How To Standardize Occlusive Dressing Biocompatibility Tests

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Occlusive Dressing Biocompatibility Standards

Occlusive dressing biocompatibility standards play a crucial role in ensuring the safety and efficacy of medical devices used in wound care. These standards are designed to evaluate the potential adverse effects of occlusive dressings on human tissue and assess their overall compatibility with the biological environment.

The development of standardized biocompatibility tests for occlusive dressings has been an ongoing process, driven by the need for consistent and reliable evaluation methods across the medical device industry. Key organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) have been at the forefront of establishing these standards.

One of the primary standards governing biocompatibility testing is ISO 10993, which provides a comprehensive framework for evaluating the biological safety of medical devices. This standard includes specific guidelines for assessing the biocompatibility of materials used in occlusive dressings, covering aspects such as cytotoxicity, sensitization, and irritation.

The standardization process involves several key components, including the selection of appropriate test methods, the establishment of acceptance criteria, and the development of protocols for sample preparation and testing conditions. These elements are crucial in ensuring the reproducibility and reliability of biocompatibility assessments across different laboratories and testing facilities.

Specific test methods for occlusive dressings may include in vitro cytotoxicity assays, skin irritation tests, and sensitization studies. These tests are designed to evaluate the potential for adverse reactions when the dressing comes into contact with human skin or underlying tissue. Additionally, tests for material degradation and leachable substances are often included to assess the long-term safety of the dressing.

Standardization efforts also focus on addressing the unique characteristics of occlusive dressings, such as their ability to maintain a moist wound environment and their interaction with various wound types. This requires the development of specialized test protocols that can accurately simulate real-world conditions and assess the dressing's performance in terms of both biocompatibility and functionality.

As the field of wound care continues to evolve, with the introduction of advanced materials and technologies, the standards for biocompatibility testing must also adapt. This ongoing process involves collaboration between regulatory bodies, industry experts, and research institutions to ensure that the standards remain relevant and effective in addressing emerging challenges and innovations in occlusive dressing design.

The development of standardized biocompatibility tests for occlusive dressings has been an ongoing process, driven by the need for consistent and reliable evaluation methods across the medical device industry. Key organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) have been at the forefront of establishing these standards.

One of the primary standards governing biocompatibility testing is ISO 10993, which provides a comprehensive framework for evaluating the biological safety of medical devices. This standard includes specific guidelines for assessing the biocompatibility of materials used in occlusive dressings, covering aspects such as cytotoxicity, sensitization, and irritation.

The standardization process involves several key components, including the selection of appropriate test methods, the establishment of acceptance criteria, and the development of protocols for sample preparation and testing conditions. These elements are crucial in ensuring the reproducibility and reliability of biocompatibility assessments across different laboratories and testing facilities.

Specific test methods for occlusive dressings may include in vitro cytotoxicity assays, skin irritation tests, and sensitization studies. These tests are designed to evaluate the potential for adverse reactions when the dressing comes into contact with human skin or underlying tissue. Additionally, tests for material degradation and leachable substances are often included to assess the long-term safety of the dressing.

Standardization efforts also focus on addressing the unique characteristics of occlusive dressings, such as their ability to maintain a moist wound environment and their interaction with various wound types. This requires the development of specialized test protocols that can accurately simulate real-world conditions and assess the dressing's performance in terms of both biocompatibility and functionality.

As the field of wound care continues to evolve, with the introduction of advanced materials and technologies, the standards for biocompatibility testing must also adapt. This ongoing process involves collaboration between regulatory bodies, industry experts, and research institutions to ensure that the standards remain relevant and effective in addressing emerging challenges and innovations in occlusive dressing design.

Market Demand Analysis

The market demand for standardized occlusive dressing biocompatibility tests has been steadily increasing in recent years, driven by the growing emphasis on patient safety and regulatory compliance in the healthcare industry. Occlusive dressings, which create a moist environment to promote wound healing, are widely used in various medical applications, including surgical wound care, chronic wound management, and burn treatment.

The global wound care market, which includes occlusive dressings, is projected to reach significant growth in the coming years. This expansion is fueled by factors such as the rising prevalence of chronic wounds, an aging population, and the increasing incidence of diabetes and obesity. As the market for occlusive dressings expands, so does the need for standardized biocompatibility testing to ensure product safety and efficacy.

Healthcare providers and regulatory bodies are placing greater emphasis on evidence-based practices and product safety. This has led to a heightened demand for reliable and consistent biocompatibility testing methods for occlusive dressings. Standardized tests help manufacturers demonstrate compliance with regulatory requirements and provide assurance to healthcare professionals and patients regarding the safety of these medical devices.

The pharmaceutical and medical device industries are also driving the demand for standardized biocompatibility tests. As companies develop new and innovative occlusive dressing materials and technologies, they require robust testing protocols to evaluate the biocompatibility of their products. Standardized tests can help streamline the product development process, reduce time-to-market, and facilitate regulatory approval.

Furthermore, the increasing focus on personalized medicine and advanced wound care solutions is creating new opportunities for occlusive dressing manufacturers. This trend is expected to drive further demand for standardized biocompatibility tests that can accurately assess the safety and performance of novel materials and designs.

The global nature of the medical device market also contributes to the need for standardized testing methods. As manufacturers seek to expand their presence in international markets, they must comply with various regulatory requirements across different regions. Harmonized biocompatibility testing standards can help facilitate market access and reduce the burden of multiple testing protocols for different jurisdictions.

In conclusion, the market demand for standardized occlusive dressing biocompatibility tests is robust and expected to grow. This demand is driven by factors such as regulatory requirements, patient safety concerns, market expansion, and technological advancements in wound care. Stakeholders across the healthcare industry recognize the importance of reliable and consistent testing methods to ensure the safety and efficacy of occlusive dressings in clinical practice.

The global wound care market, which includes occlusive dressings, is projected to reach significant growth in the coming years. This expansion is fueled by factors such as the rising prevalence of chronic wounds, an aging population, and the increasing incidence of diabetes and obesity. As the market for occlusive dressings expands, so does the need for standardized biocompatibility testing to ensure product safety and efficacy.

Healthcare providers and regulatory bodies are placing greater emphasis on evidence-based practices and product safety. This has led to a heightened demand for reliable and consistent biocompatibility testing methods for occlusive dressings. Standardized tests help manufacturers demonstrate compliance with regulatory requirements and provide assurance to healthcare professionals and patients regarding the safety of these medical devices.

The pharmaceutical and medical device industries are also driving the demand for standardized biocompatibility tests. As companies develop new and innovative occlusive dressing materials and technologies, they require robust testing protocols to evaluate the biocompatibility of their products. Standardized tests can help streamline the product development process, reduce time-to-market, and facilitate regulatory approval.

Furthermore, the increasing focus on personalized medicine and advanced wound care solutions is creating new opportunities for occlusive dressing manufacturers. This trend is expected to drive further demand for standardized biocompatibility tests that can accurately assess the safety and performance of novel materials and designs.

The global nature of the medical device market also contributes to the need for standardized testing methods. As manufacturers seek to expand their presence in international markets, they must comply with various regulatory requirements across different regions. Harmonized biocompatibility testing standards can help facilitate market access and reduce the burden of multiple testing protocols for different jurisdictions.

In conclusion, the market demand for standardized occlusive dressing biocompatibility tests is robust and expected to grow. This demand is driven by factors such as regulatory requirements, patient safety concerns, market expansion, and technological advancements in wound care. Stakeholders across the healthcare industry recognize the importance of reliable and consistent testing methods to ensure the safety and efficacy of occlusive dressings in clinical practice.

Current Challenges in Testing

The standardization of occlusive dressing biocompatibility tests faces several significant challenges in the current landscape. One of the primary issues is the lack of a universally accepted protocol for conducting these tests. Different regulatory bodies and industry standards often have varying requirements, leading to inconsistencies in test methodologies and results interpretation across different regions and organizations.

Another major challenge is the complexity of simulating real-world conditions in laboratory settings. Occlusive dressings interact with the skin and wound environment in multifaceted ways, and replicating these interactions accurately in vitro is extremely difficult. This complexity often leads to discrepancies between laboratory test results and clinical outcomes, raising questions about the predictive value of current testing methods.

The diversity of materials used in occlusive dressings further complicates standardization efforts. With a wide range of polymers, adhesives, and active ingredients being employed, developing a one-size-fits-all testing approach is challenging. Each material may require specific considerations in terms of extraction methods, exposure times, and evaluation criteria, making it difficult to establish a standardized protocol that is both comprehensive and universally applicable.

Moreover, the dynamic nature of wound healing processes poses additional challenges. Occlusive dressings are designed to interact with the wound environment over time, but most current testing methods provide only a snapshot of biocompatibility at a single point. Developing standardized methods that can assess long-term biocompatibility and account for the changing wound environment remains a significant hurdle.

The selection of appropriate biological endpoints and evaluation criteria is another area of contention. While some tests focus on cytotoxicity and irritation, others may emphasize factors like moisture management or antimicrobial efficacy. Determining which endpoints are most relevant for predicting clinical performance and safety is an ongoing debate in the field.

Additionally, the lack of standardized reference materials for occlusive dressing biocompatibility tests hinders the comparison of results across different laboratories and studies. Without well-characterized positive and negative controls, it becomes challenging to validate test methods and ensure consistency in results interpretation.

Finally, the rapid pace of innovation in occlusive dressing technologies often outpaces the development of standardized testing methods. As new materials and designs emerge, existing test protocols may become outdated or inadequate, necessitating continuous revision and adaptation of testing standards to keep up with technological advancements in the field.

Another major challenge is the complexity of simulating real-world conditions in laboratory settings. Occlusive dressings interact with the skin and wound environment in multifaceted ways, and replicating these interactions accurately in vitro is extremely difficult. This complexity often leads to discrepancies between laboratory test results and clinical outcomes, raising questions about the predictive value of current testing methods.

The diversity of materials used in occlusive dressings further complicates standardization efforts. With a wide range of polymers, adhesives, and active ingredients being employed, developing a one-size-fits-all testing approach is challenging. Each material may require specific considerations in terms of extraction methods, exposure times, and evaluation criteria, making it difficult to establish a standardized protocol that is both comprehensive and universally applicable.

Moreover, the dynamic nature of wound healing processes poses additional challenges. Occlusive dressings are designed to interact with the wound environment over time, but most current testing methods provide only a snapshot of biocompatibility at a single point. Developing standardized methods that can assess long-term biocompatibility and account for the changing wound environment remains a significant hurdle.

The selection of appropriate biological endpoints and evaluation criteria is another area of contention. While some tests focus on cytotoxicity and irritation, others may emphasize factors like moisture management or antimicrobial efficacy. Determining which endpoints are most relevant for predicting clinical performance and safety is an ongoing debate in the field.

Additionally, the lack of standardized reference materials for occlusive dressing biocompatibility tests hinders the comparison of results across different laboratories and studies. Without well-characterized positive and negative controls, it becomes challenging to validate test methods and ensure consistency in results interpretation.

Finally, the rapid pace of innovation in occlusive dressing technologies often outpaces the development of standardized testing methods. As new materials and designs emerge, existing test protocols may become outdated or inadequate, necessitating continuous revision and adaptation of testing standards to keep up with technological advancements in the field.

Existing Test Methodologies

01 Biocompatible materials for occlusive dressings

Occlusive dressings can be made from biocompatible materials to ensure compatibility with the skin and wound environment. These materials may include polymers, hydrogels, or natural substances that do not cause adverse reactions when in contact with the body. The use of biocompatible materials helps to minimize irritation and promote healing.- Biocompatible materials for occlusive dressings: Occlusive dressings are designed using biocompatible materials to ensure compatibility with the patient's skin and wound environment. These materials may include polymers, hydrogels, or natural substances that do not cause adverse reactions or irritation when in contact with the skin or wound bed. The biocompatibility of these materials is crucial for promoting healing and preventing complications.

- Moisture management in occlusive dressings: Effective occlusive dressings incorporate moisture management features to maintain an optimal wound healing environment. These dressings are designed to prevent excessive moisture loss while allowing for proper gas exchange. The ability to control moisture levels helps prevent maceration of surrounding skin and promotes faster healing of the wound.

- Antimicrobial properties in occlusive dressings: Some occlusive dressings are formulated with antimicrobial agents to prevent infection and promote wound healing. These dressings may incorporate substances such as silver, iodine, or other antimicrobial compounds that help reduce the risk of bacterial colonization while maintaining biocompatibility with the wound site.

- Adhesive systems for occlusive dressings: Biocompatible adhesive systems are crucial for occlusive dressings to ensure proper adherence to the skin without causing irritation or damage upon removal. These adhesives are designed to provide a secure seal while being gentle on the skin, allowing for easy application and removal without compromising the wound healing process.

- Breathable film technology in occlusive dressings: Advanced occlusive dressings incorporate breathable film technology that allows for gas exchange while maintaining a barrier against external contaminants. These films are designed to be biocompatible and permeable to oxygen and water vapor, promoting a moist wound healing environment while preventing bacterial infiltration and excessive fluid accumulation.

02 Breathable occlusive dressings

Developing occlusive dressings that allow for some degree of breathability while maintaining a moist wound environment. These dressings can help prevent maceration of the skin while still providing the benefits of occlusion. The balance between occlusion and breathability is crucial for optimal wound healing and biocompatibility.Expand Specific Solutions03 Antimicrobial properties in occlusive dressings

Incorporating antimicrobial agents into occlusive dressings to prevent infection while maintaining biocompatibility. These agents can help create a barrier against pathogens without causing harm to the wound or surrounding skin. The challenge lies in selecting antimicrobial substances that are effective yet biocompatible.Expand Specific Solutions04 Adhesive technologies for occlusive dressings

Developing biocompatible adhesives for occlusive dressings that provide secure attachment without causing skin irritation or damage upon removal. These adhesives should be gentle on the skin while maintaining the occlusive seal. Advanced adhesive technologies can improve the overall biocompatibility and effectiveness of occlusive dressings.Expand Specific Solutions05 Smart occlusive dressings with biocompatible sensors

Integrating biocompatible sensors into occlusive dressings to monitor wound healing progress, pH levels, or other relevant parameters. These smart dressings can provide valuable information about the wound environment without compromising biocompatibility. The challenge is to develop sensors that are both accurate and safe for prolonged skin contact.Expand Specific Solutions

Key Industry Players

The standardization of occlusive dressing biocompatibility tests is in a developing stage, with the market showing significant growth potential due to increasing demand for advanced wound care products. The global wound dressing market size is projected to expand rapidly, driven by rising chronic diseases and surgical procedures. Technologically, the field is advancing, with companies like Daiichi Sankyo, SCHOTT AG, and Evolved by Nature leading innovations. These firms are focusing on developing biocompatible materials and improving testing methodologies. However, the technology is not yet fully mature, indicating opportunities for further research and development in standardizing biocompatibility testing protocols for occlusive dressings.

Daiichi Sankyo Co., Ltd.

Technical Solution: Daiichi Sankyo has developed a standardized approach for occlusive dressing biocompatibility tests, focusing on in vitro cytotoxicity, sensitization, and irritation assessments. Their method involves using human dermal fibroblasts and keratinocytes in 3D skin models to evaluate potential adverse effects. The company has implemented a tiered testing strategy, starting with less complex in vitro assays and progressing to more sophisticated 3D skin models and in vivo studies if necessary. This approach allows for a comprehensive evaluation of the dressing's biocompatibility while minimizing animal testing[1][3]. Additionally, Daiichi Sankyo has incorporated advanced imaging techniques and molecular biomarkers to detect early signs of cellular stress or inflammation, enhancing the sensitivity and specificity of their biocompatibility assessments[2].

Strengths: Comprehensive approach combining in vitro and 3D skin models; reduced reliance on animal testing; enhanced sensitivity through advanced imaging and biomarkers. Weaknesses: Potentially time-consuming and costly due to the tiered approach; may require specialized equipment and expertise.

The Regents of the University of California

Technical Solution: The University of California has developed a standardized protocol for occlusive dressing biocompatibility testing that emphasizes reproducibility and clinical relevance. Their approach integrates multiple assessment methods, including in vitro cell culture systems, ex vivo skin models, and controlled human skin patch tests. The protocol incorporates a novel microfluidic device that mimics the dynamic environment of wound healing, allowing for real-time monitoring of cellular responses to the dressing materials[4]. Additionally, they have implemented advanced proteomics and metabolomics analyses to identify potential biomarkers of adverse reactions, enhancing the predictive power of their biocompatibility assessments[5]. The university's method also includes a standardized scoring system for evaluating skin irritation and sensitization, which has been validated across multiple research centers to ensure consistency in results interpretation[6].

Strengths: Comprehensive approach combining in vitro, ex vivo, and in vivo methods; innovative microfluidic device for dynamic testing; standardized scoring system for consistent interpretation. Weaknesses: Complex methodology may require specialized equipment and expertise; potentially higher costs due to advanced analytical techniques.

Innovative Testing Approaches

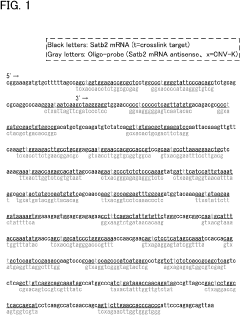

Nucleic acid detection method and oligonucleotide probe

PatentPendingUS20230193398A1

Innovation

- Incorporating a photocrosslinkable functional group into the oligonucleotide probe, which forms a crosslinked structure with the target sequence upon light irradiation, allowing for denaturation conditions that maintain specific hybridization products while dissociating non-specific ones, thereby improving detection accuracy and reproducibility.

Non-or minimally invasive monitoring methods

PatentInactiveUS20050176084A1

Innovation

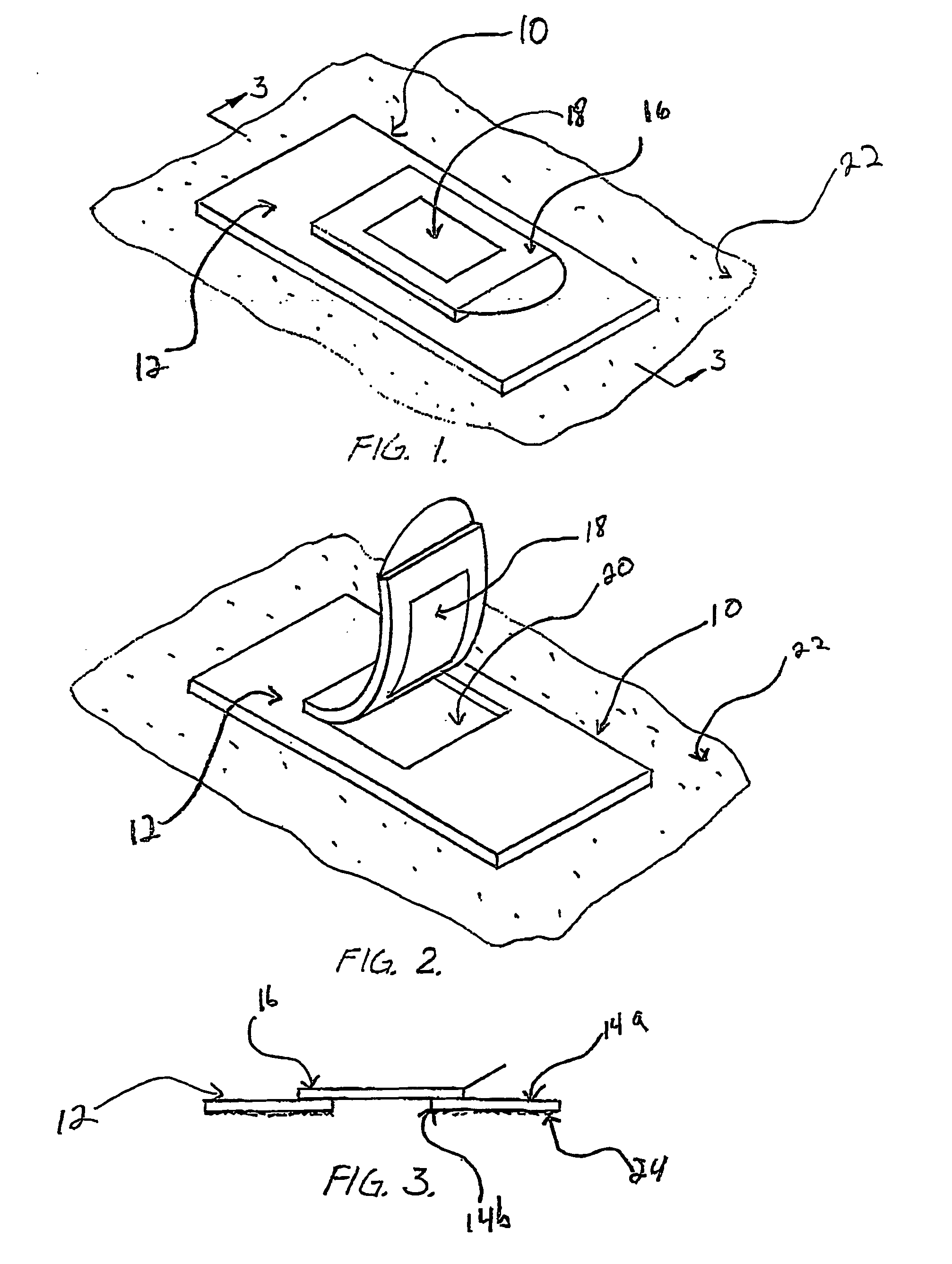

- A method for non-invasive or minimally invasive monitoring that involves disrupting the skin surface to access analytes, using a resealable occlusive dressing to maintain hydration and allow access to analytes, and employing a sensing apparatus to detect the presence or concentration of analytes, such as glucose, through transdermal access.

Regulatory Framework

The regulatory framework for standardizing occlusive dressing biocompatibility tests is primarily governed by international standards and guidelines set forth by regulatory bodies. The International Organization for Standardization (ISO) plays a crucial role in establishing these standards, particularly through ISO 10993, which outlines the biological evaluation of medical devices.

ISO 10993-1 provides the general principles for evaluating the biocompatibility of medical devices, including occlusive dressings. This standard emphasizes a risk-based approach to determine the appropriate tests required for each specific device. For occlusive dressings, key considerations include cytotoxicity, sensitization, and irritation potential.

The U.S. Food and Drug Administration (FDA) has adopted ISO 10993 as part of its regulatory framework for medical devices. The FDA's guidance document "Use of International Standard ISO 10993-1" provides additional clarity on how manufacturers should apply these standards in their biocompatibility assessments. This guidance emphasizes the importance of considering the specific materials, manufacturing processes, and intended use of the occlusive dressing when designing biocompatibility tests.

In the European Union, the Medical Device Regulation (MDR) 2017/745 sets the regulatory requirements for medical devices, including occlusive dressings. The MDR references harmonized standards, including ISO 10993, as a means of demonstrating compliance with its essential requirements. Manufacturers must conduct a thorough risk assessment and provide clinical evidence of safety and performance.

The Japanese Pharmaceuticals and Medical Devices Agency (PMDA) also follows similar principles, aligning its requirements with international standards. The PMDA's guidance on biological safety evaluation of medical devices closely mirrors ISO 10993, ensuring consistency in biocompatibility testing approaches across major global markets.

To standardize occlusive dressing biocompatibility tests, manufacturers must adhere to these regulatory frameworks while considering the specific characteristics of their products. This includes selecting appropriate test methods, determining the duration of contact with the skin, and evaluating any potential chemical leachables or degradation products.

Regulatory bodies are increasingly emphasizing the use of in vitro methods and alternative testing approaches to reduce animal testing where possible. This trend is reflected in updates to ISO 10993 and regulatory guidance documents, encouraging manufacturers to explore new methodologies for biocompatibility assessment while maintaining scientific rigor and patient safety.

ISO 10993-1 provides the general principles for evaluating the biocompatibility of medical devices, including occlusive dressings. This standard emphasizes a risk-based approach to determine the appropriate tests required for each specific device. For occlusive dressings, key considerations include cytotoxicity, sensitization, and irritation potential.

The U.S. Food and Drug Administration (FDA) has adopted ISO 10993 as part of its regulatory framework for medical devices. The FDA's guidance document "Use of International Standard ISO 10993-1" provides additional clarity on how manufacturers should apply these standards in their biocompatibility assessments. This guidance emphasizes the importance of considering the specific materials, manufacturing processes, and intended use of the occlusive dressing when designing biocompatibility tests.

In the European Union, the Medical Device Regulation (MDR) 2017/745 sets the regulatory requirements for medical devices, including occlusive dressings. The MDR references harmonized standards, including ISO 10993, as a means of demonstrating compliance with its essential requirements. Manufacturers must conduct a thorough risk assessment and provide clinical evidence of safety and performance.

The Japanese Pharmaceuticals and Medical Devices Agency (PMDA) also follows similar principles, aligning its requirements with international standards. The PMDA's guidance on biological safety evaluation of medical devices closely mirrors ISO 10993, ensuring consistency in biocompatibility testing approaches across major global markets.

To standardize occlusive dressing biocompatibility tests, manufacturers must adhere to these regulatory frameworks while considering the specific characteristics of their products. This includes selecting appropriate test methods, determining the duration of contact with the skin, and evaluating any potential chemical leachables or degradation products.

Regulatory bodies are increasingly emphasizing the use of in vitro methods and alternative testing approaches to reduce animal testing where possible. This trend is reflected in updates to ISO 10993 and regulatory guidance documents, encouraging manufacturers to explore new methodologies for biocompatibility assessment while maintaining scientific rigor and patient safety.

Ethical Considerations

The standardization of occlusive dressing biocompatibility tests raises several ethical considerations that must be carefully addressed. These considerations are crucial to ensure the safety and well-being of both human subjects and animals involved in the testing process, as well as to maintain the integrity of scientific research.

One primary ethical concern is the use of animal models in biocompatibility testing. While animal testing has been a traditional approach, there is a growing emphasis on reducing, refining, and replacing animal experiments. Researchers must justify the necessity of animal testing and explore alternative methods whenever possible, such as in vitro cell culture systems or computer simulations.

When animal testing is deemed necessary, strict protocols must be in place to minimize suffering and ensure humane treatment. This includes appropriate anesthesia, pain management, and euthanasia procedures. Additionally, the principle of using the minimum number of animals required to obtain statistically significant results should be adhered to.

Human subject participation in clinical trials for occlusive dressing biocompatibility tests also presents ethical challenges. Informed consent is paramount, with participants fully understanding the potential risks and benefits of their involvement. Researchers must ensure that vulnerable populations are not exploited and that the selection of participants is fair and unbiased.

Transparency and data integrity are critical ethical considerations in standardizing these tests. All research methods, results, and potential conflicts of interest should be fully disclosed. This includes reporting both positive and negative outcomes to prevent publication bias and ensure a comprehensive understanding of the dressing's biocompatibility.

The ethical use of biological samples obtained during testing is another important aspect. Proper consent for sample collection, storage, and future use must be obtained. Researchers should also consider the cultural and religious sensitivities surrounding the use of certain biological materials.

Environmental ethics should not be overlooked in the standardization process. The production and disposal of occlusive dressings and testing materials should be evaluated for their environmental impact. Sustainable practices and eco-friendly alternatives should be incorporated where possible.

Lastly, the standardization process itself must be conducted ethically, with input from diverse stakeholders including scientists, ethicists, regulatory bodies, and patient advocacy groups. This collaborative approach ensures that the resulting standards are comprehensive, fair, and reflective of various perspectives and concerns.

One primary ethical concern is the use of animal models in biocompatibility testing. While animal testing has been a traditional approach, there is a growing emphasis on reducing, refining, and replacing animal experiments. Researchers must justify the necessity of animal testing and explore alternative methods whenever possible, such as in vitro cell culture systems or computer simulations.

When animal testing is deemed necessary, strict protocols must be in place to minimize suffering and ensure humane treatment. This includes appropriate anesthesia, pain management, and euthanasia procedures. Additionally, the principle of using the minimum number of animals required to obtain statistically significant results should be adhered to.

Human subject participation in clinical trials for occlusive dressing biocompatibility tests also presents ethical challenges. Informed consent is paramount, with participants fully understanding the potential risks and benefits of their involvement. Researchers must ensure that vulnerable populations are not exploited and that the selection of participants is fair and unbiased.

Transparency and data integrity are critical ethical considerations in standardizing these tests. All research methods, results, and potential conflicts of interest should be fully disclosed. This includes reporting both positive and negative outcomes to prevent publication bias and ensure a comprehensive understanding of the dressing's biocompatibility.

The ethical use of biological samples obtained during testing is another important aspect. Proper consent for sample collection, storage, and future use must be obtained. Researchers should also consider the cultural and religious sensitivities surrounding the use of certain biological materials.

Environmental ethics should not be overlooked in the standardization process. The production and disposal of occlusive dressings and testing materials should be evaluated for their environmental impact. Sustainable practices and eco-friendly alternatives should be incorporated where possible.

Lastly, the standardization process itself must be conducted ethically, with input from diverse stakeholders including scientists, ethicists, regulatory bodies, and patient advocacy groups. This collaborative approach ensures that the resulting standards are comprehensive, fair, and reflective of various perspectives and concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!