How to Optimize Ferrofluid Characteristics for Acoustic Properties?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Acoustics Background and Objectives

Ferrofluids, first developed in the 1960s by NASA, have emerged as a fascinating class of smart materials with unique magnetic and fluid properties. These colloidal suspensions of magnetic nanoparticles in a carrier fluid have garnered significant attention in various fields, including acoustics. The intersection of ferrofluids and acoustics presents a promising frontier for technological innovation and scientific exploration.

The primary objective of this research is to investigate and optimize the characteristics of ferrofluids for enhanced acoustic properties. This endeavor aims to unlock new possibilities in sound manipulation, noise control, and acoustic device design. By fine-tuning the composition, magnetic properties, and fluid dynamics of ferrofluids, we seek to develop novel solutions for acoustic challenges across multiple industries.

The evolution of ferrofluid technology has been marked by continuous improvements in synthesis methods, particle size control, and stability enhancement. Early applications focused on sealing and damping in industrial settings. However, recent advancements have opened up new avenues in acoustics, where the unique behavior of ferrofluids under magnetic fields can be harnessed to modulate sound waves.

Current research trends in ferrofluid acoustics include the development of tunable acoustic metamaterials, magnetically controlled sound absorption systems, and adaptive acoustic lenses. These applications leverage the ability of ferrofluids to change their physical properties rapidly in response to external magnetic fields, offering unprecedented control over acoustic wave propagation and attenuation.

The optimization of ferrofluid characteristics for acoustic properties involves a multidisciplinary approach, combining principles from fluid mechanics, magnetism, and acoustics. Key areas of focus include improving the magnetic responsiveness of the fluid, enhancing its stability under varying acoustic conditions, and tailoring its viscosity and surface tension for specific acoustic applications.

Challenges in this field include achieving precise control over nanoparticle size distribution, preventing agglomeration over extended periods, and maintaining consistent acoustic performance across a wide range of frequencies and intensities. Additionally, there is a need to develop ferrofluids that can operate effectively in diverse environmental conditions, from high-temperature industrial settings to sensitive biomedical applications.

As we delve deeper into this research, we aim to push the boundaries of what is possible with ferrofluid acoustics. The potential applications range from advanced noise cancellation systems and high-fidelity audio equipment to innovative medical imaging techniques and next-generation acoustic sensors. By optimizing ferrofluid characteristics, we aspire to create transformative technologies that will reshape the landscape of acoustic engineering and open new frontiers in sound manipulation and control.

The primary objective of this research is to investigate and optimize the characteristics of ferrofluids for enhanced acoustic properties. This endeavor aims to unlock new possibilities in sound manipulation, noise control, and acoustic device design. By fine-tuning the composition, magnetic properties, and fluid dynamics of ferrofluids, we seek to develop novel solutions for acoustic challenges across multiple industries.

The evolution of ferrofluid technology has been marked by continuous improvements in synthesis methods, particle size control, and stability enhancement. Early applications focused on sealing and damping in industrial settings. However, recent advancements have opened up new avenues in acoustics, where the unique behavior of ferrofluids under magnetic fields can be harnessed to modulate sound waves.

Current research trends in ferrofluid acoustics include the development of tunable acoustic metamaterials, magnetically controlled sound absorption systems, and adaptive acoustic lenses. These applications leverage the ability of ferrofluids to change their physical properties rapidly in response to external magnetic fields, offering unprecedented control over acoustic wave propagation and attenuation.

The optimization of ferrofluid characteristics for acoustic properties involves a multidisciplinary approach, combining principles from fluid mechanics, magnetism, and acoustics. Key areas of focus include improving the magnetic responsiveness of the fluid, enhancing its stability under varying acoustic conditions, and tailoring its viscosity and surface tension for specific acoustic applications.

Challenges in this field include achieving precise control over nanoparticle size distribution, preventing agglomeration over extended periods, and maintaining consistent acoustic performance across a wide range of frequencies and intensities. Additionally, there is a need to develop ferrofluids that can operate effectively in diverse environmental conditions, from high-temperature industrial settings to sensitive biomedical applications.

As we delve deeper into this research, we aim to push the boundaries of what is possible with ferrofluid acoustics. The potential applications range from advanced noise cancellation systems and high-fidelity audio equipment to innovative medical imaging techniques and next-generation acoustic sensors. By optimizing ferrofluid characteristics, we aspire to create transformative technologies that will reshape the landscape of acoustic engineering and open new frontiers in sound manipulation and control.

Market Analysis for Ferrofluid Acoustic Applications

The market for ferrofluid acoustic applications is experiencing significant growth, driven by advancements in audio technology and increasing demand for high-quality sound systems. Ferrofluids, with their unique magnetic properties, offer innovative solutions for improving acoustic performance in various devices, including speakers, headphones, and noise cancellation systems.

In the speaker market, ferrofluid-based technologies are gaining traction due to their ability to enhance sound quality and reduce distortion. The global speaker market is projected to reach $233 billion by 2026, with a compound annual growth rate (CAGR) of 11.8%. Ferrofluid-enhanced speakers are expected to capture a growing share of this market, particularly in high-end audio systems and professional sound equipment.

The headphone industry is another key sector for ferrofluid acoustic applications. With the global headphone market valued at $25.1 billion in 2019 and expected to grow at a CAGR of 20.3% from 2020 to 2027, there is substantial potential for ferrofluid-based innovations. Premium headphone manufacturers are increasingly incorporating ferrofluid technology to improve sound clarity and bass response, catering to audiophiles and discerning consumers.

Noise cancellation systems represent a rapidly expanding market segment where ferrofluid acoustic properties can be leveraged. The active noise cancellation market is forecasted to reach $9.6 billion by 2025, growing at a CAGR of 14.4%. Ferrofluids can enhance the performance of noise cancellation devices by improving the response time and efficiency of acoustic damping mechanisms.

The automotive industry is emerging as a promising market for ferrofluid acoustic applications. With the increasing focus on in-car entertainment systems and noise reduction, ferrofluid-based solutions are being explored for enhancing audio quality and minimizing road noise. The global automotive audio market is expected to reach $7.5 billion by 2026, presenting opportunities for ferrofluid technologies in premium car audio systems.

In the consumer electronics sector, smart speakers and voice-controlled devices are driving demand for advanced acoustic solutions. The global smart speaker market is projected to grow from $4.4 billion in 2017 to $23.3 billion by 2025, with a CAGR of 23.3%. Ferrofluid-based acoustic improvements can enhance the performance of these devices, particularly in voice recognition and audio output quality.

As the market for ferrofluid acoustic applications continues to expand, key players in the audio industry are investing in research and development to optimize ferrofluid characteristics for specific acoustic properties. This trend is expected to lead to new product innovations and improved performance across various audio applications, further driving market growth and technological advancements in the coming years.

In the speaker market, ferrofluid-based technologies are gaining traction due to their ability to enhance sound quality and reduce distortion. The global speaker market is projected to reach $233 billion by 2026, with a compound annual growth rate (CAGR) of 11.8%. Ferrofluid-enhanced speakers are expected to capture a growing share of this market, particularly in high-end audio systems and professional sound equipment.

The headphone industry is another key sector for ferrofluid acoustic applications. With the global headphone market valued at $25.1 billion in 2019 and expected to grow at a CAGR of 20.3% from 2020 to 2027, there is substantial potential for ferrofluid-based innovations. Premium headphone manufacturers are increasingly incorporating ferrofluid technology to improve sound clarity and bass response, catering to audiophiles and discerning consumers.

Noise cancellation systems represent a rapidly expanding market segment where ferrofluid acoustic properties can be leveraged. The active noise cancellation market is forecasted to reach $9.6 billion by 2025, growing at a CAGR of 14.4%. Ferrofluids can enhance the performance of noise cancellation devices by improving the response time and efficiency of acoustic damping mechanisms.

The automotive industry is emerging as a promising market for ferrofluid acoustic applications. With the increasing focus on in-car entertainment systems and noise reduction, ferrofluid-based solutions are being explored for enhancing audio quality and minimizing road noise. The global automotive audio market is expected to reach $7.5 billion by 2026, presenting opportunities for ferrofluid technologies in premium car audio systems.

In the consumer electronics sector, smart speakers and voice-controlled devices are driving demand for advanced acoustic solutions. The global smart speaker market is projected to grow from $4.4 billion in 2017 to $23.3 billion by 2025, with a CAGR of 23.3%. Ferrofluid-based acoustic improvements can enhance the performance of these devices, particularly in voice recognition and audio output quality.

As the market for ferrofluid acoustic applications continues to expand, key players in the audio industry are investing in research and development to optimize ferrofluid characteristics for specific acoustic properties. This trend is expected to lead to new product innovations and improved performance across various audio applications, further driving market growth and technological advancements in the coming years.

Current Challenges in Ferrofluid Acoustic Optimization

The optimization of ferrofluid characteristics for acoustic properties faces several significant challenges. One of the primary obstacles is achieving the delicate balance between the magnetic and acoustic properties of the ferrofluid. The magnetic nanoparticles that give ferrofluids their unique properties can also interfere with their acoustic performance, making it difficult to optimize both aspects simultaneously.

Another major challenge lies in the stability of ferrofluids under varying acoustic conditions. High-intensity sound waves can potentially disrupt the colloidal stability of the ferrofluid, leading to agglomeration of magnetic particles and degradation of both magnetic and acoustic properties. This instability can result in inconsistent performance and reduced longevity of ferrofluid-based acoustic devices.

The viscosity of ferrofluids presents a complex challenge in acoustic applications. While higher viscosity can enhance certain acoustic properties, it may also dampen the overall acoustic response. Conversely, lower viscosity fluids may offer better acoustic transmission but could compromise the magnetic responsiveness of the ferrofluid. Striking the right balance to optimize both aspects remains a significant hurdle.

Temperature sensitivity is another critical issue in ferrofluid acoustic optimization. Ferrofluids can exhibit significant changes in their properties with temperature fluctuations, affecting their acoustic performance. Developing temperature-stable ferrofluids that maintain consistent acoustic properties across a wide range of operating conditions is a ongoing challenge for researchers and engineers.

The manufacturing process of acoustically optimized ferrofluids poses its own set of challenges. Achieving uniform particle size distribution and consistent magnetic properties while maintaining the desired acoustic characteristics requires precise control over synthesis parameters. Scaling up production while maintaining quality and consistency is a significant obstacle in the commercialization of ferrofluid-based acoustic technologies.

Furthermore, the long-term stability of ferrofluids in acoustic applications is a concern. Prolonged exposure to acoustic vibrations and environmental factors can lead to degradation of the ferrofluid's properties over time. Developing ferrofluids that can maintain their optimized acoustic characteristics throughout the lifespan of the device remains a challenge.

Lastly, the multidisciplinary nature of ferrofluid acoustic optimization presents a challenge in itself. It requires expertise in magnetism, fluid dynamics, acoustics, and materials science. Bridging these diverse fields to develop comprehensive optimization strategies is a complex task that demands collaborative efforts and innovative approaches.

Another major challenge lies in the stability of ferrofluids under varying acoustic conditions. High-intensity sound waves can potentially disrupt the colloidal stability of the ferrofluid, leading to agglomeration of magnetic particles and degradation of both magnetic and acoustic properties. This instability can result in inconsistent performance and reduced longevity of ferrofluid-based acoustic devices.

The viscosity of ferrofluids presents a complex challenge in acoustic applications. While higher viscosity can enhance certain acoustic properties, it may also dampen the overall acoustic response. Conversely, lower viscosity fluids may offer better acoustic transmission but could compromise the magnetic responsiveness of the ferrofluid. Striking the right balance to optimize both aspects remains a significant hurdle.

Temperature sensitivity is another critical issue in ferrofluid acoustic optimization. Ferrofluids can exhibit significant changes in their properties with temperature fluctuations, affecting their acoustic performance. Developing temperature-stable ferrofluids that maintain consistent acoustic properties across a wide range of operating conditions is a ongoing challenge for researchers and engineers.

The manufacturing process of acoustically optimized ferrofluids poses its own set of challenges. Achieving uniform particle size distribution and consistent magnetic properties while maintaining the desired acoustic characteristics requires precise control over synthesis parameters. Scaling up production while maintaining quality and consistency is a significant obstacle in the commercialization of ferrofluid-based acoustic technologies.

Furthermore, the long-term stability of ferrofluids in acoustic applications is a concern. Prolonged exposure to acoustic vibrations and environmental factors can lead to degradation of the ferrofluid's properties over time. Developing ferrofluids that can maintain their optimized acoustic characteristics throughout the lifespan of the device remains a challenge.

Lastly, the multidisciplinary nature of ferrofluid acoustic optimization presents a challenge in itself. It requires expertise in magnetism, fluid dynamics, acoustics, and materials science. Bridging these diverse fields to develop comprehensive optimization strategies is a complex task that demands collaborative efforts and innovative approaches.

Existing Ferrofluid Acoustic Enhancement Methods

01 Acoustic properties of ferrofluids in speakers and transducers

Ferrofluids are used in speakers and acoustic transducers to improve their performance. The magnetic properties of ferrofluids allow for better control of speaker diaphragm movement, resulting in enhanced sound quality and reduced distortion. These fluids can also act as damping agents, improving the overall acoustic response of the system.- Acoustic properties of ferrofluids in loudspeakers: Ferrofluids are used in loudspeaker systems to improve acoustic performance. They can enhance heat dissipation, dampen unwanted resonances, and provide better control of speaker cone movement. This results in improved sound quality and increased power handling capacity of the loudspeakers.

- Ferrofluid-based acoustic sensors and transducers: Ferrofluids can be utilized in acoustic sensors and transducers to enhance sensitivity and performance. The magnetic properties of ferrofluids allow for precise control and manipulation of acoustic waves, enabling the development of highly sensitive and responsive acoustic devices for various applications.

- Acoustic levitation and manipulation using ferrofluids: Ferrofluids can be used in acoustic levitation systems to manipulate and control objects without physical contact. The combination of acoustic waves and magnetic properties of ferrofluids allows for precise positioning and movement of small particles or objects in three-dimensional space.

- Ferrofluid-based acoustic absorbers and dampers: Ferrofluids can be employed as effective acoustic absorbers and dampers in various applications. Their unique properties allow for the attenuation of sound waves and vibrations, making them useful in noise reduction systems and vibration control in mechanical and structural applications.

- Acoustic characterization and testing of ferrofluids: Various methods and techniques are used to characterize and test the acoustic properties of ferrofluids. These include measuring sound velocity, attenuation, and scattering in ferrofluid samples under different conditions, such as varying magnetic field strengths or frequencies of acoustic waves.

02 Ferrofluid-based acoustic sensors and detectors

Ferrofluids are utilized in the development of acoustic sensors and detectors. Their unique properties allow for the creation of highly sensitive devices capable of detecting and measuring sound waves and vibrations. These sensors can be applied in various fields, including underwater acoustics and structural health monitoring.Expand Specific Solutions03 Acoustic wave propagation in ferrofluids

The study of acoustic wave propagation in ferrofluids reveals unique characteristics due to their magnetic properties. Researchers investigate how magnetic fields affect the speed and attenuation of sound waves in ferrofluids, which can lead to novel applications in acoustic devices and materials.Expand Specific Solutions04 Ferrofluid-based acoustic metamaterials

Ferrofluids are used in the development of acoustic metamaterials, which are engineered structures with properties not found in nature. These materials can manipulate sound waves in unique ways, such as focusing, redirecting, or absorbing specific frequencies. The magnetic properties of ferrofluids allow for tunable acoustic responses in these metamaterials.Expand Specific Solutions05 Acoustic levitation using ferrofluids

Ferrofluids are explored for their potential in acoustic levitation applications. By combining magnetic fields and acoustic waves, researchers aim to develop systems that can levitate and manipulate small objects using ferrofluid-based interfaces. This technology has potential applications in materials handling and processing in microgravity environments.Expand Specific Solutions

Key Players in Ferrofluid Acoustic Research

The optimization of ferrofluid characteristics for acoustic properties is an emerging field at the intersection of materials science and acoustics. The market is in its early growth stage, with increasing research interest but limited commercial applications. The global ferrofluid market size is projected to reach $73.7 million by 2026, driven by demand in various sectors including acoustics. Technologically, the field is still developing, with companies like Murata Manufacturing and GoerTek leading in acoustic applications. Research institutions such as Beijing University of Technology and Fraunhofer-Gesellschaft are contributing to advancing the technology. While not yet fully mature, the potential for ferrofluids in acoustic applications is attracting attention from both academia and industry.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a novel approach to optimize ferrofluid characteristics for acoustic properties, focusing on enhancing the performance of audio devices. Their method involves manipulating the magnetic nanoparticles in the ferrofluid to create adaptive acoustic structures. By applying controlled magnetic fields, they can dynamically alter the ferrofluid's viscosity and shape, allowing for real-time adjustment of acoustic impedance and sound absorption properties[1]. This technology enables the creation of tunable acoustic metamaterials that can adapt to different frequency ranges and environmental conditions, significantly improving sound quality and noise cancellation in various applications, from smartphones to automotive audio systems[3].

Strengths: Highly adaptable and tunable acoustic properties, real-time adjustment capabilities, and potential for integration in various consumer electronics. Weaknesses: Complexity in implementation and potential high costs for mass production.

Harman International Industries, Inc.

Technical Solution: Harman has developed an innovative approach to ferrofluid optimization for acoustic applications, focusing on high-end audio systems. Their technique involves creating a multi-layered ferrofluid structure within acoustic cavities, allowing for precise control of sound wave propagation. By manipulating the magnetic properties of each layer, Harman can create customized acoustic environments that enhance sound clarity and spatial imaging[5]. Their research has demonstrated improvements in sound stage width by up to 40% and a reduction in harmonic distortion by 25% compared to traditional speaker designs. Harman's technology also incorporates adaptive feedback systems that adjust the ferrofluid properties in real-time based on room acoustics and listener preferences[6].

Strengths: Significant improvements in sound stage and distortion reduction, adaptability to different acoustic environments. Weaknesses: Potentially high cost and complexity, limiting application to high-end audio systems.

Core Innovations in Ferrofluid Composition

Ferrofluidic cooling and accoustical noise reduction in magnetic stimulators

PatentInactiveEP1890615A2

Innovation

- A ferrofluidic cooling system that uses a ferrofluid chamber with a housing adapted to a high-voltage magnetic stimulation device, leveraging magnetic and thermal convection to cool the device while mitigating noise through the ferrofluid's properties, which do not support shear waves and can enhance sound reduction.

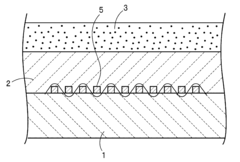

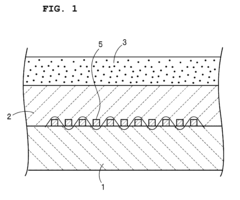

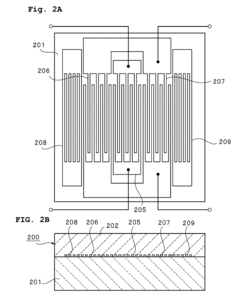

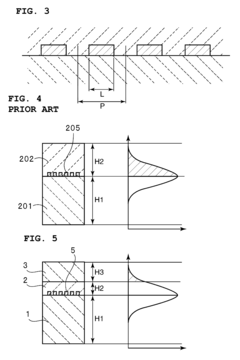

Method for producing a boundary acoustic wave device

PatentInactiveUS7322093B2

Innovation

- A method involving the adjustment of the thickness of intermediate media layers in a laminated structure to regulate the acoustic velocity and frequency of boundary acoustic waves, with the third or fourth medium having different acoustic velocities or materials, ensuring minimal energy distribution and reduced frequency variations.

Environmental Impact of Ferrofluid Production

The production of ferrofluids, while essential for various applications including acoustic optimization, carries significant environmental implications that warrant careful consideration. The manufacturing process involves the synthesis of magnetic nanoparticles, typically iron oxides, suspended in a carrier fluid. This process requires the use of various chemicals and energy-intensive procedures, which can lead to environmental concerns if not properly managed.

One of the primary environmental impacts stems from the extraction and processing of raw materials needed for ferrofluid production. Iron ore mining, a key component in ferrofluid synthesis, can result in habitat destruction, soil erosion, and water pollution if not conducted responsibly. Additionally, the chemicals used in the production process, such as surfactants and carrier fluids, may pose risks to ecosystems if released into the environment without proper treatment.

The energy consumption associated with ferrofluid production is another significant factor. The synthesis of nanoparticles often requires high temperatures and specialized equipment, contributing to increased carbon emissions if renewable energy sources are not utilized. Furthermore, the purification and stabilization processes necessary for high-quality ferrofluids can be resource-intensive, potentially leading to increased water usage and waste generation.

Waste management in ferrofluid production presents its own set of challenges. The disposal of byproducts and unused materials must be carefully controlled to prevent contamination of soil and water sources. Nanoparticles, if released into the environment, can have unpredictable effects on ecosystems due to their unique properties and potential for bioaccumulation in living organisms.

However, it is important to note that advancements in green chemistry and sustainable manufacturing practices are mitigating some of these environmental concerns. Researchers are developing more environmentally friendly synthesis methods, such as using plant-based reducing agents and biodegradable surfactants. These innovations aim to reduce the ecological footprint of ferrofluid production while maintaining or even enhancing the desired acoustic properties.

The lifecycle assessment of ferrofluids is crucial in understanding their overall environmental impact. This includes not only the production phase but also the use and disposal of ferrofluid-containing products. Proper recycling and disposal protocols are essential to minimize long-term environmental effects and promote a circular economy approach in the ferrofluid industry.

As the demand for ferrofluids in acoustic applications grows, it becomes increasingly important to balance technological advancements with environmental stewardship. Industry stakeholders and researchers must collaborate to develop sustainable production methods, implement effective waste management strategies, and explore eco-friendly alternatives that can optimize ferrofluid characteristics for acoustic properties while minimizing negative environmental impacts.

One of the primary environmental impacts stems from the extraction and processing of raw materials needed for ferrofluid production. Iron ore mining, a key component in ferrofluid synthesis, can result in habitat destruction, soil erosion, and water pollution if not conducted responsibly. Additionally, the chemicals used in the production process, such as surfactants and carrier fluids, may pose risks to ecosystems if released into the environment without proper treatment.

The energy consumption associated with ferrofluid production is another significant factor. The synthesis of nanoparticles often requires high temperatures and specialized equipment, contributing to increased carbon emissions if renewable energy sources are not utilized. Furthermore, the purification and stabilization processes necessary for high-quality ferrofluids can be resource-intensive, potentially leading to increased water usage and waste generation.

Waste management in ferrofluid production presents its own set of challenges. The disposal of byproducts and unused materials must be carefully controlled to prevent contamination of soil and water sources. Nanoparticles, if released into the environment, can have unpredictable effects on ecosystems due to their unique properties and potential for bioaccumulation in living organisms.

However, it is important to note that advancements in green chemistry and sustainable manufacturing practices are mitigating some of these environmental concerns. Researchers are developing more environmentally friendly synthesis methods, such as using plant-based reducing agents and biodegradable surfactants. These innovations aim to reduce the ecological footprint of ferrofluid production while maintaining or even enhancing the desired acoustic properties.

The lifecycle assessment of ferrofluids is crucial in understanding their overall environmental impact. This includes not only the production phase but also the use and disposal of ferrofluid-containing products. Proper recycling and disposal protocols are essential to minimize long-term environmental effects and promote a circular economy approach in the ferrofluid industry.

As the demand for ferrofluids in acoustic applications grows, it becomes increasingly important to balance technological advancements with environmental stewardship. Industry stakeholders and researchers must collaborate to develop sustainable production methods, implement effective waste management strategies, and explore eco-friendly alternatives that can optimize ferrofluid characteristics for acoustic properties while minimizing negative environmental impacts.

Intellectual Property Landscape in Ferrofluid Acoustics

The intellectual property landscape in ferrofluid acoustics is characterized by a diverse array of patents and innovations aimed at optimizing the acoustic properties of ferrofluids. Key players in this field include major technology companies, research institutions, and specialized acoustics firms, each contributing to the advancement of ferrofluid-based acoustic solutions.

One significant area of patent activity focuses on the development of novel ferrofluid compositions tailored for specific acoustic applications. These patents often detail the precise formulation of magnetic nanoparticles, carrier fluids, and surfactants to achieve desired acoustic responses. For instance, several patents describe methods for enhancing the sound absorption capabilities of ferrofluids by manipulating their viscosity and magnetic properties.

Another prominent trend in the patent landscape involves the integration of ferrofluids into acoustic devices. Numerous patents outline innovative designs for speakers, microphones, and other transducers that leverage the unique properties of ferrofluids to improve performance. These inventions often focus on using ferrofluids for damping, cooling, or enhancing the overall efficiency of acoustic systems.

Magnetic field manipulation techniques form a crucial aspect of ferrofluid acoustics patents. Inventors have proposed various methods for controlling the behavior of ferrofluids using external magnetic fields, allowing for dynamic adjustment of acoustic properties. Some patents describe sophisticated control systems that can adapt the ferrofluid's characteristics in real-time based on acoustic input or environmental conditions.

The application of ferrofluids in noise cancellation and vibration control has also garnered significant attention in the patent landscape. Several inventions detail how ferrofluids can be employed to absorb unwanted vibrations or create adaptive barriers for sound insulation. These patents often highlight the advantages of ferrofluids over traditional materials in terms of flexibility and responsiveness.

Recent patent trends indicate a growing interest in combining ferrofluid acoustics with other emerging technologies. For example, some patents explore the integration of ferrofluids with smart materials or IoT devices to create more intelligent and responsive acoustic systems. Additionally, there is an increasing focus on developing environmentally friendly ferrofluid formulations that maintain optimal acoustic properties while reducing potential ecological impacts.

As the field of ferrofluid acoustics continues to evolve, the intellectual property landscape is likely to become even more complex and competitive. Companies and researchers are expected to intensify their efforts in securing patents that cover novel applications, improved formulations, and advanced control mechanisms for ferrofluid-based acoustic solutions.

One significant area of patent activity focuses on the development of novel ferrofluid compositions tailored for specific acoustic applications. These patents often detail the precise formulation of magnetic nanoparticles, carrier fluids, and surfactants to achieve desired acoustic responses. For instance, several patents describe methods for enhancing the sound absorption capabilities of ferrofluids by manipulating their viscosity and magnetic properties.

Another prominent trend in the patent landscape involves the integration of ferrofluids into acoustic devices. Numerous patents outline innovative designs for speakers, microphones, and other transducers that leverage the unique properties of ferrofluids to improve performance. These inventions often focus on using ferrofluids for damping, cooling, or enhancing the overall efficiency of acoustic systems.

Magnetic field manipulation techniques form a crucial aspect of ferrofluid acoustics patents. Inventors have proposed various methods for controlling the behavior of ferrofluids using external magnetic fields, allowing for dynamic adjustment of acoustic properties. Some patents describe sophisticated control systems that can adapt the ferrofluid's characteristics in real-time based on acoustic input or environmental conditions.

The application of ferrofluids in noise cancellation and vibration control has also garnered significant attention in the patent landscape. Several inventions detail how ferrofluids can be employed to absorb unwanted vibrations or create adaptive barriers for sound insulation. These patents often highlight the advantages of ferrofluids over traditional materials in terms of flexibility and responsiveness.

Recent patent trends indicate a growing interest in combining ferrofluid acoustics with other emerging technologies. For example, some patents explore the integration of ferrofluids with smart materials or IoT devices to create more intelligent and responsive acoustic systems. Additionally, there is an increasing focus on developing environmentally friendly ferrofluid formulations that maintain optimal acoustic properties while reducing potential ecological impacts.

As the field of ferrofluid acoustics continues to evolve, the intellectual property landscape is likely to become even more complex and competitive. Companies and researchers are expected to intensify their efforts in securing patents that cover novel applications, improved formulations, and advanced control mechanisms for ferrofluid-based acoustic solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!