How To Measure Oxygen Permeability In Occlusive Dressings

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oxygen Permeability Measurement Objectives

The measurement of oxygen permeability in occlusive dressings is a critical aspect of wound care technology. This research aims to develop and validate accurate, reliable, and reproducible methods for quantifying oxygen transmission through these specialized medical materials. The primary objective is to establish standardized protocols that can be widely adopted in both research and industrial settings, ensuring consistency across different laboratories and manufacturers.

One key goal is to determine the optimal experimental conditions for measuring oxygen permeability, including temperature, humidity, and pressure differentials. These parameters significantly influence the performance of occlusive dressings and must be carefully controlled to obtain meaningful results. Additionally, the research seeks to identify the most suitable instrumentation and analytical techniques for precise oxygen detection and quantification.

Another important objective is to investigate the relationship between oxygen permeability and other crucial properties of occlusive dressings, such as moisture vapor transmission rate (MVTR) and bacterial barrier function. Understanding these correlations will provide valuable insights into the overall performance of wound dressings and guide future product development.

The study also aims to explore the impact of various dressing compositions and structures on oxygen permeability. This includes evaluating different polymeric materials, composite structures, and novel formulations to determine their effectiveness in controlling oxygen transmission while maintaining other essential wound healing properties.

Furthermore, the research intends to develop mathematical models and predictive tools that can accurately estimate oxygen permeability based on material properties and environmental conditions. These models will be invaluable for rapid screening of new materials and optimizing dressing designs without the need for extensive experimental testing.

Lastly, the project seeks to establish a comprehensive database of oxygen permeability values for a wide range of commercial and experimental occlusive dressings. This resource will serve as a benchmark for comparing new products and materials, facilitating innovation in the field of wound care technology.

By achieving these objectives, the research will significantly advance our understanding of oxygen permeability in occlusive dressings and provide the wound care industry with essential tools and knowledge for developing more effective products. This, in turn, will lead to improved patient outcomes and accelerated wound healing processes.

One key goal is to determine the optimal experimental conditions for measuring oxygen permeability, including temperature, humidity, and pressure differentials. These parameters significantly influence the performance of occlusive dressings and must be carefully controlled to obtain meaningful results. Additionally, the research seeks to identify the most suitable instrumentation and analytical techniques for precise oxygen detection and quantification.

Another important objective is to investigate the relationship between oxygen permeability and other crucial properties of occlusive dressings, such as moisture vapor transmission rate (MVTR) and bacterial barrier function. Understanding these correlations will provide valuable insights into the overall performance of wound dressings and guide future product development.

The study also aims to explore the impact of various dressing compositions and structures on oxygen permeability. This includes evaluating different polymeric materials, composite structures, and novel formulations to determine their effectiveness in controlling oxygen transmission while maintaining other essential wound healing properties.

Furthermore, the research intends to develop mathematical models and predictive tools that can accurately estimate oxygen permeability based on material properties and environmental conditions. These models will be invaluable for rapid screening of new materials and optimizing dressing designs without the need for extensive experimental testing.

Lastly, the project seeks to establish a comprehensive database of oxygen permeability values for a wide range of commercial and experimental occlusive dressings. This resource will serve as a benchmark for comparing new products and materials, facilitating innovation in the field of wound care technology.

By achieving these objectives, the research will significantly advance our understanding of oxygen permeability in occlusive dressings and provide the wound care industry with essential tools and knowledge for developing more effective products. This, in turn, will lead to improved patient outcomes and accelerated wound healing processes.

Market Demand for Occlusive Dressings

The market demand for occlusive dressings has been steadily increasing due to their effectiveness in wound management and healing. These dressings create a moist environment that promotes faster healing, reduces pain, and minimizes scarring. The global occlusive dressings market is experiencing significant growth, driven by factors such as the rising prevalence of chronic wounds, an aging population, and increasing awareness of advanced wound care techniques.

In recent years, there has been a growing emphasis on the importance of oxygen permeability in occlusive dressings. Healthcare professionals and patients alike are recognizing the benefits of dressings that allow controlled oxygen transmission to the wound site. This has led to a surge in demand for occlusive dressings with enhanced oxygen permeability features.

The market for occlusive dressings is segmented based on various factors, including material type, application, and end-user. Polyurethane-based occlusive dressings are gaining popularity due to their excellent oxygen permeability characteristics. Additionally, there is an increasing demand for dressings specifically designed for chronic wounds, such as diabetic foot ulcers and pressure sores.

The healthcare sector, particularly hospitals and wound care centers, remains the primary end-user of occlusive dressings. However, there is a growing trend towards home healthcare, which is creating new opportunities for market expansion. Patients and caregivers are seeking user-friendly occlusive dressings that can be easily applied and monitored at home.

Geographically, North America and Europe currently dominate the occlusive dressings market, owing to advanced healthcare infrastructure and higher awareness of wound care technologies. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand for occlusive dressings, driven by improving healthcare access and rising disposable incomes.

The COVID-19 pandemic has had a mixed impact on the occlusive dressings market. While elective surgeries were postponed, leading to a temporary decline in demand, the increased focus on healthcare and wound management has created new opportunities for market growth.

Looking ahead, the market for occlusive dressings is poised for continued expansion. Manufacturers are investing in research and development to create innovative products with improved oxygen permeability and other advanced features. The integration of smart technologies, such as sensors for real-time wound monitoring, is expected to further drive market growth and meet evolving consumer needs.

In recent years, there has been a growing emphasis on the importance of oxygen permeability in occlusive dressings. Healthcare professionals and patients alike are recognizing the benefits of dressings that allow controlled oxygen transmission to the wound site. This has led to a surge in demand for occlusive dressings with enhanced oxygen permeability features.

The market for occlusive dressings is segmented based on various factors, including material type, application, and end-user. Polyurethane-based occlusive dressings are gaining popularity due to their excellent oxygen permeability characteristics. Additionally, there is an increasing demand for dressings specifically designed for chronic wounds, such as diabetic foot ulcers and pressure sores.

The healthcare sector, particularly hospitals and wound care centers, remains the primary end-user of occlusive dressings. However, there is a growing trend towards home healthcare, which is creating new opportunities for market expansion. Patients and caregivers are seeking user-friendly occlusive dressings that can be easily applied and monitored at home.

Geographically, North America and Europe currently dominate the occlusive dressings market, owing to advanced healthcare infrastructure and higher awareness of wound care technologies. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand for occlusive dressings, driven by improving healthcare access and rising disposable incomes.

The COVID-19 pandemic has had a mixed impact on the occlusive dressings market. While elective surgeries were postponed, leading to a temporary decline in demand, the increased focus on healthcare and wound management has created new opportunities for market growth.

Looking ahead, the market for occlusive dressings is poised for continued expansion. Manufacturers are investing in research and development to create innovative products with improved oxygen permeability and other advanced features. The integration of smart technologies, such as sensors for real-time wound monitoring, is expected to further drive market growth and meet evolving consumer needs.

Current Challenges in Oxygen Permeability Testing

Measuring oxygen permeability in occlusive dressings presents several significant challenges that researchers and manufacturers must overcome to ensure accurate and reliable results. One of the primary difficulties lies in the complex nature of wound dressings, which often consist of multiple layers with varying compositions and structures. This heterogeneity can lead to inconsistent oxygen transmission rates across different areas of the dressing, making it challenging to obtain representative measurements.

Another major hurdle is the need for precise control of environmental conditions during testing. Factors such as temperature, humidity, and atmospheric pressure can significantly influence oxygen permeability. Even slight variations in these parameters can lead to substantial differences in test results, necessitating highly controlled testing environments and sophisticated equipment to maintain consistent conditions throughout the measurement process.

The small size and delicate nature of many occlusive dressings also pose technical challenges. Traditional oxygen permeability testing methods, often designed for larger or more robust materials, may not be suitable for these specialized medical products. This limitation has driven the need for the development of miniaturized testing apparatus and more sensitive detection methods capable of accurately measuring oxygen transmission through thin, flexible dressing materials.

Furthermore, the presence of moisture in wound dressings complicates oxygen permeability measurements. Occlusive dressings are designed to maintain a moist wound environment, which is crucial for healing. However, this moisture can interfere with oxygen permeability testing, as it can affect the transmission of oxygen through the material. Developing methods to account for or control moisture levels during testing without compromising the integrity of the dressing or the accuracy of the measurements remains a significant challenge.

The dynamic nature of wound dressings in real-world applications also presents difficulties in translating laboratory test results to clinical performance. Dressings may change their properties over time when in contact with wound exudates or as they absorb moisture from the environment. Capturing these dynamic changes in oxygen permeability and correlating them with clinical outcomes is a complex task that requires innovative approaches and long-term studies.

Lastly, the lack of standardized testing protocols specifically designed for occlusive dressings hinders the comparison of results across different studies and products. While general standards for oxygen permeability testing exist, they may not fully address the unique characteristics and requirements of wound dressings. Developing and implementing standardized methods tailored to occlusive dressings is crucial for advancing research and improving product development in this field.

Another major hurdle is the need for precise control of environmental conditions during testing. Factors such as temperature, humidity, and atmospheric pressure can significantly influence oxygen permeability. Even slight variations in these parameters can lead to substantial differences in test results, necessitating highly controlled testing environments and sophisticated equipment to maintain consistent conditions throughout the measurement process.

The small size and delicate nature of many occlusive dressings also pose technical challenges. Traditional oxygen permeability testing methods, often designed for larger or more robust materials, may not be suitable for these specialized medical products. This limitation has driven the need for the development of miniaturized testing apparatus and more sensitive detection methods capable of accurately measuring oxygen transmission through thin, flexible dressing materials.

Furthermore, the presence of moisture in wound dressings complicates oxygen permeability measurements. Occlusive dressings are designed to maintain a moist wound environment, which is crucial for healing. However, this moisture can interfere with oxygen permeability testing, as it can affect the transmission of oxygen through the material. Developing methods to account for or control moisture levels during testing without compromising the integrity of the dressing or the accuracy of the measurements remains a significant challenge.

The dynamic nature of wound dressings in real-world applications also presents difficulties in translating laboratory test results to clinical performance. Dressings may change their properties over time when in contact with wound exudates or as they absorb moisture from the environment. Capturing these dynamic changes in oxygen permeability and correlating them with clinical outcomes is a complex task that requires innovative approaches and long-term studies.

Lastly, the lack of standardized testing protocols specifically designed for occlusive dressings hinders the comparison of results across different studies and products. While general standards for oxygen permeability testing exist, they may not fully address the unique characteristics and requirements of wound dressings. Developing and implementing standardized methods tailored to occlusive dressings is crucial for advancing research and improving product development in this field.

Existing Oxygen Permeability Measurement Methods

01 Oxygen-permeable materials for occlusive dressings

Occlusive dressings can be made with oxygen-permeable materials to allow for better wound healing. These materials, such as silicone or polyurethane films, provide a barrier against external contaminants while still allowing oxygen to reach the wound site. This balance of occlusion and permeability can promote faster healing and reduce the risk of infection.- Oxygen-permeable materials for occlusive dressings: Occlusive dressings can be made with oxygen-permeable materials to allow for gas exchange while maintaining a moist wound environment. These materials, such as silicone-based polymers or certain synthetic fabrics, allow oxygen to reach the wound bed while preventing excessive moisture loss. This balance promotes healing and reduces the risk of infection.

- Controlled oxygen permeability in wound dressings: Some occlusive dressings are designed with controlled oxygen permeability to optimize wound healing. These dressings may have layers or regions with different levels of oxygen permeability, allowing for customized oxygen delivery to the wound based on its specific needs. This approach can help manage wound exudate while maintaining an appropriate oxygen level at the wound surface.

- Oxygen-generating occlusive dressings: Innovative occlusive dressings incorporate oxygen-generating compounds or materials to actively supply oxygen to the wound area. These dressings may use chemical reactions or other mechanisms to produce and release oxygen directly at the wound site, promoting healing even in low-oxygen environments or for wounds with poor circulation.

- Multilayer occlusive dressings with varying oxygen permeability: Advanced occlusive dressings often feature multiple layers with different oxygen permeability characteristics. This design allows for precise control of oxygen levels at different depths of the wound, potentially combining highly permeable layers near the wound surface with less permeable outer layers to maintain moisture balance and protect against external contaminants.

- Smart occlusive dressings with adjustable oxygen permeability: Cutting-edge research is focusing on developing smart occlusive dressings with adjustable oxygen permeability. These dressings may incorporate sensors or responsive materials that can alter their oxygen permeability based on the wound's changing needs or external stimuli. This adaptive approach aims to optimize healing conditions throughout different stages of wound recovery.

02 Controlled oxygen permeability in wound dressings

Some occlusive dressings are designed with controlled oxygen permeability to optimize wound healing. These dressings can adjust their oxygen permeability based on the wound's needs, providing an ideal environment for different stages of healing. This can be achieved through the use of specialized polymers or multi-layer structures that regulate oxygen flow.Expand Specific Solutions03 Incorporation of oxygen-releasing agents

Certain occlusive dressings incorporate oxygen-releasing agents to enhance wound oxygenation. These agents, such as hydrogen peroxide-based compounds or oxygen-enriched materials, can provide a sustained release of oxygen to the wound site, even in the absence of external air flow. This approach can be particularly beneficial for deep or chronic wounds that may have limited access to atmospheric oxygen.Expand Specific Solutions04 Moisture vapor transmission rate (MVTR) and oxygen permeability

The relationship between moisture vapor transmission rate (MVTR) and oxygen permeability is crucial in occlusive dressings. Dressings with optimized MVTR can maintain a moist wound environment while still allowing for adequate oxygen exchange. This balance is essential for promoting wound healing and preventing maceration of surrounding skin.Expand Specific Solutions05 Smart occlusive dressings with variable oxygen permeability

Advanced occlusive dressings are being developed with smart materials that can adjust their oxygen permeability in response to wound conditions. These dressings may use sensors or responsive polymers to detect changes in the wound environment and modify their permeability accordingly. This dynamic approach aims to provide optimal healing conditions throughout different stages of wound recovery.Expand Specific Solutions

Key Players in Wound Care and Testing Equipment

The oxygen permeability measurement in occlusive dressings market is in a growth phase, driven by increasing demand for advanced wound care products. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like FUJIFILM Corp., Novartis AG, and Alcon AG leading innovation. These firms are developing sophisticated measurement techniques and materials to enhance oxygen permeability. The technology's maturity varies, with established players like ExxonMobil Chemical Patents, Inc. and Eastman Chemical Co. refining existing methods, while newer entrants like SiO2 Medical Products, Inc. are introducing novel approaches, indicating a dynamic and competitive landscape.

Novartis AG

Technical Solution: Novartis AG, through its research in advanced wound care, has developed a method for measuring oxygen permeability in occlusive dressings using a combination of electrochemical sensors and microfluidic devices. Their approach involves creating a miniaturized testing platform that simulates the wound environment, complete with controlled humidity and temperature[9]. The system uses Clark-type oxygen electrodes to measure dissolved oxygen levels on both sides of the dressing, allowing for the calculation of oxygen flux and permeability[10]. Novartis has also incorporated machine learning algorithms to analyze the permeability data, enabling the prediction of dressing performance under various clinical conditions. This integrated approach allows for high-throughput screening of new dressing materials and formulations.

Strengths: Simulates realistic wound environments, high-throughput capabilities, and predictive modeling of dressing performance. Weaknesses: Complex system integration and potential high development costs.

Alcon AG

Technical Solution: Alcon AG, leveraging its expertise in ophthalmic products, has adapted its contact lens oxygen permeability measurement techniques for use with occlusive dressings. Their method employs polarographic oxygen sensors in a specially designed diffusion cell[11]. The cell maintains precise control over temperature, humidity, and gas composition on both sides of the dressing sample. Alcon's system can measure oxygen transmissibility (Dk/t) values ranging from 0 to 200 Barrer/cm, covering the full spectrum of occlusive to highly permeable dressings[12]. The company has also developed a unique edge-correction algorithm to account for lateral diffusion effects, improving measurement accuracy for thin dressings. This technology enables rapid and reliable assessment of oxygen permeability in various dressing materials and designs.

Strengths: Wide measurement range, precise environmental control, and advanced edge-correction algorithms. Weaknesses: May require adaptation for very large or irregularly shaped dressings.

Innovations in Oxygen Permeability Sensing

Processable filled, curable halogenated isoolefin elastomers

PatentActiveUS7905263B2

Innovation

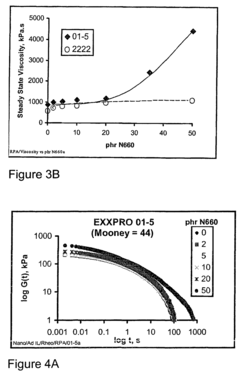

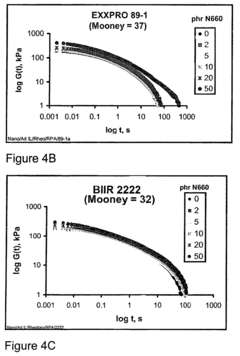

- Developing halogenated isoolefin elastomers with specific Mooney viscosity, molecular weight, and branching index characteristics, such as brominated isobutylene-methylstyrene (BIMSM) elastomers, which exhibit similar stress relaxation properties to conventional bromobutyl rubbers when filled with carbon black, improving melt properties and processability.

Regulatory Standards for Occlusive Dressings

Regulatory standards for occlusive dressings play a crucial role in ensuring the safety and efficacy of these medical devices. The measurement of oxygen permeability in occlusive dressings is subject to various regulatory requirements and guidelines established by international and national bodies. These standards aim to maintain consistency in testing methods and product quality across the industry.

The International Organization for Standardization (ISO) has developed specific standards for wound dressings, including ISO 10993-1, which addresses the biological evaluation of medical devices. This standard provides a framework for assessing the biocompatibility of materials used in occlusive dressings, including considerations for oxygen permeability.

In the United States, the Food and Drug Administration (FDA) regulates occlusive dressings as medical devices. The FDA's guidance document on "Premarket Notification [510(k)] Submissions for Wound Dressings" outlines the requirements for manufacturers, including the need to demonstrate the safety and effectiveness of their products. While not explicitly stating a specific method for measuring oxygen permeability, the FDA expects manufacturers to provide data on the dressing's ability to maintain a moist wound environment while allowing for adequate gas exchange.

The European Union's Medical Device Regulation (MDR) also sets standards for occlusive dressings. Under the MDR, manufacturers must comply with the Essential Requirements, which include demonstrating that their devices achieve their intended performance and do not compromise the clinical condition or safety of patients. This implicitly requires manufacturers to provide data on oxygen permeability for occlusive dressings where relevant.

In addition to these overarching regulatory frameworks, specific standards have been developed for testing oxygen permeability in materials used for medical applications. ASTM International's standard D3985 provides a test method for oxygen gas transmission rate through plastic film and sheeting, which can be adapted for use with occlusive dressing materials.

The Japanese Industrial Standards (JIS) also include methods for measuring gas permeability in films and sheets, such as JIS K7126, which could be applicable to occlusive dressings. These standards provide detailed procedures for conducting permeability tests, ensuring reproducibility and reliability of results across different laboratories and manufacturers.

Regulatory bodies often require manufacturers to validate their testing methods and demonstrate that their products meet the established standards. This may involve submitting detailed reports on the testing procedures, equipment used, and results obtained when measuring oxygen permeability in occlusive dressings. Compliance with these standards is typically a prerequisite for obtaining market approval and maintaining certification for medical devices.

As the field of wound care continues to evolve, regulatory standards are periodically reviewed and updated to reflect advancements in technology and clinical practice. Manufacturers and researchers must stay informed about these changes to ensure ongoing compliance and to contribute to the development of improved standards for measuring oxygen permeability in occlusive dressings.

The International Organization for Standardization (ISO) has developed specific standards for wound dressings, including ISO 10993-1, which addresses the biological evaluation of medical devices. This standard provides a framework for assessing the biocompatibility of materials used in occlusive dressings, including considerations for oxygen permeability.

In the United States, the Food and Drug Administration (FDA) regulates occlusive dressings as medical devices. The FDA's guidance document on "Premarket Notification [510(k)] Submissions for Wound Dressings" outlines the requirements for manufacturers, including the need to demonstrate the safety and effectiveness of their products. While not explicitly stating a specific method for measuring oxygen permeability, the FDA expects manufacturers to provide data on the dressing's ability to maintain a moist wound environment while allowing for adequate gas exchange.

The European Union's Medical Device Regulation (MDR) also sets standards for occlusive dressings. Under the MDR, manufacturers must comply with the Essential Requirements, which include demonstrating that their devices achieve their intended performance and do not compromise the clinical condition or safety of patients. This implicitly requires manufacturers to provide data on oxygen permeability for occlusive dressings where relevant.

In addition to these overarching regulatory frameworks, specific standards have been developed for testing oxygen permeability in materials used for medical applications. ASTM International's standard D3985 provides a test method for oxygen gas transmission rate through plastic film and sheeting, which can be adapted for use with occlusive dressing materials.

The Japanese Industrial Standards (JIS) also include methods for measuring gas permeability in films and sheets, such as JIS K7126, which could be applicable to occlusive dressings. These standards provide detailed procedures for conducting permeability tests, ensuring reproducibility and reliability of results across different laboratories and manufacturers.

Regulatory bodies often require manufacturers to validate their testing methods and demonstrate that their products meet the established standards. This may involve submitting detailed reports on the testing procedures, equipment used, and results obtained when measuring oxygen permeability in occlusive dressings. Compliance with these standards is typically a prerequisite for obtaining market approval and maintaining certification for medical devices.

As the field of wound care continues to evolve, regulatory standards are periodically reviewed and updated to reflect advancements in technology and clinical practice. Manufacturers and researchers must stay informed about these changes to ensure ongoing compliance and to contribute to the development of improved standards for measuring oxygen permeability in occlusive dressings.

Impact on Wound Healing Outcomes

The impact of oxygen permeability in occlusive dressings on wound healing outcomes is a critical aspect of wound care management. Oxygen plays a vital role in the wound healing process, influencing cellular metabolism, collagen synthesis, and tissue regeneration. The ability of occlusive dressings to regulate oxygen levels at the wound site can significantly affect healing rates and overall outcomes.

Occlusive dressings with controlled oxygen permeability can create an optimal microenvironment for wound healing. By maintaining a balance between moisture retention and gas exchange, these dressings promote the formation of granulation tissue and facilitate epithelialization. Studies have shown that wounds treated with oxygen-permeable occlusive dressings exhibit faster healing rates compared to those treated with impermeable dressings or left exposed to air.

The level of oxygen permeability in occlusive dressings can influence various aspects of wound healing. Adequate oxygen supply supports the proliferation and migration of fibroblasts, which are essential for the production of extracellular matrix components. This, in turn, enhances the strength and integrity of the newly formed tissue. Additionally, oxygen availability affects the activity of immune cells, such as neutrophils and macrophages, which play crucial roles in wound debridement and infection control.

Oxygen permeability also impacts the management of chronic wounds, such as diabetic ulcers and pressure sores. These wounds often suffer from poor tissue oxygenation due to compromised blood supply. Occlusive dressings with optimized oxygen permeability can help address this issue by allowing controlled oxygen diffusion to the wound bed, potentially accelerating the healing process in these challenging cases.

Furthermore, the ability to measure and control oxygen permeability in occlusive dressings enables healthcare professionals to tailor treatment strategies for specific wound types and patient conditions. This personalized approach can lead to improved healing outcomes, reduced complications, and enhanced patient comfort. By selecting dressings with appropriate oxygen permeability characteristics, clinicians can optimize the wound healing environment and promote faster recovery.

It is important to note that while oxygen is crucial for wound healing, excessive levels can be detrimental. High oxygen concentrations may lead to the formation of reactive oxygen species, which can cause cellular damage and impair healing. Therefore, the ability to accurately measure and control oxygen permeability in occlusive dressings is essential for achieving the right balance and maximizing positive outcomes in wound care.

Occlusive dressings with controlled oxygen permeability can create an optimal microenvironment for wound healing. By maintaining a balance between moisture retention and gas exchange, these dressings promote the formation of granulation tissue and facilitate epithelialization. Studies have shown that wounds treated with oxygen-permeable occlusive dressings exhibit faster healing rates compared to those treated with impermeable dressings or left exposed to air.

The level of oxygen permeability in occlusive dressings can influence various aspects of wound healing. Adequate oxygen supply supports the proliferation and migration of fibroblasts, which are essential for the production of extracellular matrix components. This, in turn, enhances the strength and integrity of the newly formed tissue. Additionally, oxygen availability affects the activity of immune cells, such as neutrophils and macrophages, which play crucial roles in wound debridement and infection control.

Oxygen permeability also impacts the management of chronic wounds, such as diabetic ulcers and pressure sores. These wounds often suffer from poor tissue oxygenation due to compromised blood supply. Occlusive dressings with optimized oxygen permeability can help address this issue by allowing controlled oxygen diffusion to the wound bed, potentially accelerating the healing process in these challenging cases.

Furthermore, the ability to measure and control oxygen permeability in occlusive dressings enables healthcare professionals to tailor treatment strategies for specific wound types and patient conditions. This personalized approach can lead to improved healing outcomes, reduced complications, and enhanced patient comfort. By selecting dressings with appropriate oxygen permeability characteristics, clinicians can optimize the wound healing environment and promote faster recovery.

It is important to note that while oxygen is crucial for wound healing, excessive levels can be detrimental. High oxygen concentrations may lead to the formation of reactive oxygen species, which can cause cellular damage and impair healing. Therefore, the ability to accurately measure and control oxygen permeability in occlusive dressings is essential for achieving the right balance and maximizing positive outcomes in wound care.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!