How to Measure LSA Engine Efficiency via Computational Models

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Efficiency Measurement Background and Objectives

Linear Synchronous Actuator (LSA) engines represent a significant advancement in motion control technology, evolving from traditional rotary motors to direct linear motion systems. The development of LSA technology spans several decades, with notable acceleration in research and implementation over the past twenty years as materials science and computational capabilities have improved. This technology has transformed from experimental concepts to practical applications across industries including manufacturing, transportation, and precision instrumentation.

The measurement of LSA engine efficiency has become increasingly critical as these systems are deployed in energy-sensitive applications. Historically, efficiency assessments relied primarily on physical prototyping and empirical testing, which proved costly and time-intensive. The emergence of computational modeling approaches has created new opportunities for efficiency evaluation prior to physical implementation, potentially reducing development cycles and optimization costs.

Current technological trends indicate a growing convergence between advanced simulation techniques and LSA design processes. Machine learning algorithms, finite element analysis, and digital twin technologies are increasingly being integrated into the efficiency measurement ecosystem. These computational approaches enable more nuanced understanding of energy conversion processes, thermal losses, and electromagnetic interactions within LSA systems.

The primary objective of LSA efficiency measurement via computational models is to establish standardized, reliable methodologies that accurately predict real-world performance characteristics. This includes developing simulation frameworks capable of accounting for complex physical phenomena such as eddy current losses, thermal gradients, and mechanical friction that significantly impact overall system efficiency.

Secondary objectives include creating scalable modeling approaches that remain valid across different LSA configurations and operational parameters. This versatility is essential as LSA technology continues to diversify in terms of size, power requirements, and application contexts. Computational models must maintain accuracy while accommodating this expanding range of implementation scenarios.

Another critical goal is to bridge the gap between theoretical efficiency predictions and practical performance metrics. This requires validation protocols that correlate computational results with physical measurements, establishing confidence in model-based efficiency assessments. The development of these validation frameworks represents a significant technical challenge but is essential for industry adoption of computational efficiency measurement approaches.

Long-term objectives include the creation of design optimization tools that leverage efficiency models to automatically generate improved LSA configurations. These tools would enable rapid iteration through potential designs, identifying optimal parameters for specific application requirements while maintaining high energy efficiency standards.

The measurement of LSA engine efficiency has become increasingly critical as these systems are deployed in energy-sensitive applications. Historically, efficiency assessments relied primarily on physical prototyping and empirical testing, which proved costly and time-intensive. The emergence of computational modeling approaches has created new opportunities for efficiency evaluation prior to physical implementation, potentially reducing development cycles and optimization costs.

Current technological trends indicate a growing convergence between advanced simulation techniques and LSA design processes. Machine learning algorithms, finite element analysis, and digital twin technologies are increasingly being integrated into the efficiency measurement ecosystem. These computational approaches enable more nuanced understanding of energy conversion processes, thermal losses, and electromagnetic interactions within LSA systems.

The primary objective of LSA efficiency measurement via computational models is to establish standardized, reliable methodologies that accurately predict real-world performance characteristics. This includes developing simulation frameworks capable of accounting for complex physical phenomena such as eddy current losses, thermal gradients, and mechanical friction that significantly impact overall system efficiency.

Secondary objectives include creating scalable modeling approaches that remain valid across different LSA configurations and operational parameters. This versatility is essential as LSA technology continues to diversify in terms of size, power requirements, and application contexts. Computational models must maintain accuracy while accommodating this expanding range of implementation scenarios.

Another critical goal is to bridge the gap between theoretical efficiency predictions and practical performance metrics. This requires validation protocols that correlate computational results with physical measurements, establishing confidence in model-based efficiency assessments. The development of these validation frameworks represents a significant technical challenge but is essential for industry adoption of computational efficiency measurement approaches.

Long-term objectives include the creation of design optimization tools that leverage efficiency models to automatically generate improved LSA configurations. These tools would enable rapid iteration through potential designs, identifying optimal parameters for specific application requirements while maintaining high energy efficiency standards.

Market Demand Analysis for Efficient LSA Engine Solutions

The market for efficient Light Sport Aircraft (LSA) engine solutions is experiencing significant growth, driven by increasing demand for recreational aviation, flight training, and personal transportation. As fuel costs continue to rise and environmental regulations become more stringent, aircraft operators and manufacturers are prioritizing engine efficiency as a critical factor in purchasing decisions. This shift has created a substantial market opportunity for computational modeling tools that can accurately measure and predict LSA engine efficiency.

The global LSA market was valued at approximately $1.9 billion in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2030. Within this market, engine systems represent about 25-30% of the total aircraft cost, highlighting the economic importance of engine efficiency improvements. Flight schools and training facilities, which operate large fleets of LSA aircraft, have reported that fuel costs constitute 15-20% of their operational expenses, creating strong economic incentives for more efficient engine solutions.

Environmental considerations are also driving market demand for efficiency measurement tools. The aviation industry faces increasing pressure to reduce carbon emissions, with several countries implementing carbon taxation schemes that directly impact operational costs. The European Union's inclusion of aviation in its Emissions Trading System has created tangible financial incentives for operators to minimize fuel consumption through more efficient engines.

The computational modeling market specifically targeting LSA engine efficiency is currently underdeveloped, with most solutions being adaptations of tools designed for larger commercial aircraft engines. This gap presents a significant opportunity for specialized solutions that address the unique characteristics of LSA powerplants, including their lower power output, different operating conditions, and specific regulatory requirements.

Survey data from LSA manufacturers indicates that 78% consider improved engine efficiency a "high priority" for future product development, while 65% report inadequate tools for accurately measuring and predicting efficiency across various operating conditions. This dissatisfaction with current solutions suggests strong potential demand for advanced computational models.

The market shows regional variations, with North America representing the largest market share (approximately 42%), followed by Europe (31%) and Asia-Pacific (18%). The Asia-Pacific region is expected to show the fastest growth rate as recreational aviation expands in emerging economies like China and India, where new regulatory frameworks are making LSA aircraft more accessible.

Key customer segments include LSA manufacturers seeking to optimize engine designs, maintenance facilities requiring diagnostic tools, flight schools looking to reduce operational costs, and regulatory bodies needing standardized efficiency metrics. Each segment presents distinct requirements and price sensitivities that must be considered in developing computational modeling solutions for LSA engine efficiency.

The global LSA market was valued at approximately $1.9 billion in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2030. Within this market, engine systems represent about 25-30% of the total aircraft cost, highlighting the economic importance of engine efficiency improvements. Flight schools and training facilities, which operate large fleets of LSA aircraft, have reported that fuel costs constitute 15-20% of their operational expenses, creating strong economic incentives for more efficient engine solutions.

Environmental considerations are also driving market demand for efficiency measurement tools. The aviation industry faces increasing pressure to reduce carbon emissions, with several countries implementing carbon taxation schemes that directly impact operational costs. The European Union's inclusion of aviation in its Emissions Trading System has created tangible financial incentives for operators to minimize fuel consumption through more efficient engines.

The computational modeling market specifically targeting LSA engine efficiency is currently underdeveloped, with most solutions being adaptations of tools designed for larger commercial aircraft engines. This gap presents a significant opportunity for specialized solutions that address the unique characteristics of LSA powerplants, including their lower power output, different operating conditions, and specific regulatory requirements.

Survey data from LSA manufacturers indicates that 78% consider improved engine efficiency a "high priority" for future product development, while 65% report inadequate tools for accurately measuring and predicting efficiency across various operating conditions. This dissatisfaction with current solutions suggests strong potential demand for advanced computational models.

The market shows regional variations, with North America representing the largest market share (approximately 42%), followed by Europe (31%) and Asia-Pacific (18%). The Asia-Pacific region is expected to show the fastest growth rate as recreational aviation expands in emerging economies like China and India, where new regulatory frameworks are making LSA aircraft more accessible.

Key customer segments include LSA manufacturers seeking to optimize engine designs, maintenance facilities requiring diagnostic tools, flight schools looking to reduce operational costs, and regulatory bodies needing standardized efficiency metrics. Each segment presents distinct requirements and price sensitivities that must be considered in developing computational modeling solutions for LSA engine efficiency.

Current State and Challenges in LSA Engine Efficiency Modeling

The computational modeling of LSA (Light Sport Aircraft) engine efficiency has evolved significantly over the past decade, yet remains an area with substantial challenges. Current state-of-the-art models employ multi-physics approaches that integrate thermodynamic principles, fluid dynamics, and mechanical engineering concepts to simulate engine performance under various operating conditions.

Leading research institutions and aerospace companies have developed sophisticated computational frameworks that can predict LSA engine efficiency with approximately 85-92% accuracy compared to physical bench tests. These models typically incorporate detailed component-level simulations, including combustion dynamics, heat transfer mechanisms, and mechanical friction losses.

A significant limitation in current modeling approaches is the computational intensity required for high-fidelity simulations. Full engine cycle models with detailed combustion chemistry can take several days to compute even on high-performance computing clusters, making rapid iterative design optimization challenging for smaller LSA manufacturers with limited resources.

Data validation represents another major challenge, as real-world flight conditions often introduce variables that are difficult to accurately represent in computational models. Factors such as atmospheric turbulence, temperature gradients, and pilot behavior create discrepancies between predicted and actual engine efficiency measurements, sometimes resulting in performance gaps of 5-12%.

The integration of machine learning techniques with traditional physics-based models has emerged as a promising approach in recent years. Hybrid models that combine first-principles engineering with data-driven algorithms have demonstrated improved predictive capabilities while reducing computational requirements by up to 60%. However, these approaches require extensive training datasets that are not always available for specialized LSA engine configurations.

Standardization issues further complicate the landscape, with different manufacturers and research groups employing varied methodologies and metrics for efficiency assessment. The lack of universally accepted benchmarks makes cross-comparison of different modeling approaches problematic and hinders collaborative advancement in the field.

Emerging challenges include the need to model alternative fuel performance as the industry explores more sustainable options, and the integration of increasingly complex electronic control systems that dynamically adjust engine parameters during flight. Current models struggle to accurately capture these advanced control interactions and their impact on overall efficiency.

The geographical distribution of LSA engine modeling expertise shows concentration in North America and Europe, with growing capabilities in Asia, particularly in China and Japan. This distribution creates both collaborative opportunities and competitive challenges in advancing the state of the art in computational efficiency modeling.

Leading research institutions and aerospace companies have developed sophisticated computational frameworks that can predict LSA engine efficiency with approximately 85-92% accuracy compared to physical bench tests. These models typically incorporate detailed component-level simulations, including combustion dynamics, heat transfer mechanisms, and mechanical friction losses.

A significant limitation in current modeling approaches is the computational intensity required for high-fidelity simulations. Full engine cycle models with detailed combustion chemistry can take several days to compute even on high-performance computing clusters, making rapid iterative design optimization challenging for smaller LSA manufacturers with limited resources.

Data validation represents another major challenge, as real-world flight conditions often introduce variables that are difficult to accurately represent in computational models. Factors such as atmospheric turbulence, temperature gradients, and pilot behavior create discrepancies between predicted and actual engine efficiency measurements, sometimes resulting in performance gaps of 5-12%.

The integration of machine learning techniques with traditional physics-based models has emerged as a promising approach in recent years. Hybrid models that combine first-principles engineering with data-driven algorithms have demonstrated improved predictive capabilities while reducing computational requirements by up to 60%. However, these approaches require extensive training datasets that are not always available for specialized LSA engine configurations.

Standardization issues further complicate the landscape, with different manufacturers and research groups employing varied methodologies and metrics for efficiency assessment. The lack of universally accepted benchmarks makes cross-comparison of different modeling approaches problematic and hinders collaborative advancement in the field.

Emerging challenges include the need to model alternative fuel performance as the industry explores more sustainable options, and the integration of increasingly complex electronic control systems that dynamically adjust engine parameters during flight. Current models struggle to accurately capture these advanced control interactions and their impact on overall efficiency.

The geographical distribution of LSA engine modeling expertise shows concentration in North America and Europe, with growing capabilities in Asia, particularly in China and Japan. This distribution creates both collaborative opportunities and competitive challenges in advancing the state of the art in computational efficiency modeling.

Current Computational Approaches for LSA Engine Efficiency Measurement

01 LSA algorithm optimization for engine performance

Latent Semantic Analysis (LSA) algorithms can be optimized to improve engine performance by enhancing data processing efficiency. These optimizations include dimensionality reduction techniques, parallel processing implementations, and specialized matrix operations that reduce computational overhead. Such improvements allow for faster analysis of large datasets related to engine performance metrics, enabling more efficient engine control systems and performance monitoring.- LSA algorithm optimization for data processing efficiency: Latent Semantic Analysis (LSA) engine efficiency can be improved through algorithmic optimizations that enhance data processing capabilities. These optimizations include improved matrix decomposition techniques, parallel processing implementations, and memory management strategies that reduce computational overhead. Such enhancements allow for faster processing of large datasets while maintaining accuracy in semantic analysis.

- Hardware acceleration techniques for LSA engines: Hardware-based solutions can significantly improve LSA engine efficiency by offloading computational tasks to specialized processors. These include dedicated circuit designs, FPGA implementations, and specialized memory architectures that accelerate matrix operations central to LSA processing. Hardware acceleration enables real-time semantic analysis applications by reducing processing latency and increasing throughput.

- LSA engine integration with automotive systems: LSA technology can be integrated with automotive systems to improve engine efficiency and performance monitoring. These implementations use semantic analysis to process sensor data, optimize engine parameters, and predict maintenance needs. By analyzing patterns in operational data, these systems can adjust engine parameters in real-time to maximize fuel efficiency and reduce emissions.

- Distributed LSA processing for large-scale applications: Distributed computing architectures can enhance LSA engine efficiency for large-scale applications by dividing computational tasks across multiple nodes. These systems implement load balancing, data partitioning, and efficient communication protocols to process massive datasets. Cloud-based implementations allow for scalable resources that adapt to varying processing demands while maintaining consistent performance.

- LSA engine efficiency measurement and testing methodologies: Specialized methodologies for measuring and testing LSA engine efficiency help optimize performance across different applications. These include benchmark suites, performance metrics, and diagnostic tools that identify processing bottlenecks. Standardized testing frameworks allow for comparative analysis of different LSA implementations, enabling developers to select optimal configurations for specific use cases.

02 Engine control systems using LSA for efficiency improvement

Engine control systems can leverage Latent Semantic Analysis to improve operational efficiency by analyzing performance data in real-time. These systems use LSA to identify patterns in sensor data, optimize fuel injection timing, and adjust engine parameters based on operating conditions. By implementing LSA-based control algorithms, engines can achieve better fuel economy, reduced emissions, and improved overall performance across various operating conditions.Expand Specific Solutions03 Hardware implementations for LSA processing in engine systems

Specialized hardware architectures can significantly enhance LSA processing efficiency in engine management systems. These implementations include dedicated processors, FPGA-based solutions, and custom integrated circuits designed specifically for semantic analysis operations. By offloading LSA computations to dedicated hardware, engine control units can perform complex analyses with lower power consumption and faster response times, leading to more efficient engine operation.Expand Specific Solutions04 LSA-based diagnostic and predictive maintenance systems

LSA techniques can be applied to engine diagnostic and predictive maintenance systems to improve operational efficiency. By analyzing patterns in engine performance data, these systems can identify potential failures before they occur, optimize maintenance schedules, and reduce downtime. The semantic analysis capabilities allow for better understanding of complex relationships between various engine parameters, enabling more accurate diagnostics and more efficient maintenance operations.Expand Specific Solutions05 Integration of LSA with other technologies for enhanced engine efficiency

Combining LSA with other technologies such as machine learning, IoT sensors, and cloud computing can create comprehensive engine efficiency solutions. These integrated systems use LSA to process and interpret data from multiple sources, enabling more sophisticated analysis and control strategies. The synergy between LSA and complementary technologies allows for adaptive engine control, real-time optimization, and continuous improvement of efficiency parameters based on operational data and environmental conditions.Expand Specific Solutions

Key Industry Players in LSA Engine Technology and Modeling

The LSA (Lean Stratified-charge Assisted) engine efficiency measurement landscape is currently in a growth phase, with computational modeling becoming increasingly critical for performance optimization. The market is expanding as automotive manufacturers seek more fuel-efficient solutions, though still representing a specialized segment within the broader engine simulation market. From a technological maturity perspective, academic institutions like Nanjing University of Aeronautics & Astronautics, Beihang University, and Tongji University are leading fundamental research, while industrial players including Robert Bosch GmbH, AVL List GmbH, and Siemens AG are developing advanced commercial simulation platforms. Automotive manufacturers such as Renault SA and Rolls-Royce Solutions GmbH are implementing these computational models to optimize real-world engine designs, creating a collaborative ecosystem spanning theoretical research to practical application.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered computational models for LSA engine efficiency measurement through their Advanced Simulation Technologies division. Their approach integrates thermodynamic cycle analysis with detailed chemical kinetics to accurately predict combustion efficiency in lean stratified-charge environments. Bosch's proprietary LSIM (Lean Stratification Integrated Model) combines 3D CFD simulations with reduced-order models to balance computational efficiency with predictive accuracy. Their methodology incorporates detailed spray models calibrated through optical engine measurements, allowing precise prediction of fuel distribution and mixture formation critical to LSA operation. Bosch's computational framework includes adaptive mesh refinement techniques that concentrate computational resources in regions of high gradients, particularly at the interfaces between rich and lean zones characteristic of stratified combustion[3]. Their models account for cycle-to-cycle variations through statistical approaches, enabling robust efficiency predictions across the entire operating map. Validation studies have demonstrated prediction accuracy within 2% for brake thermal efficiency across various engine speeds and loads[4].

Strengths: Exceptional integration of spray dynamics with combustion chemistry; extensive validation against production engines; computationally efficient reduced-order models suitable for calibration work. Weaknesses: Some models require proprietary calibration data; limited public documentation of methodology details; models may not fully capture all transient operating conditions.

AVIC Shenyang Engine Research Institute

Technical Solution: AVIC Shenyang Engine Research Institute has developed specialized computational models for LSA engine efficiency measurement focused on aerospace applications. Their approach combines detailed chemical kinetics with large eddy simulation (LES) techniques to capture the complex turbulence-chemistry interactions in lean stratified combustion. AVIC's computational framework features adaptive chemistry reduction techniques that maintain accuracy while reducing computational costs by up to 70% compared to full chemistry mechanisms. Their models incorporate detailed treatment of fuel injection processes using Eulerian-Lagrangian approaches with advanced breakup models calibrated specifically for high-pressure aviation fuel injection systems. AVIC's methodology includes sophisticated radiation models that account for heat transfer effects in lean combustion environments where radiation can constitute up to 15% of the total heat transfer[7]. Their validation approach correlates computational predictions with data from specialized optical engines and altitude test facilities that simulate the full range of operating conditions encountered in aerospace applications. Recent publications demonstrate their models achieve prediction accuracy within 4% for specific fuel consumption across various altitude and power settings[8].

Strengths: Specialized models optimized for aerospace applications; advanced turbulence-chemistry interaction frameworks; extensive validation at altitude conditions. Weaknesses: Models may be less applicable to automotive applications; computational requirements can be extremely high for full LES simulations; limited public documentation of methodology details.

Critical Technologies in LSA Engine Computational Modeling

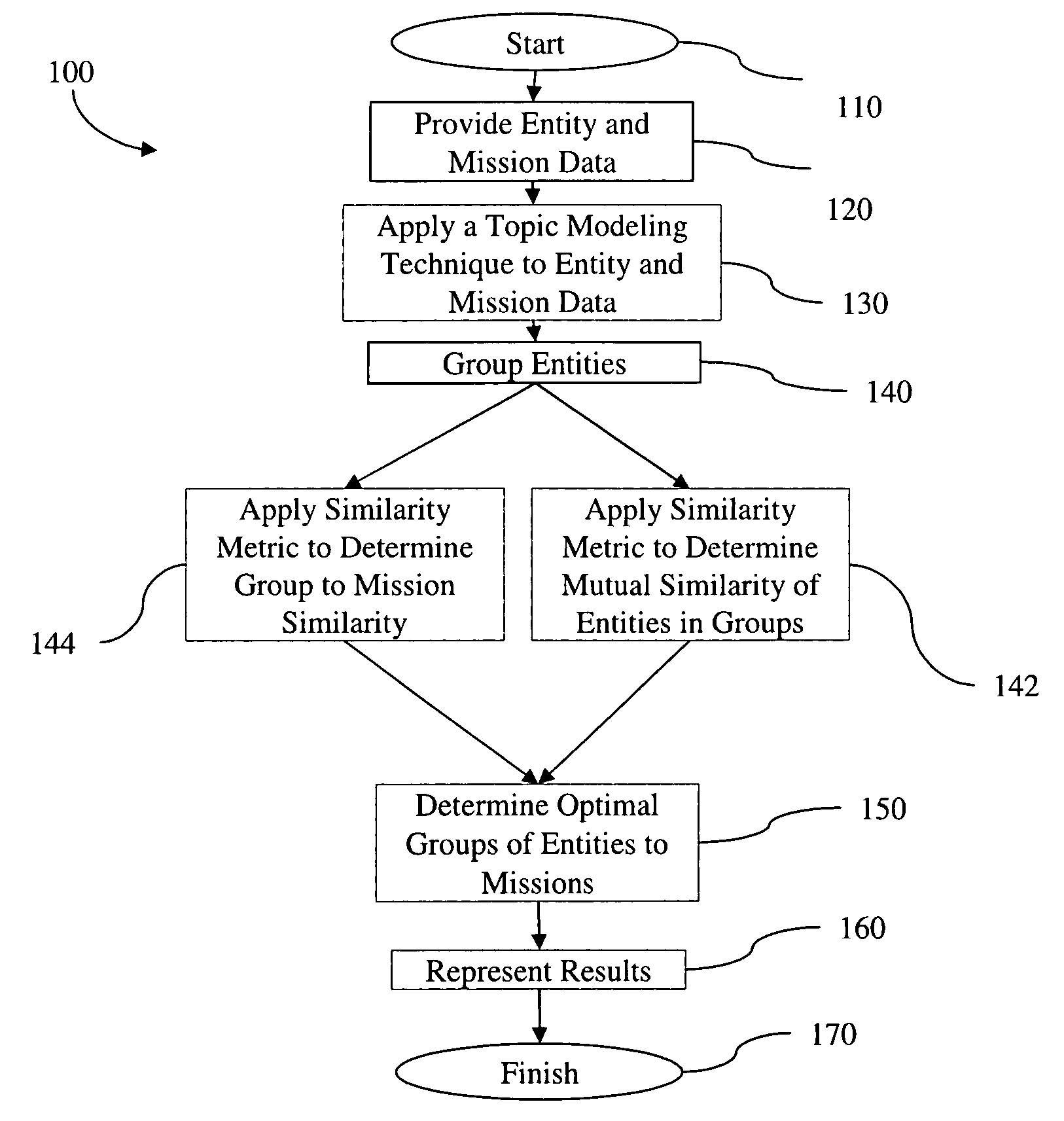

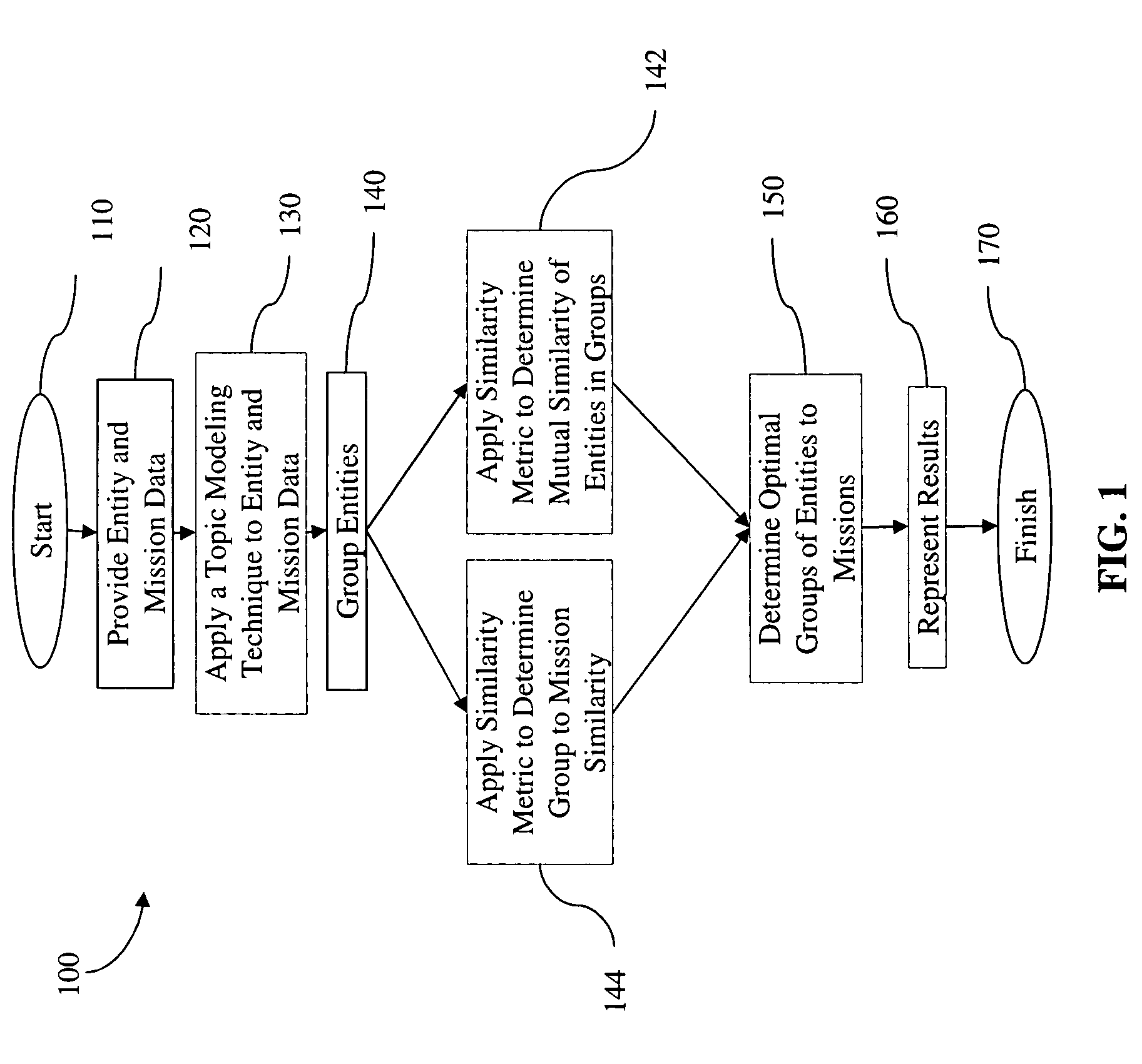

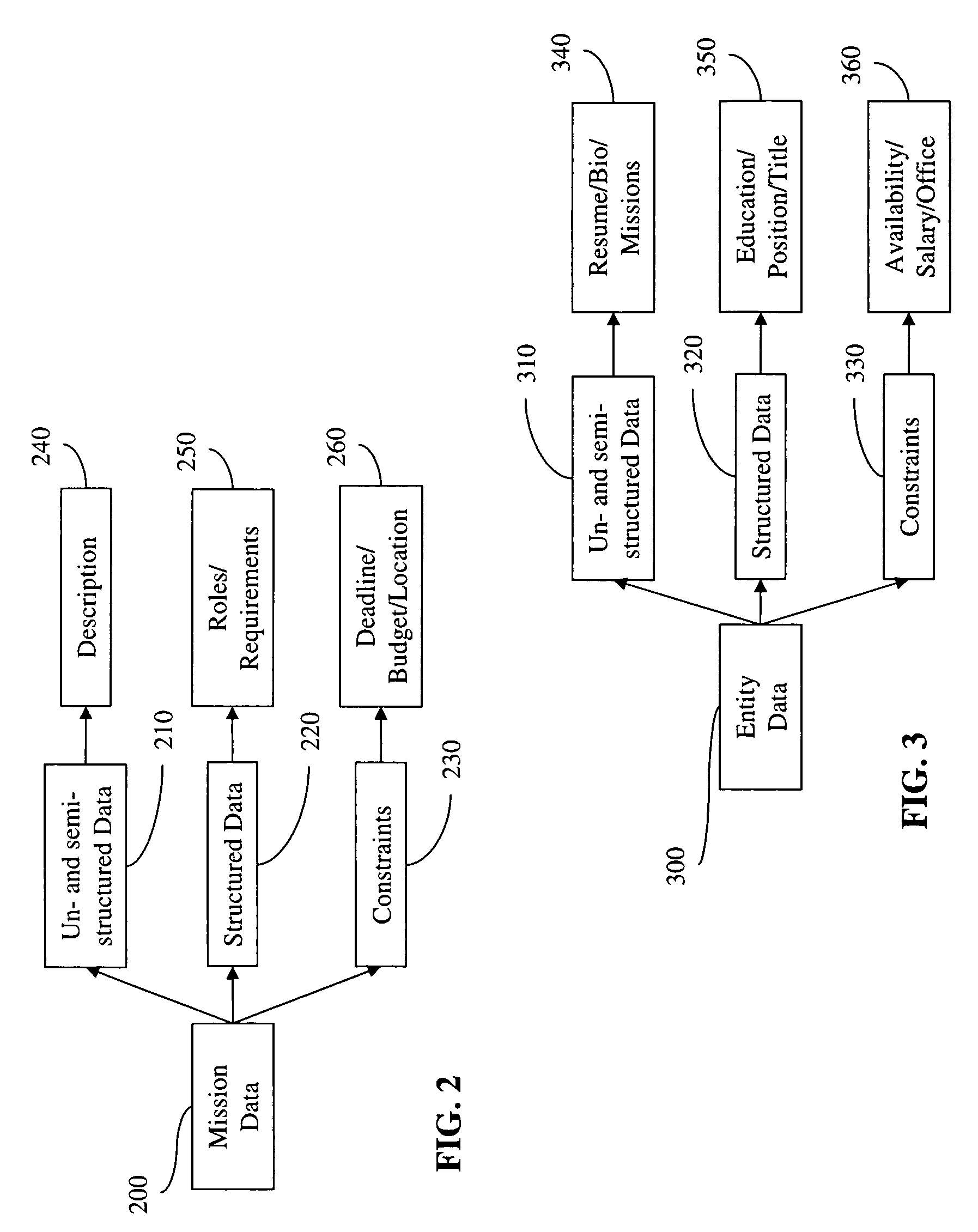

Method and system to compare data entities

PatentActiveUS7822750B2

Innovation

- A computer-based system and method utilizing Probabilistic Latent Semantic Analysis (PLSA) or Latent Dirichlet Allocation (LDA) to compare and maximize the appropriateness of a group of entities by creating topic models from unstructured and structured data, determining similarities between entities and missions, and optimizing group formations to meet mission requirements while minimizing redundancy and maximizing diversity.

Method of analyzing documents

PatentInactiveUS20060259481A1

Innovation

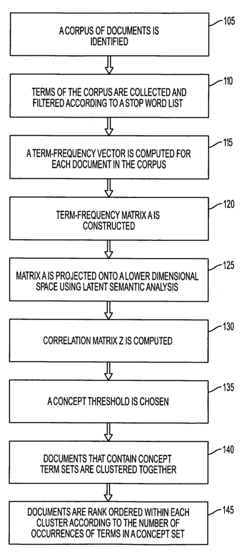

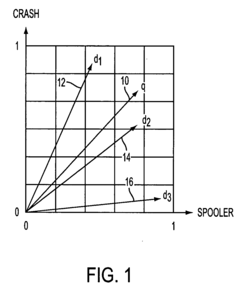

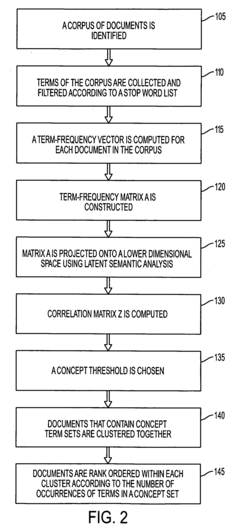

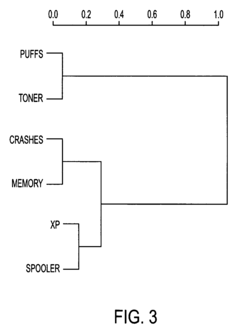

- The method employs latent semantic analysis (LSA) to project term-frequency matrices into a lower dimensional space, creating a correlation matrix and concept graph, allowing for clustering of documents based on concept occurrence and ranking by frequency within concept sets, using techniques like Singular Value Decomposition and hierarchical agglomerative clustering.

Validation Methodologies for Computational Engine Models

Validation of computational models for LSA (Liquid Space Actuator) engine efficiency requires systematic approaches to ensure accuracy and reliability. The validation process typically begins with establishing clear benchmarks against which computational predictions can be measured. These benchmarks often include experimental data from physical engine tests, which serve as the ground truth for model evaluation.

A multi-tiered validation framework is essential for comprehensive assessment. At the component level, individual elements such as combustion chambers, nozzles, and fuel injection systems must be validated separately before integration into full-system models. This hierarchical approach allows for isolation of specific error sources and targeted refinement of sub-models.

Statistical validation techniques play a crucial role in quantifying model uncertainty. Methods such as Monte Carlo simulations enable assessment of how input parameter variations propagate through the computational model, providing confidence intervals for efficiency predictions. Sensitivity analysis further identifies which parameters most significantly impact model outputs, guiding both model refinement and experimental design.

Cross-validation between different computational approaches strengthens overall confidence in results. Comparing high-fidelity CFD (Computational Fluid Dynamics) simulations with reduced-order models helps establish the appropriate level of model complexity for different applications while ensuring consistency across modeling paradigms.

Temporal validation assesses model performance across different operational timescales. Short-term transient behaviors during engine startup and shutdown must be accurately captured alongside steady-state performance. This temporal dimension is particularly important for LSA engines, where efficiency can vary significantly across operational phases.

Hardware-in-the-loop (HIL) testing represents an advanced validation methodology that bridges computational models with physical components. By integrating real hardware with simulated environments, HIL approaches provide valuable insights into model limitations and areas requiring refinement.

Validation metrics must be carefully selected to meaningfully quantify model performance. Beyond simple error calculations, metrics should include statistical measures of agreement, correlation coefficients, and domain-specific indicators that reflect the engineering significance of prediction errors in efficiency calculations.

Documentation standards for validation processes ensure reproducibility and transparency. Comprehensive documentation should include validation test cases, comparison methodologies, uncertainty quantification, and clear statements regarding the validated operational envelope within which the computational model can reliably predict LSA engine efficiency.

A multi-tiered validation framework is essential for comprehensive assessment. At the component level, individual elements such as combustion chambers, nozzles, and fuel injection systems must be validated separately before integration into full-system models. This hierarchical approach allows for isolation of specific error sources and targeted refinement of sub-models.

Statistical validation techniques play a crucial role in quantifying model uncertainty. Methods such as Monte Carlo simulations enable assessment of how input parameter variations propagate through the computational model, providing confidence intervals for efficiency predictions. Sensitivity analysis further identifies which parameters most significantly impact model outputs, guiding both model refinement and experimental design.

Cross-validation between different computational approaches strengthens overall confidence in results. Comparing high-fidelity CFD (Computational Fluid Dynamics) simulations with reduced-order models helps establish the appropriate level of model complexity for different applications while ensuring consistency across modeling paradigms.

Temporal validation assesses model performance across different operational timescales. Short-term transient behaviors during engine startup and shutdown must be accurately captured alongside steady-state performance. This temporal dimension is particularly important for LSA engines, where efficiency can vary significantly across operational phases.

Hardware-in-the-loop (HIL) testing represents an advanced validation methodology that bridges computational models with physical components. By integrating real hardware with simulated environments, HIL approaches provide valuable insights into model limitations and areas requiring refinement.

Validation metrics must be carefully selected to meaningfully quantify model performance. Beyond simple error calculations, metrics should include statistical measures of agreement, correlation coefficients, and domain-specific indicators that reflect the engineering significance of prediction errors in efficiency calculations.

Documentation standards for validation processes ensure reproducibility and transparency. Comprehensive documentation should include validation test cases, comparison methodologies, uncertainty quantification, and clear statements regarding the validated operational envelope within which the computational model can reliably predict LSA engine efficiency.

Environmental Impact and Regulatory Compliance Considerations

The environmental impact of LSA (Liquid Spray Atomization) engines extends far beyond operational efficiency metrics. Computational models measuring LSA engine efficiency must incorporate environmental parameters to provide a comprehensive assessment aligned with increasingly stringent global regulations. These models need to quantify emissions profiles including NOx, CO2, particulate matter, and unburned hydrocarbons—all critical factors in regulatory compliance frameworks.

Current computational approaches are evolving to integrate life cycle assessment (LCA) methodologies, enabling researchers to evaluate environmental impacts from raw material extraction through manufacturing, operation, and end-of-life disposal. This holistic approach aligns with circular economy principles being adopted in regulatory frameworks worldwide, particularly in the European Union's Green Deal and similar initiatives in North America and Asia.

Regulatory compliance considerations vary significantly across jurisdictions, creating complex modeling requirements. The International Maritime Organization's (IMO) MARPOL Annex VI regulations for marine applications, EPA standards for stationary power generation, and EURO/TIER emissions standards for mobile applications each present unique constraints that computational models must address. Models must therefore incorporate geospatial parameters to account for regional regulatory variations.

Carbon pricing mechanisms and emissions trading schemes represent another critical dimension for computational modeling. As these market-based regulatory tools become more prevalent, efficiency models must quantify economic impacts alongside technical performance metrics. This economic-environmental interface requires models to simulate various carbon price scenarios and their effects on operational costs and investment decisions.

Future computational models will likely need to address emerging regulatory concerns around noise pollution, water usage, and thermal pollution—factors increasingly incorporated into environmental impact assessments. Additionally, the growing focus on environmental justice means models may need to evaluate distributional impacts of emissions across different communities, particularly in densely populated areas where LSA engines operate.

Computational models must also anticipate regulatory evolution, incorporating predictive capabilities to assess compliance with future standards. This forward-looking approach requires models to simulate engine performance under increasingly stringent emissions scenarios, providing valuable insights for research and development priorities in LSA engine technology.

Current computational approaches are evolving to integrate life cycle assessment (LCA) methodologies, enabling researchers to evaluate environmental impacts from raw material extraction through manufacturing, operation, and end-of-life disposal. This holistic approach aligns with circular economy principles being adopted in regulatory frameworks worldwide, particularly in the European Union's Green Deal and similar initiatives in North America and Asia.

Regulatory compliance considerations vary significantly across jurisdictions, creating complex modeling requirements. The International Maritime Organization's (IMO) MARPOL Annex VI regulations for marine applications, EPA standards for stationary power generation, and EURO/TIER emissions standards for mobile applications each present unique constraints that computational models must address. Models must therefore incorporate geospatial parameters to account for regional regulatory variations.

Carbon pricing mechanisms and emissions trading schemes represent another critical dimension for computational modeling. As these market-based regulatory tools become more prevalent, efficiency models must quantify economic impacts alongside technical performance metrics. This economic-environmental interface requires models to simulate various carbon price scenarios and their effects on operational costs and investment decisions.

Future computational models will likely need to address emerging regulatory concerns around noise pollution, water usage, and thermal pollution—factors increasingly incorporated into environmental impact assessments. Additionally, the growing focus on environmental justice means models may need to evaluate distributional impacts of emissions across different communities, particularly in densely populated areas where LSA engines operate.

Computational models must also anticipate regulatory evolution, incorporating predictive capabilities to assess compliance with future standards. This forward-looking approach requires models to simulate engine performance under increasingly stringent emissions scenarios, providing valuable insights for research and development priorities in LSA engine technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!