How to Reduce GC-MS Detector Drift in Long Runs

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GC-MS Detector Drift Background and Objectives

Gas Chromatography-Mass Spectrometry (GC-MS) has evolved as a cornerstone analytical technique in various scientific fields since its development in the 1950s. The integration of gas chromatography's separation capabilities with mass spectrometry's identification power created a powerful tool for complex mixture analysis. However, detector drift during extended analytical runs remains a persistent challenge that compromises data quality and reliability.

Detector drift in GC-MS manifests as gradual changes in instrument response over time, even when analyzing identical samples. This phenomenon has become increasingly problematic as modern applications demand longer analytical sequences, higher sensitivity, and greater reproducibility. The evolution of GC-MS technology has focused on improving resolution, sensitivity, and throughput, but drift compensation has not received proportional attention until recent years.

The technical trajectory shows a shift from manual post-analysis corrections toward automated real-time drift compensation systems. Early approaches relied heavily on frequent calibration and mathematical corrections, while contemporary solutions incorporate advanced algorithms, internal standards, and hardware modifications. This progression reflects the growing recognition of drift as a critical factor affecting analytical outcomes.

Current research trends indicate increasing interest in machine learning approaches for drift prediction and compensation, development of more stable detector technologies, and implementation of intelligent calibration protocols. These advancements aim to address the fundamental causes of drift rather than merely treating its symptoms.

The primary objective of this technical research is to comprehensively evaluate existing and emerging strategies for minimizing GC-MS detector drift during extended analytical runs. Specifically, we aim to identify the most effective approaches for different application scenarios, assess their implementation requirements, and determine their impact on analytical performance metrics.

Secondary objectives include mapping the technological landscape of drift reduction solutions, analyzing the cost-benefit ratio of various approaches, and forecasting future developments in this field. We also seek to establish practical guidelines for laboratories facing drift-related challenges across different industries including pharmaceutical analysis, environmental monitoring, food safety testing, and forensic applications.

By addressing these objectives, we intend to provide actionable insights that can guide strategic decisions regarding instrument upgrades, method development, and quality control procedures. The ultimate goal is to enhance the reliability and reproducibility of GC-MS analyses, particularly in high-throughput environments where extended analytical sequences are becoming increasingly common.

Detector drift in GC-MS manifests as gradual changes in instrument response over time, even when analyzing identical samples. This phenomenon has become increasingly problematic as modern applications demand longer analytical sequences, higher sensitivity, and greater reproducibility. The evolution of GC-MS technology has focused on improving resolution, sensitivity, and throughput, but drift compensation has not received proportional attention until recent years.

The technical trajectory shows a shift from manual post-analysis corrections toward automated real-time drift compensation systems. Early approaches relied heavily on frequent calibration and mathematical corrections, while contemporary solutions incorporate advanced algorithms, internal standards, and hardware modifications. This progression reflects the growing recognition of drift as a critical factor affecting analytical outcomes.

Current research trends indicate increasing interest in machine learning approaches for drift prediction and compensation, development of more stable detector technologies, and implementation of intelligent calibration protocols. These advancements aim to address the fundamental causes of drift rather than merely treating its symptoms.

The primary objective of this technical research is to comprehensively evaluate existing and emerging strategies for minimizing GC-MS detector drift during extended analytical runs. Specifically, we aim to identify the most effective approaches for different application scenarios, assess their implementation requirements, and determine their impact on analytical performance metrics.

Secondary objectives include mapping the technological landscape of drift reduction solutions, analyzing the cost-benefit ratio of various approaches, and forecasting future developments in this field. We also seek to establish practical guidelines for laboratories facing drift-related challenges across different industries including pharmaceutical analysis, environmental monitoring, food safety testing, and forensic applications.

By addressing these objectives, we intend to provide actionable insights that can guide strategic decisions regarding instrument upgrades, method development, and quality control procedures. The ultimate goal is to enhance the reliability and reproducibility of GC-MS analyses, particularly in high-throughput environments where extended analytical sequences are becoming increasingly common.

Market Demand for Stable Long-Run GC-MS Analysis

The global market for Gas Chromatography-Mass Spectrometry (GC-MS) systems continues to expand significantly, driven by increasing demand for accurate, reliable, and consistent analytical results across multiple industries. The market value for GC-MS equipment reached approximately $1.5 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028, with stable long-run analysis capabilities representing a critical factor in this growth trajectory.

Pharmaceutical and biotechnology sectors constitute the largest market segment, where long-duration stability is essential for drug development, quality control, and regulatory compliance. These industries require extended analytical runs that can last 24-72 hours while maintaining consistent detection sensitivity and accuracy. The financial impact of detector drift in these settings is substantial, with some companies reporting that recalibration and repeated analyses due to drift issues cost between $10,000-$25,000 per month in lost productivity and materials.

Environmental monitoring represents another rapidly growing application area, with regulatory bodies worldwide implementing stricter requirements for continuous monitoring of pollutants. The EPA and similar international agencies now mandate detection limits in the parts-per-trillion range for certain compounds, making detector stability during extended runs a compliance necessity rather than a luxury.

Food safety testing has emerged as a particularly demanding market segment, with requirements for both high throughput and exceptional stability. Major food producers report that unstable GC-MS systems can delay product releases by 24-48 hours, resulting in significant financial losses, particularly for perishable goods. Industry surveys indicate that 78% of food testing laboratories consider detector drift during long runs as one of their top three operational challenges.

Clinical diagnostics laboratories have also expressed growing demand for drift-free GC-MS systems, particularly as metabolomics and clinical toxicology applications expand. Hospital laboratories processing hundreds of samples daily report that detector drift necessitates frequent recalibration, reducing throughput by 15-20% and increasing per-sample analysis costs.

Research institutions and academic laboratories, while representing a smaller market segment by value, drive innovation in analytical methodologies that eventually transfer to industrial applications. These users particularly value stability during method development, where consistent detector response is essential for accurate comparison of experimental conditions.

Market research indicates that customers are willing to pay a 15-25% premium for GC-MS systems with demonstrably superior long-run stability characteristics. This represents a significant opportunity for manufacturers who can effectively address the detector drift challenge with innovative solutions.

Pharmaceutical and biotechnology sectors constitute the largest market segment, where long-duration stability is essential for drug development, quality control, and regulatory compliance. These industries require extended analytical runs that can last 24-72 hours while maintaining consistent detection sensitivity and accuracy. The financial impact of detector drift in these settings is substantial, with some companies reporting that recalibration and repeated analyses due to drift issues cost between $10,000-$25,000 per month in lost productivity and materials.

Environmental monitoring represents another rapidly growing application area, with regulatory bodies worldwide implementing stricter requirements for continuous monitoring of pollutants. The EPA and similar international agencies now mandate detection limits in the parts-per-trillion range for certain compounds, making detector stability during extended runs a compliance necessity rather than a luxury.

Food safety testing has emerged as a particularly demanding market segment, with requirements for both high throughput and exceptional stability. Major food producers report that unstable GC-MS systems can delay product releases by 24-48 hours, resulting in significant financial losses, particularly for perishable goods. Industry surveys indicate that 78% of food testing laboratories consider detector drift during long runs as one of their top three operational challenges.

Clinical diagnostics laboratories have also expressed growing demand for drift-free GC-MS systems, particularly as metabolomics and clinical toxicology applications expand. Hospital laboratories processing hundreds of samples daily report that detector drift necessitates frequent recalibration, reducing throughput by 15-20% and increasing per-sample analysis costs.

Research institutions and academic laboratories, while representing a smaller market segment by value, drive innovation in analytical methodologies that eventually transfer to industrial applications. These users particularly value stability during method development, where consistent detector response is essential for accurate comparison of experimental conditions.

Market research indicates that customers are willing to pay a 15-25% premium for GC-MS systems with demonstrably superior long-run stability characteristics. This represents a significant opportunity for manufacturers who can effectively address the detector drift challenge with innovative solutions.

Current Challenges in GC-MS Detector Stability

Gas chromatography-mass spectrometry (GC-MS) systems face significant challenges with detector stability during extended analytical runs, a problem that severely impacts data quality and reliability. Detector drift, characterized by gradual changes in signal response over time, represents one of the most persistent obstacles in maintaining consistent quantitative results across large sample batches.

The primary manifestation of detector drift appears as baseline shifts and sensitivity variations that progressively worsen throughout analytical sequences. This phenomenon is particularly problematic in high-throughput environments such as environmental monitoring, food safety testing, and pharmaceutical quality control, where hundreds of samples may be analyzed consecutively over periods exceeding 24 hours.

Several fundamental factors contribute to GC-MS detector instability. Thermal fluctuations within the ion source and detector components create variable ionization efficiency and electron multiplier response. Even minor temperature variations of 1-2°C can produce measurable drift in modern high-sensitivity instruments. Additionally, sample matrix residues gradually accumulate on critical components, altering the ionization environment and reducing transmission efficiency through the mass analyzer.

Contamination of the ion source represents another significant challenge, as non-volatile compounds from complex matrices slowly deposit on source components. This contamination progressively changes the ionization characteristics and transmission properties, leading to declining sensitivity for certain analytes while potentially enhancing others, thus distorting calibration relationships.

Electronic stability issues further compound detector drift problems. Power supply fluctuations, aging electronic components, and thermal effects on circuit performance all contribute to signal variability over extended operational periods. Modern instruments incorporate sophisticated electronic stabilization systems, yet long-term drift remains inevitable in many applications.

Vacuum system performance degradation presents another critical challenge. As carrier gas, sample components, and column bleed continuously enter the MS system, vacuum pump efficiency may gradually decline, subtly altering ionization conditions and ion transmission characteristics. This effect becomes particularly pronounced in systems utilizing diffusion pumps rather than turbomolecular pumps.

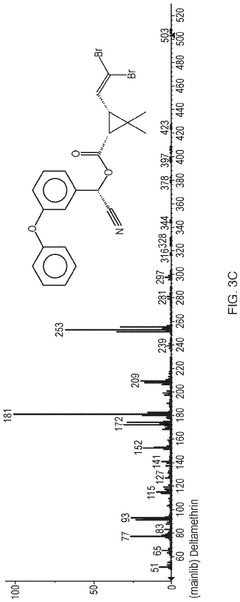

The consequences of detector drift extend beyond simple sensitivity changes. Spectral quality may deteriorate, mass calibration can shift, and fragmentation patterns may subtly change, complicating compound identification. These effects are especially problematic in untargeted screening applications where library matching depends on consistent spectral characteristics.

Current mitigation strategies include frequent calibration, internal standardization, and automated tuning procedures. However, these approaches add complexity, increase analysis time, and may not fully compensate for all drift mechanisms. The development of more robust solutions for detector stability remains a significant challenge for instrument manufacturers and analytical chemists alike.

The primary manifestation of detector drift appears as baseline shifts and sensitivity variations that progressively worsen throughout analytical sequences. This phenomenon is particularly problematic in high-throughput environments such as environmental monitoring, food safety testing, and pharmaceutical quality control, where hundreds of samples may be analyzed consecutively over periods exceeding 24 hours.

Several fundamental factors contribute to GC-MS detector instability. Thermal fluctuations within the ion source and detector components create variable ionization efficiency and electron multiplier response. Even minor temperature variations of 1-2°C can produce measurable drift in modern high-sensitivity instruments. Additionally, sample matrix residues gradually accumulate on critical components, altering the ionization environment and reducing transmission efficiency through the mass analyzer.

Contamination of the ion source represents another significant challenge, as non-volatile compounds from complex matrices slowly deposit on source components. This contamination progressively changes the ionization characteristics and transmission properties, leading to declining sensitivity for certain analytes while potentially enhancing others, thus distorting calibration relationships.

Electronic stability issues further compound detector drift problems. Power supply fluctuations, aging electronic components, and thermal effects on circuit performance all contribute to signal variability over extended operational periods. Modern instruments incorporate sophisticated electronic stabilization systems, yet long-term drift remains inevitable in many applications.

Vacuum system performance degradation presents another critical challenge. As carrier gas, sample components, and column bleed continuously enter the MS system, vacuum pump efficiency may gradually decline, subtly altering ionization conditions and ion transmission characteristics. This effect becomes particularly pronounced in systems utilizing diffusion pumps rather than turbomolecular pumps.

The consequences of detector drift extend beyond simple sensitivity changes. Spectral quality may deteriorate, mass calibration can shift, and fragmentation patterns may subtly change, complicating compound identification. These effects are especially problematic in untargeted screening applications where library matching depends on consistent spectral characteristics.

Current mitigation strategies include frequent calibration, internal standardization, and automated tuning procedures. However, these approaches add complexity, increase analysis time, and may not fully compensate for all drift mechanisms. The development of more robust solutions for detector stability remains a significant challenge for instrument manufacturers and analytical chemists alike.

Current Drift Compensation and Calibration Methods

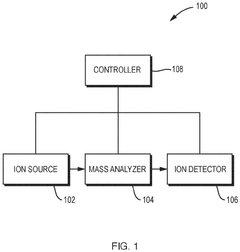

01 Calibration methods for GC-MS detector drift

Various calibration techniques are employed to address detector drift in GC-MS systems. These methods include the use of internal standards, reference compounds, and automated calibration procedures that can compensate for sensitivity changes over time. Regular calibration helps maintain accuracy and precision in analytical measurements by establishing correction factors that account for instrumental drift, ensuring reliable quantitative analysis even during extended operation periods.- Calibration methods for GC-MS detector drift: Various calibration techniques are employed to address detector drift in GC-MS systems. These methods include internal standard calibration, where known compounds are added to samples to normalize responses, and automated calibration routines that periodically measure reference standards. Advanced algorithms can also be implemented to mathematically correct for drift over time, ensuring consistent analytical results despite instrumental variations.

- Hardware modifications to reduce detector drift: Hardware innovations can significantly minimize detector drift in GC-MS systems. These include temperature-controlled detector environments, improved ion source designs with enhanced stability, and specialized electronic components that maintain consistent voltage and current supplies. Some systems incorporate reference channels that continuously monitor performance parameters to compensate for environmental fluctuations affecting detector response.

- Software solutions for drift compensation: Advanced software algorithms have been developed to address GC-MS detector drift issues. These include real-time drift correction algorithms, machine learning approaches that can predict and compensate for drift patterns, and automated data processing workflows that apply appropriate corrections based on system performance metrics. Some solutions incorporate statistical methods to distinguish between actual signal changes and instrument-related drift.

- Preventive maintenance procedures: Regular maintenance protocols can significantly reduce detector drift in GC-MS systems. These include scheduled cleaning of ion sources, replacement of filaments and other consumable components before performance degradation occurs, and systematic verification of gas flow rates and pressures. Preventive maintenance schedules based on usage patterns rather than fixed time intervals can optimize system stability and extend periods of reliable operation.

- Environmental control strategies: Controlling the operating environment of GC-MS systems is crucial for minimizing detector drift. Strategies include installation in temperature and humidity-controlled laboratories, protection from electromagnetic interference, vibration isolation systems, and stable power supplies with appropriate conditioning. Some approaches involve enclosing critical components in controlled microenvironments to shield them from external variations that could affect detector stability.

02 Hardware solutions for drift reduction

Specialized hardware components and designs can minimize detector drift in GC-MS systems. These include temperature-controlled detector chambers, improved ion source designs, and advanced electronic stabilization circuits. Hardware modifications focus on maintaining consistent operating conditions by controlling environmental factors that contribute to drift, such as temperature fluctuations and pressure variations, thereby enhancing the long-term stability of the detection system.Expand Specific Solutions03 Software algorithms for drift compensation

Advanced software algorithms are developed to detect, monitor, and compensate for detector drift in real-time. These computational approaches include baseline correction algorithms, drift pattern recognition, and mathematical models that can predict and adjust for systematic changes in detector response. Machine learning techniques are increasingly being applied to recognize complex drift patterns and automatically apply appropriate corrections, improving the reliability of analytical results without requiring frequent manual recalibration.Expand Specific Solutions04 Automated drift monitoring systems

Integrated monitoring systems continuously track detector performance parameters to identify and address drift issues before they affect analytical results. These systems employ sensors that measure critical operating conditions such as temperature, pressure, and electronic stability. When deviations are detected, automated alerts notify operators or trigger corrective actions. Some advanced systems incorporate predictive maintenance capabilities that can forecast potential drift problems based on historical performance data, allowing for preventive interventions.Expand Specific Solutions05 Novel detector designs with enhanced stability

Innovative detector designs specifically engineered to minimize drift effects in GC-MS applications. These include next-generation electron multipliers, improved ion trap configurations, and hybrid detector systems that combine multiple detection principles. Materials science advancements have led to more stable detector surfaces that resist degradation over time. Some designs incorporate self-diagnostic features that can identify when detector performance is beginning to drift, allowing for timely maintenance or replacement before analytical quality is compromised.Expand Specific Solutions

Leading Manufacturers and Research Groups in GC-MS

The GC-MS detector drift reduction market is in a growth phase, characterized by increasing demand for improved analytical stability in long-duration chromatography runs. The global analytical instrumentation market, valued at approximately $85 billion, shows steady expansion as industries require more reliable long-term analytical solutions. Leading companies like Shimadzu, IBM, and Waters (through Micromass) are at the forefront of technological maturity, developing advanced algorithms and hardware solutions to address detector drift issues. Shimadzu has pioneered automated calibration systems, while IBM applies machine learning approaches to signal processing. Research institutions like Xidian University and the Danforth Plant Science Center collaborate with industry players to develop next-generation solutions combining hardware improvements with sophisticated data correction methodologies.

Shimadzu Corp.

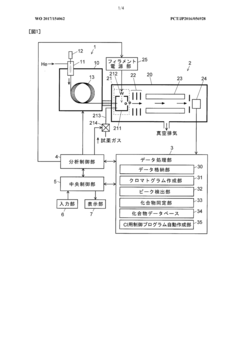

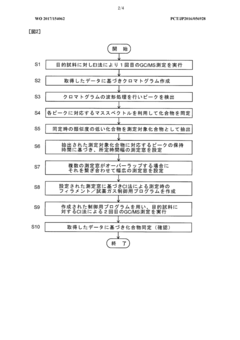

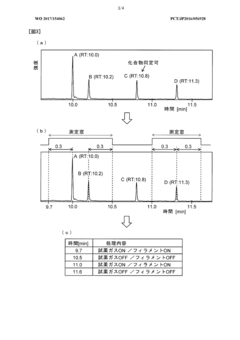

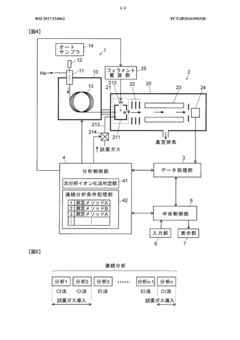

Technical Solution: Shimadzu has developed advanced GC-MS systems with proprietary drift compensation technologies. Their approach includes automated mass calibration systems that perform regular recalibration during long analytical runs to maintain mass accuracy. The company's LabSolutions software incorporates drift correction algorithms that apply mathematical corrections to compensate for detector sensitivity changes over time. Shimadzu's hardware innovations include temperature-controlled ion sources and quadrupole assemblies that minimize thermal expansion effects causing drift[1]. Their latest GC-MS systems feature Active Time Management (ATM) technology that monitors detector performance in real-time and applies dynamic voltage adjustments to the electron multiplier to maintain consistent response factors throughout extended analytical sequences[2]. Additionally, Shimadzu has implemented dual-stage electron multipliers with extended lifetimes and more stable response characteristics specifically designed to address long-term drift issues.

Strengths: Comprehensive integrated approach combining hardware stabilization with software correction algorithms; excellent temperature control systems that minimize thermal drift; proprietary detector technology with extended lifetime. Weaknesses: Solutions may be proprietary and limited to Shimadzu instruments; some drift compensation features require premium software packages; implementation complexity may require specialized training.

International Business Machines Corp.

Technical Solution: IBM has applied its expertise in data analytics and artificial intelligence to address GC-MS detector drift challenges. Their approach leverages machine learning algorithms to model and predict detector drift patterns based on historical performance data. IBM's solution incorporates neural network models that can identify complex, non-linear drift patterns that traditional correction methods might miss. The system continuously learns from instrument performance data, improving prediction accuracy over time[5]. IBM has developed specialized signal processing techniques that can distinguish between actual analytical signals and drift-related artifacts. Their cloud-based analytical platform allows for real-time monitoring of instrument performance across multiple laboratories, enabling predictive maintenance and early intervention before drift becomes problematic. Additionally, IBM's quantum computing research division is exploring quantum algorithms that could potentially model electron multiplier physics with unprecedented accuracy, potentially leading to next-generation detector designs with inherently improved stability characteristics[6].

Strengths: Advanced AI and machine learning capabilities for complex drift pattern recognition; cloud-based monitoring enables fleet-wide instrument optimization; continuous improvement through learning algorithms. Weaknesses: May require significant computational resources; potential data privacy concerns with cloud-based solutions; higher implementation complexity compared to traditional hardware-based approaches.

Key Innovations in Detector Stability Enhancement

Gas chromatograph mass spectrometer

PatentWO2017154062A1

Innovation

- A GC-MS system with an ion source capable of switching between electron ionization (EI) and chemical ionization (CI) methods, where the reagent gas supply and thermionic electron generation are controlled to minimize reagent gas ion adhesion by only generating ions during specific time ranges corresponding to detected compounds, thereby maintaining high sensitivity and accuracy.

Carrier gas ion scavenger to reduce peak tailing and reactions

PatentPendingEP4538697A1

Innovation

- The implementation of a scavenger gas system that supplies a gas with lower ionization energy, such as methane or a mixture of methane and ammonia, to the ionization chamber of a mass spectrometer, thereby reducing peak tailing and reactions when using non-helium carrier gases.

Quality Control Standards for Analytical Instrumentation

Quality control standards for analytical instrumentation represent a critical framework for ensuring the reliability and accuracy of GC-MS systems during extended analytical runs. These standards establish systematic protocols that laboratories must implement to minimize detector drift and maintain data integrity throughout long-duration analyses.

The foundation of effective quality control begins with the establishment of comprehensive standard operating procedures (SOPs) that define acceptable performance parameters for GC-MS systems. These parameters typically include signal-to-noise ratios, peak area reproducibility, mass accuracy, and detector response linearity. For long runs specifically, these standards must address temporal stability metrics that quantify acceptable drift rates over extended periods.

International organizations such as ISO, ASTM, and USP have developed standardized guidelines that provide benchmarks for analytical instrument performance. ISO/IEC 17025, for instance, outlines general requirements for the competence of testing and calibration laboratories, including specific provisions for instrument quality control. These standards mandate regular verification of system suitability through the analysis of certified reference materials (CRMs) at defined intervals during extended analytical sequences.

Implementation of these standards requires laboratories to establish appropriate quality control checkpoints throughout long analytical runs. This typically involves the strategic placement of QC samples at regular intervals (commonly every 10-20 samples) to monitor system performance in real-time. Statistical process control (SPC) charts derived from these QC measurements enable analysts to detect drift patterns before they compromise data quality.

Modern quality control standards increasingly incorporate automated system suitability tests (SSTs) that can evaluate multiple performance parameters simultaneously. These tests utilize specialized software algorithms to analyze detector response characteristics and flag deviations that exceed predetermined thresholds. For GC-MS specifically, these standards often include mass axis calibration checks, abundance sensitivity tests, and isotope ratio verifications.

Regulatory compliance frameworks such as FDA's GLP/GMP guidelines and EPA's quality assurance protocols have further reinforced the importance of robust quality control standards. These regulations require documented evidence of instrument performance throughout analytical campaigns, with particular emphasis on drift correction methodologies for extended analyses.

Adherence to these quality control standards not only ensures data reliability but also facilitates inter-laboratory comparability of results. By establishing uniform performance criteria and verification procedures, these standards create a foundation for consistent analytical outcomes regardless of instrument age, manufacturer, or laboratory environment.

The foundation of effective quality control begins with the establishment of comprehensive standard operating procedures (SOPs) that define acceptable performance parameters for GC-MS systems. These parameters typically include signal-to-noise ratios, peak area reproducibility, mass accuracy, and detector response linearity. For long runs specifically, these standards must address temporal stability metrics that quantify acceptable drift rates over extended periods.

International organizations such as ISO, ASTM, and USP have developed standardized guidelines that provide benchmarks for analytical instrument performance. ISO/IEC 17025, for instance, outlines general requirements for the competence of testing and calibration laboratories, including specific provisions for instrument quality control. These standards mandate regular verification of system suitability through the analysis of certified reference materials (CRMs) at defined intervals during extended analytical sequences.

Implementation of these standards requires laboratories to establish appropriate quality control checkpoints throughout long analytical runs. This typically involves the strategic placement of QC samples at regular intervals (commonly every 10-20 samples) to monitor system performance in real-time. Statistical process control (SPC) charts derived from these QC measurements enable analysts to detect drift patterns before they compromise data quality.

Modern quality control standards increasingly incorporate automated system suitability tests (SSTs) that can evaluate multiple performance parameters simultaneously. These tests utilize specialized software algorithms to analyze detector response characteristics and flag deviations that exceed predetermined thresholds. For GC-MS specifically, these standards often include mass axis calibration checks, abundance sensitivity tests, and isotope ratio verifications.

Regulatory compliance frameworks such as FDA's GLP/GMP guidelines and EPA's quality assurance protocols have further reinforced the importance of robust quality control standards. These regulations require documented evidence of instrument performance throughout analytical campaigns, with particular emphasis on drift correction methodologies for extended analyses.

Adherence to these quality control standards not only ensures data reliability but also facilitates inter-laboratory comparability of results. By establishing uniform performance criteria and verification procedures, these standards create a foundation for consistent analytical outcomes regardless of instrument age, manufacturer, or laboratory environment.

Environmental Factors Affecting GC-MS Performance

Environmental factors play a crucial role in the stability and reliability of GC-MS systems during extended analytical runs. Temperature fluctuations in the laboratory environment represent one of the most significant contributors to detector drift. Even minor variations of ±2°C can cause substantial baseline shifts and sensitivity changes, particularly affecting the performance of electron ionization sources and electron multipliers.

Humidity levels similarly impact system performance, with high humidity (>60%) potentially causing condensation within the ion source and transfer lines. This moisture accumulation can lead to oxidation of sensitive components and contribute to signal degradation over time. Conversely, extremely low humidity environments may increase static electricity, affecting the trajectory of ions and resulting in erratic detector responses.

Atmospheric pressure variations, though often overlooked, can significantly influence ionization efficiency and vacuum system performance. Barometric pressure changes during long analytical sequences may alter the gas flow dynamics within the system, affecting retention times and detector response. Modern GC-MS systems incorporate pressure compensation mechanisms, but these may be insufficient during extended operations exceeding 24 hours.

Electrical supply stability represents another critical environmental factor. Voltage fluctuations, power surges, and electromagnetic interference can directly impact electronic components responsible for signal amplification and processing. These disturbances may manifest as sudden baseline shifts or gradual signal drift that becomes more pronounced over extended analytical runs.

Laboratory air quality also deserves consideration, as airborne contaminants can enter the GC-MS system through various pathways. Volatile organic compounds from solvents, cleaning agents, or construction materials may contribute to background noise and compete with analytes during ionization. Similarly, particulate matter can accumulate on critical components, gradually altering their performance characteristics.

Vibration and mechanical stability affect chromatographic performance and detector alignment. Even subtle vibrations from nearby equipment, HVAC systems, or building infrastructure can propagate through the instrument, potentially causing column efficiency loss and detector misalignment over time. These mechanical disturbances become increasingly problematic during multi-day analytical sequences.

Addressing these environmental factors requires a comprehensive approach to laboratory design and instrument placement. Implementing strict environmental controls, including dedicated HVAC systems, voltage regulators, vibration-dampening platforms, and regular air filtration maintenance, can significantly reduce their impact on GC-MS detector drift during extended analytical runs.

Humidity levels similarly impact system performance, with high humidity (>60%) potentially causing condensation within the ion source and transfer lines. This moisture accumulation can lead to oxidation of sensitive components and contribute to signal degradation over time. Conversely, extremely low humidity environments may increase static electricity, affecting the trajectory of ions and resulting in erratic detector responses.

Atmospheric pressure variations, though often overlooked, can significantly influence ionization efficiency and vacuum system performance. Barometric pressure changes during long analytical sequences may alter the gas flow dynamics within the system, affecting retention times and detector response. Modern GC-MS systems incorporate pressure compensation mechanisms, but these may be insufficient during extended operations exceeding 24 hours.

Electrical supply stability represents another critical environmental factor. Voltage fluctuations, power surges, and electromagnetic interference can directly impact electronic components responsible for signal amplification and processing. These disturbances may manifest as sudden baseline shifts or gradual signal drift that becomes more pronounced over extended analytical runs.

Laboratory air quality also deserves consideration, as airborne contaminants can enter the GC-MS system through various pathways. Volatile organic compounds from solvents, cleaning agents, or construction materials may contribute to background noise and compete with analytes during ionization. Similarly, particulate matter can accumulate on critical components, gradually altering their performance characteristics.

Vibration and mechanical stability affect chromatographic performance and detector alignment. Even subtle vibrations from nearby equipment, HVAC systems, or building infrastructure can propagate through the instrument, potentially causing column efficiency loss and detector misalignment over time. These mechanical disturbances become increasingly problematic during multi-day analytical sequences.

Addressing these environmental factors requires a comprehensive approach to laboratory design and instrument placement. Implementing strict environmental controls, including dedicated HVAC systems, voltage regulators, vibration-dampening platforms, and regular air filtration maintenance, can significantly reduce their impact on GC-MS detector drift during extended analytical runs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!