How to Utilize Ferrofluid for Future-Ready Energy Solutions?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Energy Tech Evolution and Objectives

Ferrofluids, discovered in the 1960s by NASA, have evolved from a space-age curiosity to a potential game-changer in energy solutions. These unique liquids, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, exhibit remarkable properties when exposed to magnetic fields. The evolution of ferrofluid technology has been marked by significant advancements in synthesis methods, particle engineering, and application development.

Initially conceived for rocket fuel manipulation in zero gravity, ferrofluids have since found applications in various fields, including energy. The technology's progression has been driven by the increasing demand for more efficient and sustainable energy solutions. As global energy needs continue to grow, coupled with the urgency to reduce carbon emissions, ferrofluids present an innovative approach to addressing these challenges.

The primary objective in utilizing ferrofluids for future-ready energy solutions is to harness their unique magneto-responsive properties to enhance energy generation, storage, and transmission efficiency. Researchers aim to develop ferrofluid-based systems that can improve the performance of existing energy technologies while also enabling entirely new energy conversion and storage mechanisms.

One key goal is to enhance the efficiency of renewable energy systems. For instance, in solar thermal power plants, ferrofluids could be used to improve heat transfer and energy conversion processes. In wind turbines, ferrofluid-based seals and dampers could reduce friction and increase overall system efficiency.

Another objective is to develop novel energy storage solutions. Ferrofluids show promise in creating more efficient and compact thermal energy storage systems, potentially revolutionizing how we store and distribute heat energy. Additionally, researchers are exploring the use of ferrofluids in advanced battery technologies, aiming to increase energy density and charging speeds.

The evolution of ferrofluid technology also aims to address challenges in energy transmission. By developing ferrofluid-based coolants and insulators, scientists hope to enhance the efficiency and capacity of power transmission systems, reducing energy losses and improving grid reliability.

As we look to the future, the objectives for ferrofluid energy technology continue to expand. Researchers are exploring its potential in harvesting waste heat, developing magnetocaloric refrigeration systems, and even creating new forms of energy generation based on the unique properties of these magnetic nanofluids. The ultimate goal is to establish ferrofluids as a versatile and indispensable component in the next generation of energy solutions, contributing significantly to a more sustainable and efficient global energy landscape.

Initially conceived for rocket fuel manipulation in zero gravity, ferrofluids have since found applications in various fields, including energy. The technology's progression has been driven by the increasing demand for more efficient and sustainable energy solutions. As global energy needs continue to grow, coupled with the urgency to reduce carbon emissions, ferrofluids present an innovative approach to addressing these challenges.

The primary objective in utilizing ferrofluids for future-ready energy solutions is to harness their unique magneto-responsive properties to enhance energy generation, storage, and transmission efficiency. Researchers aim to develop ferrofluid-based systems that can improve the performance of existing energy technologies while also enabling entirely new energy conversion and storage mechanisms.

One key goal is to enhance the efficiency of renewable energy systems. For instance, in solar thermal power plants, ferrofluids could be used to improve heat transfer and energy conversion processes. In wind turbines, ferrofluid-based seals and dampers could reduce friction and increase overall system efficiency.

Another objective is to develop novel energy storage solutions. Ferrofluids show promise in creating more efficient and compact thermal energy storage systems, potentially revolutionizing how we store and distribute heat energy. Additionally, researchers are exploring the use of ferrofluids in advanced battery technologies, aiming to increase energy density and charging speeds.

The evolution of ferrofluid technology also aims to address challenges in energy transmission. By developing ferrofluid-based coolants and insulators, scientists hope to enhance the efficiency and capacity of power transmission systems, reducing energy losses and improving grid reliability.

As we look to the future, the objectives for ferrofluid energy technology continue to expand. Researchers are exploring its potential in harvesting waste heat, developing magnetocaloric refrigeration systems, and even creating new forms of energy generation based on the unique properties of these magnetic nanofluids. The ultimate goal is to establish ferrofluids as a versatile and indispensable component in the next generation of energy solutions, contributing significantly to a more sustainable and efficient global energy landscape.

Market Demand for Ferrofluid-Based Energy Solutions

The market demand for ferrofluid-based energy solutions is experiencing significant growth, driven by the increasing need for innovative and sustainable energy technologies. Ferrofluids, which are magnetic liquids composed of nanoscale ferromagnetic particles suspended in a carrier fluid, offer unique properties that make them attractive for various energy applications.

In the renewable energy sector, ferrofluids show promise in enhancing the efficiency of solar thermal systems. By using ferrofluids as heat transfer mediums, these systems can achieve improved thermal conductivity and heat transfer rates, potentially increasing overall energy conversion efficiency. This application has garnered attention from solar energy companies and researchers looking to optimize solar thermal power generation.

The wind energy industry is also exploring ferrofluid-based solutions to improve the performance of wind turbines. Ferrofluids can be utilized in advanced bearing systems, reducing friction and wear while enhancing the longevity and efficiency of turbine components. As wind energy continues to grow globally, the demand for such innovative solutions is expected to rise.

In the field of energy storage, ferrofluids are being investigated for their potential in next-generation battery technologies. Their unique magnetic properties could lead to the development of more efficient and compact energy storage systems, addressing the growing need for improved energy storage solutions in both grid-scale and portable applications.

The automotive industry, particularly in the electric vehicle (EV) sector, is showing interest in ferrofluid-based cooling systems. As EVs become more prevalent, there is a growing demand for advanced thermal management solutions to enhance battery performance and longevity. Ferrofluids offer the potential for more efficient cooling systems, which could contribute to increased EV range and reliability.

In the realm of energy harvesting, ferrofluids are being explored for their potential in converting mechanical energy into electrical energy. This application could find use in wearable devices, IoT sensors, and other small-scale energy generation scenarios, addressing the increasing demand for self-powered electronic devices.

The oil and gas industry is also investigating ferrofluid-based solutions for enhanced oil recovery techniques. By utilizing the magnetic properties of ferrofluids, companies aim to improve the efficiency of oil extraction processes, potentially leading to increased production from existing reservoirs.

As environmental concerns continue to drive the transition towards cleaner energy sources, the demand for ferrofluid-based energy solutions is expected to grow. Industries and research institutions are increasingly investing in R&D efforts to harness the unique properties of ferrofluids for energy applications, indicating a promising market outlook for these innovative technologies.

In the renewable energy sector, ferrofluids show promise in enhancing the efficiency of solar thermal systems. By using ferrofluids as heat transfer mediums, these systems can achieve improved thermal conductivity and heat transfer rates, potentially increasing overall energy conversion efficiency. This application has garnered attention from solar energy companies and researchers looking to optimize solar thermal power generation.

The wind energy industry is also exploring ferrofluid-based solutions to improve the performance of wind turbines. Ferrofluids can be utilized in advanced bearing systems, reducing friction and wear while enhancing the longevity and efficiency of turbine components. As wind energy continues to grow globally, the demand for such innovative solutions is expected to rise.

In the field of energy storage, ferrofluids are being investigated for their potential in next-generation battery technologies. Their unique magnetic properties could lead to the development of more efficient and compact energy storage systems, addressing the growing need for improved energy storage solutions in both grid-scale and portable applications.

The automotive industry, particularly in the electric vehicle (EV) sector, is showing interest in ferrofluid-based cooling systems. As EVs become more prevalent, there is a growing demand for advanced thermal management solutions to enhance battery performance and longevity. Ferrofluids offer the potential for more efficient cooling systems, which could contribute to increased EV range and reliability.

In the realm of energy harvesting, ferrofluids are being explored for their potential in converting mechanical energy into electrical energy. This application could find use in wearable devices, IoT sensors, and other small-scale energy generation scenarios, addressing the increasing demand for self-powered electronic devices.

The oil and gas industry is also investigating ferrofluid-based solutions for enhanced oil recovery techniques. By utilizing the magnetic properties of ferrofluids, companies aim to improve the efficiency of oil extraction processes, potentially leading to increased production from existing reservoirs.

As environmental concerns continue to drive the transition towards cleaner energy sources, the demand for ferrofluid-based energy solutions is expected to grow. Industries and research institutions are increasingly investing in R&D efforts to harness the unique properties of ferrofluids for energy applications, indicating a promising market outlook for these innovative technologies.

Ferrofluid Energy Tech: Current State and Challenges

Ferrofluids, a unique class of magnetic nanomaterials, have garnered significant attention in the energy sector due to their potential for innovative applications. However, the current state of ferrofluid technology in energy solutions faces several challenges that need to be addressed for widespread adoption.

One of the primary obstacles is the stability of ferrofluids under extreme conditions. While these materials exhibit remarkable magnetic properties, their performance can degrade when exposed to high temperatures or intense magnetic fields for extended periods. This limitation restricts their use in certain energy applications, particularly those involving high-temperature environments or strong electromagnetic fields.

Another challenge lies in the scalability of ferrofluid production. Current manufacturing processes are often complex and costly, making large-scale production for industrial energy applications economically unfeasible. The development of more efficient and cost-effective production methods is crucial for the widespread implementation of ferrofluid-based energy solutions.

The environmental impact of ferrofluids is also a concern. Some ferrofluids contain toxic components or nanoparticles that may pose risks to ecosystems if not properly contained or disposed of. Research into more environmentally friendly formulations and improved containment strategies is necessary to mitigate these potential hazards.

Furthermore, the integration of ferrofluids into existing energy infrastructure presents technical hurdles. Many current energy systems are not designed to accommodate the unique properties of ferrofluids, requiring significant modifications or entirely new designs. This integration challenge slows down the adoption of ferrofluid-based technologies in the energy sector.

The long-term stability and performance of ferrofluids in energy applications remain uncertain. While laboratory tests show promising results, real-world, long-duration studies are limited. This lack of extensive field data creates hesitation among potential adopters, particularly in industries where reliability and longevity are critical factors.

Additionally, the regulatory landscape for ferrofluid applications in energy systems is still evolving. The novel nature of these materials means that existing regulations may not adequately address their use, potentially leading to delays in approval and implementation of ferrofluid-based energy solutions.

Despite these challenges, ongoing research and development efforts are making strides in addressing these issues. Innovations in nanoparticle synthesis, surface modification techniques, and advanced containment systems are improving the stability and safety of ferrofluids. Collaborative efforts between academia and industry are also driving progress in scalable production methods and practical applications, paving the way for future breakthroughs in ferrofluid energy technologies.

One of the primary obstacles is the stability of ferrofluids under extreme conditions. While these materials exhibit remarkable magnetic properties, their performance can degrade when exposed to high temperatures or intense magnetic fields for extended periods. This limitation restricts their use in certain energy applications, particularly those involving high-temperature environments or strong electromagnetic fields.

Another challenge lies in the scalability of ferrofluid production. Current manufacturing processes are often complex and costly, making large-scale production for industrial energy applications economically unfeasible. The development of more efficient and cost-effective production methods is crucial for the widespread implementation of ferrofluid-based energy solutions.

The environmental impact of ferrofluids is also a concern. Some ferrofluids contain toxic components or nanoparticles that may pose risks to ecosystems if not properly contained or disposed of. Research into more environmentally friendly formulations and improved containment strategies is necessary to mitigate these potential hazards.

Furthermore, the integration of ferrofluids into existing energy infrastructure presents technical hurdles. Many current energy systems are not designed to accommodate the unique properties of ferrofluids, requiring significant modifications or entirely new designs. This integration challenge slows down the adoption of ferrofluid-based technologies in the energy sector.

The long-term stability and performance of ferrofluids in energy applications remain uncertain. While laboratory tests show promising results, real-world, long-duration studies are limited. This lack of extensive field data creates hesitation among potential adopters, particularly in industries where reliability and longevity are critical factors.

Additionally, the regulatory landscape for ferrofluid applications in energy systems is still evolving. The novel nature of these materials means that existing regulations may not adequately address their use, potentially leading to delays in approval and implementation of ferrofluid-based energy solutions.

Despite these challenges, ongoing research and development efforts are making strides in addressing these issues. Innovations in nanoparticle synthesis, surface modification techniques, and advanced containment systems are improving the stability and safety of ferrofluids. Collaborative efforts between academia and industry are also driving progress in scalable production methods and practical applications, paving the way for future breakthroughs in ferrofluid energy technologies.

Existing Ferrofluid Energy Harvesting Methods

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide effective sealing against pressure differentials while minimizing friction. These fluids can be manipulated by magnetic fields to create dynamic seals in various mechanical systems.

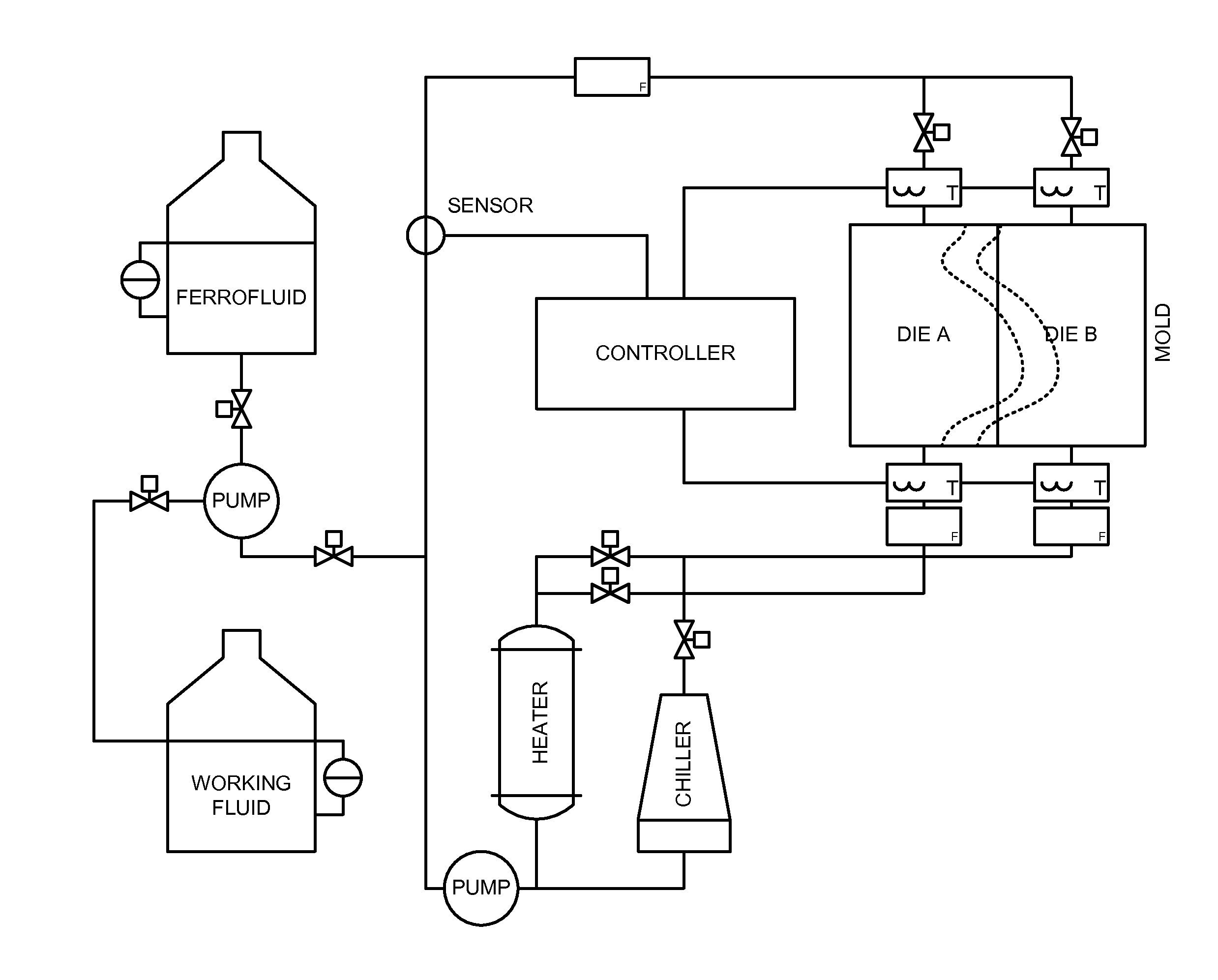

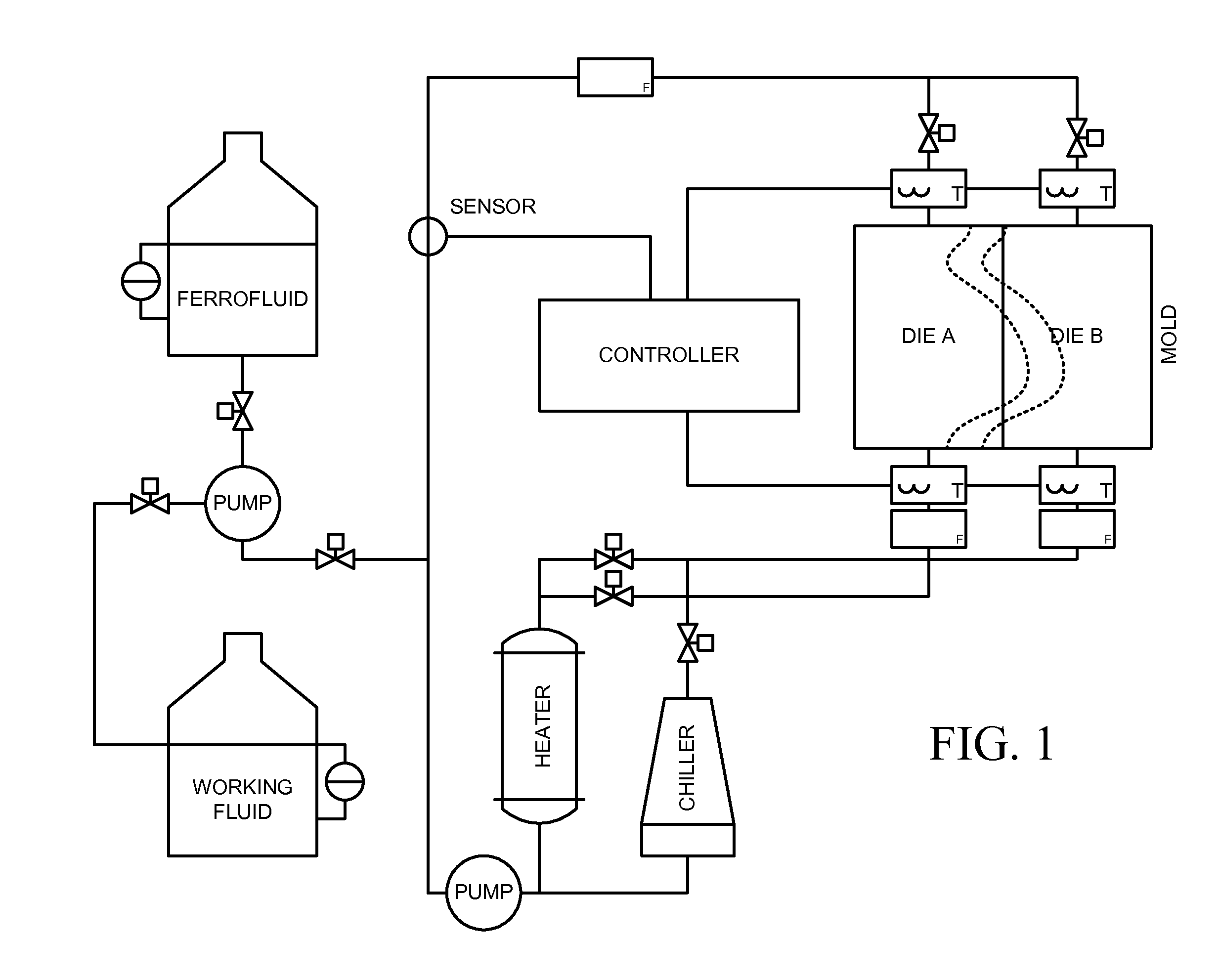

- Thermal management and cooling systems: Ferrofluids are employed in thermal management solutions, particularly in electronic cooling systems. Their unique properties allow for efficient heat transfer when subjected to magnetic fields. They can be used in heat sinks, liquid cooling systems, and thermal interfaces to enhance heat dissipation in various devices.

- Damping and vibration control: Ferrofluids are utilized in damping systems to control vibrations in mechanical and structural applications. Their viscosity can be altered by applying magnetic fields, allowing for adaptive damping in various environments. This property is exploited in shock absorbers, vibration isolators, and seismic protection systems.

- Sensing and measurement applications: Ferrofluids are employed in various sensing and measurement devices. Their magnetic properties and fluid dynamics make them suitable for use in accelerometers, inclinometers, and position sensors. They can also be used in magnetic field visualization and measurement applications.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide low-friction, contamination-resistant barriers that can be controlled by magnetic fields. These properties make them ideal for use in various industrial and mechanical systems.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids exhibit enhanced heat transfer properties due to their ability to be manipulated by magnetic fields. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The magnetic nanoparticles in the fluid can be directed to areas of high heat concentration, improving overall thermal management.Expand Specific Solutions04 Magnetic field sensing and measurement

Ferrofluids are employed in various sensing and measurement applications due to their unique response to magnetic fields. They can be used in devices for detecting and measuring magnetic field strength, orientation, and gradients. This property is utilized in the development of sensors, compasses, and scientific instruments.Expand Specific Solutions05 Biomedical and therapeutic applications

Ferrofluids have emerging applications in biomedicine and therapeutics. They can be used for targeted drug delivery, magnetic hyperthermia treatment of cancer, and as contrast agents in magnetic resonance imaging (MRI). The ability to control these fluids using external magnetic fields offers new possibilities in minimally invasive medical procedures and diagnostics.Expand Specific Solutions

Key Players in Ferrofluid Energy Industry

The ferrofluid energy solutions market is in an early growth stage, with increasing research and development efforts across academia and industry. While the market size remains relatively small, it shows promising potential for future expansion. Technologically, ferrofluid applications in energy are still emerging, with varying levels of maturity across different use cases. Key players driving innovation include academic institutions like Colorado School of Mines, Nanjing University of Aeronautics & Astronautics, and Massachusetts Institute of Technology, as well as companies such as Quidnet Energy and Siemens Energy. Collaboration between research centers and industry partners is accelerating progress towards commercialization of ferrofluid-based energy technologies.

Quidnet Energy, Inc.

Technical Solution: Quidnet Energy is developing an innovative energy storage system that utilizes ferrofluids in combination with geomechanical pumped storage technology. Their approach involves injecting water into subsurface rock formations to create pressure, which is later released to generate electricity. Ferrofluids are being explored as a means to enhance the efficiency of this process by improving fluid control and reducing friction losses in the system[10]. The company's technology aims to provide long-duration energy storage solutions that can help integrate renewable energy sources into the grid more effectively, with potential storage capacities ranging from 10 to 1000 MWh[11].

Strengths: Novel approach to large-scale energy storage, potential for integration with renewable energy systems, and utilization of existing geological formations. Weaknesses: Limited track record in commercial applications, and potential environmental concerns related to subsurface fluid injection.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has been exploring the use of ferrofluids in enhanced oil recovery (EOR) techniques. Their research focuses on using magnetically-guided ferrofluids to improve the efficiency of oil extraction from reservoirs. The ferrofluid is injected into oil wells and manipulated using external magnetic fields to navigate through porous rock formations, displacing trapped oil and increasing recovery rates[4]. Additionally, Shell is investigating the potential of ferrofluids in heat transfer applications for geothermal energy systems, where the magnetic properties of the fluid can be used to control flow and heat distribution in underground reservoirs[5].

Strengths: Potential to significantly increase oil recovery rates in existing wells, and innovative application in geothermal energy systems. Weaknesses: Environmental concerns related to the use of nanoparticles in oil extraction, and potential high costs associated with large-scale implementation.

Core Innovations in Ferrofluid Energy Technology

A method of generating electrical energy

PatentWO2015005764A2

Innovation

- A method involving wrapping a coil around a radiator, adding ferrofluid to the carrier liquid, and flowing it through a closed circuit to generate electricity from thermal and kinetic energy, utilizing existing radiator systems like car cooling and desktop computer systems, with ferrofluids coated to prevent agglomeration and enhance magnetic stability.

Method and apparatus for improving heat transfer in industrial water systems with ferrofluids

PatentActiveUS20120199320A1

Innovation

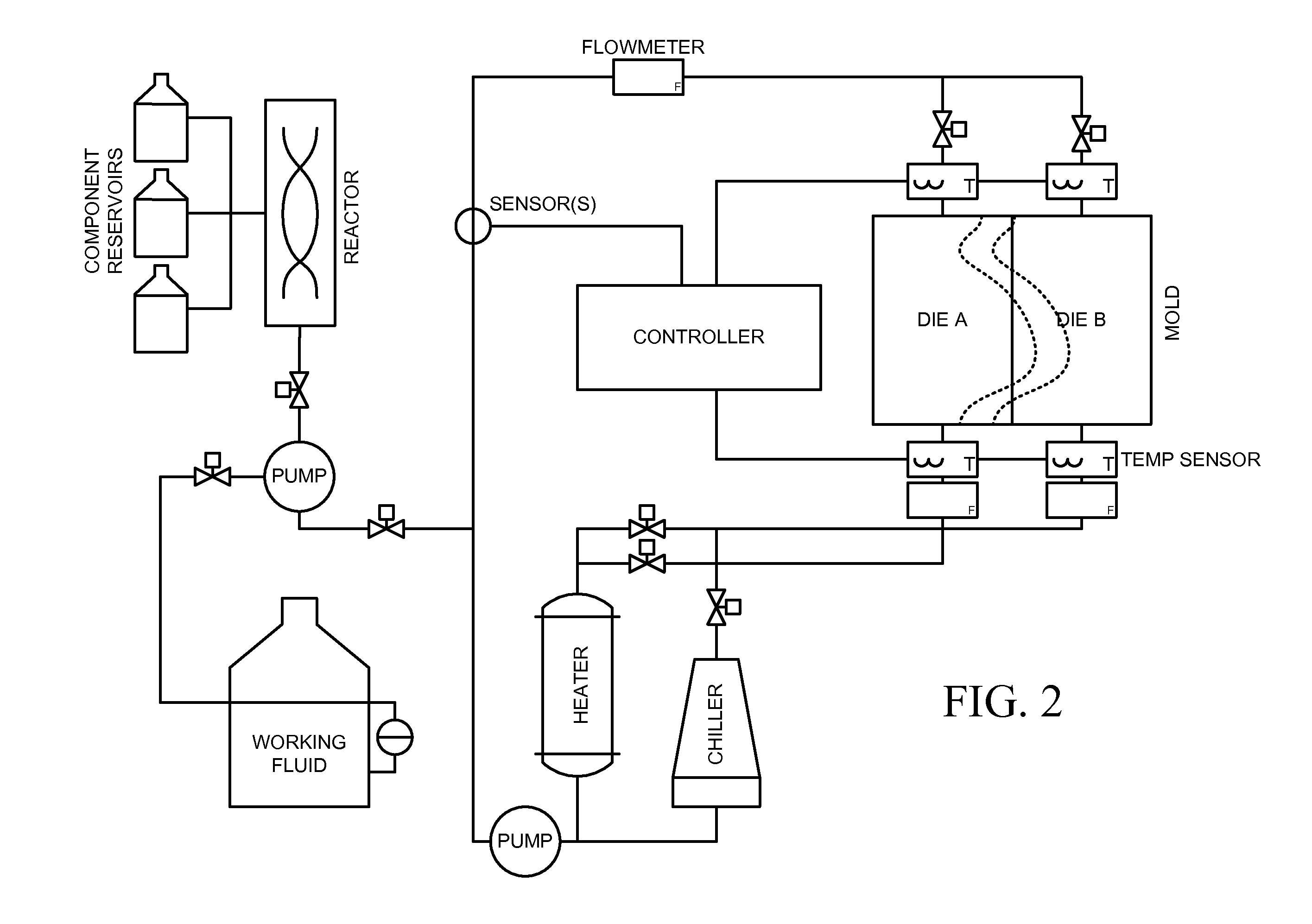

- A method involving the preparation of a consistent ferrofluid with particles less than 5 nm in diameter, which can be economically added to heat transfer fluids and monitored/controlled using direct measurement techniques to achieve enhanced heat transfer efficiency, utilizing an in-line reactor for cost-effective manufacturing and compatibility with existing water treatment additives.

Environmental Impact of Ferrofluid Energy Solutions

The environmental impact of ferrofluid-based energy solutions is a critical consideration in their development and implementation. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that can enhance energy efficiency and performance in various applications. However, their potential environmental consequences must be carefully evaluated.

One of the primary environmental concerns associated with ferrofluid energy solutions is the potential for nanoparticle release into ecosystems. The magnetic nanoparticles used in ferrofluids, typically iron oxides, may pose risks to aquatic and terrestrial environments if not properly contained or disposed of. Studies have shown that nanoparticles can accumulate in organisms and potentially disrupt food chains, highlighting the need for robust containment and disposal protocols.

On the positive side, ferrofluid-based energy solutions have the potential to improve energy efficiency and reduce overall environmental impact compared to conventional technologies. For instance, in solar thermal systems, ferrofluids can enhance heat transfer and energy conversion, potentially leading to reduced fossil fuel consumption and associated greenhouse gas emissions. Similarly, in wind turbines, ferrofluid seals can improve efficiency and reduce maintenance requirements, extending the lifespan of renewable energy infrastructure.

The production of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves energy-intensive processes and the use of chemicals that may have environmental implications. However, advancements in green chemistry and sustainable manufacturing practices are addressing these concerns, with researchers developing more environmentally friendly production methods.

Lifecycle assessment of ferrofluid energy solutions is crucial to understanding their overall environmental impact. This includes evaluating the sourcing of raw materials, manufacturing processes, operational efficiency, and end-of-life disposal or recycling. Preliminary studies suggest that the long-term environmental benefits of improved energy efficiency may outweigh the initial production impacts, but more comprehensive analyses are needed.

As ferrofluid technologies advance, there is growing emphasis on developing biodegradable or environmentally benign ferrofluids. These innovations aim to mitigate potential ecosystem risks while maintaining the beneficial properties of ferrofluids. For example, research into plant-based carrier fluids and biocompatible magnetic nanoparticles shows promise for creating more environmentally friendly ferrofluid formulations.

In conclusion, while ferrofluid energy solutions offer significant potential for improving energy efficiency and sustainability, their environmental impact must be carefully managed. Ongoing research and development efforts are focused on addressing potential risks and enhancing the overall environmental profile of these innovative technologies. As the field progresses, a balanced approach considering both the benefits and potential environmental consequences will be essential for the responsible development and deployment of ferrofluid-based energy solutions.

One of the primary environmental concerns associated with ferrofluid energy solutions is the potential for nanoparticle release into ecosystems. The magnetic nanoparticles used in ferrofluids, typically iron oxides, may pose risks to aquatic and terrestrial environments if not properly contained or disposed of. Studies have shown that nanoparticles can accumulate in organisms and potentially disrupt food chains, highlighting the need for robust containment and disposal protocols.

On the positive side, ferrofluid-based energy solutions have the potential to improve energy efficiency and reduce overall environmental impact compared to conventional technologies. For instance, in solar thermal systems, ferrofluids can enhance heat transfer and energy conversion, potentially leading to reduced fossil fuel consumption and associated greenhouse gas emissions. Similarly, in wind turbines, ferrofluid seals can improve efficiency and reduce maintenance requirements, extending the lifespan of renewable energy infrastructure.

The production of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves energy-intensive processes and the use of chemicals that may have environmental implications. However, advancements in green chemistry and sustainable manufacturing practices are addressing these concerns, with researchers developing more environmentally friendly production methods.

Lifecycle assessment of ferrofluid energy solutions is crucial to understanding their overall environmental impact. This includes evaluating the sourcing of raw materials, manufacturing processes, operational efficiency, and end-of-life disposal or recycling. Preliminary studies suggest that the long-term environmental benefits of improved energy efficiency may outweigh the initial production impacts, but more comprehensive analyses are needed.

As ferrofluid technologies advance, there is growing emphasis on developing biodegradable or environmentally benign ferrofluids. These innovations aim to mitigate potential ecosystem risks while maintaining the beneficial properties of ferrofluids. For example, research into plant-based carrier fluids and biocompatible magnetic nanoparticles shows promise for creating more environmentally friendly ferrofluid formulations.

In conclusion, while ferrofluid energy solutions offer significant potential for improving energy efficiency and sustainability, their environmental impact must be carefully managed. Ongoing research and development efforts are focused on addressing potential risks and enhancing the overall environmental profile of these innovative technologies. As the field progresses, a balanced approach considering both the benefits and potential environmental consequences will be essential for the responsible development and deployment of ferrofluid-based energy solutions.

Scalability and Integration Challenges

The scalability and integration of ferrofluid technology for future-ready energy solutions present significant challenges that must be addressed to realize its full potential. One of the primary obstacles is the production of ferrofluids at industrial scales while maintaining consistent quality and performance. Current manufacturing processes are often limited to small batches, making it difficult to meet the demands of large-scale energy applications. Scaling up production requires substantial investment in specialized equipment and the development of more efficient synthesis methods.

Integration of ferrofluid-based systems into existing energy infrastructure poses another set of challenges. Many current energy systems are not designed to accommodate the unique properties of ferrofluids, necessitating significant modifications or complete redesigns. This includes addressing issues such as containment, fluid circulation, and long-term stability under various operating conditions. The magnetic properties of ferrofluids also introduce complexities in system design, requiring careful consideration of electromagnetic interactions and potential interference with other components.

Compatibility with existing materials and technologies is a crucial factor in the scalability of ferrofluid applications. The corrosive nature of some ferrofluids can lead to degradation of containment vessels and other system components, limiting their lifespan and increasing maintenance requirements. Developing new materials or protective coatings that can withstand long-term exposure to ferrofluids is essential for ensuring the reliability and durability of ferrofluid-based energy solutions.

Environmental and safety concerns also play a significant role in the scalability and integration of ferrofluid technology. The potential environmental impact of large-scale ferrofluid production and use must be carefully assessed and mitigated. This includes addressing issues such as the disposal of spent ferrofluids and the potential for accidental releases. Safety protocols for handling and working with ferrofluids at industrial scales need to be developed and implemented to protect workers and the surrounding environment.

Cost considerations are another critical factor in scaling up ferrofluid technology. The current high cost of producing high-quality ferrofluids limits their widespread adoption in energy applications. Reducing production costs through improved manufacturing processes and the use of more readily available materials is essential for making ferrofluid-based energy solutions economically viable on a large scale. Additionally, the long-term economic benefits of ferrofluid technology must be clearly demonstrated to justify the initial investment required for integration into existing energy systems.

Integration of ferrofluid-based systems into existing energy infrastructure poses another set of challenges. Many current energy systems are not designed to accommodate the unique properties of ferrofluids, necessitating significant modifications or complete redesigns. This includes addressing issues such as containment, fluid circulation, and long-term stability under various operating conditions. The magnetic properties of ferrofluids also introduce complexities in system design, requiring careful consideration of electromagnetic interactions and potential interference with other components.

Compatibility with existing materials and technologies is a crucial factor in the scalability of ferrofluid applications. The corrosive nature of some ferrofluids can lead to degradation of containment vessels and other system components, limiting their lifespan and increasing maintenance requirements. Developing new materials or protective coatings that can withstand long-term exposure to ferrofluids is essential for ensuring the reliability and durability of ferrofluid-based energy solutions.

Environmental and safety concerns also play a significant role in the scalability and integration of ferrofluid technology. The potential environmental impact of large-scale ferrofluid production and use must be carefully assessed and mitigated. This includes addressing issues such as the disposal of spent ferrofluids and the potential for accidental releases. Safety protocols for handling and working with ferrofluids at industrial scales need to be developed and implemented to protect workers and the surrounding environment.

Cost considerations are another critical factor in scaling up ferrofluid technology. The current high cost of producing high-quality ferrofluids limits their widespread adoption in energy applications. Reducing production costs through improved manufacturing processes and the use of more readily available materials is essential for making ferrofluid-based energy solutions economically viable on a large scale. Additionally, the long-term economic benefits of ferrofluid technology must be clearly demonstrated to justify the initial investment required for integration into existing energy systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!