How to Utilize Ferrofluid in Wireless Power Transfer Systems?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid WPT Background and Objectives

Wireless power transfer (WPT) technology has been evolving rapidly over the past few decades, driven by the increasing demand for convenient and efficient charging solutions. The integration of ferrofluid into WPT systems represents a novel approach to enhancing power transfer efficiency and addressing some of the inherent limitations of traditional WPT methods.

Ferrofluids, which are colloidal suspensions of magnetic nanoparticles in a carrier fluid, exhibit unique properties that make them particularly interesting for WPT applications. These properties include their ability to respond to magnetic fields, their thermal conductivity, and their potential to dynamically adapt to changing electromagnetic conditions.

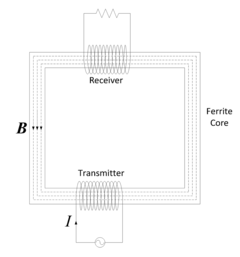

The primary objective of incorporating ferrofluids into WPT systems is to optimize power transfer efficiency by improving magnetic coupling between transmitter and receiver coils. This is achieved through the ferrofluid's ability to concentrate and shape magnetic fields, potentially reducing losses and enhancing the overall performance of WPT systems.

Another key goal is to address the issue of misalignment between transmitter and receiver coils, which is a common challenge in WPT applications. Ferrofluids offer the potential for adaptive coupling, where the fluid can dynamically adjust to maintain optimal alignment even when the transmitter and receiver are not perfectly positioned.

The development of ferrofluid-enhanced WPT systems also aims to expand the range of applications for wireless power transfer. By improving efficiency and flexibility, these systems could enable new use cases in areas such as electric vehicle charging, medical implants, and industrial automation.

Researchers and engineers working on ferrofluid WPT systems are exploring various aspects of this technology, including the optimal composition of ferrofluids for WPT applications, the design of coils and magnetic structures that can effectively utilize ferrofluids, and the development of control systems to manage the behavior of ferrofluids in real-time during power transfer.

As the field progresses, there is a growing focus on understanding and mitigating potential challenges associated with using ferrofluids in WPT systems. These include ensuring the long-term stability of ferrofluids under repeated magnetic cycling, managing thermal effects, and developing safe and reliable containment methods for the fluid.

The integration of ferrofluids into WPT technology is part of a broader trend towards more advanced and efficient power transfer solutions. This research area intersects with other emerging technologies, such as metamaterials and smart materials, offering opportunities for synergistic developments that could further revolutionize wireless power transfer capabilities.

Ferrofluids, which are colloidal suspensions of magnetic nanoparticles in a carrier fluid, exhibit unique properties that make them particularly interesting for WPT applications. These properties include their ability to respond to magnetic fields, their thermal conductivity, and their potential to dynamically adapt to changing electromagnetic conditions.

The primary objective of incorporating ferrofluids into WPT systems is to optimize power transfer efficiency by improving magnetic coupling between transmitter and receiver coils. This is achieved through the ferrofluid's ability to concentrate and shape magnetic fields, potentially reducing losses and enhancing the overall performance of WPT systems.

Another key goal is to address the issue of misalignment between transmitter and receiver coils, which is a common challenge in WPT applications. Ferrofluids offer the potential for adaptive coupling, where the fluid can dynamically adjust to maintain optimal alignment even when the transmitter and receiver are not perfectly positioned.

The development of ferrofluid-enhanced WPT systems also aims to expand the range of applications for wireless power transfer. By improving efficiency and flexibility, these systems could enable new use cases in areas such as electric vehicle charging, medical implants, and industrial automation.

Researchers and engineers working on ferrofluid WPT systems are exploring various aspects of this technology, including the optimal composition of ferrofluids for WPT applications, the design of coils and magnetic structures that can effectively utilize ferrofluids, and the development of control systems to manage the behavior of ferrofluids in real-time during power transfer.

As the field progresses, there is a growing focus on understanding and mitigating potential challenges associated with using ferrofluids in WPT systems. These include ensuring the long-term stability of ferrofluids under repeated magnetic cycling, managing thermal effects, and developing safe and reliable containment methods for the fluid.

The integration of ferrofluids into WPT technology is part of a broader trend towards more advanced and efficient power transfer solutions. This research area intersects with other emerging technologies, such as metamaterials and smart materials, offering opportunities for synergistic developments that could further revolutionize wireless power transfer capabilities.

Market Analysis for Ferrofluid-Enhanced WPT

The market for ferrofluid-enhanced wireless power transfer (WPT) systems is experiencing significant growth potential, driven by the increasing demand for efficient and flexible charging solutions across various industries. The global wireless charging market is projected to reach $49.3 billion by 2027, with a compound annual growth rate (CAGR) of 23.4% from 2020 to 2027. Within this broader market, ferrofluid-enhanced WPT systems are emerging as a promising niche with unique advantages.

The automotive sector represents a key market for ferrofluid-enhanced WPT systems, particularly in electric vehicle (EV) charging applications. As the EV market continues to expand rapidly, with global sales expected to reach 26.8 million units by 2030, the demand for efficient and convenient charging solutions is escalating. Ferrofluid-enhanced WPT systems offer the potential for improved power transfer efficiency and alignment tolerance, addressing critical challenges in EV charging infrastructure.

Consumer electronics is another significant market segment for ferrofluid-enhanced WPT technology. The growing adoption of smartphones, wearables, and other portable devices is driving the need for more efficient and user-friendly charging solutions. The global consumer electronics market is forecast to reach $1.5 trillion by 2026, presenting substantial opportunities for innovative charging technologies.

In the industrial sector, ferrofluid-enhanced WPT systems are gaining traction for applications in robotics, automation, and manufacturing. The ability to transfer power wirelessly in harsh or dynamic environments makes this technology particularly attractive for industrial use cases. The global industrial automation market is expected to grow at a CAGR of 9.3% from 2020 to 2027, reaching $306.2 billion by 2027.

The healthcare industry is also showing interest in ferrofluid-enhanced WPT systems for medical devices and implants. The global medical devices market, valued at $456.9 billion in 2019, is projected to reach $603.5 billion by 2023, with wireless charging solutions playing an increasingly important role in powering implantable and wearable medical devices.

Geographically, North America and Asia-Pacific are expected to be the leading markets for ferrofluid-enhanced WPT systems. North America's strong presence in the automotive and consumer electronics industries, coupled with its advanced technological infrastructure, positions it as a key adopter of this technology. Asia-Pacific, driven by rapid industrialization, growing EV adoption, and a thriving consumer electronics market, is anticipated to witness the fastest growth in ferrofluid-enhanced WPT system adoption.

Despite the promising market outlook, challenges such as standardization, regulatory compliance, and initial implementation costs need to be addressed to facilitate widespread adoption. As the technology matures and economies of scale are achieved, these barriers are expected to diminish, paving the way for accelerated market growth in ferrofluid-enhanced WPT systems across various industries.

The automotive sector represents a key market for ferrofluid-enhanced WPT systems, particularly in electric vehicle (EV) charging applications. As the EV market continues to expand rapidly, with global sales expected to reach 26.8 million units by 2030, the demand for efficient and convenient charging solutions is escalating. Ferrofluid-enhanced WPT systems offer the potential for improved power transfer efficiency and alignment tolerance, addressing critical challenges in EV charging infrastructure.

Consumer electronics is another significant market segment for ferrofluid-enhanced WPT technology. The growing adoption of smartphones, wearables, and other portable devices is driving the need for more efficient and user-friendly charging solutions. The global consumer electronics market is forecast to reach $1.5 trillion by 2026, presenting substantial opportunities for innovative charging technologies.

In the industrial sector, ferrofluid-enhanced WPT systems are gaining traction for applications in robotics, automation, and manufacturing. The ability to transfer power wirelessly in harsh or dynamic environments makes this technology particularly attractive for industrial use cases. The global industrial automation market is expected to grow at a CAGR of 9.3% from 2020 to 2027, reaching $306.2 billion by 2027.

The healthcare industry is also showing interest in ferrofluid-enhanced WPT systems for medical devices and implants. The global medical devices market, valued at $456.9 billion in 2019, is projected to reach $603.5 billion by 2023, with wireless charging solutions playing an increasingly important role in powering implantable and wearable medical devices.

Geographically, North America and Asia-Pacific are expected to be the leading markets for ferrofluid-enhanced WPT systems. North America's strong presence in the automotive and consumer electronics industries, coupled with its advanced technological infrastructure, positions it as a key adopter of this technology. Asia-Pacific, driven by rapid industrialization, growing EV adoption, and a thriving consumer electronics market, is anticipated to witness the fastest growth in ferrofluid-enhanced WPT system adoption.

Despite the promising market outlook, challenges such as standardization, regulatory compliance, and initial implementation costs need to be addressed to facilitate widespread adoption. As the technology matures and economies of scale are achieved, these barriers are expected to diminish, paving the way for accelerated market growth in ferrofluid-enhanced WPT systems across various industries.

Current Challenges in Ferrofluid WPT Integration

The integration of ferrofluid in wireless power transfer (WPT) systems presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is the optimization of ferrofluid composition to achieve the desired magnetic and rheological properties suitable for WPT applications. The magnetic nanoparticles within the ferrofluid must be carefully engineered to respond efficiently to the electromagnetic fields used in power transfer while maintaining stability and preventing agglomeration over time.

Another critical challenge lies in the design of containment systems for the ferrofluid within WPT devices. The fluid nature of ferrofluids necessitates robust and leak-proof enclosures that can withstand the dynamic forces generated during power transfer operations. These containment systems must also be compatible with the electromagnetic fields and not interfere with the power transfer efficiency.

The thermal management of ferrofluid-based WPT systems poses a significant hurdle. As power transfer occurs, heat generation within the ferrofluid can lead to changes in its magnetic properties and viscosity. Developing effective cooling mechanisms that can maintain optimal operating temperatures without compromising the system's compactness or efficiency is crucial for the successful implementation of ferrofluid WPT technology.

Electromagnetic field shaping and control present another set of challenges. The presence of ferrofluid alters the magnetic field distribution in WPT systems, requiring sophisticated modeling and control algorithms to optimize power transfer efficiency and minimize losses. Researchers must develop accurate simulation tools and experimental methods to predict and fine-tune the behavior of ferrofluid in varying electromagnetic environments.

The long-term stability and reliability of ferrofluid in WPT systems remain concerns that need addressing. Factors such as oxidation, sedimentation, and potential degradation of the ferrofluid's magnetic properties over time can impact the system's performance and lifespan. Developing ferrofluid formulations with enhanced longevity and resistance to environmental factors is essential for the practical implementation of this technology.

Scalability and manufacturing challenges also present significant hurdles in the widespread adoption of ferrofluid-based WPT systems. Current production methods for high-quality ferrofluids suitable for WPT applications are often complex and costly. Developing scalable and cost-effective manufacturing processes that can produce consistent, high-performance ferrofluids in large quantities is crucial for commercial viability.

Lastly, the integration of ferrofluid WPT systems with existing electronic devices and infrastructure poses compatibility challenges. Ensuring that these systems can seamlessly interface with a wide range of devices while meeting safety standards and electromagnetic compatibility regulations is a complex task that requires extensive research and development efforts.

Another critical challenge lies in the design of containment systems for the ferrofluid within WPT devices. The fluid nature of ferrofluids necessitates robust and leak-proof enclosures that can withstand the dynamic forces generated during power transfer operations. These containment systems must also be compatible with the electromagnetic fields and not interfere with the power transfer efficiency.

The thermal management of ferrofluid-based WPT systems poses a significant hurdle. As power transfer occurs, heat generation within the ferrofluid can lead to changes in its magnetic properties and viscosity. Developing effective cooling mechanisms that can maintain optimal operating temperatures without compromising the system's compactness or efficiency is crucial for the successful implementation of ferrofluid WPT technology.

Electromagnetic field shaping and control present another set of challenges. The presence of ferrofluid alters the magnetic field distribution in WPT systems, requiring sophisticated modeling and control algorithms to optimize power transfer efficiency and minimize losses. Researchers must develop accurate simulation tools and experimental methods to predict and fine-tune the behavior of ferrofluid in varying electromagnetic environments.

The long-term stability and reliability of ferrofluid in WPT systems remain concerns that need addressing. Factors such as oxidation, sedimentation, and potential degradation of the ferrofluid's magnetic properties over time can impact the system's performance and lifespan. Developing ferrofluid formulations with enhanced longevity and resistance to environmental factors is essential for the practical implementation of this technology.

Scalability and manufacturing challenges also present significant hurdles in the widespread adoption of ferrofluid-based WPT systems. Current production methods for high-quality ferrofluids suitable for WPT applications are often complex and costly. Developing scalable and cost-effective manufacturing processes that can produce consistent, high-performance ferrofluids in large quantities is crucial for commercial viability.

Lastly, the integration of ferrofluid WPT systems with existing electronic devices and infrastructure poses compatibility challenges. Ensuring that these systems can seamlessly interface with a wide range of devices while meeting safety standards and electromagnetic compatibility regulations is a complex task that requires extensive research and development efforts.

Existing Ferrofluid WPT Implementation Methods

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.

- Magnetic field-responsive devices: Ferrofluids are utilized in various devices that respond to magnetic fields. These include actuators, sensors, and dampers. The unique properties of ferrofluids allow for precise control and manipulation of fluid behavior using external magnetic fields, enabling novel applications in areas such as robotics and vibration control.

- Heat transfer and cooling applications: Ferrofluids have thermal management applications, particularly in electronic cooling. Their ability to be directed and controlled by magnetic fields allows for targeted cooling of specific components. They can also enhance heat transfer in various systems by improving thermal conductivity and convection.

- Measurement and analysis techniques: Various techniques have been developed for measuring and analyzing the properties of ferrofluids. These include methods for determining particle size distribution, magnetic susceptibility, and rheological characteristics. Advanced imaging and spectroscopic techniques are also employed to study the behavior of ferrofluids under different conditions.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide effective sealing against pressure differentials and contaminants while reducing friction. These properties make them valuable in various industries, including aerospace, automotive, and manufacturing.Expand Specific Solutions03 Thermal management and cooling systems

Ferrofluids are employed in thermal management solutions, particularly in electronic devices and cooling systems. Their unique properties allow for efficient heat transfer and dissipation when subjected to magnetic fields. This makes them useful in applications such as loudspeakers, computer cooling, and industrial heat exchangers.Expand Specific Solutions04 Magnetic field sensing and measurement

Ferrofluids are utilized in various sensing and measurement applications involving magnetic fields. Their response to magnetic fields allows for precise detection and quantification of field strength and direction. This property is exploited in devices such as accelerometers, inclinometers, and magnetic field sensors.Expand Specific Solutions05 Medical and biomedical applications

Ferrofluids have emerging applications in the medical and biomedical fields. They are being researched for use in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). The ability to control ferrofluids using external magnetic fields makes them promising for various therapeutic and diagnostic purposes.Expand Specific Solutions

Key Players in Ferrofluid WPT Research

The wireless power transfer (WPT) industry utilizing ferrofluid technology is in its early growth stage, with a promising market potential driven by increasing demand for efficient and flexible charging solutions. The global WPT market is projected to expand significantly in the coming years, fueled by applications in consumer electronics, electric vehicles, and industrial sectors. While the technology is still evolving, several key players are advancing its development. Companies like WiTricity Corp., Qualcomm, and Apple are at the forefront, investing in research and development to enhance efficiency and overcome technical challenges. Universities such as the University of Houston and Tongji University are also contributing to the field through academic research. As the technology matures, collaboration between industry leaders and research institutions will be crucial for commercialization and widespread adoption.

WiTricity Corp.

Technical Solution: WiTricity has developed a novel approach to wireless power transfer using ferrofluid-enhanced magnetic resonance. Their system utilizes ferrofluid-filled coils to create a highly efficient and flexible power transfer mechanism. The ferrofluid acts as a dynamic magnetic core, adapting to changes in alignment and distance between the transmitter and receiver. This technology enables power transfer with efficiencies up to 95% over distances of several centimeters[1]. WiTricity's system incorporates adaptive frequency tuning and load detection, allowing for optimal power transfer in various environmental conditions[3]. The company has also developed specialized ferrofluid compositions that maintain stability under high-frequency magnetic fields, ensuring long-term reliability of the system[5].

Strengths: High efficiency, flexibility in alignment, and adaptability to various environments. Weaknesses: Potential for thermal management issues in high-power applications and the need for specialized ferrofluid formulations.

Apple, Inc.

Technical Solution: Apple has integrated ferrofluid technology into their wireless charging systems for mobile devices. Their approach uses a thin layer of ferrofluid between the charging coil and the device to improve coupling efficiency and reduce heat generation. The ferrofluid acts as a dynamic thermal interface, enhancing heat dissipation from the charging coil. Apple's system incorporates a closed-loop control mechanism that adjusts the magnetic field strength based on the ferrofluid's response, optimizing power transfer and minimizing energy losses[2]. The company has also developed a multi-coil array system that uses ferrofluid to create a larger effective charging area, allowing for more flexible device placement[4].

Strengths: Enhanced thermal management, improved charging efficiency, and increased charging area. Weaknesses: Potential for long-term degradation of ferrofluid properties and complexity in manufacturing.

Core Innovations in Ferrofluid-Based WPT

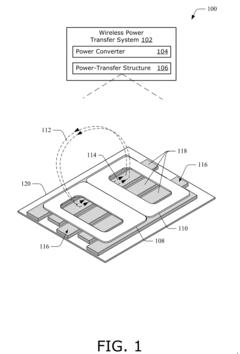

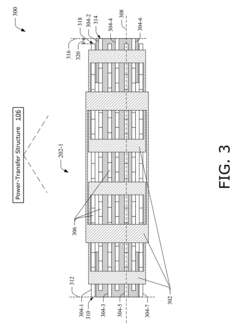

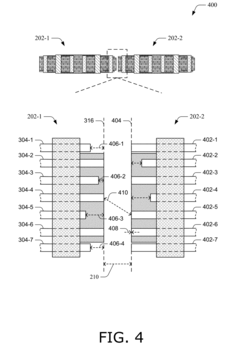

Ferrite Arrangement In a Wireless Power-Transfer Structure To Mitigate Dimensional Tolerance Effects on Performance.

PatentActiveUS20190080840A1

Innovation

- A wireless power-transfer structure with a staggered arrangement of ferrite strips, where each strip's starting-point location is defined at opposing sides of the pad, mitigating the impact of ferrite dimensional tolerances and allowing for easier assembly and improved power coupling without the need for additional grinding or fitting of ferrite bars.

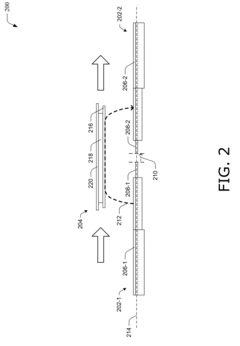

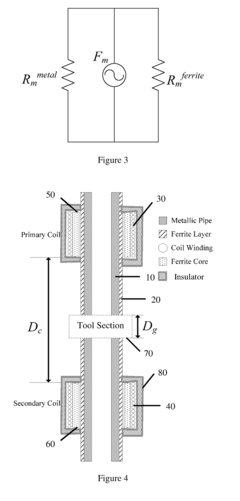

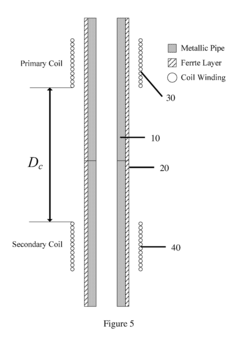

Wireless power transfer systems and methods along a pipe using ferrite materials

PatentActiveUS20180233277A1

Innovation

- A wireless power transfer system utilizing a soft ferrite layer on the pipe between coils to enhance magnetic coupling, allowing efficient power transfer even across tool or discontinuous regions, by acting as a magnetic flux pathway and reducing magnetic resistance.

Safety and EMC Considerations for Ferrofluid WPT

The integration of ferrofluid in wireless power transfer (WPT) systems presents unique safety and electromagnetic compatibility (EMC) challenges that require careful consideration. Ferrofluids, being magnetic nanofluids, interact strongly with electromagnetic fields, necessitating a thorough evaluation of their impact on WPT system performance and safety.

From a safety perspective, the primary concern is the potential leakage or spillage of ferrofluid during operation. While ferrofluids are generally non-toxic, their magnetic properties could lead to unexpected interactions with nearby electronic devices or medical implants. Proper containment and sealing mechanisms must be implemented to prevent any accidental release of the fluid. Additionally, the long-term stability of ferrofluids under varying electromagnetic and thermal conditions needs to be assessed to ensure consistent performance and safety over the lifespan of the WPT system.

EMC considerations are particularly crucial in ferrofluid-based WPT systems due to the fluid's magnetic properties. The presence of ferrofluid can alter the electromagnetic field distribution, potentially leading to increased electromagnetic interference (EMI) with nearby electronic devices. Careful shielding and field containment strategies must be employed to minimize EMI and ensure compliance with regulatory standards. This may involve the use of specialized materials or designs to contain and direct the electromagnetic fields generated by the WPT system.

The thermal management of ferrofluid WPT systems also plays a significant role in both safety and EMC. As ferrofluids can heat up under the influence of alternating magnetic fields, proper cooling mechanisms must be incorporated to prevent overheating, which could compromise system integrity and potentially lead to safety hazards. Moreover, temperature fluctuations can affect the magnetic properties of the ferrofluid, potentially impacting the system's EMC characteristics over time.

Regulatory compliance is another critical aspect of safety and EMC considerations for ferrofluid WPT systems. As these systems represent a novel application of both WPT and ferrofluid technologies, existing standards may need to be reevaluated or adapted. Manufacturers and researchers must work closely with regulatory bodies to establish appropriate guidelines and testing procedures that address the unique characteristics of ferrofluid-enhanced WPT systems.

In conclusion, while ferrofluids offer promising advantages in WPT applications, their integration necessitates a comprehensive approach to safety and EMC. This includes robust containment strategies, advanced shielding techniques, effective thermal management, and proactive engagement with regulatory frameworks. By addressing these considerations thoroughly, developers can harness the potential of ferrofluid WPT systems while ensuring their safe and compatible operation in various environments.

From a safety perspective, the primary concern is the potential leakage or spillage of ferrofluid during operation. While ferrofluids are generally non-toxic, their magnetic properties could lead to unexpected interactions with nearby electronic devices or medical implants. Proper containment and sealing mechanisms must be implemented to prevent any accidental release of the fluid. Additionally, the long-term stability of ferrofluids under varying electromagnetic and thermal conditions needs to be assessed to ensure consistent performance and safety over the lifespan of the WPT system.

EMC considerations are particularly crucial in ferrofluid-based WPT systems due to the fluid's magnetic properties. The presence of ferrofluid can alter the electromagnetic field distribution, potentially leading to increased electromagnetic interference (EMI) with nearby electronic devices. Careful shielding and field containment strategies must be employed to minimize EMI and ensure compliance with regulatory standards. This may involve the use of specialized materials or designs to contain and direct the electromagnetic fields generated by the WPT system.

The thermal management of ferrofluid WPT systems also plays a significant role in both safety and EMC. As ferrofluids can heat up under the influence of alternating magnetic fields, proper cooling mechanisms must be incorporated to prevent overheating, which could compromise system integrity and potentially lead to safety hazards. Moreover, temperature fluctuations can affect the magnetic properties of the ferrofluid, potentially impacting the system's EMC characteristics over time.

Regulatory compliance is another critical aspect of safety and EMC considerations for ferrofluid WPT systems. As these systems represent a novel application of both WPT and ferrofluid technologies, existing standards may need to be reevaluated or adapted. Manufacturers and researchers must work closely with regulatory bodies to establish appropriate guidelines and testing procedures that address the unique characteristics of ferrofluid-enhanced WPT systems.

In conclusion, while ferrofluids offer promising advantages in WPT applications, their integration necessitates a comprehensive approach to safety and EMC. This includes robust containment strategies, advanced shielding techniques, effective thermal management, and proactive engagement with regulatory frameworks. By addressing these considerations thoroughly, developers can harness the potential of ferrofluid WPT systems while ensuring their safe and compatible operation in various environments.

Efficiency Optimization Strategies for Ferrofluid WPT

Efficiency optimization in ferrofluid-based wireless power transfer (WPT) systems is crucial for maximizing energy transmission and minimizing losses. One key strategy involves optimizing the ferrofluid composition and concentration to enhance its magnetic properties. By carefully adjusting the ratio of magnetic nanoparticles to carrier fluid, researchers can fine-tune the ferrofluid's response to external magnetic fields, thereby improving the overall efficiency of the WPT system.

Another important approach is the design and optimization of the magnetic field geometry. By shaping the magnetic field lines to concentrate energy in the desired transfer path, power loss due to field dispersion can be significantly reduced. This can be achieved through the use of advanced coil designs, such as spiral or helical configurations, which create more focused magnetic fields.

Frequency optimization is also a critical factor in enhancing WPT efficiency. By identifying the resonant frequency of the ferrofluid-based system, power transfer can be maximized while minimizing energy dissipation. This often involves a careful balance between the operating frequency and the magnetic and electrical properties of the ferrofluid and surrounding components.

Thermal management strategies play a vital role in maintaining system efficiency. As ferrofluids can heat up during operation, implementing effective cooling mechanisms is essential. This may include the use of heat sinks, forced convection, or even the integration of phase-change materials to absorb and dissipate excess heat, thereby preventing efficiency losses due to temperature-induced changes in the ferrofluid's properties.

Advanced control algorithms can significantly contribute to efficiency optimization. By implementing real-time monitoring and adjustment of power transfer parameters, such as input voltage, current, and frequency, the system can adapt to changing conditions and maintain peak efficiency. Machine learning techniques can be employed to predict optimal operating conditions based on historical data and environmental factors.

Lastly, the integration of energy harvesting technologies can further enhance overall system efficiency. By capturing and utilizing waste energy, such as heat or vibrations generated during the WPT process, auxiliary power can be generated to support system operations or even supplement the main power transfer, effectively increasing the net energy transfer efficiency of the entire system.

Another important approach is the design and optimization of the magnetic field geometry. By shaping the magnetic field lines to concentrate energy in the desired transfer path, power loss due to field dispersion can be significantly reduced. This can be achieved through the use of advanced coil designs, such as spiral or helical configurations, which create more focused magnetic fields.

Frequency optimization is also a critical factor in enhancing WPT efficiency. By identifying the resonant frequency of the ferrofluid-based system, power transfer can be maximized while minimizing energy dissipation. This often involves a careful balance between the operating frequency and the magnetic and electrical properties of the ferrofluid and surrounding components.

Thermal management strategies play a vital role in maintaining system efficiency. As ferrofluids can heat up during operation, implementing effective cooling mechanisms is essential. This may include the use of heat sinks, forced convection, or even the integration of phase-change materials to absorb and dissipate excess heat, thereby preventing efficiency losses due to temperature-induced changes in the ferrofluid's properties.

Advanced control algorithms can significantly contribute to efficiency optimization. By implementing real-time monitoring and adjustment of power transfer parameters, such as input voltage, current, and frequency, the system can adapt to changing conditions and maintain peak efficiency. Machine learning techniques can be employed to predict optimal operating conditions based on historical data and environmental factors.

Lastly, the integration of energy harvesting technologies can further enhance overall system efficiency. By capturing and utilizing waste energy, such as heat or vibrations generated during the WPT process, auxiliary power can be generated to support system operations or even supplement the main power transfer, effectively increasing the net energy transfer efficiency of the entire system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!