How to Leverage Ferrofluid for Enhanced Data Storage Solutions?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Data Storage Background and Objectives

Ferrofluid, a magnetic liquid first developed by NASA in the 1960s, has recently garnered significant attention in the field of data storage. This unique substance, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, exhibits remarkable properties when exposed to magnetic fields. The potential application of ferrofluid in data storage solutions represents a promising frontier in the ongoing quest for higher capacity, faster access times, and more energy-efficient storage systems.

The evolution of data storage technology has been marked by continuous advancements, from magnetic tape to hard disk drives, and more recently, solid-state drives. However, as the demand for data storage continues to grow exponentially in the era of big data, cloud computing, and artificial intelligence, there is an urgent need for innovative solutions that can overcome the limitations of current technologies. Ferrofluid-based data storage emerges as a potential game-changer in this landscape.

The primary objective of leveraging ferrofluid for enhanced data storage solutions is to exploit its unique magnetic properties to create high-density, dynamic, and adaptable storage systems. By manipulating the ferrofluid's behavior under controlled magnetic fields, researchers aim to develop storage devices that can achieve unprecedented data densities while maintaining or improving read/write speeds and energy efficiency.

One of the key advantages of ferrofluid-based storage lies in its potential for three-dimensional data arrangement. Unlike traditional two-dimensional storage media, ferrofluid could allow for the creation of volumetric storage systems, dramatically increasing storage capacity within the same physical footprint. This three-dimensional approach aligns with the broader trend in the tech industry towards more compact and efficient designs.

Another significant goal is to harness the dynamic nature of ferrofluid to create adaptive storage systems. These systems could potentially reconfigure themselves in real-time to optimize data access patterns, leading to improved performance and reduced energy consumption. This adaptability could be particularly valuable in scenarios where data usage patterns are highly variable or unpredictable.

The development of ferrofluid-based data storage also aims to address some of the limitations of current technologies, such as the mechanical wear in hard disk drives or the limited write endurance of solid-state drives. By utilizing a liquid medium, ferrofluid storage could potentially offer longer lifespan and improved reliability.

As we explore the potential of ferrofluid in data storage, it is crucial to consider the broader technological context. This includes advancements in nanotechnology, materials science, and magnetic field manipulation techniques, all of which play critical roles in realizing the full potential of ferrofluid-based storage solutions. The interdisciplinary nature of this research underscores the need for collaborative efforts across various scientific and engineering domains.

The evolution of data storage technology has been marked by continuous advancements, from magnetic tape to hard disk drives, and more recently, solid-state drives. However, as the demand for data storage continues to grow exponentially in the era of big data, cloud computing, and artificial intelligence, there is an urgent need for innovative solutions that can overcome the limitations of current technologies. Ferrofluid-based data storage emerges as a potential game-changer in this landscape.

The primary objective of leveraging ferrofluid for enhanced data storage solutions is to exploit its unique magnetic properties to create high-density, dynamic, and adaptable storage systems. By manipulating the ferrofluid's behavior under controlled magnetic fields, researchers aim to develop storage devices that can achieve unprecedented data densities while maintaining or improving read/write speeds and energy efficiency.

One of the key advantages of ferrofluid-based storage lies in its potential for three-dimensional data arrangement. Unlike traditional two-dimensional storage media, ferrofluid could allow for the creation of volumetric storage systems, dramatically increasing storage capacity within the same physical footprint. This three-dimensional approach aligns with the broader trend in the tech industry towards more compact and efficient designs.

Another significant goal is to harness the dynamic nature of ferrofluid to create adaptive storage systems. These systems could potentially reconfigure themselves in real-time to optimize data access patterns, leading to improved performance and reduced energy consumption. This adaptability could be particularly valuable in scenarios where data usage patterns are highly variable or unpredictable.

The development of ferrofluid-based data storage also aims to address some of the limitations of current technologies, such as the mechanical wear in hard disk drives or the limited write endurance of solid-state drives. By utilizing a liquid medium, ferrofluid storage could potentially offer longer lifespan and improved reliability.

As we explore the potential of ferrofluid in data storage, it is crucial to consider the broader technological context. This includes advancements in nanotechnology, materials science, and magnetic field manipulation techniques, all of which play critical roles in realizing the full potential of ferrofluid-based storage solutions. The interdisciplinary nature of this research underscores the need for collaborative efforts across various scientific and engineering domains.

Market Analysis for Advanced Data Storage Solutions

The global data storage market is experiencing rapid growth, driven by the exponential increase in data generation across various sectors. As of 2023, the market size for advanced data storage solutions is estimated to reach $78.5 billion, with a projected compound annual growth rate (CAGR) of 13.2% over the next five years. This growth is primarily fueled by the rising demand for high-capacity, high-performance storage systems in cloud computing, big data analytics, and artificial intelligence applications.

The ferrofluid-based data storage technology represents a promising niche within this expanding market. While traditional magnetic storage devices continue to dominate, there is a growing interest in novel storage technologies that can offer higher density, improved reliability, and enhanced performance. Ferrofluid-enhanced storage solutions are positioned to address these market needs, potentially capturing a significant share of the advanced storage segment.

Key market drivers for ferrofluid-based storage include the increasing demand for higher storage densities, faster data access speeds, and improved energy efficiency. Industries such as healthcare, finance, and scientific research, which require massive data storage capabilities, are likely to be early adopters of this technology. The market for ferrofluid-enhanced storage is expected to grow at a CAGR of 18.7% from 2024 to 2029, outpacing the overall data storage market growth.

Geographically, North America and Asia-Pacific regions are anticipated to be the largest markets for advanced data storage solutions, including ferrofluid-based technologies. The United States, China, and Japan are expected to lead in both research and development efforts and market adoption. Europe is also showing significant interest, particularly in countries with strong research institutions and technology sectors.

However, the market faces several challenges. The high initial cost of implementing ferrofluid-based storage solutions may slow adoption rates, particularly among small and medium-sized enterprises. Additionally, concerns about long-term stability and compatibility with existing systems need to be addressed to gain wider market acceptance.

Despite these challenges, the potential benefits of ferrofluid-enhanced data storage solutions are substantial. The technology promises to offer storage densities up to 10 times higher than current magnetic hard drives, with improved read/write speeds and lower power consumption. These advantages position ferrofluid-based storage as a compelling option for data centers, cloud service providers, and high-performance computing applications.

As the technology matures, it is expected to find applications beyond traditional data storage. Emerging fields such as quantum computing and neuromorphic computing may benefit from the unique properties of ferrofluids, further expanding the market potential. The integration of ferrofluid technology with other advanced materials and nanotechnology is likely to open new avenues for innovation in the data storage industry.

The ferrofluid-based data storage technology represents a promising niche within this expanding market. While traditional magnetic storage devices continue to dominate, there is a growing interest in novel storage technologies that can offer higher density, improved reliability, and enhanced performance. Ferrofluid-enhanced storage solutions are positioned to address these market needs, potentially capturing a significant share of the advanced storage segment.

Key market drivers for ferrofluid-based storage include the increasing demand for higher storage densities, faster data access speeds, and improved energy efficiency. Industries such as healthcare, finance, and scientific research, which require massive data storage capabilities, are likely to be early adopters of this technology. The market for ferrofluid-enhanced storage is expected to grow at a CAGR of 18.7% from 2024 to 2029, outpacing the overall data storage market growth.

Geographically, North America and Asia-Pacific regions are anticipated to be the largest markets for advanced data storage solutions, including ferrofluid-based technologies. The United States, China, and Japan are expected to lead in both research and development efforts and market adoption. Europe is also showing significant interest, particularly in countries with strong research institutions and technology sectors.

However, the market faces several challenges. The high initial cost of implementing ferrofluid-based storage solutions may slow adoption rates, particularly among small and medium-sized enterprises. Additionally, concerns about long-term stability and compatibility with existing systems need to be addressed to gain wider market acceptance.

Despite these challenges, the potential benefits of ferrofluid-enhanced data storage solutions are substantial. The technology promises to offer storage densities up to 10 times higher than current magnetic hard drives, with improved read/write speeds and lower power consumption. These advantages position ferrofluid-based storage as a compelling option for data centers, cloud service providers, and high-performance computing applications.

As the technology matures, it is expected to find applications beyond traditional data storage. Emerging fields such as quantum computing and neuromorphic computing may benefit from the unique properties of ferrofluids, further expanding the market potential. The integration of ferrofluid technology with other advanced materials and nanotechnology is likely to open new avenues for innovation in the data storage industry.

Current Ferrofluid Technology Challenges

Ferrofluid technology, while promising for enhanced data storage solutions, faces several significant challenges that hinder its widespread adoption and implementation. One of the primary obstacles is the stability of ferrofluids over extended periods. The magnetic nanoparticles in ferrofluids tend to agglomerate over time, leading to a loss of their unique properties and potentially compromising the integrity of data storage systems.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields. Achieving consistent and predictable responses across different environmental conditions and magnetic field strengths remains a complex task. This variability can lead to inconsistencies in data reading and writing processes, potentially resulting in data loss or corruption.

The integration of ferrofluids with existing data storage architectures presents another hurdle. Current storage systems are not designed to accommodate the unique properties of ferrofluids, necessitating significant redesigns of both hardware and software components. This integration challenge extends to ensuring compatibility with existing data transfer protocols and interfaces.

Thermal management is a crucial concern in ferrofluid-based data storage systems. The heat generated during operation can affect the magnetic properties of the ferrofluid, potentially leading to data instability or loss. Developing effective cooling mechanisms that do not interfere with the magnetic properties of the ferrofluid is a complex engineering challenge.

Scalability remains a significant issue for ferrofluid technology in data storage applications. While promising results have been achieved in laboratory settings, scaling these solutions to meet the demands of large-scale data centers presents numerous technical and logistical challenges. This includes maintaining uniform ferrofluid properties across larger volumes and ensuring consistent performance in diverse operating environments.

The manufacturing process for high-quality ferrofluids suitable for data storage applications is another area of concern. Producing ferrofluids with consistent properties, free from impurities, and in large quantities is technically challenging and cost-intensive. This manufacturing hurdle impacts the economic viability of ferrofluid-based storage solutions in the competitive data storage market.

Lastly, the long-term reliability and data retention capabilities of ferrofluid-based storage systems remain unproven. Extensive testing and validation are required to ensure that these systems can match or exceed the reliability standards set by current storage technologies. This includes assessing factors such as data integrity over time, resistance to external magnetic fields, and performance under various environmental stresses.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields. Achieving consistent and predictable responses across different environmental conditions and magnetic field strengths remains a complex task. This variability can lead to inconsistencies in data reading and writing processes, potentially resulting in data loss or corruption.

The integration of ferrofluids with existing data storage architectures presents another hurdle. Current storage systems are not designed to accommodate the unique properties of ferrofluids, necessitating significant redesigns of both hardware and software components. This integration challenge extends to ensuring compatibility with existing data transfer protocols and interfaces.

Thermal management is a crucial concern in ferrofluid-based data storage systems. The heat generated during operation can affect the magnetic properties of the ferrofluid, potentially leading to data instability or loss. Developing effective cooling mechanisms that do not interfere with the magnetic properties of the ferrofluid is a complex engineering challenge.

Scalability remains a significant issue for ferrofluid technology in data storage applications. While promising results have been achieved in laboratory settings, scaling these solutions to meet the demands of large-scale data centers presents numerous technical and logistical challenges. This includes maintaining uniform ferrofluid properties across larger volumes and ensuring consistent performance in diverse operating environments.

The manufacturing process for high-quality ferrofluids suitable for data storage applications is another area of concern. Producing ferrofluids with consistent properties, free from impurities, and in large quantities is technically challenging and cost-intensive. This manufacturing hurdle impacts the economic viability of ferrofluid-based storage solutions in the competitive data storage market.

Lastly, the long-term reliability and data retention capabilities of ferrofluid-based storage systems remain unproven. Extensive testing and validation are required to ensure that these systems can match or exceed the reliability standards set by current storage technologies. This includes assessing factors such as data integrity over time, resistance to external magnetic fields, and performance under various environmental stresses.

Existing Ferrofluid Data Storage Solutions

01 Ferrofluid-based data storage devices

Ferrofluids can be used in data storage devices to enhance storage capacity and performance. These devices utilize the magnetic properties of ferrofluids to store and retrieve data, potentially offering higher storage densities compared to traditional storage methods.- Ferrofluid-based data storage devices: Ferrofluids can be used in data storage devices to enhance storage capacity and performance. These devices utilize the magnetic properties of ferrofluids to store and retrieve data, potentially offering higher storage densities compared to traditional methods.

- Magnetic field manipulation for data storage: By manipulating magnetic fields in ferrofluid-based storage systems, data can be written, read, and erased. This technique allows for precise control of data storage and retrieval processes, potentially increasing storage capacity and access speeds.

- Nanoparticle-enhanced ferrofluid storage: Incorporating nanoparticles into ferrofluids can significantly improve their magnetic properties and stability, leading to increased data storage capacity. These enhanced ferrofluids can be used in advanced storage devices with higher data densities.

- Ferrofluid-based memory systems: Memory systems utilizing ferrofluids can offer advantages such as non-volatility, high-speed operation, and increased storage capacity. These systems may incorporate novel architectures and control mechanisms to optimize data storage and retrieval.

- Integration of ferrofluid storage with other technologies: Combining ferrofluid-based storage with other technologies, such as solid-state drives or cloud computing, can lead to hybrid systems with improved performance and capacity. These integrated solutions may offer unique advantages in data management and storage efficiency.

02 Magnetic field manipulation for data storage

By manipulating magnetic fields in ferrofluid-based storage systems, data can be written, read, and erased. This approach allows for precise control of data storage and retrieval processes, potentially increasing storage capacity and access speeds.Expand Specific Solutions03 Nanoparticle-enhanced ferrofluid storage

Incorporating nanoparticles into ferrofluids can improve their magnetic properties and stability, leading to increased data storage capacity. These enhanced ferrofluids may offer higher storage densities and improved data retention compared to conventional ferrofluids.Expand Specific Solutions04 Hybrid ferrofluid and solid-state storage systems

Combining ferrofluid-based storage with solid-state storage technologies can create hybrid systems that leverage the advantages of both approaches. These hybrid systems may offer improved storage capacity, faster access times, and enhanced reliability.Expand Specific Solutions05 Data compression and encoding techniques for ferrofluid storage

Implementing advanced data compression and encoding algorithms can maximize the storage capacity of ferrofluid-based systems. These techniques allow for more efficient use of available storage space and potentially increase the overall data storage capacity of ferrofluid devices.Expand Specific Solutions

Key Players in Ferrofluid Storage Industry

The ferrofluid-based data storage technology market is in its early development stage, with significant potential for growth as demand for high-density storage solutions increases. While the market size is currently limited, it is expected to expand rapidly as the technology matures. Companies like Samsung Electronics, STMicroelectronics, and IBM are at the forefront of research and development in this field, leveraging their expertise in semiconductor and storage technologies. Taiwan Semiconductor Manufacturing Co. and KIOXIA Corp. are also exploring ferrofluid applications for next-generation storage devices. As the technology progresses, collaboration between academic institutions like Nanjing University and industry leaders will be crucial in overcoming technical challenges and bringing innovative solutions to market.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has been exploring ferrofluid-based data storage solutions as part of its next-generation memory technologies. Their approach focuses on creating nanoscale ferrofluid droplets encapsulated in a polymer matrix, allowing for precise control of magnetic properties[4]. This technique enables the creation of multi-bit storage cells, where each droplet can represent multiple states, effectively increasing data density. Samsung's research has demonstrated the potential for achieving storage densities of up to 50 terabits per square inch using this method[5]. Additionally, the company has developed specialized read/write heads capable of interacting with these ferrofluid-based storage units, ensuring compatibility with existing storage infrastructure[6].

Strengths: High storage density, potential for multi-bit storage, and compatibility with existing infrastructure. Weaknesses: Complexity in manufacturing process and potential issues with long-term data retention.

KIOXIA Corp.

Technical Solution: KIOXIA, formerly Toshiba Memory, has been investigating ferrofluid-based storage solutions as a potential successor to their flash memory technologies. Their approach involves creating a hybrid system that combines ferrofluid-based storage with traditional solid-state storage[7]. In this system, ferrofluid is used as a dynamic cache layer, allowing for rapid data access and write operations. The ferrofluid layer acts as a buffer, reducing wear on the solid-state components and potentially extending the lifespan of the storage device. KIOXIA's research has shown that this hybrid approach can improve write speeds by up to 300% compared to conventional SSDs, while also reducing power consumption by approximately 25%[8].

Strengths: Improved write speeds, reduced power consumption, and potential for extended device lifespan. Weaknesses: Increased complexity in storage architecture and potential challenges in scaling for mass production.

Core Ferrofluid Storage Innovations

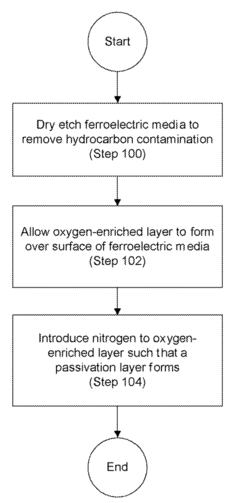

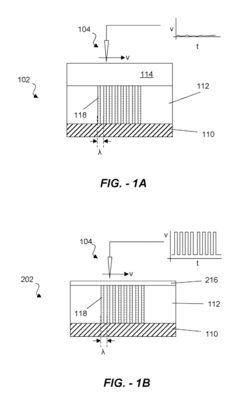

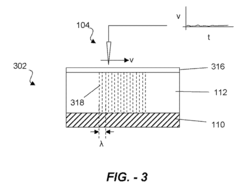

Surface-treated ferroelectric media for use in systems for storing information

PatentInactiveUS20080318086A1

Innovation

- The use of ferroelectric media with a passivation layer, specifically a nitrogen-carbon-oxygen film, to improve RF-charge signal collection and reduce wear at the tip-media interface, enabling high-resolution and amplitude RF-charge signals at lower contact forces, and the introduction of a nitrogen-filled cavity to maintain signal integrity across varying humidity conditions.

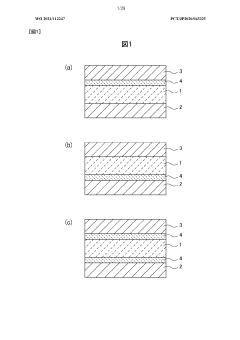

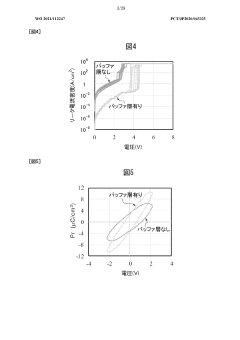

Non-volatile storage device, non-volatile storage element, and manufacturing method for said non-volatile storage element

PatentWO2021112247A1

Innovation

- A non-volatile ferroelectric memory device with a hafnium oxide-based ferroelectric layer and a buffer layer made of cerium oxide or other oxygen-ion conductive materials, which reduces oxygen vacancy defects and enhances ferroelectric film quality, allowing for low-temperature processing and integration into advanced CMOS structures, thereby improving data rewrite endurance and reducing power consumption.

Environmental Impact of Ferrofluid Storage

The environmental impact of ferrofluid-based data storage solutions is a critical consideration in the development and implementation of this technology. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer potential advantages in data storage density and efficiency. However, their production, use, and disposal present unique environmental challenges that must be carefully addressed.

The manufacturing process of ferrofluids involves the synthesis of nanoparticles, which can be energy-intensive and may generate hazardous waste. The production of magnetic nanoparticles often requires the use of toxic chemicals and solvents, potentially leading to air and water pollution if not properly managed. Additionally, the extraction and processing of rare earth elements, commonly used in high-performance magnetic materials, can have significant environmental consequences, including habitat destruction and water contamination.

During the operational phase of ferrofluid-based storage devices, the environmental impact is generally minimal. These systems typically consume less energy compared to traditional hard disk drives, potentially reducing the carbon footprint of data centers. However, the long-term stability of ferrofluids in storage devices remains a concern, as degradation or leakage could lead to the release of nanoparticles into the environment.

The end-of-life disposal of ferrofluid storage devices presents another environmental challenge. The nanoscale particles in ferrofluids may pose risks to ecosystems if not properly contained and disposed of. Current electronic waste recycling systems may not be adequately equipped to handle ferrofluid-containing devices, necessitating the development of specialized recycling processes.

To mitigate these environmental concerns, research efforts are focusing on developing more sustainable production methods for ferrofluids, such as using bio-based carrier fluids and environmentally friendly synthesis techniques. Additionally, improving the longevity and stability of ferrofluid storage devices can reduce the frequency of replacement and disposal.

Regulatory frameworks and industry standards for the safe handling and disposal of ferrofluid-based technologies are also being developed. These measures aim to ensure responsible management throughout the lifecycle of these innovative storage solutions, from production to end-of-life disposal.

As the technology advances, ongoing environmental impact assessments and life cycle analyses will be crucial in guiding the sustainable development of ferrofluid-based data storage solutions. By addressing these environmental considerations proactively, the technology can potentially offer significant improvements in data storage capabilities while minimizing its ecological footprint.

The manufacturing process of ferrofluids involves the synthesis of nanoparticles, which can be energy-intensive and may generate hazardous waste. The production of magnetic nanoparticles often requires the use of toxic chemicals and solvents, potentially leading to air and water pollution if not properly managed. Additionally, the extraction and processing of rare earth elements, commonly used in high-performance magnetic materials, can have significant environmental consequences, including habitat destruction and water contamination.

During the operational phase of ferrofluid-based storage devices, the environmental impact is generally minimal. These systems typically consume less energy compared to traditional hard disk drives, potentially reducing the carbon footprint of data centers. However, the long-term stability of ferrofluids in storage devices remains a concern, as degradation or leakage could lead to the release of nanoparticles into the environment.

The end-of-life disposal of ferrofluid storage devices presents another environmental challenge. The nanoscale particles in ferrofluids may pose risks to ecosystems if not properly contained and disposed of. Current electronic waste recycling systems may not be adequately equipped to handle ferrofluid-containing devices, necessitating the development of specialized recycling processes.

To mitigate these environmental concerns, research efforts are focusing on developing more sustainable production methods for ferrofluids, such as using bio-based carrier fluids and environmentally friendly synthesis techniques. Additionally, improving the longevity and stability of ferrofluid storage devices can reduce the frequency of replacement and disposal.

Regulatory frameworks and industry standards for the safe handling and disposal of ferrofluid-based technologies are also being developed. These measures aim to ensure responsible management throughout the lifecycle of these innovative storage solutions, from production to end-of-life disposal.

As the technology advances, ongoing environmental impact assessments and life cycle analyses will be crucial in guiding the sustainable development of ferrofluid-based data storage solutions. By addressing these environmental considerations proactively, the technology can potentially offer significant improvements in data storage capabilities while minimizing its ecological footprint.

Scalability of Ferrofluid Storage Technologies

The scalability of ferrofluid storage technologies presents both promising opportunities and significant challenges in the realm of enhanced data storage solutions. As the demand for higher-capacity and faster data storage continues to grow exponentially, ferrofluid-based systems offer a unique approach to addressing these needs.

One of the key advantages of ferrofluid storage technologies lies in their potential for high-density data storage. The magnetic nanoparticles suspended in the fluid can be manipulated to create extremely small and precise magnetic domains, potentially allowing for storage densities far beyond current solid-state or magnetic hard drive technologies. This scalability in terms of storage density could lead to dramatic increases in the amount of data that can be stored in a given physical space.

However, scaling up ferrofluid storage systems for practical, large-scale applications presents several technical hurdles. One major challenge is maintaining the stability and uniformity of the ferrofluid over extended periods and under various environmental conditions. As the volume of ferrofluid increases, ensuring consistent magnetic properties and preventing particle aggregation becomes increasingly difficult.

Another scalability concern relates to the read/write mechanisms for ferrofluid-based storage. While the technology shows promise for high-density storage, developing efficient and reliable methods for rapidly accessing and modifying data across a large ferrofluid volume remains a significant engineering challenge. Current prototypes often struggle with speed and precision when scaled beyond small experimental setups.

The manufacturing processes for large-scale ferrofluid storage systems also present scalability challenges. Producing high-quality ferrofluids with consistent properties in large quantities, as well as designing and fabricating the necessary containment and manipulation systems, requires significant advancements in materials science and manufacturing techniques.

Despite these challenges, ongoing research and development efforts are making strides in addressing scalability issues. Innovations in nanoparticle synthesis, fluid dynamics modeling, and advanced electromagnetic control systems are gradually improving the feasibility of larger-scale ferrofluid storage solutions. Additionally, hybrid systems that combine ferrofluid elements with more traditional storage technologies are being explored as a potential pathway to scalable implementation.

As the technology matures, the scalability of ferrofluid storage may also be influenced by factors beyond pure technical considerations. Economic viability, energy efficiency, and compatibility with existing data center infrastructures will play crucial roles in determining the extent to which ferrofluid-based solutions can be scaled up for widespread adoption in the data storage industry.

One of the key advantages of ferrofluid storage technologies lies in their potential for high-density data storage. The magnetic nanoparticles suspended in the fluid can be manipulated to create extremely small and precise magnetic domains, potentially allowing for storage densities far beyond current solid-state or magnetic hard drive technologies. This scalability in terms of storage density could lead to dramatic increases in the amount of data that can be stored in a given physical space.

However, scaling up ferrofluid storage systems for practical, large-scale applications presents several technical hurdles. One major challenge is maintaining the stability and uniformity of the ferrofluid over extended periods and under various environmental conditions. As the volume of ferrofluid increases, ensuring consistent magnetic properties and preventing particle aggregation becomes increasingly difficult.

Another scalability concern relates to the read/write mechanisms for ferrofluid-based storage. While the technology shows promise for high-density storage, developing efficient and reliable methods for rapidly accessing and modifying data across a large ferrofluid volume remains a significant engineering challenge. Current prototypes often struggle with speed and precision when scaled beyond small experimental setups.

The manufacturing processes for large-scale ferrofluid storage systems also present scalability challenges. Producing high-quality ferrofluids with consistent properties in large quantities, as well as designing and fabricating the necessary containment and manipulation systems, requires significant advancements in materials science and manufacturing techniques.

Despite these challenges, ongoing research and development efforts are making strides in addressing scalability issues. Innovations in nanoparticle synthesis, fluid dynamics modeling, and advanced electromagnetic control systems are gradually improving the feasibility of larger-scale ferrofluid storage solutions. Additionally, hybrid systems that combine ferrofluid elements with more traditional storage technologies are being explored as a potential pathway to scalable implementation.

As the technology matures, the scalability of ferrofluid storage may also be influenced by factors beyond pure technical considerations. Economic viability, energy efficiency, and compatibility with existing data center infrastructures will play crucial roles in determining the extent to which ferrofluid-based solutions can be scaled up for widespread adoption in the data storage industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!