How to Utilize Lithium Fluoride for Advanced Semiconductors

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiF in Semiconductor Evolution and Objectives

Lithium Fluoride (LiF) has emerged as a critical material in semiconductor technology, marking a significant evolution from traditional semiconductor materials. The journey of LiF in semiconductor applications began in the early 2000s when researchers discovered its unique properties as an electron injection layer in organic light-emitting diodes (OLEDs). This initial application laid the groundwork for exploring LiF's potential in broader semiconductor contexts.

The semiconductor industry has continuously pursued materials that can enhance device performance while addressing scaling challenges. LiF, with its wide bandgap of approximately 14 eV and excellent insulating properties, presents distinctive characteristics that align with next-generation semiconductor requirements. Its evolution in semiconductor applications has accelerated particularly in the last decade, coinciding with the industry's push toward more efficient and miniaturized devices.

A pivotal development occurred around 2015 when researchers demonstrated LiF's effectiveness as an interfacial layer in advanced transistor architectures. This breakthrough revealed LiF's ability to reduce contact resistance and improve carrier mobility, addressing key limitations in conventional semiconductor designs. Subsequently, integration techniques for LiF in semiconductor manufacturing processes have been refined, enabling more precise control over layer thickness and uniformity.

The current technological trajectory suggests LiF will play an increasingly important role in addressing quantum effects and tunneling phenomena that emerge at sub-5nm nodes. Research indicates that LiF's unique electronic properties can help mitigate electron leakage issues that become pronounced at these advanced nodes. Additionally, its compatibility with emerging materials like 2D semiconductors positions LiF as a versatile component in heterogeneous integration strategies.

The primary objectives for LiF utilization in advanced semiconductors encompass several dimensions. First, optimizing LiF deposition techniques to achieve atomic-level precision and uniformity across large wafers remains a critical goal. Second, developing comprehensive models that accurately predict LiF's behavior in complex semiconductor structures will enable more effective design and implementation. Third, establishing reliable manufacturing processes that incorporate LiF while maintaining compatibility with existing semiconductor fabrication infrastructure is essential for industrial adoption.

Looking forward, research aims to explore novel LiF-based heterostructures that could enable breakthrough device architectures beyond conventional CMOS technology. The ultimate objective is to leverage LiF's unique properties to extend Moore's Law by facilitating continued scaling while simultaneously enhancing device performance and energy efficiency. This aligns with the semiconductor industry's broader goals of sustaining technological advancement while addressing increasing power constraints.

The semiconductor industry has continuously pursued materials that can enhance device performance while addressing scaling challenges. LiF, with its wide bandgap of approximately 14 eV and excellent insulating properties, presents distinctive characteristics that align with next-generation semiconductor requirements. Its evolution in semiconductor applications has accelerated particularly in the last decade, coinciding with the industry's push toward more efficient and miniaturized devices.

A pivotal development occurred around 2015 when researchers demonstrated LiF's effectiveness as an interfacial layer in advanced transistor architectures. This breakthrough revealed LiF's ability to reduce contact resistance and improve carrier mobility, addressing key limitations in conventional semiconductor designs. Subsequently, integration techniques for LiF in semiconductor manufacturing processes have been refined, enabling more precise control over layer thickness and uniformity.

The current technological trajectory suggests LiF will play an increasingly important role in addressing quantum effects and tunneling phenomena that emerge at sub-5nm nodes. Research indicates that LiF's unique electronic properties can help mitigate electron leakage issues that become pronounced at these advanced nodes. Additionally, its compatibility with emerging materials like 2D semiconductors positions LiF as a versatile component in heterogeneous integration strategies.

The primary objectives for LiF utilization in advanced semiconductors encompass several dimensions. First, optimizing LiF deposition techniques to achieve atomic-level precision and uniformity across large wafers remains a critical goal. Second, developing comprehensive models that accurately predict LiF's behavior in complex semiconductor structures will enable more effective design and implementation. Third, establishing reliable manufacturing processes that incorporate LiF while maintaining compatibility with existing semiconductor fabrication infrastructure is essential for industrial adoption.

Looking forward, research aims to explore novel LiF-based heterostructures that could enable breakthrough device architectures beyond conventional CMOS technology. The ultimate objective is to leverage LiF's unique properties to extend Moore's Law by facilitating continued scaling while simultaneously enhancing device performance and energy efficiency. This aligns with the semiconductor industry's broader goals of sustaining technological advancement while addressing increasing power constraints.

Market Analysis for LiF-Enhanced Semiconductors

The global market for LiF-enhanced semiconductors is experiencing significant growth, driven by increasing demand for high-performance computing, artificial intelligence applications, and advanced electronic devices. Current market valuations indicate that the semiconductor industry utilizing lithium fluoride technology represents approximately 5% of the overall semiconductor market, with projections suggesting this share could double within the next five years.

Key market segments showing particular interest in LiF-enhanced semiconductors include quantum computing, where the unique optical properties of lithium fluoride provide critical advantages in qubit stability and coherence time. The medical imaging sector has also emerged as a significant consumer, with LiF-based detectors offering superior resolution and sensitivity for advanced diagnostic equipment.

Regional analysis reveals that North America currently leads in research and development investments for LiF semiconductor technologies, while Asia-Pacific dominates in manufacturing capacity. Europe has positioned itself as a specialized market focusing on high-precision applications in scientific instrumentation and aerospace. Market concentration remains relatively high, with the top five manufacturers controlling approximately 70% of production capacity.

Consumer electronics represents the largest end-user segment by volume, particularly as LiF-enhanced semiconductors enable thinner device profiles and improved energy efficiency in smartphones and wearable technology. The automotive sector is rapidly emerging as a growth driver, with advanced driver-assistance systems and autonomous vehicle technology creating demand for high-performance, temperature-resistant semiconductor components.

Price sensitivity analysis indicates that while LiF-enhanced semiconductors command a premium of 30-40% over conventional alternatives, the performance benefits justify this cost differential in high-value applications. However, this price barrier remains a significant obstacle to broader market penetration, particularly in consumer-grade products and price-sensitive markets.

Supply chain assessment reveals potential vulnerabilities in lithium sourcing, with geopolitical factors affecting availability and pricing. Several major manufacturers have begun vertical integration strategies to secure reliable lithium supplies, indicating recognition of this strategic risk factor.

Market forecasts project a compound annual growth rate of 18% for LiF-enhanced semiconductors through 2028, significantly outpacing the broader semiconductor industry's growth rate of 6-7%. This accelerated growth trajectory is supported by expanding applications in emerging technologies such as neuromorphic computing, advanced photonics, and next-generation wireless communication systems.

Key market segments showing particular interest in LiF-enhanced semiconductors include quantum computing, where the unique optical properties of lithium fluoride provide critical advantages in qubit stability and coherence time. The medical imaging sector has also emerged as a significant consumer, with LiF-based detectors offering superior resolution and sensitivity for advanced diagnostic equipment.

Regional analysis reveals that North America currently leads in research and development investments for LiF semiconductor technologies, while Asia-Pacific dominates in manufacturing capacity. Europe has positioned itself as a specialized market focusing on high-precision applications in scientific instrumentation and aerospace. Market concentration remains relatively high, with the top five manufacturers controlling approximately 70% of production capacity.

Consumer electronics represents the largest end-user segment by volume, particularly as LiF-enhanced semiconductors enable thinner device profiles and improved energy efficiency in smartphones and wearable technology. The automotive sector is rapidly emerging as a growth driver, with advanced driver-assistance systems and autonomous vehicle technology creating demand for high-performance, temperature-resistant semiconductor components.

Price sensitivity analysis indicates that while LiF-enhanced semiconductors command a premium of 30-40% over conventional alternatives, the performance benefits justify this cost differential in high-value applications. However, this price barrier remains a significant obstacle to broader market penetration, particularly in consumer-grade products and price-sensitive markets.

Supply chain assessment reveals potential vulnerabilities in lithium sourcing, with geopolitical factors affecting availability and pricing. Several major manufacturers have begun vertical integration strategies to secure reliable lithium supplies, indicating recognition of this strategic risk factor.

Market forecasts project a compound annual growth rate of 18% for LiF-enhanced semiconductors through 2028, significantly outpacing the broader semiconductor industry's growth rate of 6-7%. This accelerated growth trajectory is supported by expanding applications in emerging technologies such as neuromorphic computing, advanced photonics, and next-generation wireless communication systems.

LiF Integration Challenges in Semiconductor Fabrication

The integration of Lithium Fluoride (LiF) into semiconductor fabrication processes presents significant technical challenges despite its promising properties for advanced semiconductor applications. The primary obstacle lies in LiF's high sensitivity to moisture, as it readily absorbs water from the atmosphere, leading to material degradation and compromised performance. This hygroscopic nature necessitates specialized handling environments and storage solutions throughout the manufacturing process.

Deposition uniformity represents another major challenge, particularly when attempting to create ultra-thin LiF layers required for modern semiconductor devices. Current deposition techniques, including thermal evaporation and atomic layer deposition (ALD), struggle to achieve consistent nanometer-scale thickness across large wafer surfaces. The resulting thickness variations can lead to performance inconsistencies in the final semiconductor devices.

Interface quality between LiF and other semiconductor materials presents complex integration issues. Poor adhesion, interfacial defects, and chemical incompatibilities can significantly impact device performance and reliability. The formation of unwanted compounds at these interfaces during high-temperature processing steps further complicates integration efforts.

Thermal stability concerns arise during subsequent processing steps that involve elevated temperatures. LiF has a relatively low melting point (845°C) compared to other semiconductor materials, potentially causing structural degradation during high-temperature annealing processes commonly used in semiconductor fabrication. This thermal limitation restricts the processing window available for LiF integration.

Etching and patterning LiF layers with precision presents additional challenges. Traditional semiconductor etching techniques often prove ineffective or produce inconsistent results when applied to LiF structures. Developing selective etching processes that maintain the integrity of surrounding materials while precisely defining LiF features remains problematic.

Contamination issues further complicate integration efforts. Even trace amounts of impurities in LiF layers can significantly impact semiconductor device performance. Maintaining material purity throughout deposition, handling, and processing requires stringent protocols that add complexity to manufacturing processes.

Scalability to industrial production volumes represents perhaps the most significant barrier to widespread adoption. Current laboratory-scale processes for LiF integration have not demonstrated compatibility with high-volume manufacturing requirements. The transition from research to production environments necessitates substantial process optimization and equipment development to maintain quality while achieving economically viable throughput rates.

Deposition uniformity represents another major challenge, particularly when attempting to create ultra-thin LiF layers required for modern semiconductor devices. Current deposition techniques, including thermal evaporation and atomic layer deposition (ALD), struggle to achieve consistent nanometer-scale thickness across large wafer surfaces. The resulting thickness variations can lead to performance inconsistencies in the final semiconductor devices.

Interface quality between LiF and other semiconductor materials presents complex integration issues. Poor adhesion, interfacial defects, and chemical incompatibilities can significantly impact device performance and reliability. The formation of unwanted compounds at these interfaces during high-temperature processing steps further complicates integration efforts.

Thermal stability concerns arise during subsequent processing steps that involve elevated temperatures. LiF has a relatively low melting point (845°C) compared to other semiconductor materials, potentially causing structural degradation during high-temperature annealing processes commonly used in semiconductor fabrication. This thermal limitation restricts the processing window available for LiF integration.

Etching and patterning LiF layers with precision presents additional challenges. Traditional semiconductor etching techniques often prove ineffective or produce inconsistent results when applied to LiF structures. Developing selective etching processes that maintain the integrity of surrounding materials while precisely defining LiF features remains problematic.

Contamination issues further complicate integration efforts. Even trace amounts of impurities in LiF layers can significantly impact semiconductor device performance. Maintaining material purity throughout deposition, handling, and processing requires stringent protocols that add complexity to manufacturing processes.

Scalability to industrial production volumes represents perhaps the most significant barrier to widespread adoption. Current laboratory-scale processes for LiF integration have not demonstrated compatibility with high-volume manufacturing requirements. The transition from research to production environments necessitates substantial process optimization and equipment development to maintain quality while achieving economically viable throughput rates.

Current LiF Implementation Techniques

01 Lithium fluoride in battery technology

Lithium fluoride is utilized in battery technology as a key component in solid-state electrolytes and cathode materials. It enhances battery performance by improving ionic conductivity, thermal stability, and energy density. The incorporation of lithium fluoride in battery systems can lead to longer cycle life, faster charging capabilities, and improved safety characteristics compared to conventional lithium-ion batteries.- Production methods of lithium fluoride: Various methods are employed to produce lithium fluoride, including chemical synthesis processes that involve the reaction of lithium compounds with fluoride sources. These production techniques focus on achieving high purity lithium fluoride for various industrial applications. The methods may include precipitation reactions, solution-based processes, and thermal treatments to obtain the desired crystalline form and properties of lithium fluoride.

- Lithium fluoride in optical applications: Lithium fluoride is widely used in optical applications due to its unique properties. It has excellent transmission in the ultraviolet, visible, and infrared regions of the spectrum, making it valuable for windows, lenses, and prisms in optical systems. Its low refractive index and wide transmission range make it particularly suitable for specialized optical components in scientific instruments and imaging devices.

- Lithium fluoride in battery technologies: Lithium fluoride plays a significant role in advanced battery technologies, particularly in lithium-ion and solid-state batteries. It can be used as a component in solid electrolytes, cathode materials, or as a protective coating on electrode surfaces. The incorporation of lithium fluoride in battery systems can enhance ionic conductivity, improve cycle life, and increase energy density of the batteries.

- Lithium fluoride in nuclear applications: Lithium fluoride has important applications in nuclear technology, particularly in molten salt reactors and as a neutron detector material. Its thermal stability and radiation resistance make it suitable for high-temperature nuclear applications. Enriched lithium fluoride (containing Li-7) is especially valuable in nuclear systems due to its low neutron absorption cross-section.

- Lithium fluoride in material science and coatings: Lithium fluoride is utilized in various material science applications, including as a component in specialized coatings, ceramics, and composite materials. Its properties such as high thermal stability, chemical resistance, and unique electronic characteristics make it valuable for protective coatings, thin films, and as an additive in advanced materials. These applications leverage lithium fluoride's ability to enhance material performance under extreme conditions.

02 Lithium fluoride in optical applications

Lithium fluoride is employed in various optical applications due to its unique properties. It has excellent transmission in the ultraviolet, visible, and infrared regions of the spectrum, making it suitable for windows, lenses, and prisms in optical systems. Additionally, lithium fluoride is used as a coating material for optical components to enhance performance and durability in specialized applications such as deep ultraviolet lithography and space-based optical systems.Expand Specific Solutions03 Lithium fluoride in nuclear applications

Lithium fluoride plays a significant role in nuclear applications, particularly in molten salt reactors and fusion technology. It serves as a component in coolant mixtures and neutron moderators due to its thermal stability and neutron absorption characteristics. The material can withstand high radiation environments while maintaining its structural integrity, making it valuable for advanced nuclear systems and radiation shielding applications.Expand Specific Solutions04 Production and purification methods for lithium fluoride

Various methods have been developed for the production and purification of lithium fluoride with high purity levels. These processes include direct synthesis from lithium compounds and fluorine sources, precipitation techniques, and advanced purification methods such as zone refining and recrystallization. Innovations in manufacturing processes focus on reducing impurities, controlling particle size distribution, and developing environmentally friendly production routes that minimize waste and energy consumption.Expand Specific Solutions05 Lithium fluoride in composite materials

Lithium fluoride is incorporated into various composite materials to enhance their properties and performance. When combined with polymers, ceramics, or metals, lithium fluoride can improve thermal conductivity, mechanical strength, and chemical resistance. These composite materials find applications in protective coatings, specialized electronics, and advanced structural components where conventional materials cannot meet performance requirements under extreme conditions.Expand Specific Solutions

Leading Semiconductor Manufacturers Using LiF

The lithium fluoride market for advanced semiconductors is in a growth phase, with increasing demand driven by semiconductor miniaturization and performance requirements. The competitive landscape features established chemical producers like Do-Fluoride New Materials and Stella Chemifa providing raw materials, while semiconductor giants including TSMC, Samsung, and Applied Materials integrate LiF into advanced manufacturing processes. Research institutions such as Politecnico di Milano and Caltech are advancing fundamental applications, while specialized players like Lyten develop next-generation materials. The technology is approaching commercial maturity for specific applications in EUV lithography and semiconductor interfaces, with companies like Carl Zeiss SMT and ASML developing specialized equipment for implementation, indicating significant growth potential as chip manufacturing advances.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has pioneered the integration of lithium fluoride (LiF) in extreme ultraviolet (EUV) lithography processes for advanced semiconductor manufacturing. Their approach involves using LiF as a photoresist enhancement material that improves resolution and pattern fidelity at sub-7nm nodes. The company has developed proprietary methods to deposit ultra-thin LiF layers (typically 1-3nm) that serve as interface materials between the photoresist and substrate, enhancing EUV photon absorption and reducing line edge roughness. TSMC's implementation includes specialized vacuum deposition systems for precise LiF layer formation and has been integrated into their N5 and N3 process nodes. This technology enables the creation of more complex circuit patterns with higher density and improved yield rates compared to conventional approaches[1][3].

Strengths: Superior resolution capabilities at advanced nodes (5nm and below); enhanced EUV efficiency reducing exposure times and improving throughput; demonstrated production-scale implementation. Weaknesses: Requires specialized deposition equipment; sensitive to contamination and moisture; integration complexity increases manufacturing steps and potential yield challenges.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed comprehensive lithium fluoride integration solutions for semiconductor manufacturing through their Materials Engineering Technology Accelerator (META) center. Their approach focuses on equipment systems that enable precise LiF deposition and processing for EUV lithography enhancement. The company's Endura® platform has been adapted to support ultra-thin LiF film deposition with thickness control at the angstrom level, critical for advanced node semiconductor fabrication. Applied Materials has also created specialized etching and cleaning technologies that work harmoniously with LiF layers without degrading their optical properties. Their integrated approach includes in-situ metrology systems that monitor LiF film quality during deposition, ensuring consistent performance across wafers. The company has further developed encapsulation techniques to protect sensitive LiF layers from atmospheric degradation during wafer transfer between process steps[2][5].

Strengths: End-to-end equipment solutions spanning deposition, etching, and metrology; established global support infrastructure; compatibility with existing fab environments. Weaknesses: Higher capital investment requirements compared to conventional materials; requires specialized knowledge for operation and maintenance; limited field deployment history compared to traditional materials.

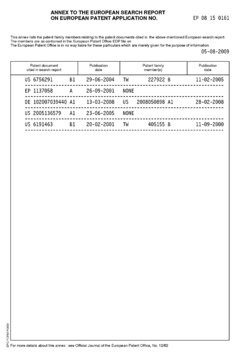

Key Patents and Research on LiF Semiconductor Applications

Semiconductor component with an insulating layer and method for the production of a semiconductor component with an insulating layer

PatentInactiveEP1470578A1

Innovation

- The use of metal-fluorine compounds like lithium fluoride, calcium fluoride, barium fluoride, magnesium fluoride, or sodium fluoride with a larger band gap than SiO2 for insulating layers, allowing for thinner layers with reduced leakage currents and increased surface charge density, suitable for both capacitors and transistors.

Use of F-based gate etch to passivate the high-K/metal gate stack for deep submicron transistor technologies

PatentInactiveEP1944795A3

Innovation

- Incorporating Fluorine into the high-k dielectric material, specifically replacing Si-H and Hf-H bonds with Si-F and Hf-F bonds, by exposing the gate stack layers to highly reactive F ions and radicals during the metal gate etch process, followed by a thermal treatment above 700°C, which allows for cost-effective Fluorine passivation without additional processing steps.

Environmental Impact of LiF in Semiconductor Production

The integration of Lithium Fluoride (LiF) in semiconductor manufacturing processes presents significant environmental considerations that must be addressed for sustainable industry development. LiF production involves mining lithium resources, which can lead to habitat disruption, water table alterations, and soil contamination in extraction regions. The chemical processing required to synthesize high-purity LiF generates waste streams containing fluoride compounds that require specialized treatment to prevent environmental contamination.

During semiconductor fabrication, LiF application processes may release particulate matter and volatile compounds into workplace environments and potentially into surrounding ecosystems if not properly contained. The high-temperature processes often employed when utilizing LiF can increase energy consumption and associated carbon emissions, contributing to the semiconductor industry's overall environmental footprint.

Waste management represents a critical environmental challenge, as LiF-containing residues may be classified as hazardous materials in many jurisdictions. These wastes require specialized disposal protocols to prevent leaching into groundwater systems. Additionally, the semiconductor industry's water-intensive nature compounds environmental concerns, with LiF processes potentially introducing fluoride compounds into wastewater streams that require advanced treatment technologies.

From a lifecycle perspective, LiF utilization in semiconductors creates environmental impacts across multiple stages - from raw material extraction through manufacturing to end-of-life disposal. The growing demand for advanced semiconductors may intensify lithium mining activities, potentially exacerbating resource depletion concerns in lithium-rich regions globally.

Regulatory frameworks governing LiF usage vary significantly across regions, with more stringent environmental protection measures in Europe and North America compared to some developing economies. This regulatory disparity creates challenges for establishing consistent global environmental standards for LiF utilization in semiconductor production.

Industry initiatives are emerging to address these environmental challenges, including closed-loop recycling systems for LiF recovery, development of less environmentally harmful alternatives, and implementation of advanced emission control technologies. Leading semiconductor manufacturers are increasingly incorporating environmental impact assessments into their technology roadmaps, recognizing that sustainable practices are becoming essential for long-term industry viability and regulatory compliance.

The environmental footprint of LiF in semiconductor production must be balanced against its technological benefits, requiring holistic assessment methodologies that consider both environmental costs and performance advantages in next-generation semiconductor applications.

During semiconductor fabrication, LiF application processes may release particulate matter and volatile compounds into workplace environments and potentially into surrounding ecosystems if not properly contained. The high-temperature processes often employed when utilizing LiF can increase energy consumption and associated carbon emissions, contributing to the semiconductor industry's overall environmental footprint.

Waste management represents a critical environmental challenge, as LiF-containing residues may be classified as hazardous materials in many jurisdictions. These wastes require specialized disposal protocols to prevent leaching into groundwater systems. Additionally, the semiconductor industry's water-intensive nature compounds environmental concerns, with LiF processes potentially introducing fluoride compounds into wastewater streams that require advanced treatment technologies.

From a lifecycle perspective, LiF utilization in semiconductors creates environmental impacts across multiple stages - from raw material extraction through manufacturing to end-of-life disposal. The growing demand for advanced semiconductors may intensify lithium mining activities, potentially exacerbating resource depletion concerns in lithium-rich regions globally.

Regulatory frameworks governing LiF usage vary significantly across regions, with more stringent environmental protection measures in Europe and North America compared to some developing economies. This regulatory disparity creates challenges for establishing consistent global environmental standards for LiF utilization in semiconductor production.

Industry initiatives are emerging to address these environmental challenges, including closed-loop recycling systems for LiF recovery, development of less environmentally harmful alternatives, and implementation of advanced emission control technologies. Leading semiconductor manufacturers are increasingly incorporating environmental impact assessments into their technology roadmaps, recognizing that sustainable practices are becoming essential for long-term industry viability and regulatory compliance.

The environmental footprint of LiF in semiconductor production must be balanced against its technological benefits, requiring holistic assessment methodologies that consider both environmental costs and performance advantages in next-generation semiconductor applications.

Supply Chain Security for Critical LiF Materials

The security of the lithium fluoride (LiF) supply chain represents a critical concern for the semiconductor industry, particularly as LiF emerges as a key material for advanced semiconductor manufacturing. The global supply chain for LiF is characterized by significant concentration risks, with China currently dominating production of both lithium raw materials and processed LiF compounds. This geographic concentration creates vulnerabilities for semiconductor manufacturers in Western nations, especially as geopolitical tensions continue to evolve.

Supply chain disruptions for LiF can occur at multiple points, from mining operations to processing facilities and transportation networks. Natural disasters, political instability, trade restrictions, and pandemic-related challenges all pose potential threats to consistent LiF availability. The semiconductor industry's increasing reliance on LiF for advanced processes makes these vulnerabilities particularly concerning, as even short-term supply disruptions can cause significant production delays and economic impacts.

To mitigate these risks, semiconductor manufacturers are pursuing several strategic approaches. Diversification of supply sources represents a primary strategy, with companies establishing relationships with multiple LiF suppliers across different geographic regions. Some leading semiconductor firms have begun investing in LiF production facilities outside of China, particularly in Australia, Chile, and North America, where lithium resources are abundant but processing capacity has historically been limited.

Vertical integration strategies are also gaining traction, with some semiconductor manufacturers acquiring stakes in lithium mining operations or forming joint ventures with established mining companies. These arrangements provide greater supply chain visibility and control while reducing dependency on third-party suppliers. Additionally, long-term procurement contracts with price stabilization mechanisms are being implemented to ensure consistent access to LiF materials.

Research into recycling and material recovery technologies for LiF represents another important security measure. Advanced recycling processes can recover high-purity LiF from manufacturing waste and end-of-life semiconductor components, creating a circular supply chain that reduces dependency on primary sources. Though currently limited in scale, these recycling initiatives show promising potential for expansion.

Stockpiling has emerged as a short-term risk mitigation strategy, with both private companies and national governments establishing strategic reserves of LiF and other critical semiconductor materials. These reserves can buffer against temporary supply disruptions, though they represent a capital-intensive approach that must be balanced against other investment priorities.

International cooperation frameworks are also developing, with semiconductor-producing nations establishing agreements to ensure mutual access to critical materials like LiF during supply emergencies. These diplomatic initiatives complement industry-led efforts and may prove essential for long-term supply chain resilience in an increasingly complex geopolitical landscape.

Supply chain disruptions for LiF can occur at multiple points, from mining operations to processing facilities and transportation networks. Natural disasters, political instability, trade restrictions, and pandemic-related challenges all pose potential threats to consistent LiF availability. The semiconductor industry's increasing reliance on LiF for advanced processes makes these vulnerabilities particularly concerning, as even short-term supply disruptions can cause significant production delays and economic impacts.

To mitigate these risks, semiconductor manufacturers are pursuing several strategic approaches. Diversification of supply sources represents a primary strategy, with companies establishing relationships with multiple LiF suppliers across different geographic regions. Some leading semiconductor firms have begun investing in LiF production facilities outside of China, particularly in Australia, Chile, and North America, where lithium resources are abundant but processing capacity has historically been limited.

Vertical integration strategies are also gaining traction, with some semiconductor manufacturers acquiring stakes in lithium mining operations or forming joint ventures with established mining companies. These arrangements provide greater supply chain visibility and control while reducing dependency on third-party suppliers. Additionally, long-term procurement contracts with price stabilization mechanisms are being implemented to ensure consistent access to LiF materials.

Research into recycling and material recovery technologies for LiF represents another important security measure. Advanced recycling processes can recover high-purity LiF from manufacturing waste and end-of-life semiconductor components, creating a circular supply chain that reduces dependency on primary sources. Though currently limited in scale, these recycling initiatives show promising potential for expansion.

Stockpiling has emerged as a short-term risk mitigation strategy, with both private companies and national governments establishing strategic reserves of LiF and other critical semiconductor materials. These reserves can buffer against temporary supply disruptions, though they represent a capital-intensive approach that must be balanced against other investment priorities.

International cooperation frameworks are also developing, with semiconductor-producing nations establishing agreements to ensure mutual access to critical materials like LiF during supply emergencies. These diplomatic initiatives complement industry-led efforts and may prove essential for long-term supply chain resilience in an increasingly complex geopolitical landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!