How to Tackle Graphene Battery's Environmental Challenges?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries have emerged as a promising technology in the energy storage landscape, offering potential solutions to the limitations of traditional lithium-ion batteries. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which sparked intense research into its applications across various fields, including energy storage.

Initially, graphene was primarily used as an additive to enhance the performance of existing battery technologies. Researchers found that incorporating graphene into electrode materials could significantly improve conductivity, charge/discharge rates, and overall battery life. This marked the first phase of graphene battery development, focusing on incremental improvements to existing systems.

As understanding of graphene's properties deepened, scientists began exploring the possibility of using graphene as a primary component in battery construction. This led to the development of graphene-based anodes and cathodes, which demonstrated remarkable theoretical capacities and stability. However, translating these laboratory-scale successes into commercially viable products proved challenging due to manufacturing complexities and cost considerations.

The next significant milestone in graphene battery evolution came with the advent of graphene-enhanced electrolytes. These novel electrolytes promised to address issues such as dendrite formation and electrolyte degradation, which are common problems in conventional batteries. This development opened up new avenues for improving battery safety and longevity.

Recent years have seen a shift towards more holistic graphene battery designs, integrating graphene-based components across multiple battery elements. This approach aims to leverage synergies between graphene-enhanced electrodes, electrolytes, and other battery components to achieve unprecedented performance metrics.

The primary objectives driving graphene battery research and development are multifaceted. Foremost among these is the goal of significantly increasing energy density, potentially enabling electric vehicles with ranges comparable to or exceeding those of conventional combustion engine vehicles. Another critical objective is to dramatically reduce charging times, with some researchers aiming for ultra-fast charging capabilities that could rival the refueling time of gasoline vehicles.

Improving the cycle life and overall lifespan of batteries is another key objective, with graphene's exceptional durability offering promising pathways to batteries that can withstand thousands of charge-discharge cycles without significant degradation. Additionally, there is a strong focus on enhancing safety, leveraging graphene's thermal and mechanical properties to create more stable and resilient battery systems.

As environmental concerns take center stage in technological development, a crucial objective in graphene battery research is to address sustainability challenges. This includes developing eco-friendly production methods for graphene, exploring recyclable battery designs, and minimizing the use of rare or toxic materials in battery construction.

Initially, graphene was primarily used as an additive to enhance the performance of existing battery technologies. Researchers found that incorporating graphene into electrode materials could significantly improve conductivity, charge/discharge rates, and overall battery life. This marked the first phase of graphene battery development, focusing on incremental improvements to existing systems.

As understanding of graphene's properties deepened, scientists began exploring the possibility of using graphene as a primary component in battery construction. This led to the development of graphene-based anodes and cathodes, which demonstrated remarkable theoretical capacities and stability. However, translating these laboratory-scale successes into commercially viable products proved challenging due to manufacturing complexities and cost considerations.

The next significant milestone in graphene battery evolution came with the advent of graphene-enhanced electrolytes. These novel electrolytes promised to address issues such as dendrite formation and electrolyte degradation, which are common problems in conventional batteries. This development opened up new avenues for improving battery safety and longevity.

Recent years have seen a shift towards more holistic graphene battery designs, integrating graphene-based components across multiple battery elements. This approach aims to leverage synergies between graphene-enhanced electrodes, electrolytes, and other battery components to achieve unprecedented performance metrics.

The primary objectives driving graphene battery research and development are multifaceted. Foremost among these is the goal of significantly increasing energy density, potentially enabling electric vehicles with ranges comparable to or exceeding those of conventional combustion engine vehicles. Another critical objective is to dramatically reduce charging times, with some researchers aiming for ultra-fast charging capabilities that could rival the refueling time of gasoline vehicles.

Improving the cycle life and overall lifespan of batteries is another key objective, with graphene's exceptional durability offering promising pathways to batteries that can withstand thousands of charge-discharge cycles without significant degradation. Additionally, there is a strong focus on enhancing safety, leveraging graphene's thermal and mechanical properties to create more stable and resilient battery systems.

As environmental concerns take center stage in technological development, a crucial objective in graphene battery research is to address sustainability challenges. This includes developing eco-friendly production methods for graphene, exploring recyclable battery designs, and minimizing the use of rare or toxic materials in battery construction.

Market Demand for Sustainable Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the increasing demand for sustainable and efficient power solutions. As concerns about climate change and environmental sustainability intensify, there is a growing need for advanced energy storage technologies that can support the transition to renewable energy sources. Graphene batteries, with their potential for high energy density, rapid charging capabilities, and long cycle life, are positioned to play a significant role in meeting this demand.

The market for sustainable energy storage is expanding across various sectors, including electric vehicles, renewable energy integration, and consumer electronics. In the automotive industry, the shift towards electric vehicles is creating a substantial demand for high-performance batteries that can offer extended range and faster charging times. Graphene batteries, with their potential to overcome the limitations of traditional lithium-ion batteries, are attracting significant attention from automakers and battery manufacturers.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and large-scale energy storage solutions. Graphene batteries could provide the means to store excess energy during peak production periods and release it during times of high demand, thereby enhancing grid stability and reliability. This application is particularly crucial for remote and off-grid locations, where energy storage is essential for maintaining a consistent power supply.

The consumer electronics market is another area where the demand for sustainable energy storage is rapidly growing. Consumers are increasingly seeking devices with longer battery life, faster charging capabilities, and improved overall performance. Graphene batteries have the potential to meet these requirements, offering a more sustainable alternative to conventional battery technologies.

However, the market demand for sustainable energy storage also comes with stringent environmental requirements. Consumers and regulators are placing greater emphasis on the entire lifecycle of battery technologies, from raw material sourcing to end-of-life disposal and recycling. This focus on sustainability presents both challenges and opportunities for graphene battery technology, as it must not only deliver superior performance but also address environmental concerns throughout its lifecycle.

The growing awareness of the environmental impact of battery production and disposal is driving research and development efforts towards more sustainable manufacturing processes and materials. This trend aligns well with the potential of graphene batteries, which could offer improved recyclability and reduced environmental footprint compared to traditional battery technologies. As a result, there is a significant market opportunity for graphene battery solutions that can effectively balance performance, cost, and environmental sustainability.

The market for sustainable energy storage is expanding across various sectors, including electric vehicles, renewable energy integration, and consumer electronics. In the automotive industry, the shift towards electric vehicles is creating a substantial demand for high-performance batteries that can offer extended range and faster charging times. Graphene batteries, with their potential to overcome the limitations of traditional lithium-ion batteries, are attracting significant attention from automakers and battery manufacturers.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and large-scale energy storage solutions. Graphene batteries could provide the means to store excess energy during peak production periods and release it during times of high demand, thereby enhancing grid stability and reliability. This application is particularly crucial for remote and off-grid locations, where energy storage is essential for maintaining a consistent power supply.

The consumer electronics market is another area where the demand for sustainable energy storage is rapidly growing. Consumers are increasingly seeking devices with longer battery life, faster charging capabilities, and improved overall performance. Graphene batteries have the potential to meet these requirements, offering a more sustainable alternative to conventional battery technologies.

However, the market demand for sustainable energy storage also comes with stringent environmental requirements. Consumers and regulators are placing greater emphasis on the entire lifecycle of battery technologies, from raw material sourcing to end-of-life disposal and recycling. This focus on sustainability presents both challenges and opportunities for graphene battery technology, as it must not only deliver superior performance but also address environmental concerns throughout its lifecycle.

The growing awareness of the environmental impact of battery production and disposal is driving research and development efforts towards more sustainable manufacturing processes and materials. This trend aligns well with the potential of graphene batteries, which could offer improved recyclability and reduced environmental footprint compared to traditional battery technologies. As a result, there is a significant market opportunity for graphene battery solutions that can effectively balance performance, cost, and environmental sustainability.

Environmental Challenges in Graphene Battery Production

The production of graphene batteries presents several environmental challenges that need to be addressed for sustainable development. One of the primary concerns is the energy-intensive nature of graphene synthesis. Traditional methods, such as chemical vapor deposition (CVD) and exfoliation, require high temperatures and often involve the use of harmful chemicals, leading to significant energy consumption and potential environmental pollution.

The extraction and processing of raw materials for graphene production, particularly graphite, can have detrimental effects on local ecosystems. Mining activities may result in deforestation, soil erosion, and water pollution, impacting biodiversity and surrounding communities. Additionally, the use of strong acids and solvents in graphene production can generate hazardous waste, posing risks to both human health and the environment if not properly managed.

Another challenge lies in the potential release of graphene nanoparticles during manufacturing processes. These particles, due to their small size, can easily become airborne and may have unforeseen impacts on air quality and human health. Long-term exposure to graphene nanoparticles is still not fully understood, raising concerns about potential respiratory issues and other health risks for workers in production facilities.

Water usage and contamination are also significant environmental concerns in graphene battery production. The purification and processing of graphene often require large volumes of water, which can strain local water resources. Moreover, the wastewater generated during production may contain toxic substances and nanoparticles, necessitating advanced treatment methods to prevent water pollution.

The end-of-life management of graphene batteries poses another set of environmental challenges. As these batteries reach the end of their useful life, proper recycling and disposal methods must be developed to prevent the release of potentially harmful materials into the environment. The complex composition of graphene batteries, including various metals and nanomaterials, makes recycling more challenging compared to traditional lithium-ion batteries.

Addressing these environmental challenges requires a multifaceted approach. Developing cleaner and more energy-efficient production methods, such as electrochemical exfoliation or green reduction techniques, can help reduce the carbon footprint of graphene synthesis. Implementing closed-loop systems for water and chemical recycling in production facilities can minimize resource consumption and waste generation. Furthermore, investing in research to better understand the long-term environmental impacts of graphene nanoparticles and developing effective containment strategies are crucial steps towards sustainable graphene battery production.

The extraction and processing of raw materials for graphene production, particularly graphite, can have detrimental effects on local ecosystems. Mining activities may result in deforestation, soil erosion, and water pollution, impacting biodiversity and surrounding communities. Additionally, the use of strong acids and solvents in graphene production can generate hazardous waste, posing risks to both human health and the environment if not properly managed.

Another challenge lies in the potential release of graphene nanoparticles during manufacturing processes. These particles, due to their small size, can easily become airborne and may have unforeseen impacts on air quality and human health. Long-term exposure to graphene nanoparticles is still not fully understood, raising concerns about potential respiratory issues and other health risks for workers in production facilities.

Water usage and contamination are also significant environmental concerns in graphene battery production. The purification and processing of graphene often require large volumes of water, which can strain local water resources. Moreover, the wastewater generated during production may contain toxic substances and nanoparticles, necessitating advanced treatment methods to prevent water pollution.

The end-of-life management of graphene batteries poses another set of environmental challenges. As these batteries reach the end of their useful life, proper recycling and disposal methods must be developed to prevent the release of potentially harmful materials into the environment. The complex composition of graphene batteries, including various metals and nanomaterials, makes recycling more challenging compared to traditional lithium-ion batteries.

Addressing these environmental challenges requires a multifaceted approach. Developing cleaner and more energy-efficient production methods, such as electrochemical exfoliation or green reduction techniques, can help reduce the carbon footprint of graphene synthesis. Implementing closed-loop systems for water and chemical recycling in production facilities can minimize resource consumption and waste generation. Furthermore, investing in research to better understand the long-term environmental impacts of graphene nanoparticles and developing effective containment strategies are crucial steps towards sustainable graphene battery production.

Current Eco-friendly Graphene Battery Solutions

01 Environmental impact of graphene production

The production of graphene for use in batteries can have significant environmental impacts. The process often involves energy-intensive methods and the use of potentially harmful chemicals. Researchers are exploring more sustainable production techniques to minimize these environmental challenges, including green synthesis methods and the use of renewable energy sources in manufacturing.- Environmental impact of graphene production: The production of graphene for battery applications can have significant environmental impacts. The synthesis process often involves energy-intensive methods and the use of hazardous chemicals. Addressing these challenges requires developing more sustainable production techniques and exploring eco-friendly alternatives for graphene synthesis.

- Recycling and disposal of graphene batteries: As graphene batteries become more prevalent, proper recycling and disposal methods are crucial to minimize environmental impact. Developing efficient recycling processes for graphene-based materials and establishing proper disposal protocols are essential to prevent potential contamination and ensure resource recovery.

- Safety concerns and potential toxicity: The potential toxicity of graphene nanoparticles and their long-term effects on the environment and human health are areas of concern. Research is needed to assess the safety of graphene materials throughout their lifecycle, from production to disposal, and to develop mitigation strategies for any identified risks.

- Energy efficiency and lifecycle assessment: Improving the energy efficiency of graphene battery production and use is crucial for reducing their overall environmental footprint. Conducting comprehensive lifecycle assessments can help identify areas for improvement and guide the development of more sustainable graphene battery technologies.

- Sustainable sourcing of raw materials: Ensuring sustainable sourcing of raw materials for graphene production is essential to minimize environmental impact. This includes exploring alternative carbon sources, developing more efficient extraction methods, and implementing responsible supply chain practices to reduce the ecological footprint of graphene battery manufacturing.

02 Recycling and disposal of graphene batteries

As graphene batteries become more prevalent, the issue of recycling and proper disposal becomes crucial. Developing efficient recycling processes for graphene-based battery components is essential to reduce environmental impact and recover valuable materials. Research is ongoing to create closed-loop systems for graphene battery recycling and to address potential contamination issues during disposal.Expand Specific Solutions03 Toxicity and environmental release concerns

There are concerns about the potential toxicity of graphene nanoparticles if released into the environment. Studies are being conducted to assess the long-term effects of graphene on ecosystems and human health. Researchers are working on developing safer forms of graphene and containment strategies to prevent environmental contamination during battery production, use, and disposal.Expand Specific Solutions04 Energy storage efficiency and environmental benefits

Graphene batteries offer potential environmental benefits through improved energy storage efficiency. Their high capacity and fast charging capabilities could lead to reduced energy consumption and lower carbon emissions in various applications. Ongoing research aims to optimize these properties while addressing manufacturing and lifecycle environmental challenges.Expand Specific Solutions05 Sustainable material sourcing for graphene batteries

Ensuring sustainable sourcing of materials for graphene battery production is a key environmental challenge. Researchers are exploring alternative sources for graphene precursors, including biomass and waste materials, to reduce the environmental impact of raw material extraction. Additionally, efforts are being made to develop graphene batteries with reduced reliance on rare or environmentally problematic elements.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery market is in its early growth stage, characterized by rapid technological advancements and increasing commercial interest. The global market size for graphene batteries is projected to expand significantly in the coming years, driven by demand for high-performance energy storage solutions. While the technology shows promise, it is still evolving towards full maturity. Key players like Honeycomb Battery Co., NanoXplore, and Global Graphene Group are leading research and development efforts, with academic institutions such as Northwestern University and Harbin Institute of Technology contributing to fundamental advancements. Major technology companies like Apple and NEC are also exploring graphene battery applications, indicating growing industry adoption. However, environmental challenges remain a critical focus area for sustainable commercialization.

NanoXplore, Inc.

Technical Solution: NanoXplore has developed a proprietary graphene production process that addresses environmental concerns in graphene battery manufacturing. Their method uses a plasma-based technique to produce high-quality graphene with significantly lower energy consumption compared to traditional methods[12]. The company has also focused on developing graphene-enhanced battery materials that improve energy density and cycle life while reducing the reliance on environmentally harmful materials. NanoXplore's graphene-based anodes have shown potential to replace conventional graphite anodes, offering improved performance and reduced environmental impact[13]. Additionally, they have implemented a closed-loop production system that minimizes waste and maximizes material recycling in their graphene battery production process[14].

Strengths: Eco-friendly graphene production, improved battery performance, and efficient material recycling. Weaknesses: Potential challenges in scaling up production and integrating with existing battery manufacturing processes.

Global Graphene Group, Inc.

Technical Solution: Global Graphene Group has developed a proprietary graphene-based battery technology that addresses environmental challenges. Their approach involves using graphene as a conductive additive in battery electrodes, which enhances energy density and cycle life while reducing the overall environmental impact. The company's process for graphene production utilizes a more environmentally friendly method, reducing the use of harsh chemicals and energy consumption[1]. They have also implemented a closed-loop recycling system for their graphene batteries, ensuring that up to 95% of materials can be recovered and reused at the end of the battery's life[2].

Strengths: Improved energy density, longer cycle life, and a more sustainable production process. Weaknesses: Potential higher initial costs and the need for specialized recycling infrastructure.

Innovative Green Synthesis Methods for Graphene

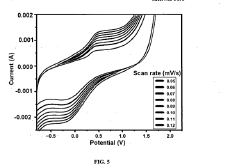

Graphite rod from discharged battery as a reliable and cost-effective working electrode for electrochemical characterization of aspartame

PatentPendingIN202341079542A

Innovation

- Graphite rods are safely extracted from discharged batteries, cleaned, and used as working electrodes for electrochemical characterization of aspartame, leveraging their high conductivity for sensitive and selective detection in a cost-effective and sustainable manner.

Systems, methods and apparatus for improving rechargeable energy storage devices and integrated circuits

PatentActiveUS20230092765A1

Innovation

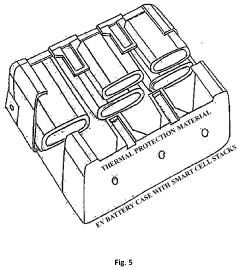

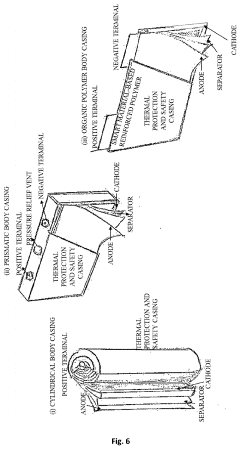

- The development of a smart rechargeable energy storage device using pure organic carbon-based graphene in a solid-state configuration, with graphene sheets forming the anode and cathode electrodes and serving as a separator, enabling faster charging, longer cycle life, and enhanced energy density, while eliminating safety hazards through self-healing and safer materials.

Life Cycle Assessment of Graphene Batteries

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impacts of graphene batteries throughout their entire lifecycle, from raw material extraction to disposal or recycling. This comprehensive analysis helps identify potential environmental challenges and opportunities for improvement in the production, use, and end-of-life stages of graphene batteries.

The production phase of graphene batteries involves the extraction and processing of raw materials, including graphene synthesis. While graphene offers superior electrical and thermal properties, its production can be energy-intensive and may involve the use of hazardous chemicals. LCA studies have shown that the environmental impact of graphene production varies significantly depending on the synthesis method used. Chemical vapor deposition (CVD) and electrochemical exfoliation methods, for instance, have different energy requirements and chemical inputs, resulting in varying carbon footprints.

During the use phase, graphene batteries demonstrate potential environmental benefits due to their improved performance characteristics. Their higher energy density and faster charging capabilities can lead to reduced energy consumption and extended lifespan compared to conventional lithium-ion batteries. This translates to lower overall environmental impact during the operational life of devices powered by graphene batteries.

The end-of-life stage presents both challenges and opportunities. Graphene batteries contain valuable materials that can be recovered and recycled, potentially reducing the need for virgin raw material extraction. However, the complex composition of these batteries requires the development of specialized recycling processes to efficiently separate and recover graphene and other components.

LCA studies have highlighted the importance of considering the entire supply chain when assessing the environmental impact of graphene batteries. This includes evaluating the sourcing of raw materials, transportation, manufacturing processes, and disposal methods. By identifying hotspots of environmental impact throughout the lifecycle, researchers and manufacturers can focus on developing more sustainable practices and technologies.

Furthermore, LCA results can inform policy decisions and guide the development of environmental regulations specific to graphene battery production and disposal. This holistic approach ensures that the potential environmental benefits of graphene batteries are realized while minimizing negative impacts across their entire lifecycle.

The production phase of graphene batteries involves the extraction and processing of raw materials, including graphene synthesis. While graphene offers superior electrical and thermal properties, its production can be energy-intensive and may involve the use of hazardous chemicals. LCA studies have shown that the environmental impact of graphene production varies significantly depending on the synthesis method used. Chemical vapor deposition (CVD) and electrochemical exfoliation methods, for instance, have different energy requirements and chemical inputs, resulting in varying carbon footprints.

During the use phase, graphene batteries demonstrate potential environmental benefits due to their improved performance characteristics. Their higher energy density and faster charging capabilities can lead to reduced energy consumption and extended lifespan compared to conventional lithium-ion batteries. This translates to lower overall environmental impact during the operational life of devices powered by graphene batteries.

The end-of-life stage presents both challenges and opportunities. Graphene batteries contain valuable materials that can be recovered and recycled, potentially reducing the need for virgin raw material extraction. However, the complex composition of these batteries requires the development of specialized recycling processes to efficiently separate and recover graphene and other components.

LCA studies have highlighted the importance of considering the entire supply chain when assessing the environmental impact of graphene batteries. This includes evaluating the sourcing of raw materials, transportation, manufacturing processes, and disposal methods. By identifying hotspots of environmental impact throughout the lifecycle, researchers and manufacturers can focus on developing more sustainable practices and technologies.

Furthermore, LCA results can inform policy decisions and guide the development of environmental regulations specific to graphene battery production and disposal. This holistic approach ensures that the potential environmental benefits of graphene batteries are realized while minimizing negative impacts across their entire lifecycle.

Regulatory Framework for Green Battery Technologies

The regulatory framework for green battery technologies plays a crucial role in addressing the environmental challenges associated with graphene batteries. As governments worldwide recognize the importance of sustainable energy storage solutions, they are implementing stringent regulations to ensure the development and production of environmentally friendly batteries.

One of the key aspects of this regulatory framework is the emphasis on lifecycle assessment. Manufacturers are required to conduct comprehensive evaluations of the environmental impact of graphene batteries from production to disposal. This includes assessing the carbon footprint of raw material extraction, manufacturing processes, and end-of-life management. By mandating these assessments, regulators aim to encourage companies to adopt more sustainable practices throughout the battery lifecycle.

Environmental standards for battery production are becoming increasingly stringent. Regulations now focus on limiting the use of hazardous materials, reducing energy consumption during manufacturing, and minimizing waste generation. For graphene batteries, this translates to stricter controls on the synthesis of graphene and the handling of potentially harmful chemicals used in the production process.

Recycling and waste management regulations are also evolving to address the unique challenges posed by graphene batteries. Governments are implementing extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the collection and recycling of their products at the end of their useful life. These programs aim to create a circular economy for battery materials, reducing the environmental impact of disposal and conserving valuable resources.

Energy efficiency standards are another critical component of the regulatory framework. As graphene batteries promise higher energy densities and faster charging capabilities, regulators are setting performance benchmarks to ensure that these advantages translate into real-world energy savings. This includes standards for minimum energy efficiency, charging efficiency, and self-discharge rates.

To promote innovation in green battery technologies, many governments are implementing incentive programs and research grants. These initiatives aim to accelerate the development of more environmentally friendly battery solutions, including improvements in graphene battery technology. By providing financial support and resources, regulators hope to overcome some of the technical and economic barriers to widespread adoption of sustainable energy storage solutions.

International cooperation is also emerging as a key feature of the regulatory landscape. As the battery supply chain spans multiple countries, harmonized standards and regulations are being developed to ensure consistent environmental protection across borders. This includes efforts to standardize labeling, safety requirements, and recycling protocols for graphene batteries and other advanced energy storage technologies.

One of the key aspects of this regulatory framework is the emphasis on lifecycle assessment. Manufacturers are required to conduct comprehensive evaluations of the environmental impact of graphene batteries from production to disposal. This includes assessing the carbon footprint of raw material extraction, manufacturing processes, and end-of-life management. By mandating these assessments, regulators aim to encourage companies to adopt more sustainable practices throughout the battery lifecycle.

Environmental standards for battery production are becoming increasingly stringent. Regulations now focus on limiting the use of hazardous materials, reducing energy consumption during manufacturing, and minimizing waste generation. For graphene batteries, this translates to stricter controls on the synthesis of graphene and the handling of potentially harmful chemicals used in the production process.

Recycling and waste management regulations are also evolving to address the unique challenges posed by graphene batteries. Governments are implementing extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the collection and recycling of their products at the end of their useful life. These programs aim to create a circular economy for battery materials, reducing the environmental impact of disposal and conserving valuable resources.

Energy efficiency standards are another critical component of the regulatory framework. As graphene batteries promise higher energy densities and faster charging capabilities, regulators are setting performance benchmarks to ensure that these advantages translate into real-world energy savings. This includes standards for minimum energy efficiency, charging efficiency, and self-discharge rates.

To promote innovation in green battery technologies, many governments are implementing incentive programs and research grants. These initiatives aim to accelerate the development of more environmentally friendly battery solutions, including improvements in graphene battery technology. By providing financial support and resources, regulators hope to overcome some of the technical and economic barriers to widespread adoption of sustainable energy storage solutions.

International cooperation is also emerging as a key feature of the regulatory landscape. As the battery supply chain spans multiple countries, harmonized standards and regulations are being developed to ensure consistent environmental protection across borders. This includes efforts to standardize labeling, safety requirements, and recycling protocols for graphene batteries and other advanced energy storage technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!