How to Solve Graphene Battery Technical Limitations?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

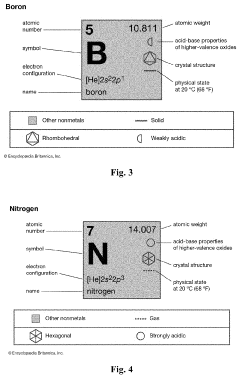

Graphene batteries have emerged as a promising technology in the energy storage landscape, offering potential solutions to the limitations of traditional lithium-ion batteries. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which sparked intense research into its applications across various fields, including energy storage.

The primary objective of graphene battery development is to overcome the technical limitations of current battery technologies, particularly in terms of energy density, charging speed, and cycle life. Researchers aim to harness graphene's exceptional properties, such as high electrical conductivity, large surface area, and mechanical strength, to create batteries that can store more energy, charge faster, and last longer than conventional alternatives.

Over the past decade, significant progress has been made in integrating graphene into battery components. Initial efforts focused on using graphene as an additive to enhance the performance of existing electrode materials. This approach led to incremental improvements in battery capacity and conductivity. As research advanced, scientists began exploring the potential of graphene as a standalone electrode material, aiming to fully exploit its unique properties.

The evolution of graphene batteries has been marked by several key milestones. Early prototypes demonstrated improved energy density and faster charging capabilities compared to traditional lithium-ion batteries. Subsequent developments focused on addressing challenges such as the production of high-quality graphene at scale and the optimization of electrode structures to maximize graphene's benefits.

Current objectives in graphene battery research include further increasing energy density to surpass that of lithium-ion batteries, reducing charging times to minutes rather than hours, and extending cycle life to thousands of charge-discharge cycles without significant degradation. Additionally, researchers are working on improving the safety aspects of graphene batteries, aiming to develop technologies that are less prone to thermal runaway and more stable under various operating conditions.

Another important goal is to develop cost-effective manufacturing processes for graphene batteries, making them commercially viable for widespread adoption. This involves optimizing production techniques for high-quality graphene and scaling up battery assembly processes to meet industrial demands.

As the technology continues to evolve, researchers are also exploring hybrid systems that combine graphene with other advanced materials to create synergistic effects. These efforts aim to push the boundaries of battery performance even further, potentially revolutionizing energy storage across various applications, from consumer electronics to electric vehicles and grid-scale storage systems.

The primary objective of graphene battery development is to overcome the technical limitations of current battery technologies, particularly in terms of energy density, charging speed, and cycle life. Researchers aim to harness graphene's exceptional properties, such as high electrical conductivity, large surface area, and mechanical strength, to create batteries that can store more energy, charge faster, and last longer than conventional alternatives.

Over the past decade, significant progress has been made in integrating graphene into battery components. Initial efforts focused on using graphene as an additive to enhance the performance of existing electrode materials. This approach led to incremental improvements in battery capacity and conductivity. As research advanced, scientists began exploring the potential of graphene as a standalone electrode material, aiming to fully exploit its unique properties.

The evolution of graphene batteries has been marked by several key milestones. Early prototypes demonstrated improved energy density and faster charging capabilities compared to traditional lithium-ion batteries. Subsequent developments focused on addressing challenges such as the production of high-quality graphene at scale and the optimization of electrode structures to maximize graphene's benefits.

Current objectives in graphene battery research include further increasing energy density to surpass that of lithium-ion batteries, reducing charging times to minutes rather than hours, and extending cycle life to thousands of charge-discharge cycles without significant degradation. Additionally, researchers are working on improving the safety aspects of graphene batteries, aiming to develop technologies that are less prone to thermal runaway and more stable under various operating conditions.

Another important goal is to develop cost-effective manufacturing processes for graphene batteries, making them commercially viable for widespread adoption. This involves optimizing production techniques for high-quality graphene and scaling up battery assembly processes to meet industrial demands.

As the technology continues to evolve, researchers are also exploring hybrid systems that combine graphene with other advanced materials to create synergistic effects. These efforts aim to push the boundaries of battery performance even further, potentially revolutionizing energy storage across various applications, from consumer electronics to electric vehicles and grid-scale storage systems.

Market Demand Analysis for Advanced Energy Storage

The market demand for advanced energy storage solutions, particularly those leveraging graphene technology, has been experiencing significant growth in recent years. This surge is driven by the increasing need for high-performance, long-lasting, and environmentally friendly energy storage systems across various sectors, including consumer electronics, electric vehicles, renewable energy, and grid storage.

In the consumer electronics sector, there is a growing demand for batteries that can provide longer life cycles, faster charging times, and higher energy densities. Graphene-based batteries have the potential to meet these requirements, offering improved performance over traditional lithium-ion batteries. This has led to increased interest from smartphone, laptop, and wearable device manufacturers in incorporating graphene technology into their products.

The electric vehicle (EV) industry is another major driver of demand for advanced energy storage solutions. As governments worldwide push for the adoption of electric vehicles to reduce carbon emissions, there is a pressing need for batteries that can provide longer driving ranges, faster charging capabilities, and improved safety. Graphene-enhanced batteries could potentially address these challenges, making them highly attractive to EV manufacturers and consumers alike.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and large-scale energy storage systems. Graphene-based batteries could play a crucial role in this area, offering higher capacity and faster charge/discharge rates compared to conventional battery technologies. This would enable better integration of renewable energy sources into the power grid and improve overall energy management.

The grid storage market is also showing increased interest in advanced energy storage solutions. As power grids become more complex and decentralized, there is a growing need for flexible and efficient energy storage systems to manage peak loads, provide backup power, and stabilize the grid. Graphene-based batteries could potentially offer the high-performance characteristics required for these applications.

However, it is important to note that while the potential market for graphene-based energy storage solutions is substantial, there are still technical limitations and challenges that need to be addressed. These include scaling up production, reducing costs, and improving the overall performance and stability of graphene-enhanced batteries. As research and development efforts continue to overcome these hurdles, the market demand for advanced energy storage solutions is expected to grow further, creating significant opportunities for companies and researchers working in this field.

In the consumer electronics sector, there is a growing demand for batteries that can provide longer life cycles, faster charging times, and higher energy densities. Graphene-based batteries have the potential to meet these requirements, offering improved performance over traditional lithium-ion batteries. This has led to increased interest from smartphone, laptop, and wearable device manufacturers in incorporating graphene technology into their products.

The electric vehicle (EV) industry is another major driver of demand for advanced energy storage solutions. As governments worldwide push for the adoption of electric vehicles to reduce carbon emissions, there is a pressing need for batteries that can provide longer driving ranges, faster charging capabilities, and improved safety. Graphene-enhanced batteries could potentially address these challenges, making them highly attractive to EV manufacturers and consumers alike.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and large-scale energy storage systems. Graphene-based batteries could play a crucial role in this area, offering higher capacity and faster charge/discharge rates compared to conventional battery technologies. This would enable better integration of renewable energy sources into the power grid and improve overall energy management.

The grid storage market is also showing increased interest in advanced energy storage solutions. As power grids become more complex and decentralized, there is a growing need for flexible and efficient energy storage systems to manage peak loads, provide backup power, and stabilize the grid. Graphene-based batteries could potentially offer the high-performance characteristics required for these applications.

However, it is important to note that while the potential market for graphene-based energy storage solutions is substantial, there are still technical limitations and challenges that need to be addressed. These include scaling up production, reducing costs, and improving the overall performance and stability of graphene-enhanced batteries. As research and development efforts continue to overcome these hurdles, the market demand for advanced energy storage solutions is expected to grow further, creating significant opportunities for companies and researchers working in this field.

Current Graphene Battery Challenges

Graphene batteries, despite their promising potential, face several significant technical challenges that hinder their widespread adoption and commercialization. One of the primary issues is the difficulty in maintaining graphene's unique properties when scaled up for mass production. The exceptional conductivity and strength observed in small-scale laboratory samples often diminish when graphene is produced in larger quantities, leading to inconsistent performance in battery applications.

Another major challenge lies in the development of efficient and cost-effective manufacturing processes for graphene-based battery components. Current production methods are often complex, energy-intensive, and expensive, making it challenging to compete with established battery technologies on a cost basis. This economic barrier significantly impedes the integration of graphene batteries into consumer electronics and electric vehicles.

The issue of electrode stability presents another critical hurdle. Graphene electrodes tend to suffer from restacking and agglomeration during charge-discharge cycles, which can lead to a reduction in the active surface area and, consequently, a decrease in battery performance over time. This degradation affects the long-term reliability and lifespan of graphene batteries, a crucial factor for their practical implementation.

Furthermore, the electrolyte compatibility with graphene-based electrodes remains a significant challenge. Finding the right electrolyte that can effectively interact with graphene while maintaining stability and safety under various operating conditions is crucial for optimizing battery performance. The development of suitable electrolytes that can withstand the high voltages and current densities associated with graphene batteries is an ongoing area of research.

Safety concerns also pose a substantial challenge in graphene battery development. The high electrical conductivity of graphene, while beneficial for battery performance, can potentially lead to short circuits if not properly managed. Addressing these safety issues through innovative cell designs and protective measures is essential for the widespread adoption of graphene battery technology.

Lastly, the challenge of achieving high energy density in graphene batteries persists. While graphene offers excellent power density, enabling rapid charging and discharging, increasing the overall energy storage capacity to match or exceed that of current lithium-ion batteries remains a significant technical hurdle. Overcoming this limitation is crucial for graphene batteries to become a viable alternative in applications requiring long-lasting power sources.

Another major challenge lies in the development of efficient and cost-effective manufacturing processes for graphene-based battery components. Current production methods are often complex, energy-intensive, and expensive, making it challenging to compete with established battery technologies on a cost basis. This economic barrier significantly impedes the integration of graphene batteries into consumer electronics and electric vehicles.

The issue of electrode stability presents another critical hurdle. Graphene electrodes tend to suffer from restacking and agglomeration during charge-discharge cycles, which can lead to a reduction in the active surface area and, consequently, a decrease in battery performance over time. This degradation affects the long-term reliability and lifespan of graphene batteries, a crucial factor for their practical implementation.

Furthermore, the electrolyte compatibility with graphene-based electrodes remains a significant challenge. Finding the right electrolyte that can effectively interact with graphene while maintaining stability and safety under various operating conditions is crucial for optimizing battery performance. The development of suitable electrolytes that can withstand the high voltages and current densities associated with graphene batteries is an ongoing area of research.

Safety concerns also pose a substantial challenge in graphene battery development. The high electrical conductivity of graphene, while beneficial for battery performance, can potentially lead to short circuits if not properly managed. Addressing these safety issues through innovative cell designs and protective measures is essential for the widespread adoption of graphene battery technology.

Lastly, the challenge of achieving high energy density in graphene batteries persists. While graphene offers excellent power density, enabling rapid charging and discharging, increasing the overall energy storage capacity to match or exceed that of current lithium-ion batteries remains a significant technical hurdle. Overcoming this limitation is crucial for graphene batteries to become a viable alternative in applications requiring long-lasting power sources.

Existing Graphene Battery Solutions

01 Scalability and manufacturing challenges

The production of graphene batteries faces significant scalability issues. Manufacturing high-quality graphene in large quantities for commercial battery production remains a technical challenge. The process of creating defect-free graphene sheets and integrating them into battery structures is complex and costly, limiting mass production capabilities.- Electrolyte compatibility issues: Graphene batteries face challenges with electrolyte compatibility. The high surface area of graphene can lead to unwanted reactions with the electrolyte, potentially causing degradation of the battery performance over time. This can result in reduced capacity and shorter lifespan of the battery. Researchers are working on developing electrolytes that are more stable when in contact with graphene electrodes.

- Manufacturing scalability: Scaling up the production of graphene for battery applications presents significant technical challenges. Current methods for producing high-quality graphene in large quantities are limited and often expensive. This affects the commercial viability of graphene batteries. Efforts are being made to develop more efficient and cost-effective manufacturing processes to enable mass production of graphene-based battery components.

- Structural stability during cycling: Graphene electrodes can suffer from structural instability during repeated charge-discharge cycles. The expansion and contraction of the graphene layers can lead to mechanical stress and eventual degradation of the electrode structure. This affects the long-term performance and reliability of graphene batteries. Research is focused on developing more stable graphene-based electrode structures that can withstand prolonged cycling.

- Energy density limitations: While graphene offers high conductivity, achieving high energy density in graphene batteries remains a challenge. The lightweight nature of graphene can limit the overall energy storage capacity of the battery. Researchers are exploring ways to increase the energy density of graphene-based electrodes, such as creating hybrid materials or optimizing the graphene structure to accommodate more charge-storing elements.

- Thermal management issues: Graphene batteries can face thermal management challenges due to the high electrical conductivity of graphene. Rapid charging and discharging can lead to heat generation, which needs to be effectively managed to prevent safety issues and maintain battery performance. Developing efficient thermal management systems for graphene batteries is an area of ongoing research and development.

02 Electrolyte compatibility and stability

Graphene batteries face challenges with electrolyte compatibility and long-term stability. The high surface area of graphene can lead to undesired reactions with the electrolyte, potentially causing degradation of the battery components over time. Finding suitable electrolytes that maintain stability while maximizing the benefits of graphene electrodes is a key technical limitation.Expand Specific Solutions03 Thermal management and safety concerns

The high electrical conductivity of graphene can lead to thermal management issues in batteries. Rapid charging and discharging may cause localized heating, potentially leading to safety concerns. Developing effective heat dissipation mechanisms and ensuring the overall safety of graphene-based battery systems remain significant technical challenges.Expand Specific Solutions04 Electrode design and performance optimization

Optimizing the design of graphene-based electrodes to maximize battery performance is a complex task. Challenges include controlling the porosity, thickness, and surface functionalization of graphene layers to enhance charge storage capacity and cycling stability. Balancing these factors while maintaining good electrical conductivity and mechanical strength is a key technical limitation.Expand Specific Solutions05 Integration with existing battery technologies

Integrating graphene into existing battery technologies and manufacturing processes presents significant challenges. Adapting current production lines and ensuring compatibility with other battery components while leveraging the unique properties of graphene is a complex task. Overcoming these integration hurdles is crucial for the widespread adoption of graphene in commercial battery applications.Expand Specific Solutions

Key Players in Graphene Battery Development

The graphene battery market is in its early growth stage, characterized by significant research and development efforts across academia and industry. Major players like Honeycomb Battery Co., Nanotek Instruments, and Global Graphene Group are driving innovation in this field. The market size is expanding, fueled by increasing demand for high-performance energy storage solutions in electric vehicles and consumer electronics. However, technical limitations persist, particularly in scaling production and ensuring long-term stability. Universities such as Northwestern, King Abdullah University of Science & Technology, and The University of Queensland are contributing to fundamental research, while companies like Nexeon and Vorbeck Materials are focusing on commercialization. The technology's maturity is progressing, with advancements in electrode materials and manufacturing processes, but widespread adoption remains a challenge due to cost and performance barriers.

Nanotek Instruments, Inc.

Technical Solution: Nanotek Instruments has developed a graphene-based composite material for lithium-ion battery electrodes to address graphene battery limitations. Their approach involves creating a three-dimensional graphene network that serves as both a conductive additive and a structural support for high-capacity active materials. The company's proprietary process uses chemical vapor deposition (CVD) to grow graphene directly on a porous metal foam substrate, creating a highly conductive and mechanically robust scaffold[10]. This 3D graphene structure is then infilled with active materials such as silicon or metal oxides, resulting in electrodes with high capacity and excellent cycling stability. Nanotek's technology has demonstrated up to 3 times the capacity of conventional graphite anodes while maintaining good cycle life[11]. The company has also developed scalable manufacturing processes for their 3D graphene composites, which is crucial for commercial viability[12].

Strengths: High capacity, excellent cycling stability, and potential for scalable production. Weaknesses: Complex manufacturing process and potential high production costs.

Nexeon Ltd.

Technical Solution: Nexeon has developed a silicon-graphene composite material for lithium-ion battery anodes to address graphene battery limitations. Their approach involves using silicon-dominant active materials combined with a proprietary graphene-based conductive additive. This composite structure allows for high silicon content while maintaining good electrical conductivity and structural stability. Nexeon's technology utilizes a unique surface modification process for the silicon particles, which helps to form a stable solid-electrolyte interphase (SEI) layer, crucial for long-term cycling performance[4]. The company has also developed a scalable production process for their silicon-graphene materials, using readily available raw materials and conventional equipment, which is essential for commercial adoption[5]. Nexeon's anodes have demonstrated up to 20% higher volumetric capacity compared to conventional graphite anodes, with improved cycle life[6].

Strengths: High energy density, improved cycle life, and scalable production process. Weaknesses: Potential challenges in integrating with existing battery manufacturing processes and possible higher material costs.

Core Graphene Battery Innovations

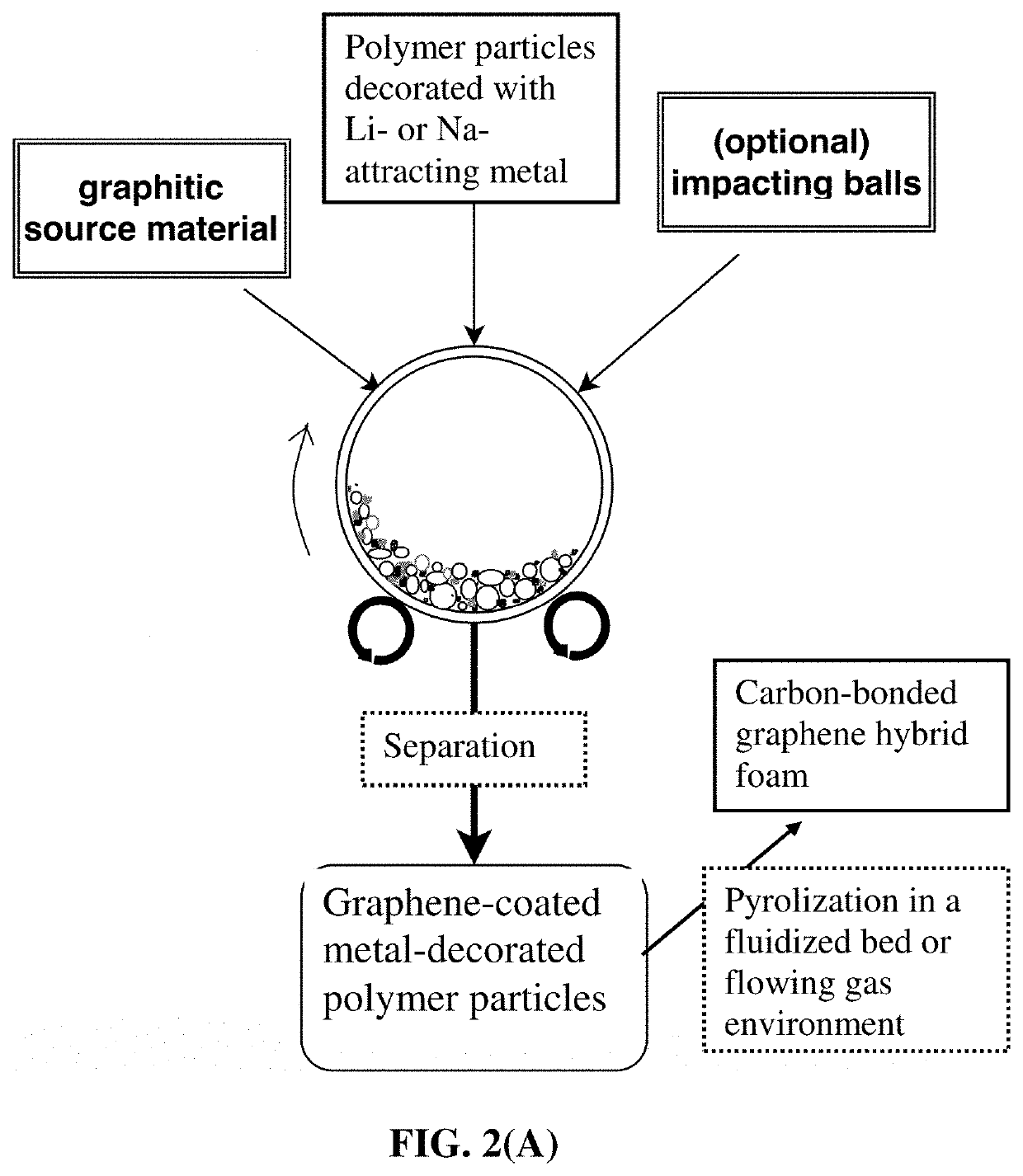

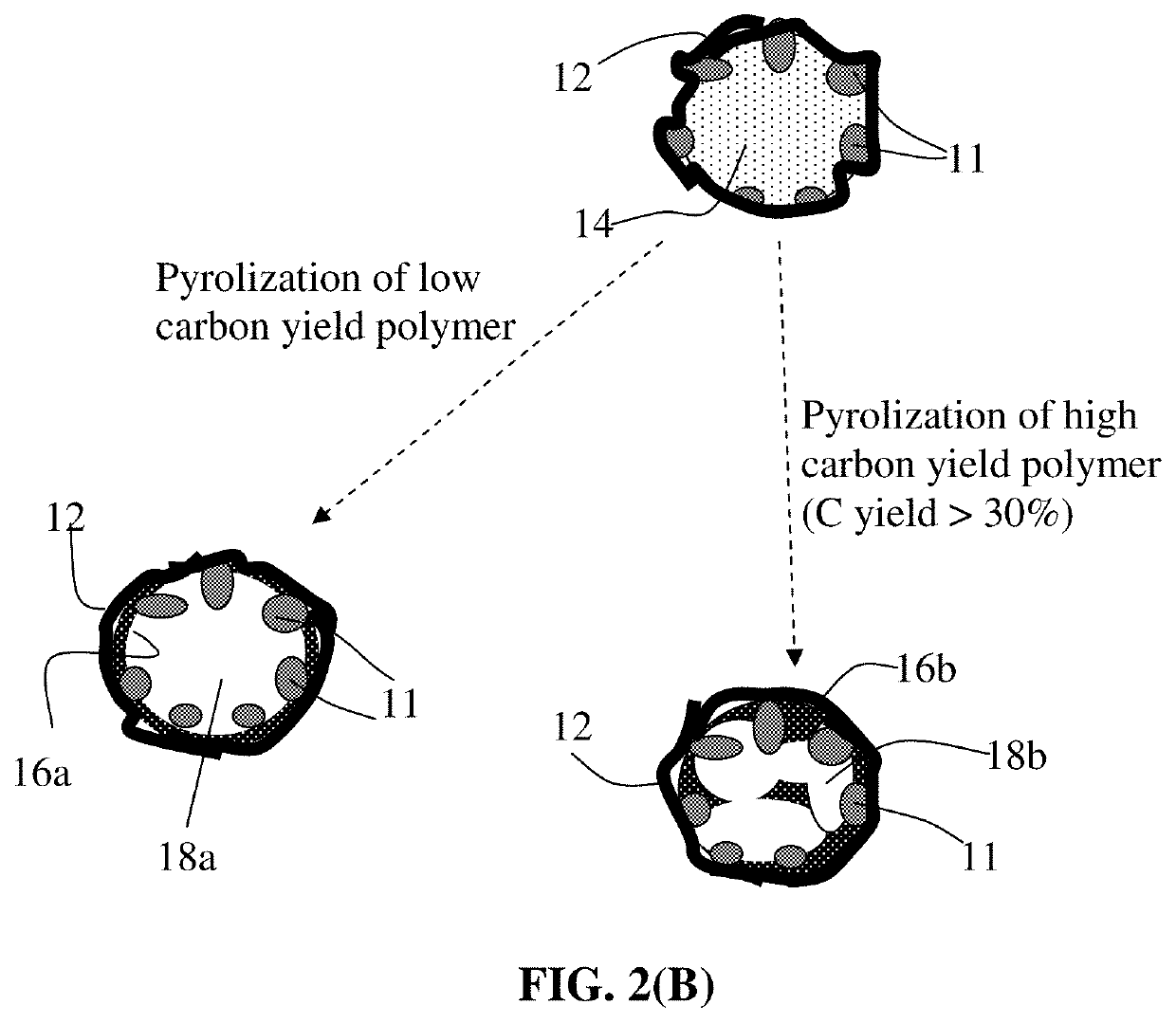

Process for producing particulates of graphene/carbon-encapsulated alkali metal, electrodes, and alkali metal battery

PatentPendingUS20200280055A1

Innovation

- The development of porous graphene/carbon hybrid particulates with a lithium- or sodium-attracting metal embedded in the pores, which acts as a substrate to suppress dendrite formation and enhance ion conductivity, allowing for stable and efficient lithium or sodium ion deposition and release during charge-discharge cycles.

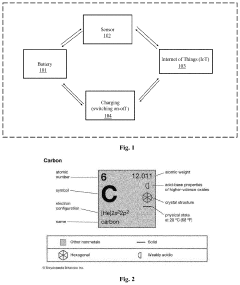

Systems, methods and apparatus for improving rechargeable energy storage devices and integrated circuits

PatentActiveUS20230092765A1

Innovation

- The development of a smart rechargeable energy storage device using pure organic carbon-based graphene in a solid-state configuration, with graphene sheets forming the anode and cathode electrodes and serving as a separator, enabling faster charging, longer cycle life, and enhanced energy density, while eliminating safety hazards through self-healing and safer materials.

Environmental Impact of Graphene Batteries

The environmental impact of graphene batteries is a crucial consideration as this technology advances towards widespread adoption. While graphene batteries offer significant improvements in energy density and charging speed compared to traditional lithium-ion batteries, their production and disposal processes require careful examination.

The manufacturing of graphene involves energy-intensive processes, potentially leading to increased carbon emissions if not managed properly. However, the long-term environmental benefits of graphene batteries may outweigh these initial costs. Their extended lifespan and improved efficiency could reduce the overall number of batteries needed, thereby decreasing waste and resource consumption in the long run.

One of the key environmental advantages of graphene batteries is their potential to reduce the reliance on rare earth metals and other environmentally problematic materials used in conventional batteries. This shift could alleviate the environmental degradation associated with mining these resources and reduce the geopolitical tensions surrounding their supply chains.

The recyclability of graphene batteries is another critical factor in assessing their environmental impact. Early research suggests that graphene-based materials may be more easily recyclable than traditional battery components, potentially creating a more circular and sustainable battery lifecycle. However, large-scale recycling processes for graphene batteries are still in development and require further optimization.

Water usage and potential contamination during graphene production and battery manufacturing are additional environmental concerns that need to be addressed. Implementing closed-loop water systems and developing more water-efficient production methods could help mitigate these issues.

The end-of-life management of graphene batteries is an area that demands attention. While they may offer improved recyclability, proper disposal and recycling infrastructure must be established to prevent environmental contamination and maximize resource recovery. This includes developing specialized recycling techniques and establishing collection systems to ensure these batteries do not end up in landfills.

As graphene battery technology evolves, ongoing life cycle assessments will be crucial to fully understand and optimize their environmental impact. This includes evaluating the entire supply chain, from raw material extraction to end-of-life disposal, and comparing the results with existing battery technologies. Such comprehensive analyses will guide the development of more sustainable production methods and inform policy decisions regarding the adoption and regulation of graphene batteries.

The manufacturing of graphene involves energy-intensive processes, potentially leading to increased carbon emissions if not managed properly. However, the long-term environmental benefits of graphene batteries may outweigh these initial costs. Their extended lifespan and improved efficiency could reduce the overall number of batteries needed, thereby decreasing waste and resource consumption in the long run.

One of the key environmental advantages of graphene batteries is their potential to reduce the reliance on rare earth metals and other environmentally problematic materials used in conventional batteries. This shift could alleviate the environmental degradation associated with mining these resources and reduce the geopolitical tensions surrounding their supply chains.

The recyclability of graphene batteries is another critical factor in assessing their environmental impact. Early research suggests that graphene-based materials may be more easily recyclable than traditional battery components, potentially creating a more circular and sustainable battery lifecycle. However, large-scale recycling processes for graphene batteries are still in development and require further optimization.

Water usage and potential contamination during graphene production and battery manufacturing are additional environmental concerns that need to be addressed. Implementing closed-loop water systems and developing more water-efficient production methods could help mitigate these issues.

The end-of-life management of graphene batteries is an area that demands attention. While they may offer improved recyclability, proper disposal and recycling infrastructure must be established to prevent environmental contamination and maximize resource recovery. This includes developing specialized recycling techniques and establishing collection systems to ensure these batteries do not end up in landfills.

As graphene battery technology evolves, ongoing life cycle assessments will be crucial to fully understand and optimize their environmental impact. This includes evaluating the entire supply chain, from raw material extraction to end-of-life disposal, and comparing the results with existing battery technologies. Such comprehensive analyses will guide the development of more sustainable production methods and inform policy decisions regarding the adoption and regulation of graphene batteries.

Graphene Battery Manufacturing Processes

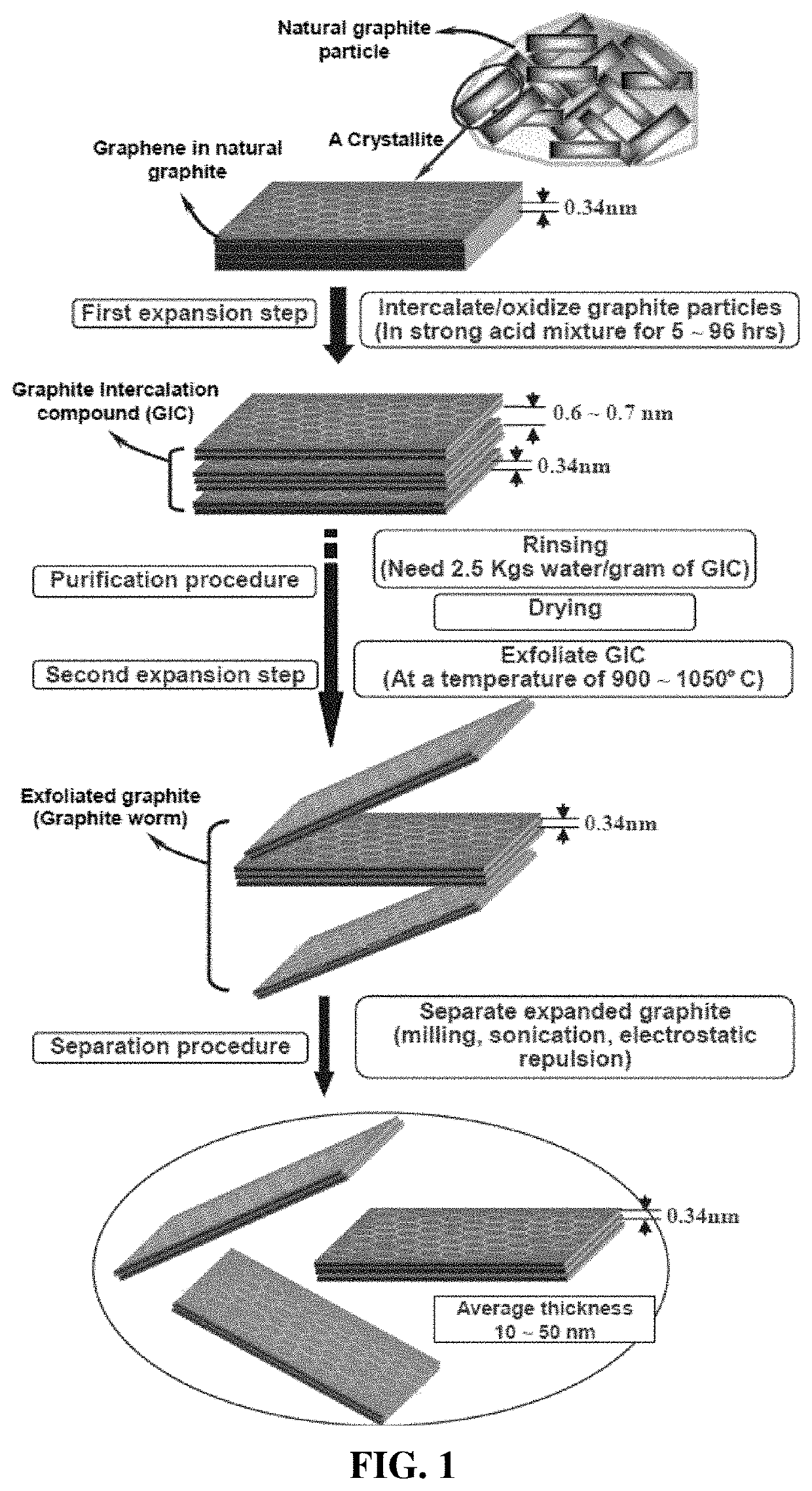

The manufacturing processes for graphene batteries involve several complex steps that require precision and advanced technology. The first stage typically begins with the production of high-quality graphene, which can be achieved through various methods such as chemical vapor deposition (CVD), liquid-phase exfoliation, or electrochemical exfoliation. Each method has its advantages and challenges, with CVD often preferred for its ability to produce large-area, high-quality graphene sheets.

Once the graphene is produced, it must be carefully integrated into the battery structure. This often involves creating a composite material by combining graphene with other battery components such as electrolytes and active materials. The process of mixing and dispersing graphene uniformly throughout the battery material is crucial for achieving optimal performance and requires specialized equipment and techniques.

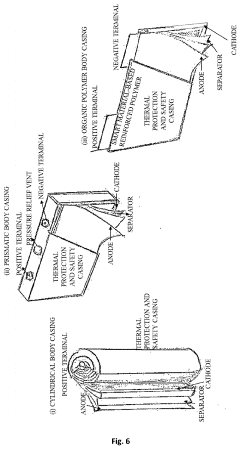

The next critical step in the manufacturing process is the formation of electrodes. Graphene-enhanced electrodes can be created through techniques such as roll-to-roll processing, which allows for continuous production of large-area electrodes. This method involves depositing graphene and other active materials onto a flexible substrate, which is then rolled and cut to the desired size and shape.

Assembly of the battery components is another key phase in the manufacturing process. This includes layering the graphene-enhanced electrodes with separators and electrolytes, followed by packaging the cell in a suitable casing. The assembly process must be carried out in a controlled environment to prevent contamination and ensure the integrity of the battery structure.

Quality control is an integral part of the manufacturing process, with various testing procedures implemented at different stages. These may include electrical performance tests, safety evaluations, and durability assessments to ensure that the graphene batteries meet the required specifications and standards.

One of the main challenges in graphene battery manufacturing is scaling up production while maintaining consistency and quality. As the demand for high-performance batteries grows, manufacturers are continually working to optimize their processes and develop new techniques that allow for mass production without compromising on the unique properties of graphene.

Addressing technical limitations in graphene battery manufacturing often involves interdisciplinary collaboration between materials scientists, chemical engineers, and process engineers. Ongoing research focuses on improving graphene synthesis methods, enhancing the integration of graphene into battery components, and developing more efficient assembly techniques to overcome current production bottlenecks and reduce manufacturing costs.

Once the graphene is produced, it must be carefully integrated into the battery structure. This often involves creating a composite material by combining graphene with other battery components such as electrolytes and active materials. The process of mixing and dispersing graphene uniformly throughout the battery material is crucial for achieving optimal performance and requires specialized equipment and techniques.

The next critical step in the manufacturing process is the formation of electrodes. Graphene-enhanced electrodes can be created through techniques such as roll-to-roll processing, which allows for continuous production of large-area electrodes. This method involves depositing graphene and other active materials onto a flexible substrate, which is then rolled and cut to the desired size and shape.

Assembly of the battery components is another key phase in the manufacturing process. This includes layering the graphene-enhanced electrodes with separators and electrolytes, followed by packaging the cell in a suitable casing. The assembly process must be carried out in a controlled environment to prevent contamination and ensure the integrity of the battery structure.

Quality control is an integral part of the manufacturing process, with various testing procedures implemented at different stages. These may include electrical performance tests, safety evaluations, and durability assessments to ensure that the graphene batteries meet the required specifications and standards.

One of the main challenges in graphene battery manufacturing is scaling up production while maintaining consistency and quality. As the demand for high-performance batteries grows, manufacturers are continually working to optimize their processes and develop new techniques that allow for mass production without compromising on the unique properties of graphene.

Addressing technical limitations in graphene battery manufacturing often involves interdisciplinary collaboration between materials scientists, chemical engineers, and process engineers. Ongoing research focuses on improving graphene synthesis methods, enhancing the integration of graphene into battery components, and developing more efficient assembly techniques to overcome current production bottlenecks and reduce manufacturing costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!