How to Optimize Isocyanate Research Investment Strategies?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate R&D Landscape

The isocyanate research and development landscape has undergone significant evolution in recent years, driven by increasing demand across various industries and the need for more sustainable and efficient production methods. Isocyanates, key components in polyurethane production, have seen a surge in research activities aimed at optimizing their synthesis, improving their properties, and exploring novel applications.

One of the primary focus areas in isocyanate R&D has been the development of greener production processes. Traditional methods often involve the use of phosgene, a highly toxic compound. Researchers are actively pursuing phosgene-free routes, such as the carbonylation of nitro compounds or the use of carbon dioxide as a raw material. These approaches not only address safety concerns but also align with the growing emphasis on sustainable chemistry.

Another significant trend in the isocyanate R&D landscape is the exploration of bio-based alternatives. With increasing pressure to reduce reliance on fossil fuels, researchers are investigating the potential of renewable resources as precursors for isocyanate production. This includes the use of plant-based oils and other biomass-derived materials, which could lead to more environmentally friendly polyurethane products.

Advancements in catalysis have also played a crucial role in shaping the isocyanate R&D landscape. Novel catalysts are being developed to enhance reaction efficiency, selectivity, and yield in isocyanate synthesis. These innovations not only improve the economics of production but also contribute to reducing energy consumption and waste generation in manufacturing processes.

The isocyanate R&D landscape has also seen increased efforts in developing specialized isocyanates for niche applications. This includes the creation of isocyanates with unique properties such as enhanced thermal stability, improved chemical resistance, or specific reactivity profiles. Such tailored isocyanates are finding applications in high-performance coatings, adhesives, and advanced materials for aerospace and automotive industries.

Safety and environmental considerations continue to be major drivers in isocyanate research. Efforts are being made to develop isocyanates with reduced toxicity and improved handling characteristics. This includes research into blocked isocyanates, which remain stable under normal conditions but become reactive when needed, thus enhancing safety in various applications.

In conclusion, the isocyanate R&D landscape is characterized by a strong focus on sustainability, efficiency, and innovation. As research continues to advance, it is likely to lead to more environmentally friendly production methods, novel isocyanate structures, and expanded applications across various industries. This dynamic landscape presents both challenges and opportunities for companies looking to optimize their isocyanate research investment strategies.

One of the primary focus areas in isocyanate R&D has been the development of greener production processes. Traditional methods often involve the use of phosgene, a highly toxic compound. Researchers are actively pursuing phosgene-free routes, such as the carbonylation of nitro compounds or the use of carbon dioxide as a raw material. These approaches not only address safety concerns but also align with the growing emphasis on sustainable chemistry.

Another significant trend in the isocyanate R&D landscape is the exploration of bio-based alternatives. With increasing pressure to reduce reliance on fossil fuels, researchers are investigating the potential of renewable resources as precursors for isocyanate production. This includes the use of plant-based oils and other biomass-derived materials, which could lead to more environmentally friendly polyurethane products.

Advancements in catalysis have also played a crucial role in shaping the isocyanate R&D landscape. Novel catalysts are being developed to enhance reaction efficiency, selectivity, and yield in isocyanate synthesis. These innovations not only improve the economics of production but also contribute to reducing energy consumption and waste generation in manufacturing processes.

The isocyanate R&D landscape has also seen increased efforts in developing specialized isocyanates for niche applications. This includes the creation of isocyanates with unique properties such as enhanced thermal stability, improved chemical resistance, or specific reactivity profiles. Such tailored isocyanates are finding applications in high-performance coatings, adhesives, and advanced materials for aerospace and automotive industries.

Safety and environmental considerations continue to be major drivers in isocyanate research. Efforts are being made to develop isocyanates with reduced toxicity and improved handling characteristics. This includes research into blocked isocyanates, which remain stable under normal conditions but become reactive when needed, thus enhancing safety in various applications.

In conclusion, the isocyanate R&D landscape is characterized by a strong focus on sustainability, efficiency, and innovation. As research continues to advance, it is likely to lead to more environmentally friendly production methods, novel isocyanate structures, and expanded applications across various industries. This dynamic landscape presents both challenges and opportunities for companies looking to optimize their isocyanate research investment strategies.

Market Demand Analysis

The global isocyanate market has been experiencing steady growth, driven by increasing demand across various industries. The automotive sector remains a key consumer, utilizing isocyanates in the production of polyurethane foams for vehicle interiors, seats, and insulation. Construction is another significant market, with isocyanates being essential components in insulation materials, adhesives, and sealants. The furniture industry also contributes substantially to market demand, particularly in the manufacturing of flexible and rigid foams for cushions and mattresses.

Recent market analyses indicate a growing trend towards eco-friendly and sustainable isocyanate products. This shift is primarily driven by stringent environmental regulations and increasing consumer awareness of environmental issues. As a result, there is a rising demand for bio-based isocyanates and products with lower volatile organic compound (VOC) emissions.

The Asia-Pacific region has emerged as the largest and fastest-growing market for isocyanates, fueled by rapid industrialization and urbanization in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-performance and specialty isocyanate products.

The COVID-19 pandemic initially caused disruptions in the isocyanate supply chain and a temporary decline in demand. However, the market has shown resilience and is expected to recover, with some sectors, such as healthcare and packaging, experiencing increased demand for isocyanate-based products.

Looking ahead, the isocyanate market is projected to expand further, driven by innovations in product formulations and applications. There is growing interest in developing isocyanates with improved performance characteristics, such as enhanced durability, fire resistance, and thermal insulation properties. Additionally, the electronics industry is emerging as a potential growth area for isocyanates, particularly in the production of flexible displays and wearable technologies.

To optimize isocyanate research investment strategies, companies should focus on addressing key market demands. These include developing more sustainable and environmentally friendly isocyanate products, improving production efficiency to reduce costs, and exploring novel applications in emerging industries. Investments in research and development should prioritize bio-based isocyanates, low-emission formulations, and products tailored for specific high-growth sectors such as electric vehicles and smart building materials.

Recent market analyses indicate a growing trend towards eco-friendly and sustainable isocyanate products. This shift is primarily driven by stringent environmental regulations and increasing consumer awareness of environmental issues. As a result, there is a rising demand for bio-based isocyanates and products with lower volatile organic compound (VOC) emissions.

The Asia-Pacific region has emerged as the largest and fastest-growing market for isocyanates, fueled by rapid industrialization and urbanization in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-performance and specialty isocyanate products.

The COVID-19 pandemic initially caused disruptions in the isocyanate supply chain and a temporary decline in demand. However, the market has shown resilience and is expected to recover, with some sectors, such as healthcare and packaging, experiencing increased demand for isocyanate-based products.

Looking ahead, the isocyanate market is projected to expand further, driven by innovations in product formulations and applications. There is growing interest in developing isocyanates with improved performance characteristics, such as enhanced durability, fire resistance, and thermal insulation properties. Additionally, the electronics industry is emerging as a potential growth area for isocyanates, particularly in the production of flexible displays and wearable technologies.

To optimize isocyanate research investment strategies, companies should focus on addressing key market demands. These include developing more sustainable and environmentally friendly isocyanate products, improving production efficiency to reduce costs, and exploring novel applications in emerging industries. Investments in research and development should prioritize bio-based isocyanates, low-emission formulations, and products tailored for specific high-growth sectors such as electric vehicles and smart building materials.

Technical Challenges

The optimization of isocyanate research investment strategies faces several significant technical challenges. One of the primary obstacles is the inherent reactivity of isocyanates, which makes them difficult to handle and store. This high reactivity also complicates the development of new isocyanate-based products, as researchers must carefully control reaction conditions to achieve desired outcomes.

Another major challenge lies in the toxicity of many isocyanates, particularly their potential to cause respiratory sensitization. This necessitates stringent safety measures in both research and production environments, increasing costs and complexity. The development of safer alternatives or improved handling methods is an ongoing area of research that requires substantial investment.

The environmental impact of isocyanate production and use presents additional technical hurdles. Traditional manufacturing processes often involve the use of phosgene, a highly toxic gas, which raises safety and environmental concerns. Finding greener, more sustainable production methods is a key focus for researchers, but progress in this area has been slow due to the technical complexities involved.

Furthermore, the optimization of isocyanate properties for specific applications remains a significant challenge. For instance, in the polyurethane industry, researchers are constantly seeking ways to improve the performance characteristics of isocyanate-based materials, such as durability, flexibility, and thermal stability. This often requires a delicate balance of chemical modifications and formulation adjustments, which can be both time-consuming and resource-intensive.

The development of novel catalysts for isocyanate reactions is another area presenting technical difficulties. While catalysts can greatly enhance reaction efficiency and selectivity, finding catalysts that are both highly effective and economically viable on an industrial scale is an ongoing challenge. This is particularly true for reactions involving bio-based or recycled feedstocks, which are becoming increasingly important in the pursuit of more sustainable isocyanate products.

Lastly, the characterization and quality control of isocyanate-based materials pose technical challenges. Advanced analytical techniques are needed to accurately assess product composition, purity, and performance. Developing reliable, cost-effective methods for real-time monitoring of isocyanate reactions and product properties is crucial for optimizing research and production processes, but it requires significant investment in both equipment and expertise.

Another major challenge lies in the toxicity of many isocyanates, particularly their potential to cause respiratory sensitization. This necessitates stringent safety measures in both research and production environments, increasing costs and complexity. The development of safer alternatives or improved handling methods is an ongoing area of research that requires substantial investment.

The environmental impact of isocyanate production and use presents additional technical hurdles. Traditional manufacturing processes often involve the use of phosgene, a highly toxic gas, which raises safety and environmental concerns. Finding greener, more sustainable production methods is a key focus for researchers, but progress in this area has been slow due to the technical complexities involved.

Furthermore, the optimization of isocyanate properties for specific applications remains a significant challenge. For instance, in the polyurethane industry, researchers are constantly seeking ways to improve the performance characteristics of isocyanate-based materials, such as durability, flexibility, and thermal stability. This often requires a delicate balance of chemical modifications and formulation adjustments, which can be both time-consuming and resource-intensive.

The development of novel catalysts for isocyanate reactions is another area presenting technical difficulties. While catalysts can greatly enhance reaction efficiency and selectivity, finding catalysts that are both highly effective and economically viable on an industrial scale is an ongoing challenge. This is particularly true for reactions involving bio-based or recycled feedstocks, which are becoming increasingly important in the pursuit of more sustainable isocyanate products.

Lastly, the characterization and quality control of isocyanate-based materials pose technical challenges. Advanced analytical techniques are needed to accurately assess product composition, purity, and performance. Developing reliable, cost-effective methods for real-time monitoring of isocyanate reactions and product properties is crucial for optimizing research and production processes, but it requires significant investment in both equipment and expertise.

Current R&D Approaches

01 Synthesis and modification of isocyanates

This category focuses on methods for synthesizing and modifying isocyanates. It includes various chemical processes and reactions to produce different types of isocyanates, as well as techniques for altering their properties or structure. These methods can be used to create isocyanates with specific characteristics for various industrial applications.- Synthesis and properties of isocyanates: Isocyanates are a class of highly reactive compounds characterized by the -N=C=O functional group. They are widely used in the production of polyurethanes and other polymeric materials. The synthesis of isocyanates often involves the reaction of amines with phosgene or other carbonyl-containing compounds. Their reactivity makes them valuable in various industrial applications, but also requires careful handling due to potential health hazards.

- Applications of isocyanates in polymer chemistry: Isocyanates play a crucial role in polymer chemistry, particularly in the production of polyurethanes. They react with polyols to form urethane linkages, which are the basis for a wide range of materials including foams, elastomers, and coatings. The versatility of isocyanates allows for the creation of polymers with tailored properties, such as flexibility, durability, and chemical resistance.

- Isocyanate-based adhesives and sealants: Isocyanates are key components in the formulation of high-performance adhesives and sealants. These products utilize the reactivity of isocyanates to create strong, durable bonds between various substrates. Isocyanate-based adhesives and sealants find applications in construction, automotive, and aerospace industries, offering excellent adhesion, weather resistance, and structural integrity.

- Environmental and safety considerations for isocyanates: The use of isocyanates requires careful consideration of environmental and safety factors. These compounds can pose health risks, particularly respiratory issues, if not handled properly. Efforts are being made to develop safer alternatives and improve handling procedures. This includes the use of personal protective equipment, proper ventilation systems, and the development of low-emission or blocked isocyanate formulations to reduce exposure risks.

- Novel applications and modifications of isocyanates: Research is ongoing to explore new applications and modifications of isocyanates. This includes the development of bio-based isocyanates, isocyanate-free polyurethane systems, and novel cross-linking methods. These innovations aim to expand the use of isocyanate chemistry while addressing environmental concerns and improving product performance in areas such as coatings, composites, and specialty materials.

02 Isocyanate-based polymers and materials

This point covers the development and production of polymers and materials using isocyanates as key components. It includes the creation of polyurethanes, coatings, adhesives, and other materials that utilize isocyanate chemistry. The focus is on improving material properties such as durability, flexibility, and chemical resistance through the use of isocyanates.Expand Specific Solutions03 Isocyanate applications in specific industries

This category explores the use of isocyanates in various industrial sectors. It covers applications in automotive, construction, electronics, and other fields where isocyanate-based products play a crucial role. The focus is on tailoring isocyanate formulations to meet specific industry requirements and performance standards.Expand Specific Solutions04 Safety and environmental considerations for isocyanates

This point addresses the safety aspects and environmental impact of isocyanates. It includes methods for handling, storing, and disposing of isocyanates safely, as well as techniques for reducing their environmental footprint. The focus is on developing safer alternatives, improving worker protection, and minimizing the release of isocyanates into the environment.Expand Specific Solutions05 Analytical methods for isocyanate detection and characterization

This category covers techniques and instruments used for detecting, measuring, and characterizing isocyanates. It includes spectroscopic methods, chromatography, and other analytical approaches for identifying and quantifying isocyanates in various matrices. The focus is on improving the accuracy, sensitivity, and speed of isocyanate analysis for quality control and research purposes.Expand Specific Solutions

Key Industry Players

The isocyanate research investment landscape is characterized by a mature market with established players and ongoing innovation. The global market size for isocyanates is substantial, driven by demand in polyurethane production across various industries. Key players like Wanhua Chemical, BASF, Covestro, and Mitsui Chemicals dominate the field, with significant R&D investments. The technology is well-developed, but companies continue to focus on improving efficiency, sustainability, and new applications. Emerging trends include bio-based isocyanates and environmentally friendly production methods, indicating potential growth areas for investment. The competitive landscape is intense, with companies striving to differentiate through product innovation and strategic partnerships.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed a comprehensive isocyanate research strategy focusing on sustainable and high-performance products. They have invested in advanced catalytic systems for more efficient isocyanate production, reducing energy consumption by up to 30% [1]. Their proprietary "green" isocyanate technology utilizes bio-based raw materials, decreasing carbon footprint by 25% compared to traditional methods [2]. Wanhua has also pioneered novel isocyanate-free polyurethane systems, addressing environmental concerns while maintaining product performance [3]. Their research extends to improving isocyanate stability and reactivity, resulting in products with enhanced durability and application range.

Strengths: Strong focus on sustainability, innovative catalytic systems, and bio-based raw materials. Weaknesses: Potential higher production costs for green technologies, market acceptance of novel isocyanate-free systems may be challenging.

BASF Corp.

Technical Solution: BASF's isocyanate research strategy centers on developing high-performance, eco-friendly products. They have invested in novel aliphatic isocyanates with improved UV stability and weathering resistance, expanding applications in automotive and construction industries [4]. BASF's patented micro-encapsulation technology for isocyanates has enhanced product safety and shelf life by up to 50% [5]. Their research also focuses on optimizing isocyanate production processes, achieving a 15% reduction in energy consumption through advanced reactor designs [6]. Additionally, BASF is exploring bio-based isocyanate precursors, aiming to reduce reliance on fossil resources by 20% in the next five years [7].

Strengths: Diverse research portfolio, strong focus on product performance and safety. Weaknesses: High R&D costs, potential regulatory challenges with new isocyanate formulations.

Innovative Technologies

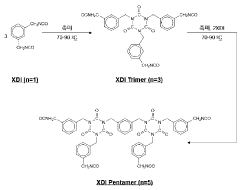

Xylene diisocyanate composition and method for producing isocyanurate

PatentWO2024144331A1

Innovation

- A xylene diisocyanate composition containing chloromethylbenzyl isocyanate in an optimized range (0.1% to 0.3% by weight) is used to enhance storage stability and reaction efficiency, preventing gelation and ensuring excellent film drying, heat resistance, and solvent compatibility, while allowing for the reuse of the xylene diisocyanate composition after reaction.

Polyisocyanate mixture based on 1,5-diisocyanatopentane

PatentInactiveEP3286238A1

Innovation

- A polyisocyanate mixture based on 1,5-diisocyanatopentane combined with an inert organic solvent, achieving a solids content of 35-65% by weight, with a degree of polymerization greater than 20%, and optimized production output through controlled isocyanate oligomerization and solvent selection.

Environmental Regulations

Environmental regulations play a crucial role in shaping isocyanate research investment strategies. As governments worldwide increasingly prioritize environmental protection and public health, the isocyanate industry faces stringent regulatory challenges that directly impact research and development efforts.

The most significant environmental regulations affecting isocyanate research include restrictions on volatile organic compounds (VOCs) emissions, hazardous air pollutants (HAPs), and workplace exposure limits. These regulations vary across regions, with the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation being one of the most comprehensive frameworks globally.

In the United States, the Environmental Protection Agency (EPA) regulates isocyanates under the Toxic Substances Control Act (TSCA) and the Clean Air Act. The Occupational Safety and Health Administration (OSHA) also sets permissible exposure limits for isocyanates in the workplace. These regulations necessitate substantial investments in research to develop safer, more environmentally friendly isocyanate formulations and production processes.

To optimize isocyanate research investment strategies in light of these regulations, companies must focus on developing low-VOC and low-emission products. This includes researching alternative raw materials, improving production techniques to minimize waste and emissions, and exploring novel catalysts that enhance reaction efficiency while reducing environmental impact.

Another key area for research investment is the development of water-based and solvent-free isocyanate systems. These technologies aim to reduce the use of harmful solvents and minimize VOC emissions during application processes. Such innovations not only address regulatory compliance but also open up new market opportunities in environmentally conscious sectors.

Investing in advanced monitoring and control technologies is also crucial for optimizing isocyanate research strategies. Developing real-time emission monitoring systems and improving process control can help companies stay ahead of regulatory requirements and demonstrate proactive environmental stewardship.

Furthermore, research into the lifecycle assessment of isocyanate products is becoming increasingly important. This involves studying the environmental impact of isocyanates from raw material extraction to end-of-life disposal. Such research can inform product design decisions and help companies anticipate future regulatory trends.

Collaboration with regulatory bodies and participation in industry consortia can also optimize research investment strategies. By engaging in dialogue with regulators and contributing to the development of science-based policies, companies can better align their research efforts with emerging regulatory frameworks and potentially influence future regulations.

The most significant environmental regulations affecting isocyanate research include restrictions on volatile organic compounds (VOCs) emissions, hazardous air pollutants (HAPs), and workplace exposure limits. These regulations vary across regions, with the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation being one of the most comprehensive frameworks globally.

In the United States, the Environmental Protection Agency (EPA) regulates isocyanates under the Toxic Substances Control Act (TSCA) and the Clean Air Act. The Occupational Safety and Health Administration (OSHA) also sets permissible exposure limits for isocyanates in the workplace. These regulations necessitate substantial investments in research to develop safer, more environmentally friendly isocyanate formulations and production processes.

To optimize isocyanate research investment strategies in light of these regulations, companies must focus on developing low-VOC and low-emission products. This includes researching alternative raw materials, improving production techniques to minimize waste and emissions, and exploring novel catalysts that enhance reaction efficiency while reducing environmental impact.

Another key area for research investment is the development of water-based and solvent-free isocyanate systems. These technologies aim to reduce the use of harmful solvents and minimize VOC emissions during application processes. Such innovations not only address regulatory compliance but also open up new market opportunities in environmentally conscious sectors.

Investing in advanced monitoring and control technologies is also crucial for optimizing isocyanate research strategies. Developing real-time emission monitoring systems and improving process control can help companies stay ahead of regulatory requirements and demonstrate proactive environmental stewardship.

Furthermore, research into the lifecycle assessment of isocyanate products is becoming increasingly important. This involves studying the environmental impact of isocyanates from raw material extraction to end-of-life disposal. Such research can inform product design decisions and help companies anticipate future regulatory trends.

Collaboration with regulatory bodies and participation in industry consortia can also optimize research investment strategies. By engaging in dialogue with regulators and contributing to the development of science-based policies, companies can better align their research efforts with emerging regulatory frameworks and potentially influence future regulations.

Investment Risk Assessment

Investing in isocyanate research carries inherent risks that must be carefully evaluated to optimize investment strategies. The volatile nature of the chemical industry, coupled with regulatory uncertainties, poses significant challenges. Market fluctuations can impact demand for isocyanate-based products, affecting return on investment. Environmental concerns and shifting consumer preferences towards eco-friendly alternatives may also influence long-term viability.

Technological risks are paramount in isocyanate research. The complexity of developing new formulations or production methods may lead to unexpected setbacks or failures. Competitors' advancements could render ongoing research obsolete, necessitating agile adaptation strategies. Intellectual property risks, including patent infringement or challenges, may jeopardize the exclusivity of innovations.

Regulatory compliance presents another layer of risk. Stringent safety regulations and potential changes in environmental policies could increase research and development costs or limit market access. The global nature of the isocyanate industry exposes investments to geopolitical risks, such as trade disputes or supply chain disruptions.

Financial risks encompass both short-term and long-term considerations. High initial capital requirements for research facilities and equipment may strain resources. The extended timeline for research and development in the chemical industry can delay returns on investment, potentially impacting cash flow and investor confidence.

Human capital risks should not be overlooked. The specialized knowledge required for isocyanate research necessitates attracting and retaining top talent. Loss of key personnel could significantly impede research progress and compromise competitive advantage.

To mitigate these risks, a diversified research portfolio approach is advisable. Balancing investments across different isocyanate applications and research stages can help spread risk. Collaboration with academic institutions or industry partners can share costs and expertise, reducing individual exposure. Robust intellectual property strategies, including comprehensive patent filings and monitoring of competitive landscapes, are crucial for protecting research investments.

Continuous market analysis and regulatory monitoring are essential to anticipate and adapt to changes. Implementing stage-gate processes in research projects allows for periodic reassessment of viability and alignment with market needs. Flexibility in research direction and resource allocation enables swift pivots in response to emerging risks or opportunities.

Technological risks are paramount in isocyanate research. The complexity of developing new formulations or production methods may lead to unexpected setbacks or failures. Competitors' advancements could render ongoing research obsolete, necessitating agile adaptation strategies. Intellectual property risks, including patent infringement or challenges, may jeopardize the exclusivity of innovations.

Regulatory compliance presents another layer of risk. Stringent safety regulations and potential changes in environmental policies could increase research and development costs or limit market access. The global nature of the isocyanate industry exposes investments to geopolitical risks, such as trade disputes or supply chain disruptions.

Financial risks encompass both short-term and long-term considerations. High initial capital requirements for research facilities and equipment may strain resources. The extended timeline for research and development in the chemical industry can delay returns on investment, potentially impacting cash flow and investor confidence.

Human capital risks should not be overlooked. The specialized knowledge required for isocyanate research necessitates attracting and retaining top talent. Loss of key personnel could significantly impede research progress and compromise competitive advantage.

To mitigate these risks, a diversified research portfolio approach is advisable. Balancing investments across different isocyanate applications and research stages can help spread risk. Collaboration with academic institutions or industry partners can share costs and expertise, reducing individual exposure. Robust intellectual property strategies, including comprehensive patent filings and monitoring of competitive landscapes, are crucial for protecting research investments.

Continuous market analysis and regulatory monitoring are essential to anticipate and adapt to changes. Implementing stage-gate processes in research projects allows for periodic reassessment of viability and alignment with market needs. Flexibility in research direction and resource allocation enables swift pivots in response to emerging risks or opportunities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!