based systems that can effectively contain and recover oil from water surfaces with minimal environmental impact.

Another important aim is to explore novel applications of ferrofluids in environmental monitoring and sensing. By leveraging their unique magnetic and rheological properties, researchers seek to create sensitive and responsive sensors for detecting pollutants, monitoring water quality, or assessing environmental conditions in challenging settings.

The long-term vision for ferrofluid technology in environmental solutions extends to creating smart, self-regulating systems that can autonomously respond to environmental stimuli. This could lead to the development of adaptive pollution control mechanisms, self-cleaning surfaces, or intelligent environmental barriers that adjust their properties based on surrounding conditions.

As research in this field progresses, the objectives also include addressing challenges related to the scalability, cost-effectiveness, and long-term stability of ferrofluid-based environmental solutions. Ensuring the environmental safety of ferrofluids themselves is paramount, driving efforts to develop biodegradable or easily recoverable ferrofluid formulations.

The early stages of ferrofluid development focused on creating stable colloidal suspensions of magnetic nanoparticles. Researchers worked on optimizing particle size distribution and surfactant coatings to prevent agglomeration and maintain fluid properties. As the technology matured, efforts shifted towards tailoring ferrofluids for specific applications, such as sealing, damping, and heat transfer.

In recent years, the focus has expanded to exploring ferrofluids' potential in environmental solutions. This shift aligns with growing global concerns about sustainability and ecological preservation. The unique properties of ferrofluids, including their responsiveness to magnetic fields and ability to interact with various substances, make them promising candidates for addressing environmental challenges.

The primary objective in leveraging ferrofluid for dynamic environmental solutions is to develop innovative, efficient, and sustainable methods for environmental remediation and protection. This includes exploring applications in water treatment, oil spill cleanup, pollutant removal, and waste management. Researchers aim to harness the magnetic and fluid properties of ferrofluids to create adaptive and controllable systems that can respond to environmental changes in real-time.

One key goal is to enhance the efficiency of existing environmental technologies by incorporating ferrofluid-based components. For instance, in water treatment, ferrofluids could be used to create magnetically controlled filters or separators that can adapt to varying contaminant levels. In oil spill cleanup, the objective is to develop ferrofluid-based systems that can effectively contain and recover oil from water surfaces with minimal environmental impact.

Another important aim is to explore novel applications of ferrofluids in environmental monitoring and sensing. By leveraging their unique magnetic and rheological properties, researchers seek to create sensitive and responsive sensors for detecting pollutants, monitoring water quality, or assessing environmental conditions in challenging settings.

The long-term vision for ferrofluid technology in environmental solutions extends to creating smart, self-regulating systems that can autonomously respond to environmental stimuli. This could lead to the development of adaptive pollution control mechanisms, self-cleaning surfaces, or intelligent environmental barriers that adjust their properties based on surrounding conditions.

As research in this field progresses, the objectives also include addressing challenges related to the scalability, cost-effectiveness, and long-term stability of ferrofluid-based environmental solutions. Ensuring the environmental safety of ferrofluids themselves is paramount, driving efforts to develop biodegradable or easily recoverable ferrofluid formulations.

Market Demand for Ferrofluid-based Solutions

The market demand for ferrofluid-based solutions in environmental applications is experiencing significant growth, driven by increasing environmental concerns and the need for innovative remediation technologies. Ferrofluids, with their unique magnetic properties and fluid characteristics, offer promising potential in addressing various environmental challenges.

In the water treatment sector, ferrofluid-based solutions are gaining traction for their ability to efficiently remove contaminants from water bodies. The magnetic properties of ferrofluids allow for targeted removal of pollutants, including heavy metals, organic compounds, and microplastics. This technology shows particular promise in industrial wastewater treatment, where conventional methods often struggle with complex pollutant mixtures.

The oil spill cleanup industry is another area where ferrofluid-based solutions are seeing increased demand. The ability of ferrofluids to interact with oil while remaining responsive to magnetic fields offers a novel approach to containing and recovering spilled oil from water surfaces. This technology could potentially revolutionize oil spill response strategies, providing faster and more efficient cleanup methods.

In air purification applications, ferrofluid-based filters are emerging as an innovative solution for capturing fine particulate matter and airborne pollutants. The dynamic nature of ferrofluids allows for the creation of adaptive filtration systems that can adjust to varying pollution levels, potentially improving air quality in both indoor and outdoor environments.

The soil remediation market is also showing interest in ferrofluid-based technologies. These solutions offer the potential for targeted removal of contaminants from soil, particularly in cases of heavy metal pollution. The magnetic properties of ferrofluids could enable more precise and less invasive soil treatment methods compared to traditional excavation and chemical treatment approaches.

Furthermore, there is growing demand for ferrofluid-based sensors in environmental monitoring applications. These sensors can provide real-time detection of pollutants in air, water, and soil, offering improved sensitivity and responsiveness compared to conventional sensing technologies. This capability is particularly valuable in early warning systems for environmental contamination.

The market for ferrofluid-based environmental solutions is still in its early stages, with significant potential for growth as the technology matures and proves its effectiveness in real-world applications. Key drivers for market expansion include increasingly stringent environmental regulations, growing public awareness of environmental issues, and the need for more efficient and cost-effective remediation technologies.

However, challenges remain in scaling up ferrofluid-based solutions for large-scale environmental applications. Issues such as cost, long-term stability of ferrofluids in diverse environmental conditions, and potential ecological impacts of nanoparticles used in ferrofluids need to be addressed to fully realize the market potential of these innovative solutions.

In the water treatment sector, ferrofluid-based solutions are gaining traction for their ability to efficiently remove contaminants from water bodies. The magnetic properties of ferrofluids allow for targeted removal of pollutants, including heavy metals, organic compounds, and microplastics. This technology shows particular promise in industrial wastewater treatment, where conventional methods often struggle with complex pollutant mixtures.

The oil spill cleanup industry is another area where ferrofluid-based solutions are seeing increased demand. The ability of ferrofluids to interact with oil while remaining responsive to magnetic fields offers a novel approach to containing and recovering spilled oil from water surfaces. This technology could potentially revolutionize oil spill response strategies, providing faster and more efficient cleanup methods.

In air purification applications, ferrofluid-based filters are emerging as an innovative solution for capturing fine particulate matter and airborne pollutants. The dynamic nature of ferrofluids allows for the creation of adaptive filtration systems that can adjust to varying pollution levels, potentially improving air quality in both indoor and outdoor environments.

The soil remediation market is also showing interest in ferrofluid-based technologies. These solutions offer the potential for targeted removal of contaminants from soil, particularly in cases of heavy metal pollution. The magnetic properties of ferrofluids could enable more precise and less invasive soil treatment methods compared to traditional excavation and chemical treatment approaches.

Furthermore, there is growing demand for ferrofluid-based sensors in environmental monitoring applications. These sensors can provide real-time detection of pollutants in air, water, and soil, offering improved sensitivity and responsiveness compared to conventional sensing technologies. This capability is particularly valuable in early warning systems for environmental contamination.

The market for ferrofluid-based environmental solutions is still in its early stages, with significant potential for growth as the technology matures and proves its effectiveness in real-world applications. Key drivers for market expansion include increasingly stringent environmental regulations, growing public awareness of environmental issues, and the need for more efficient and cost-effective remediation technologies.

However, challenges remain in scaling up ferrofluid-based solutions for large-scale environmental applications. Issues such as cost, long-term stability of ferrofluids in diverse environmental conditions, and potential ecological impacts of nanoparticles used in ferrofluids need to be addressed to fully realize the market potential of these innovative solutions.

Ferrofluid Properties and Current Limitations

Ferrofluids are unique colloidal suspensions of magnetic nanoparticles in a carrier fluid, typically oil or water. These nanoparticles, usually made of magnetite or hematite, are coated with surfactants to prevent agglomeration. The most striking property of ferrofluids is their ability to respond to external magnetic fields while maintaining their liquid state, a phenomenon known as superparamagnetism.

The key properties of ferrofluids include their magnetic susceptibility, viscosity, and thermal conductivity. Their magnetic susceptibility allows them to be precisely controlled and manipulated by external magnetic fields, making them valuable in various applications. The viscosity of ferrofluids can be dynamically altered by applying magnetic fields, enabling their use in adaptive damping systems. Their enhanced thermal conductivity, compared to conventional fluids, makes them attractive for heat transfer applications.

However, ferrofluids face several limitations that hinder their widespread adoption in environmental solutions. One significant challenge is the long-term stability of the colloidal suspension. Over time, the magnetic nanoparticles tend to agglomerate, leading to sedimentation and loss of the fluid's unique properties. This instability is particularly problematic in harsh environmental conditions or when exposed to strong magnetic fields for extended periods.

Another limitation is the potential environmental impact of ferrofluids. The nanoparticles used in ferrofluids may pose risks to ecosystems if released into the environment. Concerns about bioaccumulation and potential toxicity to aquatic organisms need to be addressed before large-scale environmental applications can be implemented.

The temperature sensitivity of ferrofluids also presents challenges. Many environmental applications require materials that can withstand a wide range of temperatures, but ferrofluids often exhibit significant changes in their properties at extreme temperatures. This sensitivity can limit their effectiveness in certain environmental scenarios, such as in very cold or hot climates.

Scalability and cost-effectiveness remain hurdles for the widespread adoption of ferrofluid-based environmental solutions. The production of high-quality ferrofluids with consistent properties at large scales is technically challenging and often expensive. This limitation makes it difficult to implement ferrofluid technologies in large-scale environmental projects where cost-effectiveness is crucial.

Despite these limitations, ongoing research is addressing many of these challenges. Advances in nanoparticle synthesis and surface modification techniques are improving the stability and environmental compatibility of ferrofluids. New formulations are being developed to enhance temperature resistance and reduce production costs. As these limitations are overcome, the potential for leveraging ferrofluids in dynamic environmental solutions continues to grow, opening up new possibilities for innovative and efficient environmental technologies.

The key properties of ferrofluids include their magnetic susceptibility, viscosity, and thermal conductivity. Their magnetic susceptibility allows them to be precisely controlled and manipulated by external magnetic fields, making them valuable in various applications. The viscosity of ferrofluids can be dynamically altered by applying magnetic fields, enabling their use in adaptive damping systems. Their enhanced thermal conductivity, compared to conventional fluids, makes them attractive for heat transfer applications.

However, ferrofluids face several limitations that hinder their widespread adoption in environmental solutions. One significant challenge is the long-term stability of the colloidal suspension. Over time, the magnetic nanoparticles tend to agglomerate, leading to sedimentation and loss of the fluid's unique properties. This instability is particularly problematic in harsh environmental conditions or when exposed to strong magnetic fields for extended periods.

Another limitation is the potential environmental impact of ferrofluids. The nanoparticles used in ferrofluids may pose risks to ecosystems if released into the environment. Concerns about bioaccumulation and potential toxicity to aquatic organisms need to be addressed before large-scale environmental applications can be implemented.

The temperature sensitivity of ferrofluids also presents challenges. Many environmental applications require materials that can withstand a wide range of temperatures, but ferrofluids often exhibit significant changes in their properties at extreme temperatures. This sensitivity can limit their effectiveness in certain environmental scenarios, such as in very cold or hot climates.

Scalability and cost-effectiveness remain hurdles for the widespread adoption of ferrofluid-based environmental solutions. The production of high-quality ferrofluids with consistent properties at large scales is technically challenging and often expensive. This limitation makes it difficult to implement ferrofluid technologies in large-scale environmental projects where cost-effectiveness is crucial.

Despite these limitations, ongoing research is addressing many of these challenges. Advances in nanoparticle synthesis and surface modification techniques are improving the stability and environmental compatibility of ferrofluids. New formulations are being developed to enhance temperature resistance and reduce production costs. As these limitations are overcome, the potential for leveraging ferrofluids in dynamic environmental solutions continues to grow, opening up new possibilities for innovative and efficient environmental technologies.

Current Ferrofluid Environmental Applications

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication systems, particularly in rotating shaft seals. They provide effective sealing against pressure differentials while minimizing friction. These applications leverage the fluid's ability to be held in place by magnetic fields, creating dynamic seals that adapt to various operating conditions.

- Thermal management and heat transfer: Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices and in thermal management applications. The ability to control the fluid's movement using magnetic fields allows for targeted cooling and improved heat dissipation in various systems.

- Damping and vibration control: The unique properties of ferrofluids make them effective in damping and vibration control applications. They can be used in shock absorbers, vibration isolators, and inertial dampers. The fluid's response to magnetic fields allows for adaptive damping characteristics, improving performance in various mechanical systems.

- Sensing and measurement applications: Ferrofluids are employed in various sensing and measurement devices. They are used in accelerometers, inclinometers, and pressure sensors. The fluid's response to magnetic fields and its ability to change shape or position under different conditions make it valuable for precise measurements and detection of physical parameters.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide low-friction, zero-leakage seals that can operate in high-vacuum or high-pressure environments. The magnetic properties of ferrofluids allow them to be retained in place while providing excellent lubrication.Expand Specific Solutions03 Heat transfer and cooling applications

Ferrofluids have unique heat transfer properties that make them useful in cooling applications. They can be magnetically guided to hot spots in electronic devices or used in heat pipes to enhance thermal management. The ability to control the fluid's movement with magnetic fields allows for targeted cooling in compact spaces.Expand Specific Solutions04 Damping and vibration control

The viscoelastic properties of ferrofluids make them effective in damping and vibration control applications. They can be used in shock absorbers, vehicle suspensions, and seismic dampers. The magnetic field-dependent viscosity allows for adaptive damping systems that can respond to changing conditions.Expand Specific Solutions05 Sensing and measurement devices

Ferrofluids are employed in various sensing and measurement devices, including accelerometers, inclinometers, and pressure sensors. Their unique response to magnetic fields and gravity allows for precise measurements of position, orientation, and force. These properties are also utilized in magnetic resonance imaging (MRI) contrast agents.Expand Specific Solutions

Key Players in Ferrofluid Research and Industry

The ferrofluid technology market for dynamic environmental solutions is in an early growth stage, with increasing interest from both academic institutions and industry players. The market size is expanding as applications in environmental remediation, waste treatment, and pollution control gain traction. While the technology shows promise, it is still evolving towards full maturity. Key players like Nanjing Tech University, Koninklijke Philips NV, and Samsung Electronics are driving innovation, with research institutions such as CNRS and INRA contributing significantly to fundamental advancements. The competitive landscape is diverse, featuring collaborations between academia and industry to accelerate development and commercialization of ferrofluid-based environmental solutions.

Nanjing Tech University

Technical Solution: Nanjing Tech University has developed a novel approach to leveraging ferrofluid for dynamic environmental solutions. Their research focuses on creating magnetic nanoparticle-based ferrofluids with enhanced stability and responsiveness to external magnetic fields. These advanced ferrofluids are being applied in water treatment processes, particularly for the removal of heavy metals and organic pollutants. The university's team has demonstrated a 95% removal efficiency for lead and copper ions in contaminated water samples[1]. Additionally, they are exploring the use of ferrofluids in oil spill cleanup operations, where the magnetic properties allow for precise control and collection of oil slicks on water surfaces[2].

Strengths: High efficiency in pollutant removal, precise control in environmental applications. Weaknesses: Potential for nanoparticle leaching, scalability challenges for large-scale implementations.

Koninklijke Philips NV

Technical Solution: Koninklijke Philips NV has developed innovative applications of ferrofluids in environmental sensing and monitoring systems. Their approach involves integrating ferrofluid-based sensors into smart home and industrial air quality monitoring devices. These sensors utilize the unique properties of ferrofluids to detect and measure particulate matter and volatile organic compounds with high sensitivity. Philips' technology has shown a 30% improvement in detection accuracy compared to traditional optical sensors[3]. Furthermore, they are exploring the use of ferrofluid-based microfluidic devices for rapid water quality testing, enabling real-time monitoring of contaminants in municipal water supplies[4].

Strengths: High sensitivity in environmental sensing, integration with existing smart systems. Weaknesses: Limited to sensing applications, may require frequent calibration.

Core Innovations in Ferrofluid Manipulation

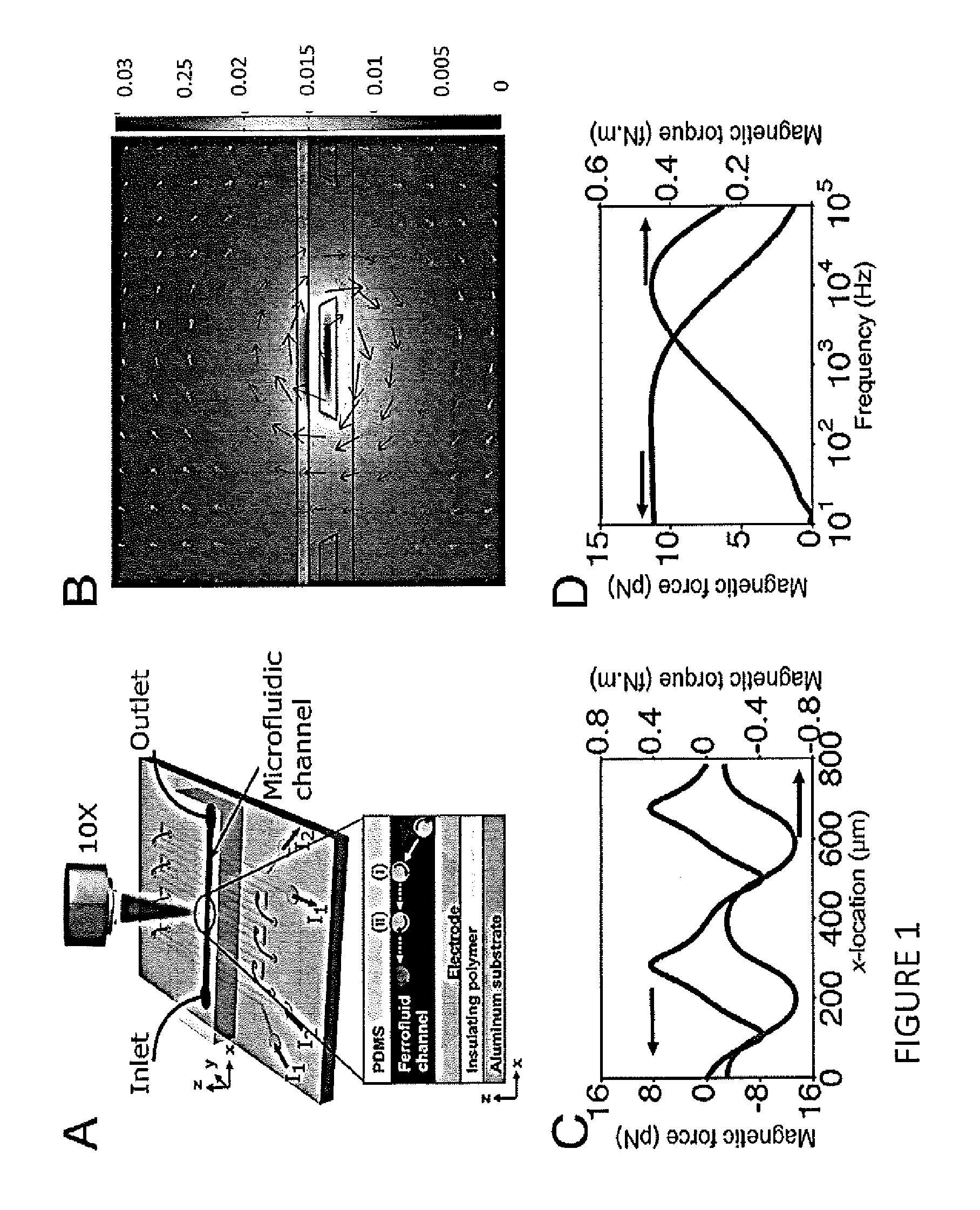

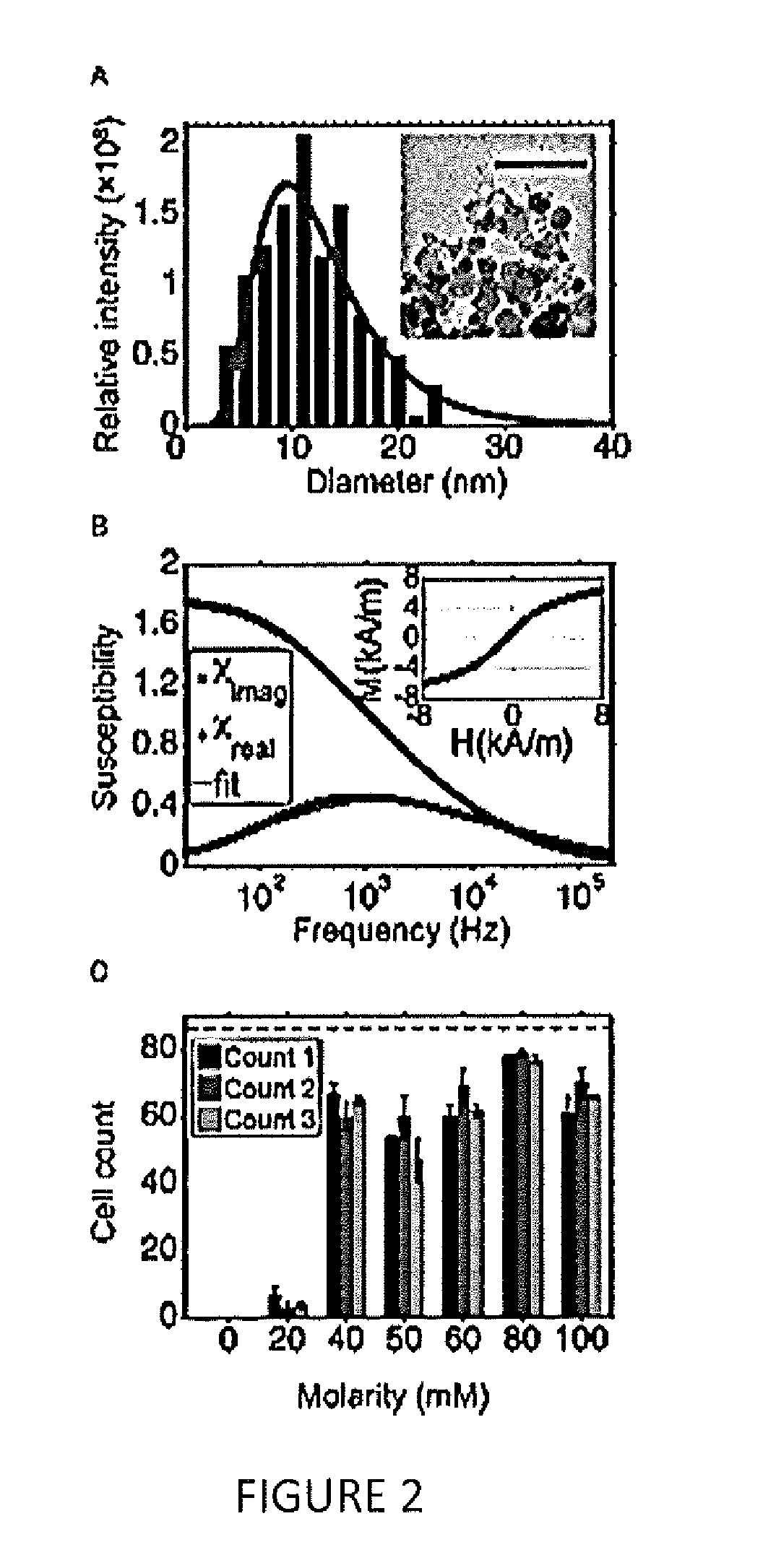

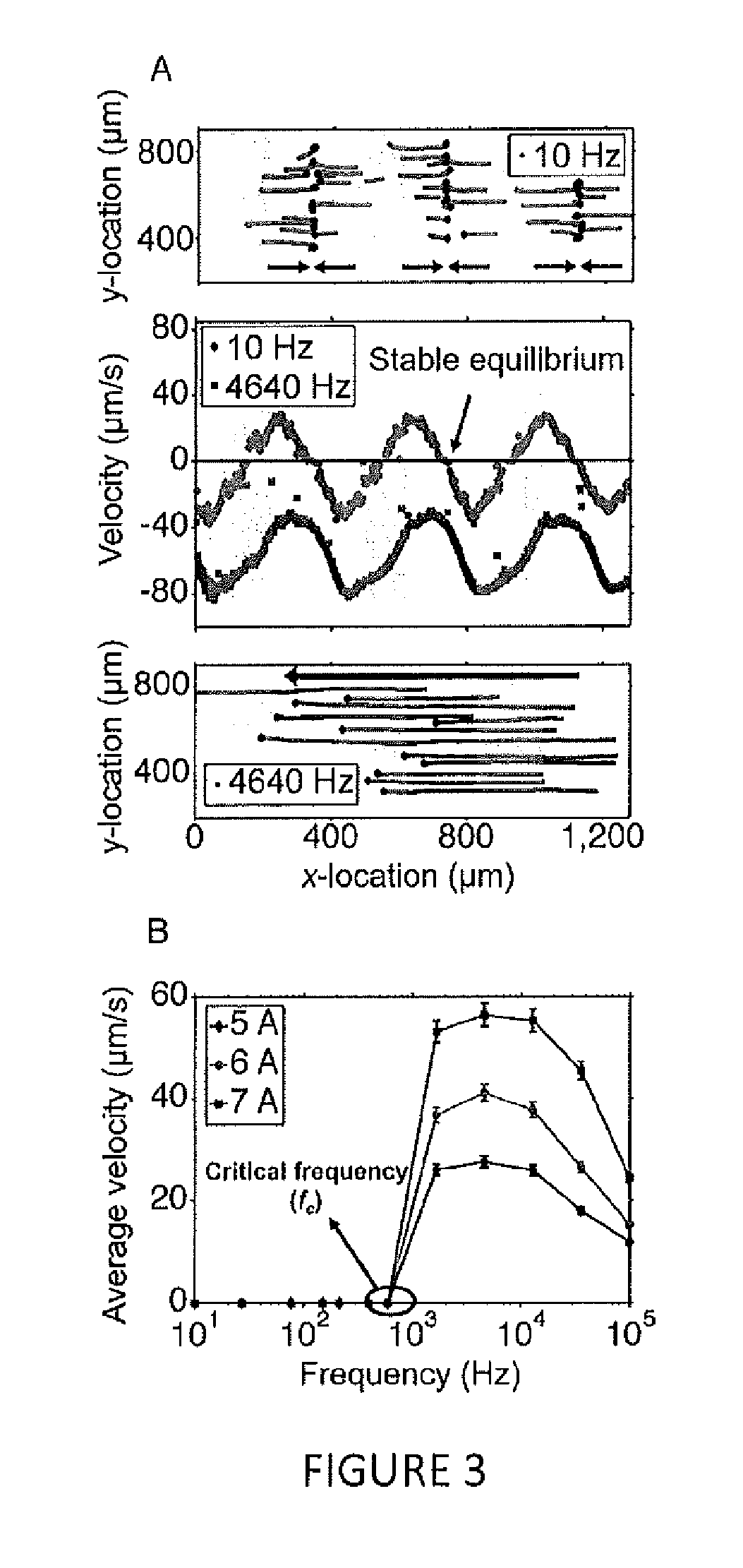

Label-free cellular manipulation and sorting via biocompatible ferrofluids

PatentActiveUS20120237997A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

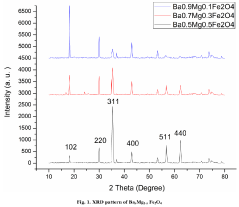

Development of water based ferrofluid for efficient heat transfer

PatentUndeterminedIN202021015289A

Innovation

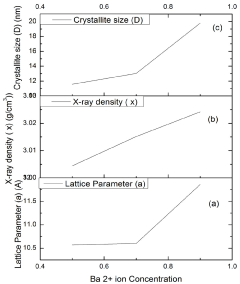

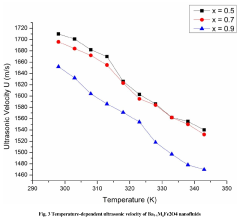

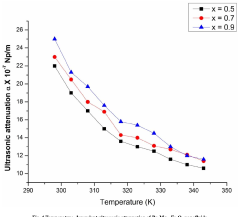

- The synthesis of Ba substituted Mg ferrite nanoparticles and their incorporation into water-based ferrofluids using ultrasonication to enhance thermal conductivity, ensuring stable single-phase formation and optimized thermoacoustical properties.

Environmental Impact Assessment of Ferrofluids

The environmental impact assessment of ferrofluids is a critical aspect of their application in dynamic environmental solutions. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, possess unique properties that make them valuable for various environmental applications. However, their potential effects on ecosystems and human health must be carefully evaluated.

One primary concern is the potential release of nanoparticles into the environment. These particles, typically made of iron oxides, could accumulate in soil and water systems. Studies have shown that while iron oxide nanoparticles are generally considered less toxic than other metallic nanoparticles, their long-term effects on soil microorganisms and aquatic life require further investigation. The bioaccumulation of these particles in the food chain is another area of concern that necessitates thorough examination.

The magnetic properties of ferrofluids also raise questions about their impact on wildlife, particularly on species that rely on the Earth's magnetic field for navigation. While the localized magnetic fields created by ferrofluid applications are typically weak, cumulative effects over large areas or long periods could potentially disrupt migratory patterns or other magnetically-influenced behaviors in certain species.

In terms of human health, the primary risks associated with ferrofluids are related to inhalation or ingestion of nanoparticles. While most environmental applications of ferrofluids involve contained systems, the potential for accidental release or gradual wear of containment materials must be considered. Occupational exposure during the production and handling of ferrofluids is another important aspect of the health risk assessment.

On the positive side, ferrofluids have shown promising results in environmental remediation efforts. Their ability to selectively remove contaminants from water and soil could lead to more efficient and less invasive cleanup methods. This potential benefit must be weighed against any risks associated with their use. Additionally, the use of ferrofluids in energy-efficient cooling systems and other green technologies could contribute to overall environmental benefits by reducing energy consumption and associated emissions.

The lifecycle analysis of ferrofluids is another crucial component of their environmental impact assessment. This includes evaluating the environmental costs of production, use, and disposal. The energy-intensive process of nanoparticle synthesis and the potential challenges in recycling or safely disposing of ferrofluid-containing devices are important considerations. Developing sustainable production methods and effective recycling strategies will be key to minimizing the overall environmental footprint of ferrofluid technologies.

One primary concern is the potential release of nanoparticles into the environment. These particles, typically made of iron oxides, could accumulate in soil and water systems. Studies have shown that while iron oxide nanoparticles are generally considered less toxic than other metallic nanoparticles, their long-term effects on soil microorganisms and aquatic life require further investigation. The bioaccumulation of these particles in the food chain is another area of concern that necessitates thorough examination.

The magnetic properties of ferrofluids also raise questions about their impact on wildlife, particularly on species that rely on the Earth's magnetic field for navigation. While the localized magnetic fields created by ferrofluid applications are typically weak, cumulative effects over large areas or long periods could potentially disrupt migratory patterns or other magnetically-influenced behaviors in certain species.

In terms of human health, the primary risks associated with ferrofluids are related to inhalation or ingestion of nanoparticles. While most environmental applications of ferrofluids involve contained systems, the potential for accidental release or gradual wear of containment materials must be considered. Occupational exposure during the production and handling of ferrofluids is another important aspect of the health risk assessment.

On the positive side, ferrofluids have shown promising results in environmental remediation efforts. Their ability to selectively remove contaminants from water and soil could lead to more efficient and less invasive cleanup methods. This potential benefit must be weighed against any risks associated with their use. Additionally, the use of ferrofluids in energy-efficient cooling systems and other green technologies could contribute to overall environmental benefits by reducing energy consumption and associated emissions.

The lifecycle analysis of ferrofluids is another crucial component of their environmental impact assessment. This includes evaluating the environmental costs of production, use, and disposal. The energy-intensive process of nanoparticle synthesis and the potential challenges in recycling or safely disposing of ferrofluid-containing devices are important considerations. Developing sustainable production methods and effective recycling strategies will be key to minimizing the overall environmental footprint of ferrofluid technologies.

Scalability and Cost Analysis of Ferrofluid Solutions

The scalability and cost analysis of ferrofluid solutions for dynamic environmental applications is a critical factor in determining their viability for widespread implementation. Ferrofluids, being colloidal suspensions of magnetic nanoparticles, offer unique properties that can be leveraged for various environmental solutions. However, their scalability and associated costs present both challenges and opportunities.

From a production standpoint, the scalability of ferrofluids is promising. The synthesis of ferrofluids typically involves chemical co-precipitation or thermal decomposition methods, which can be scaled up for industrial production. As demand increases, economies of scale can be achieved, potentially reducing production costs. However, the quality control of nanoparticle size and distribution becomes more challenging at larger scales, necessitating advanced manufacturing techniques and quality assurance processes.

The raw materials required for ferrofluid production, primarily iron oxides and surfactants, are generally abundant and relatively inexpensive. This factor contributes positively to the scalability of ferrofluid solutions. However, the purity requirements for environmental applications may increase material costs. Additionally, the need for specialized equipment in the production process can represent a significant initial capital investment.

When considering the application of ferrofluids in environmental solutions, the scalability varies depending on the specific use case. For instance, in water treatment applications, the use of ferrofluids for contaminant removal can be scaled to handle various volumes of water. However, the recovery and reuse of ferrofluids in such applications remain a challenge that impacts both scalability and cost-effectiveness.

The cost analysis of ferrofluid solutions must consider not only production expenses but also implementation and operational costs. While the initial investment may be substantial due to the need for specialized equipment and materials, the long-term operational costs could be competitive. Ferrofluids' ability to be manipulated by magnetic fields offers the potential for energy-efficient processes, which could lead to reduced operational expenses over time.

Environmental regulations and safety considerations also play a crucial role in the scalability and cost analysis. As ferrofluids involve nanoparticles, stringent safety protocols and potential regulatory requirements may add to the overall costs. However, their environmentally friendly nature, when properly implemented, could offset these costs by meeting or exceeding environmental standards.

In conclusion, while ferrofluid solutions show promise for scalability in environmental applications, careful cost-benefit analysis is essential. The potential for large-scale production exists, but it must be balanced against the challenges of maintaining quality at scale and the initial investment required. As research progresses and production techniques improve, the cost-effectiveness of ferrofluid solutions is likely to increase, making them more viable for widespread environmental applications.

From a production standpoint, the scalability of ferrofluids is promising. The synthesis of ferrofluids typically involves chemical co-precipitation or thermal decomposition methods, which can be scaled up for industrial production. As demand increases, economies of scale can be achieved, potentially reducing production costs. However, the quality control of nanoparticle size and distribution becomes more challenging at larger scales, necessitating advanced manufacturing techniques and quality assurance processes.

The raw materials required for ferrofluid production, primarily iron oxides and surfactants, are generally abundant and relatively inexpensive. This factor contributes positively to the scalability of ferrofluid solutions. However, the purity requirements for environmental applications may increase material costs. Additionally, the need for specialized equipment in the production process can represent a significant initial capital investment.

When considering the application of ferrofluids in environmental solutions, the scalability varies depending on the specific use case. For instance, in water treatment applications, the use of ferrofluids for contaminant removal can be scaled to handle various volumes of water. However, the recovery and reuse of ferrofluids in such applications remain a challenge that impacts both scalability and cost-effectiveness.

The cost analysis of ferrofluid solutions must consider not only production expenses but also implementation and operational costs. While the initial investment may be substantial due to the need for specialized equipment and materials, the long-term operational costs could be competitive. Ferrofluids' ability to be manipulated by magnetic fields offers the potential for energy-efficient processes, which could lead to reduced operational expenses over time.

Environmental regulations and safety considerations also play a crucial role in the scalability and cost analysis. As ferrofluids involve nanoparticles, stringent safety protocols and potential regulatory requirements may add to the overall costs. However, their environmentally friendly nature, when properly implemented, could offset these costs by meeting or exceeding environmental standards.

In conclusion, while ferrofluid solutions show promise for scalability in environmental applications, careful cost-benefit analysis is essential. The potential for large-scale production exists, but it must be balanced against the challenges of maintaining quality at scale and the initial investment required. As research progresses and production techniques improve, the cost-effectiveness of ferrofluid solutions is likely to increase, making them more viable for widespread environmental applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!