How to Safely Transport Battery Acid in Bulk

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Transport Background and Objectives

Battery acid, primarily composed of sulfuric acid, plays a crucial role in the functionality of lead-acid batteries, which are widely used in various industries and applications. The safe transportation of battery acid in bulk has become increasingly important due to the growing demand for batteries in automotive, renewable energy, and industrial sectors. This technological challenge has evolved over time, driven by the need to balance safety, efficiency, and cost-effectiveness in the transportation process.

The primary objective of developing safe battery acid transport methods is to minimize the risks associated with handling and moving large quantities of this corrosive substance. These risks include potential spills, leaks, and chemical reactions that could lead to environmental damage, health hazards, and equipment deterioration. As the battery industry continues to expand, the demand for efficient and secure transportation solutions has intensified, prompting ongoing research and development efforts.

Historically, the transportation of battery acid has been subject to stringent regulations and safety protocols. Early methods relied heavily on robust containment systems and extensive safety measures, which often resulted in high costs and logistical challenges. Over time, technological advancements have led to the development of more sophisticated transport solutions, incorporating materials science, chemical engineering, and advanced monitoring systems.

The evolution of battery acid transport technology has been marked by several key milestones. These include the introduction of corrosion-resistant materials for containers, the development of spill-proof designs, and the implementation of real-time monitoring systems to detect and prevent potential hazards during transit. Each of these advancements has contributed to improving the safety and reliability of battery acid transportation.

Current technological trends in this field focus on further enhancing safety measures while optimizing transportation efficiency. This includes the exploration of novel materials with superior acid-resistant properties, the integration of smart sensors and IoT technologies for real-time monitoring, and the development of more compact and lightweight containment systems that maintain high safety standards.

Looking ahead, the future of battery acid transport technology is likely to be shaped by emerging trends in the battery industry, such as the increasing adoption of electric vehicles and renewable energy storage systems. These developments will drive the need for even more advanced and scalable transport solutions capable of handling larger volumes of battery acid safely and efficiently.

The primary objective of developing safe battery acid transport methods is to minimize the risks associated with handling and moving large quantities of this corrosive substance. These risks include potential spills, leaks, and chemical reactions that could lead to environmental damage, health hazards, and equipment deterioration. As the battery industry continues to expand, the demand for efficient and secure transportation solutions has intensified, prompting ongoing research and development efforts.

Historically, the transportation of battery acid has been subject to stringent regulations and safety protocols. Early methods relied heavily on robust containment systems and extensive safety measures, which often resulted in high costs and logistical challenges. Over time, technological advancements have led to the development of more sophisticated transport solutions, incorporating materials science, chemical engineering, and advanced monitoring systems.

The evolution of battery acid transport technology has been marked by several key milestones. These include the introduction of corrosion-resistant materials for containers, the development of spill-proof designs, and the implementation of real-time monitoring systems to detect and prevent potential hazards during transit. Each of these advancements has contributed to improving the safety and reliability of battery acid transportation.

Current technological trends in this field focus on further enhancing safety measures while optimizing transportation efficiency. This includes the exploration of novel materials with superior acid-resistant properties, the integration of smart sensors and IoT technologies for real-time monitoring, and the development of more compact and lightweight containment systems that maintain high safety standards.

Looking ahead, the future of battery acid transport technology is likely to be shaped by emerging trends in the battery industry, such as the increasing adoption of electric vehicles and renewable energy storage systems. These developments will drive the need for even more advanced and scalable transport solutions capable of handling larger volumes of battery acid safely and efficiently.

Market Analysis for Bulk Battery Acid Transportation

The global market for bulk battery acid transportation has been experiencing steady growth, driven by the increasing demand for batteries across various industries. The automotive sector, in particular, has been a significant contributor to this growth, with the rise of electric vehicles (EVs) and hybrid vehicles leading to a surge in battery production. This trend is expected to continue, with projections indicating a compound annual growth rate (CAGR) of over 5% for the battery market in the coming years.

The industrial sector also plays a crucial role in the demand for bulk battery acid transportation. Large-scale energy storage systems, telecommunications infrastructure, and backup power solutions all rely heavily on batteries, further fueling the need for efficient and safe transportation of battery acid. Additionally, the growing adoption of renewable energy sources, such as solar and wind power, has led to an increased demand for energy storage solutions, indirectly boosting the battery acid transportation market.

Geographically, Asia-Pacific dominates the market, with China being the largest producer and consumer of batteries. The region's rapid industrialization and urbanization have contributed significantly to the demand for batteries and, consequently, battery acid transportation. North America and Europe follow closely, driven by their automotive industries and increasing focus on renewable energy adoption.

The market landscape for bulk battery acid transportation is characterized by a mix of specialized chemical transportation companies and logistics providers. These players are continuously investing in advanced transportation technologies and safety measures to meet the stringent regulations surrounding hazardous material transport. The competitive environment is moderately fragmented, with several regional and global players vying for market share.

Key market trends include the development of more efficient and safer transportation methods, such as specialized tanker trucks and rail cars designed specifically for battery acid. There is also a growing emphasis on sustainable practices, with companies exploring ways to reduce the environmental impact of battery acid transportation through route optimization and the use of cleaner fuel alternatives for transport vehicles.

Challenges in the market primarily revolve around safety concerns and regulatory compliance. The corrosive nature of battery acid necessitates strict adherence to transportation guidelines, which can increase operational costs. Additionally, the potential environmental risks associated with acid spills during transport have led to increased scrutiny and regulatory oversight.

Despite these challenges, the market outlook remains positive. The ongoing transition towards electric mobility and renewable energy storage solutions is expected to drive sustained demand for bulk battery acid transportation services. As technology advances and safety measures improve, the market is likely to see continued growth and innovation in the coming years.

The industrial sector also plays a crucial role in the demand for bulk battery acid transportation. Large-scale energy storage systems, telecommunications infrastructure, and backup power solutions all rely heavily on batteries, further fueling the need for efficient and safe transportation of battery acid. Additionally, the growing adoption of renewable energy sources, such as solar and wind power, has led to an increased demand for energy storage solutions, indirectly boosting the battery acid transportation market.

Geographically, Asia-Pacific dominates the market, with China being the largest producer and consumer of batteries. The region's rapid industrialization and urbanization have contributed significantly to the demand for batteries and, consequently, battery acid transportation. North America and Europe follow closely, driven by their automotive industries and increasing focus on renewable energy adoption.

The market landscape for bulk battery acid transportation is characterized by a mix of specialized chemical transportation companies and logistics providers. These players are continuously investing in advanced transportation technologies and safety measures to meet the stringent regulations surrounding hazardous material transport. The competitive environment is moderately fragmented, with several regional and global players vying for market share.

Key market trends include the development of more efficient and safer transportation methods, such as specialized tanker trucks and rail cars designed specifically for battery acid. There is also a growing emphasis on sustainable practices, with companies exploring ways to reduce the environmental impact of battery acid transportation through route optimization and the use of cleaner fuel alternatives for transport vehicles.

Challenges in the market primarily revolve around safety concerns and regulatory compliance. The corrosive nature of battery acid necessitates strict adherence to transportation guidelines, which can increase operational costs. Additionally, the potential environmental risks associated with acid spills during transport have led to increased scrutiny and regulatory oversight.

Despite these challenges, the market outlook remains positive. The ongoing transition towards electric mobility and renewable energy storage solutions is expected to drive sustained demand for bulk battery acid transportation services. As technology advances and safety measures improve, the market is likely to see continued growth and innovation in the coming years.

Current Challenges in Battery Acid Bulk Transport

The transportation of battery acid in bulk presents several significant challenges that require careful consideration and management. One of the primary concerns is the highly corrosive nature of battery acid, which can cause severe damage to both living tissues and various materials. This corrosivity necessitates specialized containment solutions that can withstand prolonged exposure without degradation or leakage.

Safety is paramount in the transport of battery acid, as any spills or leaks can pose serious health and environmental risks. The potential for acid burns, respiratory issues, and contamination of soil and water sources demands rigorous safety protocols and emergency response procedures. Additionally, the volatile nature of battery acid requires strict temperature control during transportation to prevent expansion, gas formation, or chemical reactions that could compromise container integrity.

Regulatory compliance adds another layer of complexity to battery acid transportation. Different countries and regions have varying regulations governing the handling and transport of hazardous materials, including specific requirements for packaging, labeling, and documentation. Adhering to these diverse regulations while maintaining operational efficiency can be challenging for companies operating across multiple jurisdictions.

The logistics of bulk transport also present unique challenges. The weight and volume of battery acid shipments require specialized handling equipment and vehicles capable of safely managing such loads. This often necessitates investment in purpose-built transport solutions or modifications to existing infrastructure, which can be costly and time-consuming.

Environmental concerns are increasingly shaping the landscape of battery acid transportation. The potential for ecological damage in the event of a spill has led to stricter regulations and a growing emphasis on sustainable transport practices. This shift is driving the need for more environmentally friendly packaging solutions and spill containment systems, as well as improved methods for neutralizing and disposing of battery acid in case of accidents.

The human factor remains a critical consideration in addressing these challenges. Ensuring that all personnel involved in the handling and transport of battery acid are adequately trained and equipped is essential. This includes not only drivers and logistics staff but also emergency responders who may need to deal with incidents. Developing comprehensive training programs and maintaining up-to-date safety protocols are ongoing challenges that require constant attention and resources.

Safety is paramount in the transport of battery acid, as any spills or leaks can pose serious health and environmental risks. The potential for acid burns, respiratory issues, and contamination of soil and water sources demands rigorous safety protocols and emergency response procedures. Additionally, the volatile nature of battery acid requires strict temperature control during transportation to prevent expansion, gas formation, or chemical reactions that could compromise container integrity.

Regulatory compliance adds another layer of complexity to battery acid transportation. Different countries and regions have varying regulations governing the handling and transport of hazardous materials, including specific requirements for packaging, labeling, and documentation. Adhering to these diverse regulations while maintaining operational efficiency can be challenging for companies operating across multiple jurisdictions.

The logistics of bulk transport also present unique challenges. The weight and volume of battery acid shipments require specialized handling equipment and vehicles capable of safely managing such loads. This often necessitates investment in purpose-built transport solutions or modifications to existing infrastructure, which can be costly and time-consuming.

Environmental concerns are increasingly shaping the landscape of battery acid transportation. The potential for ecological damage in the event of a spill has led to stricter regulations and a growing emphasis on sustainable transport practices. This shift is driving the need for more environmentally friendly packaging solutions and spill containment systems, as well as improved methods for neutralizing and disposing of battery acid in case of accidents.

The human factor remains a critical consideration in addressing these challenges. Ensuring that all personnel involved in the handling and transport of battery acid are adequately trained and equipped is essential. This includes not only drivers and logistics staff but also emergency responders who may need to deal with incidents. Developing comprehensive training programs and maintaining up-to-date safety protocols are ongoing challenges that require constant attention and resources.

Existing Safety Protocols for Battery Acid Transport

01 Safety measures for battery acid handling

Implementing proper safety measures when handling battery acid is crucial. This includes using appropriate personal protective equipment (PPE), such as acid-resistant gloves, goggles, and protective clothing. Proper ventilation in the work area and the use of specialized containers for acid storage and transport are also essential. Additionally, having emergency eyewash stations and safety showers nearby can help mitigate potential accidents.- Safety measures for battery acid handling: Implementing proper safety measures when handling battery acid is crucial. This includes using appropriate personal protective equipment (PPE), such as acid-resistant gloves, goggles, and protective clothing. Proper ventilation in the work area and the use of specialized containers for acid storage and transport are also essential. Additionally, having emergency eyewash stations and safety showers nearby can help mitigate potential accidents.

- Battery acid containment and spill prevention: Designing effective containment systems and implementing spill prevention measures are critical for battery acid safety. This includes using leak-proof battery casings, installing secondary containment systems, and implementing proper sealing techniques. Advanced monitoring systems can detect potential leaks early, allowing for prompt intervention. Proper maintenance and regular inspections of battery systems can also help prevent acid spills and leaks.

- Neutralization and disposal of battery acid: Proper neutralization and disposal of battery acid are essential for environmental and safety reasons. This involves using appropriate neutralizing agents, such as sodium bicarbonate or lime, to safely neutralize the acid before disposal. Implementing proper waste management protocols and adhering to local regulations for hazardous waste disposal are crucial. Recycling programs for used batteries can also help minimize environmental impact and improve overall safety.

- Battery design improvements for enhanced safety: Advancements in battery design can significantly improve safety related to battery acid. This includes developing sealed battery technologies that reduce the risk of acid leakage, implementing advanced electrolyte management systems, and using safer alternative materials. Innovations in battery casing materials and internal component designs can also enhance overall battery safety and reduce the risks associated with acid exposure.

- Safety monitoring and detection systems: Implementing advanced safety monitoring and detection systems can significantly improve battery acid safety. This includes using sensors to detect acid leaks or vapors, implementing early warning systems for potential hazards, and integrating smart monitoring technologies into battery management systems. Real-time monitoring and automated safety protocols can help prevent accidents and minimize risks associated with battery acid exposure.

02 Battery acid containment and spill prevention

Designing effective containment systems and implementing spill prevention measures are critical for battery acid safety. This includes using leak-proof battery casings, installing secondary containment systems, and implementing proper sealing techniques. Regular inspections and maintenance of battery systems can help identify potential leaks or weak points before they become hazardous.Expand Specific Solutions03 Battery acid neutralization and disposal

Proper neutralization and disposal of battery acid are essential for environmental and safety reasons. This involves using appropriate neutralizing agents, such as sodium bicarbonate or lime, to neutralize the acid before disposal. Implementing safe disposal methods and following local regulations for hazardous waste management are crucial steps in ensuring battery acid safety.Expand Specific Solutions04 Battery monitoring and maintenance for acid safety

Regular monitoring and maintenance of batteries can significantly improve acid safety. This includes implementing battery management systems that monitor acid levels, temperature, and other critical parameters. Conducting routine inspections, cleaning terminals, and replacing damaged components can help prevent acid-related incidents and extend battery life.Expand Specific Solutions05 Alternative battery technologies for improved safety

Developing and adopting alternative battery technologies can enhance overall safety by reducing or eliminating the use of corrosive acids. This includes research into solid-state batteries, gel electrolytes, and other advanced battery chemistries that offer improved safety profiles compared to traditional lead-acid batteries. These alternatives can minimize the risks associated with battery acid while potentially offering improved performance and longevity.Expand Specific Solutions

Key Players in Battery Acid Transport Industry

The market for safely transporting battery acid in bulk is in a mature stage, with established players and well-defined regulations. The global market size for hazardous material transportation, including battery acid, is substantial and growing due to increased industrial activities and battery production. Technologically, the field is moderately advanced, with companies like GS Yuasa International Ltd., Johnson Controls, Inc., and BASF Corp. leading innovations in safe packaging and transportation methods. These firms, along with others like Panasonic Holdings Corp. and Robert Bosch GmbH, are investing in research and development to improve safety measures and efficiency in battery acid transportation, addressing environmental concerns and regulatory requirements.

Johnson Controls, Inc.

Technical Solution: Johnson Controls has developed a comprehensive approach for safely transporting battery acid in bulk. Their system includes specially designed containers with multi-layer protection, including acid-resistant inner linings and shock-absorbing outer shells. These containers are equipped with advanced leak detection sensors and pressure relief valves to prevent build-up of dangerous gases[1]. The company also utilizes a proprietary tracking system that monitors temperature, pressure, and movement in real-time during transport[3]. Additionally, Johnson Controls has implemented a rigorous training program for handlers and drivers, focusing on emergency response procedures and proper handling techniques[5].

Strengths: Comprehensive safety features, real-time monitoring, and well-trained personnel. Weaknesses: Potentially higher costs due to specialized equipment and training requirements.

BASF Corp.

Technical Solution: BASF has engineered an innovative solution for bulk battery acid transportation called SafeAcid™. This system utilizes a chemical stabilization process that temporarily reduces the corrosivity of the acid during transport[2]. The process involves adding a proprietary blend of compounds that form a protective barrier around acid molecules, significantly reducing their reactivity. Upon arrival at the destination, the stabilizing effect can be easily reversed, returning the acid to its original state[4]. BASF's method also incorporates specially designed flexible containers that can withstand the reduced, but still present, corrosive effects of the treated acid. These containers are equipped with multiple layers of chemical-resistant materials and integrated spill containment systems[6].

Strengths: Reduced corrosivity during transport, reversible process, and specialized containment. Weaknesses: Additional processing steps required before and after transport, potential for incomplete reversal of stabilization.

Innovative Containment Solutions for Battery Acid

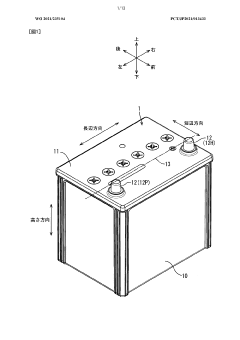

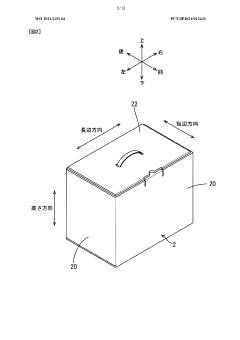

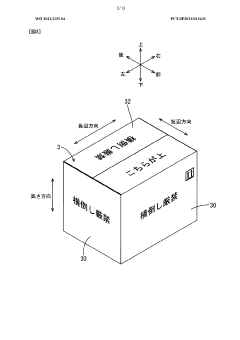

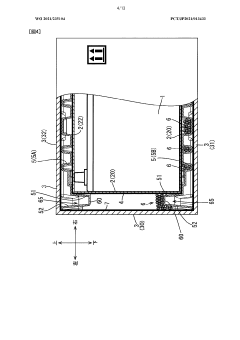

Buffer for lead-acid battery, and structure for packaging lead-acid battery

PatentWO2021235104A1

Innovation

- A pulp-molded buffer system is integrated into the packaging structure, featuring recessed areas and a frame-shaped design that absorbs impact and distributes pressure, while also being able to absorb any leaked electrolyte, improving the safety and efficiency of lead-acid battery transport.

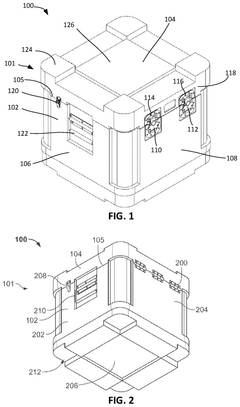

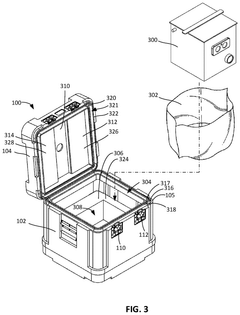

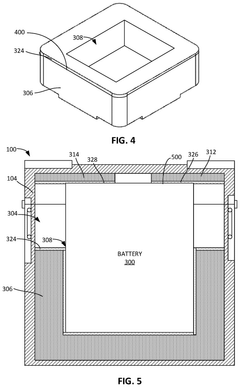

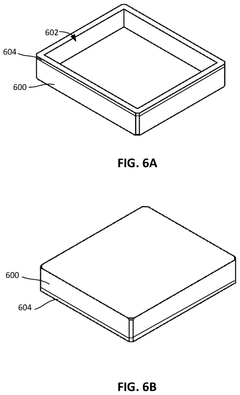

Shipping containers for batteries

PatentActiveUS12122585B2

Innovation

- Development of durable, leak-proof shipping containers with absorbent pads and foam inserts that absorb any liquid leaks, allowing for secure containment and potential use in non-hazardous shipping channels.

Regulatory Framework for Hazardous Material Transport

The regulatory framework for hazardous material transport is a complex and critical system designed to ensure the safe handling and transportation of dangerous substances, including battery acid. At the international level, the United Nations has established the Recommendations on the Transport of Dangerous Goods, which serves as a model for national and regional regulations. These recommendations provide a classification system for hazardous materials and outline general principles for their safe transport.

In the United States, the Department of Transportation (DOT) is responsible for regulating the transportation of hazardous materials. The primary regulations are found in Title 49 of the Code of Federal Regulations (49 CFR), specifically in Parts 100-185. These regulations cover all aspects of hazardous material transportation, including classification, packaging, labeling, documentation, and training requirements for personnel involved in the transport process.

For the bulk transport of battery acid, which is classified as a corrosive substance, specific regulations apply. The DOT requires that battery acid be transported in approved containers that meet certain specifications for strength, durability, and resistance to corrosion. These containers must be properly labeled with hazard warnings and identification information. Additionally, vehicles transporting bulk quantities of battery acid must display appropriate placards to alert others to the presence of hazardous materials.

The European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) governs the transport of hazardous materials in Europe. Similar to the U.S. regulations, the ADR provides detailed requirements for packaging, labeling, and vehicle specifications for transporting corrosive substances like battery acid.

In addition to these overarching regulations, many countries have their own specific rules and requirements for the transport of hazardous materials. These may include route restrictions, time-of-day limitations, or additional documentation requirements. Companies engaged in the transport of battery acid must ensure compliance with all applicable national and local regulations in addition to international standards.

Regulatory compliance also extends to emergency preparedness and response. Transporters of battery acid are required to have emergency response plans in place and to provide appropriate training to personnel. This includes procedures for handling spills, leaks, or other incidents that may occur during transport. Many regulations also mandate the carrying of specific safety equipment and the implementation of communication protocols to ensure rapid response in case of an emergency.

In the United States, the Department of Transportation (DOT) is responsible for regulating the transportation of hazardous materials. The primary regulations are found in Title 49 of the Code of Federal Regulations (49 CFR), specifically in Parts 100-185. These regulations cover all aspects of hazardous material transportation, including classification, packaging, labeling, documentation, and training requirements for personnel involved in the transport process.

For the bulk transport of battery acid, which is classified as a corrosive substance, specific regulations apply. The DOT requires that battery acid be transported in approved containers that meet certain specifications for strength, durability, and resistance to corrosion. These containers must be properly labeled with hazard warnings and identification information. Additionally, vehicles transporting bulk quantities of battery acid must display appropriate placards to alert others to the presence of hazardous materials.

The European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) governs the transport of hazardous materials in Europe. Similar to the U.S. regulations, the ADR provides detailed requirements for packaging, labeling, and vehicle specifications for transporting corrosive substances like battery acid.

In addition to these overarching regulations, many countries have their own specific rules and requirements for the transport of hazardous materials. These may include route restrictions, time-of-day limitations, or additional documentation requirements. Companies engaged in the transport of battery acid must ensure compliance with all applicable national and local regulations in addition to international standards.

Regulatory compliance also extends to emergency preparedness and response. Transporters of battery acid are required to have emergency response plans in place and to provide appropriate training to personnel. This includes procedures for handling spills, leaks, or other incidents that may occur during transport. Many regulations also mandate the carrying of specific safety equipment and the implementation of communication protocols to ensure rapid response in case of an emergency.

Environmental Impact of Battery Acid Transportation

The transportation of battery acid in bulk poses significant environmental risks that require careful consideration and management. Battery acid, primarily composed of sulfuric acid, is highly corrosive and can cause severe damage to ecosystems if released into the environment. Spills or leaks during transport can contaminate soil, water bodies, and air, leading to long-lasting ecological impacts.

Soil contamination is a primary concern when transporting battery acid. Accidental spills can result in soil acidification, altering its pH levels and rendering it inhospitable for plant growth and microbial activity. This can lead to reduced soil fertility, erosion, and loss of biodiversity in affected areas. The effects may persist for years, requiring extensive remediation efforts to restore soil health.

Water pollution is another critical environmental risk associated with battery acid transportation. If spilled into water bodies, the acid can dramatically lower pH levels, causing immediate harm to aquatic life. Fish, amphibians, and other water-dependent organisms may suffer from respiratory distress, reproductive failures, or death. The acidification of water can also disrupt entire aquatic ecosystems, affecting food chains and biodiversity.

Air quality can be impacted by battery acid transportation, particularly in the event of a spill or accident. Sulfuric acid can vaporize, creating toxic fumes that pose respiratory hazards to both humans and wildlife. These emissions can contribute to acid rain formation, further exacerbating environmental damage to forests, lakes, and buildings.

The potential for long-term environmental damage necessitates stringent safety measures and regulations for transporting battery acid. Proper containment, spill prevention systems, and emergency response protocols are essential to mitigate risks. Additionally, route planning should consider environmentally sensitive areas, avoiding proximity to water sources, protected habitats, and densely populated regions where possible.

Monitoring and rapid response capabilities are crucial for minimizing environmental impact in case of accidents. This includes having specialized cleanup teams and equipment readily available along transport routes. Advanced tracking systems and real-time monitoring can help detect and respond to potential leaks or spills promptly, reducing the extent of environmental contamination.

Sustainable practices in battery acid transportation also involve considering alternative packaging and transport methods that reduce the risk of spills. Innovations in containment materials and designs can significantly enhance safety and environmental protection. Furthermore, exploring alternatives to traditional lead-acid batteries and developing more environmentally friendly battery technologies could ultimately reduce the need for transporting large quantities of hazardous battery acid.

Soil contamination is a primary concern when transporting battery acid. Accidental spills can result in soil acidification, altering its pH levels and rendering it inhospitable for plant growth and microbial activity. This can lead to reduced soil fertility, erosion, and loss of biodiversity in affected areas. The effects may persist for years, requiring extensive remediation efforts to restore soil health.

Water pollution is another critical environmental risk associated with battery acid transportation. If spilled into water bodies, the acid can dramatically lower pH levels, causing immediate harm to aquatic life. Fish, amphibians, and other water-dependent organisms may suffer from respiratory distress, reproductive failures, or death. The acidification of water can also disrupt entire aquatic ecosystems, affecting food chains and biodiversity.

Air quality can be impacted by battery acid transportation, particularly in the event of a spill or accident. Sulfuric acid can vaporize, creating toxic fumes that pose respiratory hazards to both humans and wildlife. These emissions can contribute to acid rain formation, further exacerbating environmental damage to forests, lakes, and buildings.

The potential for long-term environmental damage necessitates stringent safety measures and regulations for transporting battery acid. Proper containment, spill prevention systems, and emergency response protocols are essential to mitigate risks. Additionally, route planning should consider environmentally sensitive areas, avoiding proximity to water sources, protected habitats, and densely populated regions where possible.

Monitoring and rapid response capabilities are crucial for minimizing environmental impact in case of accidents. This includes having specialized cleanup teams and equipment readily available along transport routes. Advanced tracking systems and real-time monitoring can help detect and respond to potential leaks or spills promptly, reducing the extent of environmental contamination.

Sustainable practices in battery acid transportation also involve considering alternative packaging and transport methods that reduce the risk of spills. Innovations in containment materials and designs can significantly enhance safety and environmental protection. Furthermore, exploring alternatives to traditional lead-acid batteries and developing more environmentally friendly battery technologies could ultimately reduce the need for transporting large quantities of hazardous battery acid.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!