How to Maximize Cost Effectiveness in Graphene Battery Use?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries have emerged as a promising technology in the energy storage landscape, offering potential advantages over traditional lithium-ion batteries. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which sparked intense research into its applications across various fields, including energy storage.

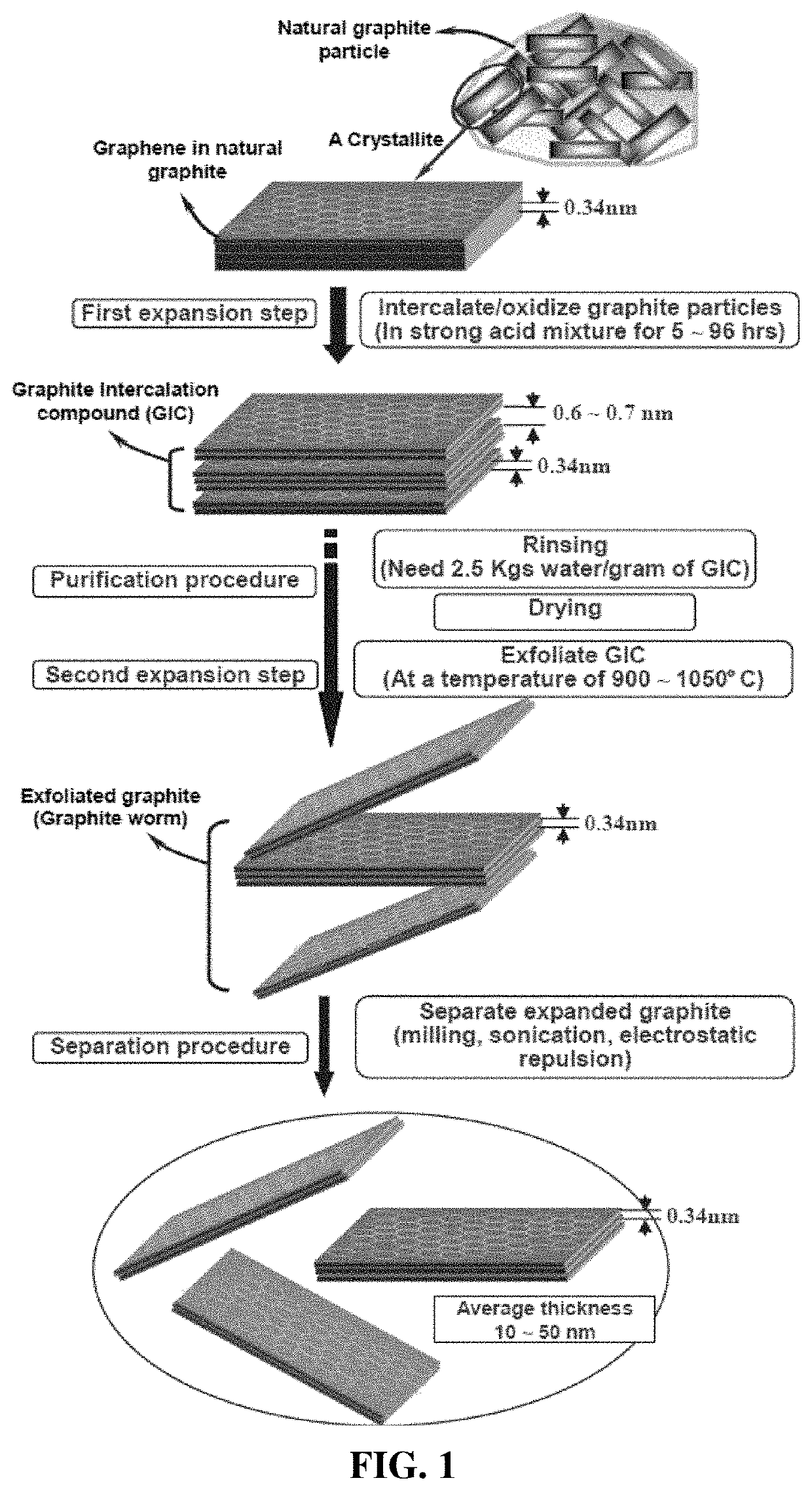

Initially, graphene was primarily used as an additive to enhance the performance of existing battery technologies. Researchers found that incorporating graphene into electrode materials could improve conductivity, stability, and overall battery performance. This phase of development focused on optimizing the integration of graphene into conventional battery designs.

As research progressed, scientists began exploring the possibility of using graphene as a primary component in battery electrodes. This shift led to the development of graphene-based anodes and cathodes, which demonstrated higher energy density and faster charging capabilities compared to traditional materials. The unique properties of graphene, such as its high surface area and excellent electrical conductivity, contributed to these improvements.

In recent years, the focus has shifted towards developing all-graphene batteries, where both electrodes and other components are primarily composed of graphene-based materials. This approach aims to fully leverage the potential of graphene in energy storage applications, potentially revolutionizing battery technology.

The primary objectives in graphene battery development are centered around maximizing cost-effectiveness while maintaining or improving performance. Key goals include increasing energy density to enable longer-lasting devices, enhancing charging speeds to reduce downtime, and improving overall battery lifespan to reduce replacement frequency and environmental impact.

Another critical objective is to scale up production processes for graphene-based battery components. Current manufacturing methods for high-quality graphene are often expensive and limited in scale, presenting a significant barrier to widespread adoption. Researchers and industry players are actively working on developing more efficient and cost-effective production techniques to make graphene batteries economically viable for mass production.

Sustainability is also a growing focus in graphene battery evolution. Objectives include reducing the environmental impact of battery production, improving recyclability, and exploring the use of more abundant and environmentally friendly materials in conjunction with graphene.

As the technology continues to evolve, the ultimate goal is to create a graphene battery that not only outperforms current lithium-ion batteries in terms of energy density, charging speed, and lifespan but also offers a compelling cost advantage. This would pave the way for widespread adoption across various applications, from consumer electronics to electric vehicles and grid-scale energy storage systems.

Initially, graphene was primarily used as an additive to enhance the performance of existing battery technologies. Researchers found that incorporating graphene into electrode materials could improve conductivity, stability, and overall battery performance. This phase of development focused on optimizing the integration of graphene into conventional battery designs.

As research progressed, scientists began exploring the possibility of using graphene as a primary component in battery electrodes. This shift led to the development of graphene-based anodes and cathodes, which demonstrated higher energy density and faster charging capabilities compared to traditional materials. The unique properties of graphene, such as its high surface area and excellent electrical conductivity, contributed to these improvements.

In recent years, the focus has shifted towards developing all-graphene batteries, where both electrodes and other components are primarily composed of graphene-based materials. This approach aims to fully leverage the potential of graphene in energy storage applications, potentially revolutionizing battery technology.

The primary objectives in graphene battery development are centered around maximizing cost-effectiveness while maintaining or improving performance. Key goals include increasing energy density to enable longer-lasting devices, enhancing charging speeds to reduce downtime, and improving overall battery lifespan to reduce replacement frequency and environmental impact.

Another critical objective is to scale up production processes for graphene-based battery components. Current manufacturing methods for high-quality graphene are often expensive and limited in scale, presenting a significant barrier to widespread adoption. Researchers and industry players are actively working on developing more efficient and cost-effective production techniques to make graphene batteries economically viable for mass production.

Sustainability is also a growing focus in graphene battery evolution. Objectives include reducing the environmental impact of battery production, improving recyclability, and exploring the use of more abundant and environmentally friendly materials in conjunction with graphene.

As the technology continues to evolve, the ultimate goal is to create a graphene battery that not only outperforms current lithium-ion batteries in terms of energy density, charging speed, and lifespan but also offers a compelling cost advantage. This would pave the way for widespread adoption across various applications, from consumer electronics to electric vehicles and grid-scale energy storage systems.

Market Analysis for Graphene Batteries

The graphene battery market is experiencing significant growth and attracting substantial investment due to its potential to revolutionize energy storage technology. As of 2023, the global graphene battery market was valued at approximately $115 million, with projections indicating a compound annual growth rate (CAGR) of over 25% from 2024 to 2030. This rapid expansion is driven by the increasing demand for high-performance energy storage solutions across various industries, including consumer electronics, automotive, and renewable energy sectors.

The automotive industry represents a key market for graphene batteries, particularly in the electric vehicle (EV) segment. Major automakers are exploring graphene-enhanced batteries to address range anxiety and charging time concerns, which are critical factors in EV adoption. The consumer electronics sector is another significant driver, with smartphone manufacturers showing interest in graphene batteries for their potential to offer faster charging times and longer battery life.

In the renewable energy sector, graphene batteries are gaining traction for grid energy storage applications. Their high energy density and rapid charge-discharge capabilities make them attractive for stabilizing power grids and storing excess energy from intermittent renewable sources like solar and wind.

Despite the promising market outlook, several challenges need to be addressed to maximize cost-effectiveness in graphene battery use. The primary hurdle is the high production cost of graphene, which currently limits widespread adoption. However, ongoing research and development efforts are focused on scaling up production and reducing costs, with some estimates suggesting that graphene prices could decrease by up to 40% in the next five years as manufacturing processes improve.

Market competition is intensifying, with both established battery manufacturers and startups entering the graphene battery space. This competition is expected to drive innovation and potentially lead to cost reductions through economies of scale and improved production techniques. Collaborations between graphene producers, battery manufacturers, and end-users are becoming more common, aiming to accelerate commercialization and reduce overall costs.

To maximize cost-effectiveness, the industry is exploring various strategies. These include optimizing graphene synthesis methods, developing hybrid materials that combine graphene with other cost-effective materials, and improving battery design to enhance performance while minimizing graphene content. Additionally, there is a growing focus on recycling and circular economy approaches to recover and reuse graphene from end-of-life batteries, which could significantly reduce raw material costs in the long term.

The automotive industry represents a key market for graphene batteries, particularly in the electric vehicle (EV) segment. Major automakers are exploring graphene-enhanced batteries to address range anxiety and charging time concerns, which are critical factors in EV adoption. The consumer electronics sector is another significant driver, with smartphone manufacturers showing interest in graphene batteries for their potential to offer faster charging times and longer battery life.

In the renewable energy sector, graphene batteries are gaining traction for grid energy storage applications. Their high energy density and rapid charge-discharge capabilities make them attractive for stabilizing power grids and storing excess energy from intermittent renewable sources like solar and wind.

Despite the promising market outlook, several challenges need to be addressed to maximize cost-effectiveness in graphene battery use. The primary hurdle is the high production cost of graphene, which currently limits widespread adoption. However, ongoing research and development efforts are focused on scaling up production and reducing costs, with some estimates suggesting that graphene prices could decrease by up to 40% in the next five years as manufacturing processes improve.

Market competition is intensifying, with both established battery manufacturers and startups entering the graphene battery space. This competition is expected to drive innovation and potentially lead to cost reductions through economies of scale and improved production techniques. Collaborations between graphene producers, battery manufacturers, and end-users are becoming more common, aiming to accelerate commercialization and reduce overall costs.

To maximize cost-effectiveness, the industry is exploring various strategies. These include optimizing graphene synthesis methods, developing hybrid materials that combine graphene with other cost-effective materials, and improving battery design to enhance performance while minimizing graphene content. Additionally, there is a growing focus on recycling and circular economy approaches to recover and reuse graphene from end-of-life batteries, which could significantly reduce raw material costs in the long term.

Graphene Battery Technology Challenges

Despite the promising potential of graphene batteries, several significant technological challenges hinder their widespread adoption and cost-effective implementation. One of the primary obstacles is the complexity and high cost associated with large-scale graphene production. Current manufacturing processes for high-quality graphene are labor-intensive and expensive, making it difficult to achieve economies of scale necessary for commercial viability.

Another major challenge lies in the integration of graphene into existing battery architectures. While graphene exhibits exceptional electrical and thermal conductivity, incorporating it effectively into battery electrodes without compromising other performance aspects remains a significant hurdle. Researchers are grappling with issues such as maintaining structural stability and preventing agglomeration of graphene sheets during charge-discharge cycles.

The development of efficient and scalable methods for functionalizing graphene is another critical challenge. Functionalization is essential for tailoring graphene's properties to specific battery applications, but current techniques often involve complex chemical processes that are difficult to scale up without sacrificing quality or increasing costs.

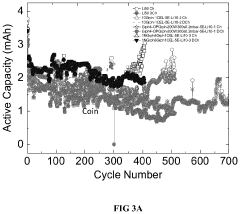

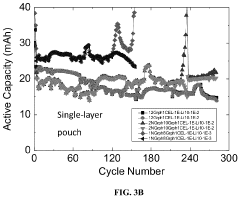

Stability and longevity of graphene-enhanced batteries pose additional challenges. While graphene can potentially improve battery life, ensuring consistent performance over thousands of charge cycles under various environmental conditions is crucial for commercial success. This requires extensive testing and optimization, which adds to development time and costs.

Furthermore, the environmental impact and safety concerns associated with graphene production and disposal need to be addressed. Developing sustainable manufacturing processes and establishing proper recycling methods for graphene batteries are essential for long-term cost-effectiveness and regulatory compliance.

Lastly, the lack of standardization in graphene quality and characterization methods presents a challenge for industry-wide adoption. Establishing universal standards and quality control measures is crucial for ensuring consistency in battery performance and facilitating comparisons between different graphene-based solutions.

Overcoming these technological challenges is vital for maximizing the cost-effectiveness of graphene batteries. It requires collaborative efforts between researchers, manufacturers, and regulatory bodies to develop innovative solutions, streamline production processes, and create a supportive ecosystem for graphene battery technology.

Another major challenge lies in the integration of graphene into existing battery architectures. While graphene exhibits exceptional electrical and thermal conductivity, incorporating it effectively into battery electrodes without compromising other performance aspects remains a significant hurdle. Researchers are grappling with issues such as maintaining structural stability and preventing agglomeration of graphene sheets during charge-discharge cycles.

The development of efficient and scalable methods for functionalizing graphene is another critical challenge. Functionalization is essential for tailoring graphene's properties to specific battery applications, but current techniques often involve complex chemical processes that are difficult to scale up without sacrificing quality or increasing costs.

Stability and longevity of graphene-enhanced batteries pose additional challenges. While graphene can potentially improve battery life, ensuring consistent performance over thousands of charge cycles under various environmental conditions is crucial for commercial success. This requires extensive testing and optimization, which adds to development time and costs.

Furthermore, the environmental impact and safety concerns associated with graphene production and disposal need to be addressed. Developing sustainable manufacturing processes and establishing proper recycling methods for graphene batteries are essential for long-term cost-effectiveness and regulatory compliance.

Lastly, the lack of standardization in graphene quality and characterization methods presents a challenge for industry-wide adoption. Establishing universal standards and quality control measures is crucial for ensuring consistency in battery performance and facilitating comparisons between different graphene-based solutions.

Overcoming these technological challenges is vital for maximizing the cost-effectiveness of graphene batteries. It requires collaborative efforts between researchers, manufacturers, and regulatory bodies to develop innovative solutions, streamline production processes, and create a supportive ecosystem for graphene battery technology.

Current Cost Reduction Strategies

01 Cost-effective production methods

Developing efficient and scalable production methods for graphene is crucial for reducing the overall cost of graphene batteries. This includes optimizing synthesis techniques, improving yield, and reducing energy consumption during production. These advancements can significantly lower the manufacturing costs, making graphene batteries more economically viable for widespread adoption.- Cost-effective production methods: Developing efficient and scalable production methods for graphene is crucial for reducing the overall cost of graphene batteries. This includes optimizing synthesis techniques, improving yield, and reducing energy consumption during production. These advancements contribute to making graphene batteries more economically viable for widespread adoption.

- Enhanced energy storage capacity: Graphene's unique properties allow for increased energy storage capacity in batteries. This improvement in energy density can lead to longer-lasting batteries, potentially reducing the total cost of ownership for end-users. The enhanced performance may justify the initial higher cost of graphene-based batteries in certain applications.

- Integration with existing battery technologies: Incorporating graphene into existing battery technologies, such as lithium-ion batteries, can improve their performance without requiring a complete overhaul of manufacturing processes. This approach may offer a more cost-effective path to implementing graphene in energy storage solutions, leveraging existing infrastructure and knowledge.

- Lifecycle and durability improvements: Graphene batteries potentially offer increased durability and longer lifecycles compared to traditional batteries. This extended lifespan can offset the initial higher cost by reducing the frequency of battery replacements, leading to long-term cost savings for consumers and businesses.

- Market analysis and cost projections: Conducting thorough market analysis and cost projections is essential for understanding the economic viability of graphene batteries. This includes assessing production costs, market demand, and potential price reductions as technology matures. Such analysis helps in determining the timeline for when graphene batteries may become cost-competitive with traditional energy storage solutions.

02 Enhanced energy storage capacity

Graphene's unique properties allow for increased energy storage capacity in batteries. By incorporating graphene into battery electrodes, the surface area and conductivity are improved, leading to higher energy density and faster charging capabilities. This enhanced performance can justify the potentially higher initial costs of graphene batteries compared to traditional alternatives.Expand Specific Solutions03 Improved battery lifespan and durability

Graphene-enhanced batteries demonstrate increased durability and longer lifespans compared to conventional batteries. The material's strength and flexibility contribute to better structural integrity, reducing degradation over time. This extended lifespan can offset the initial higher costs by reducing the frequency of battery replacements, improving the overall cost-effectiveness in long-term applications.Expand Specific Solutions04 Integration with renewable energy systems

Graphene batteries show promise in renewable energy storage applications, particularly in solar and wind power systems. Their ability to efficiently store and discharge energy can enhance the reliability and effectiveness of renewable energy sources. This integration can lead to cost savings in the broader context of sustainable energy solutions, potentially offsetting the higher upfront costs of graphene battery technology.Expand Specific Solutions05 Market analysis and cost projections

Comprehensive market analysis and cost projections are essential for assessing the long-term cost-effectiveness of graphene batteries. This includes evaluating production scalability, potential for cost reduction through technological advancements, and comparing total lifecycle costs with traditional battery technologies. Such analyses help in determining the economic viability and potential return on investment for graphene battery adoption across various industries.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery market is in its early growth stage, with significant potential for cost optimization. The industry is characterized by a mix of academic institutions, established tech companies, and specialized startups, indicating a dynamic and competitive landscape. Market size is expanding as research progresses, but commercial applications are still limited. Technological maturity varies, with companies like Honeycomb Battery Co. and Nanotek Instruments leading in commercialization efforts. Major players such as Apple and NEC Corp. are investing in research, while universities like Northwestern and Queensland are advancing fundamental understanding. The involvement of national laboratories and global chemical companies suggests a broad interest in developing cost-effective graphene battery solutions.

Northwestern University

Technical Solution: Northwestern University has developed a novel approach to maximize cost-effectiveness in graphene battery use through their advanced graphene-based electrode materials. Their research focuses on creating high-performance, low-cost graphene composites for battery electrodes. The university's team has successfully synthesized graphene-metal oxide nanocomposites that significantly enhance energy storage capacity and cycling stability[1]. By utilizing a scalable and cost-effective production method, they have managed to reduce the overall manufacturing costs while maintaining superior electrochemical performance[2]. The university's approach also includes the development of graphene-based flexible electrodes, which can be integrated into various battery form factors, potentially reducing production complexity and costs[3].

Strengths: Cutting-edge research in graphene composites, scalable production methods, and flexible electrode designs. Weaknesses: Potential challenges in large-scale commercialization and integration with existing battery manufacturing processes.

Honeycomb Battery Co.

Technical Solution: Honeycomb Battery Co. has pioneered a unique honeycomb-structured graphene battery design to maximize cost-effectiveness. Their approach involves creating a three-dimensional graphene framework that resembles a honeycomb structure, significantly increasing the surface area for energy storage[1]. This design allows for higher energy density and faster charging rates compared to traditional battery architectures. The company has developed a proprietary manufacturing process that enables the mass production of these honeycomb graphene structures at a competitive cost[2]. Additionally, Honeycomb Battery Co. has implemented advanced electrolyte formulations that work synergistically with their graphene structure, further enhancing battery performance and longevity[3].

Strengths: Innovative honeycomb design, increased energy density, and scalable manufacturing process. Weaknesses: Potential complexity in integrating the unique structure into existing battery production lines.

Innovative Graphene Synthesis Methods

Direct-formation self-assembly graphene from cellulose nanofiber aqueous solution

PatentPendingUS20240088397A1

Innovation

- A self-assembled freestanding graphene membrane or layer is formed using an aqueous dispersion of industrial-grade graphene and cellulose nanofibers with a mass ratio of 12:1 to 20:1, which improves dispersibility and allows for low-temperature direct fabrication, enabling the formation of a stable and conductive graphene scaffold for lithium metal anodes.

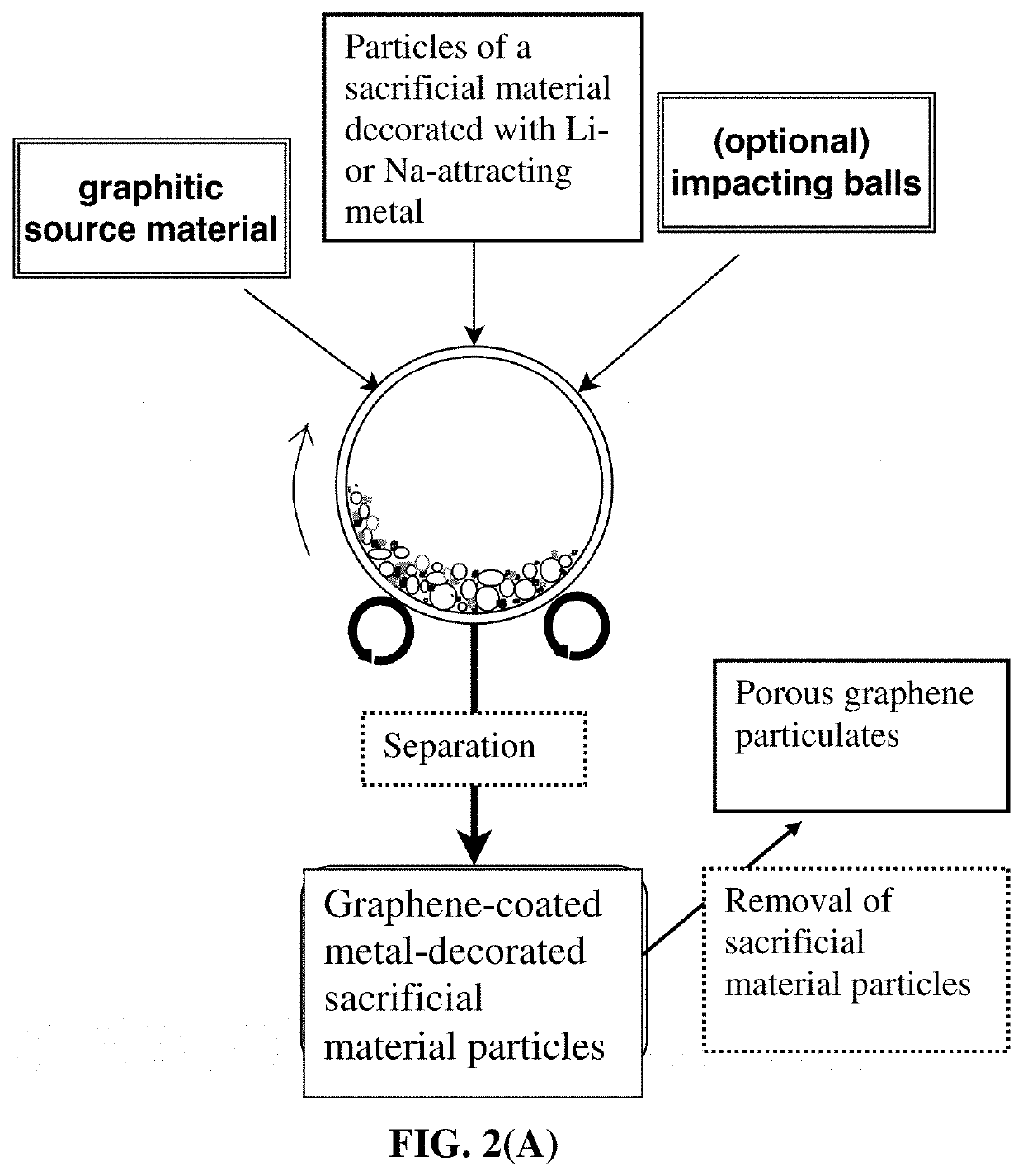

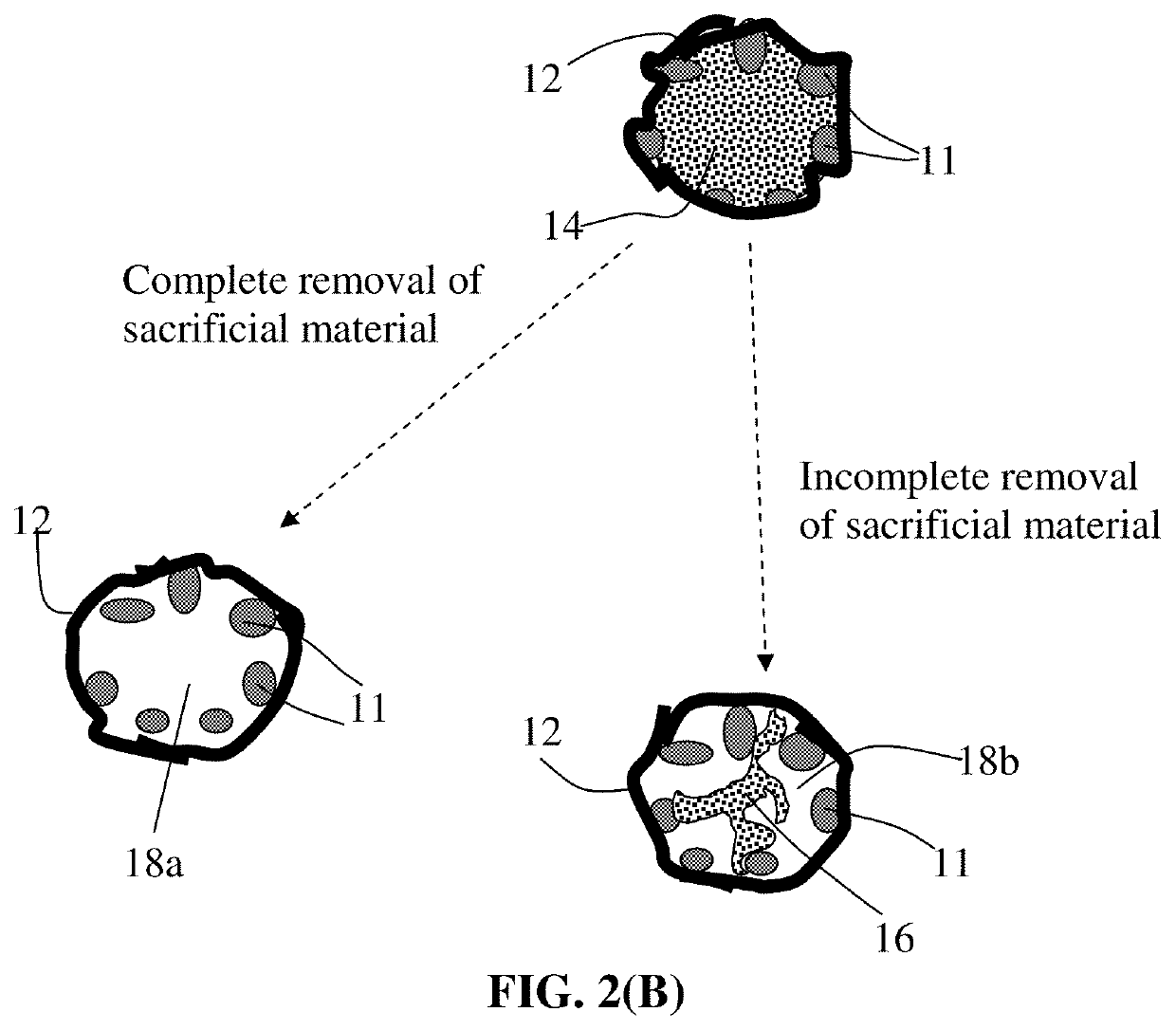

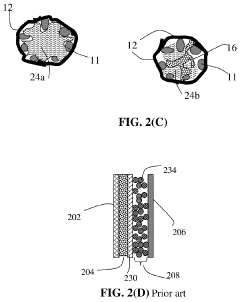

Process for producing porous particulates of graphene shell-protected alkali metal, electrodes, and alkali metal battery

PatentPendingUS20200287207A1

Innovation

- The development of porous graphene particulates pre-loaded with lithium or sodium metal, where a graphene shell encapsulates a porous core with a lithium- or sodium-attracting metal, preventing dendrite formation and enhancing ion conductivity, is used as an anode active material in lithium or sodium metal batteries.

Supply Chain Optimization for Graphene Batteries

Optimizing the supply chain for graphene batteries is crucial for maximizing cost-effectiveness in their production and deployment. The process begins with sourcing high-quality graphene materials from reliable suppliers. Establishing long-term partnerships with graphene manufacturers can lead to more stable pricing and consistent quality, which are essential for maintaining production standards and controlling costs.

Transportation and logistics play a significant role in supply chain optimization. Given the delicate nature of graphene materials, specialized handling and transportation methods are required. Implementing advanced tracking systems and temperature-controlled shipping can minimize material degradation and reduce waste, ultimately lowering overall costs. Additionally, strategically locating production facilities closer to either raw material sources or end markets can significantly reduce transportation expenses and lead times.

Inventory management is another critical aspect of supply chain optimization for graphene batteries. Implementing just-in-time (JIT) inventory systems can help reduce storage costs and minimize the risk of material obsolescence. However, this approach must be balanced with the need to maintain sufficient stock to meet production demands and account for potential supply chain disruptions.

Vertical integration within the supply chain can offer substantial cost benefits. By controlling multiple stages of production, from graphene synthesis to battery assembly, companies can reduce intermediary costs and have greater control over quality and production timelines. This approach also allows for more efficient resource allocation and faster implementation of technological improvements across the production process.

Collaboration with research institutions and other industry players can lead to innovations in production techniques and material efficiency. Sharing knowledge and resources through strategic partnerships can accelerate the development of more cost-effective manufacturing processes and improve overall supply chain efficiency.

Implementing advanced analytics and artificial intelligence in supply chain management can provide valuable insights for optimization. These technologies can help predict demand fluctuations, identify potential bottlenecks, and suggest more efficient routing and production schedules. By leveraging data-driven decision-making, companies can continuously refine their supply chain operations and adapt to changing market conditions.

Lastly, focusing on sustainability and circular economy principles in the supply chain can lead to long-term cost savings. Developing recycling processes for graphene batteries and their components can reduce reliance on raw materials and lower production costs over time. Additionally, sustainable practices can improve brand reputation and potentially open up new market opportunities, further enhancing the cost-effectiveness of graphene battery production and use.

Transportation and logistics play a significant role in supply chain optimization. Given the delicate nature of graphene materials, specialized handling and transportation methods are required. Implementing advanced tracking systems and temperature-controlled shipping can minimize material degradation and reduce waste, ultimately lowering overall costs. Additionally, strategically locating production facilities closer to either raw material sources or end markets can significantly reduce transportation expenses and lead times.

Inventory management is another critical aspect of supply chain optimization for graphene batteries. Implementing just-in-time (JIT) inventory systems can help reduce storage costs and minimize the risk of material obsolescence. However, this approach must be balanced with the need to maintain sufficient stock to meet production demands and account for potential supply chain disruptions.

Vertical integration within the supply chain can offer substantial cost benefits. By controlling multiple stages of production, from graphene synthesis to battery assembly, companies can reduce intermediary costs and have greater control over quality and production timelines. This approach also allows for more efficient resource allocation and faster implementation of technological improvements across the production process.

Collaboration with research institutions and other industry players can lead to innovations in production techniques and material efficiency. Sharing knowledge and resources through strategic partnerships can accelerate the development of more cost-effective manufacturing processes and improve overall supply chain efficiency.

Implementing advanced analytics and artificial intelligence in supply chain management can provide valuable insights for optimization. These technologies can help predict demand fluctuations, identify potential bottlenecks, and suggest more efficient routing and production schedules. By leveraging data-driven decision-making, companies can continuously refine their supply chain operations and adapt to changing market conditions.

Lastly, focusing on sustainability and circular economy principles in the supply chain can lead to long-term cost savings. Developing recycling processes for graphene batteries and their components can reduce reliance on raw materials and lower production costs over time. Additionally, sustainable practices can improve brand reputation and potentially open up new market opportunities, further enhancing the cost-effectiveness of graphene battery production and use.

Environmental Impact of Graphene Battery Manufacturing

The environmental impact of graphene battery manufacturing is a critical consideration in the pursuit of maximizing cost-effectiveness in graphene battery use. The production process of graphene batteries involves several stages that can potentially affect the environment, necessitating a comprehensive analysis of its ecological footprint.

One of the primary environmental concerns is the energy-intensive nature of graphene production. The synthesis of high-quality graphene often requires substantial energy inputs, which can lead to increased carbon emissions if not sourced from renewable energy. However, advancements in production techniques, such as chemical vapor deposition and electrochemical exfoliation, are gradually reducing the energy requirements and associated environmental impact.

Water usage and potential contamination are also significant factors to consider. The manufacturing process may involve the use of various chemicals and solvents, which, if not properly managed, could lead to water pollution. Implementing closed-loop water systems and developing more environmentally friendly synthesis methods can help mitigate these risks and improve the overall sustainability of graphene battery production.

The extraction and processing of raw materials for graphene batteries, particularly graphite, can have substantial environmental implications. Mining activities can lead to habitat destruction, soil erosion, and water pollution. However, the long lifespan and high efficiency of graphene batteries may offset some of these impacts over time by reducing the need for frequent battery replacements and improving overall energy storage efficiency.

Waste management is another crucial aspect of the environmental impact assessment. The production of graphene batteries generates various waste materials, including chemical byproducts and defective components. Developing effective recycling and disposal methods for these materials is essential to minimize environmental harm and promote a circular economy approach in battery manufacturing.

On a positive note, the unique properties of graphene offer potential environmental benefits in battery production. The high conductivity and strength of graphene allow for the creation of more efficient and durable batteries, potentially reducing the overall material requirements and extending battery lifespans. This could lead to a decrease in electronic waste and the need for frequent battery replacements, ultimately contributing to a reduction in the environmental footprint of energy storage systems.

As the technology matures, there is a growing focus on developing more sustainable manufacturing processes for graphene batteries. This includes exploring bio-based precursors for graphene production, optimizing synthesis methods to reduce energy consumption, and implementing stricter environmental controls in production facilities. These efforts aim to balance the environmental impact with the potential benefits of graphene battery technology, ensuring a more sustainable approach to energy storage solutions.

One of the primary environmental concerns is the energy-intensive nature of graphene production. The synthesis of high-quality graphene often requires substantial energy inputs, which can lead to increased carbon emissions if not sourced from renewable energy. However, advancements in production techniques, such as chemical vapor deposition and electrochemical exfoliation, are gradually reducing the energy requirements and associated environmental impact.

Water usage and potential contamination are also significant factors to consider. The manufacturing process may involve the use of various chemicals and solvents, which, if not properly managed, could lead to water pollution. Implementing closed-loop water systems and developing more environmentally friendly synthesis methods can help mitigate these risks and improve the overall sustainability of graphene battery production.

The extraction and processing of raw materials for graphene batteries, particularly graphite, can have substantial environmental implications. Mining activities can lead to habitat destruction, soil erosion, and water pollution. However, the long lifespan and high efficiency of graphene batteries may offset some of these impacts over time by reducing the need for frequent battery replacements and improving overall energy storage efficiency.

Waste management is another crucial aspect of the environmental impact assessment. The production of graphene batteries generates various waste materials, including chemical byproducts and defective components. Developing effective recycling and disposal methods for these materials is essential to minimize environmental harm and promote a circular economy approach in battery manufacturing.

On a positive note, the unique properties of graphene offer potential environmental benefits in battery production. The high conductivity and strength of graphene allow for the creation of more efficient and durable batteries, potentially reducing the overall material requirements and extending battery lifespans. This could lead to a decrease in electronic waste and the need for frequent battery replacements, ultimately contributing to a reduction in the environmental footprint of energy storage systems.

As the technology matures, there is a growing focus on developing more sustainable manufacturing processes for graphene batteries. This includes exploring bio-based precursors for graphene production, optimizing synthesis methods to reduce energy consumption, and implementing stricter environmental controls in production facilities. These efforts aim to balance the environmental impact with the potential benefits of graphene battery technology, ensuring a more sustainable approach to energy storage solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!