Hybrid Flowsheets Combining Evaporation And RO For Direct Lithium Extraction

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Technology Evolution and Objectives

Lithium extraction technologies have evolved significantly over the past century, transitioning from traditional evaporation methods to more advanced direct extraction techniques. The earliest commercial lithium production began in the 1920s, primarily utilizing mineral sources such as spodumene. By the 1950s, extraction from brine resources emerged as a cost-effective alternative, establishing solar evaporation as the dominant methodology for decades.

Traditional solar evaporation involves large-scale pond systems where lithium-rich brines are concentrated through natural evaporation over 12-24 months, achieving concentration factors of 20-50 times the original lithium content. While effective in regions with favorable climatic conditions, this method faces significant limitations in efficiency, land usage, and environmental impact.

The growing demand for lithium, driven primarily by the electric vehicle revolution and energy storage systems, has created an urgent need for more efficient extraction technologies. Global lithium demand is projected to increase from approximately 300,000 metric tons of lithium carbonate equivalent (LCE) in 2020 to over 1 million metric tons by 2025, and potentially 2 million tons by 2030, necessitating technological advancement.

Direct Lithium Extraction (DLE) technologies emerged in the early 2000s as promising alternatives, offering reduced processing time, smaller environmental footprints, and higher recovery rates. These technologies utilize various mechanisms including adsorption, ion exchange, and membrane processes to selectively extract lithium from brines.

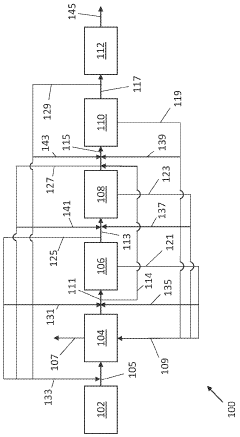

The integration of hybrid flowsheets combining evaporation and reverse osmosis (RO) represents a significant evolutionary step in lithium extraction technology. This approach aims to overcome the limitations of traditional methods while leveraging their established advantages. By incorporating RO systems, the initial concentration of lithium can be achieved more rapidly and with greater control than solar evaporation alone, while subsequent processing steps can be optimized for the pre-concentrated solution.

The primary objectives of hybrid evaporation-RO systems include: reducing water consumption by 30-50% compared to traditional methods; decreasing land footprint requirements by up to 70%; shortening production timelines from years to weeks; improving lithium recovery rates from typical 40-50% to potentially 80-90%; and enhancing the purity of extracted lithium compounds to meet battery-grade specifications (99.5% or higher).

Additionally, these hybrid systems aim to provide greater operational flexibility across diverse geographical and climatic conditions, potentially unlocking previously uneconomical lithium resources. The technology evolution pathway is now focused on optimizing these hybrid systems to achieve commercial viability at scale, with particular emphasis on membrane durability, energy efficiency, and selective lithium recovery in the presence of competing ions.

Traditional solar evaporation involves large-scale pond systems where lithium-rich brines are concentrated through natural evaporation over 12-24 months, achieving concentration factors of 20-50 times the original lithium content. While effective in regions with favorable climatic conditions, this method faces significant limitations in efficiency, land usage, and environmental impact.

The growing demand for lithium, driven primarily by the electric vehicle revolution and energy storage systems, has created an urgent need for more efficient extraction technologies. Global lithium demand is projected to increase from approximately 300,000 metric tons of lithium carbonate equivalent (LCE) in 2020 to over 1 million metric tons by 2025, and potentially 2 million tons by 2030, necessitating technological advancement.

Direct Lithium Extraction (DLE) technologies emerged in the early 2000s as promising alternatives, offering reduced processing time, smaller environmental footprints, and higher recovery rates. These technologies utilize various mechanisms including adsorption, ion exchange, and membrane processes to selectively extract lithium from brines.

The integration of hybrid flowsheets combining evaporation and reverse osmosis (RO) represents a significant evolutionary step in lithium extraction technology. This approach aims to overcome the limitations of traditional methods while leveraging their established advantages. By incorporating RO systems, the initial concentration of lithium can be achieved more rapidly and with greater control than solar evaporation alone, while subsequent processing steps can be optimized for the pre-concentrated solution.

The primary objectives of hybrid evaporation-RO systems include: reducing water consumption by 30-50% compared to traditional methods; decreasing land footprint requirements by up to 70%; shortening production timelines from years to weeks; improving lithium recovery rates from typical 40-50% to potentially 80-90%; and enhancing the purity of extracted lithium compounds to meet battery-grade specifications (99.5% or higher).

Additionally, these hybrid systems aim to provide greater operational flexibility across diverse geographical and climatic conditions, potentially unlocking previously uneconomical lithium resources. The technology evolution pathway is now focused on optimizing these hybrid systems to achieve commercial viability at scale, with particular emphasis on membrane durability, energy efficiency, and selective lithium recovery in the presence of competing ions.

Market Analysis for Hybrid Lithium Extraction Solutions

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the lithium extraction industry at approximately $6.8 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 12.3% through 2030. This accelerated demand trajectory has created significant opportunities for innovative extraction technologies.

Hybrid flowsheets combining evaporation and reverse osmosis (RO) for direct lithium extraction (DLE) are positioned at a critical intersection of market needs. Traditional evaporation pond methods, while established, face increasing scrutiny due to their extensive land requirements, water consumption, and lengthy production timelines of 18-24 months. These limitations have created a substantial market gap for more efficient extraction solutions.

The industrial battery sector represents the largest market segment for lithium, accounting for 71% of global lithium consumption. Automotive applications alone are expected to require over 2.7 million tons of lithium carbonate equivalent (LCE) by 2030, a nearly fivefold increase from 2022 levels. This dramatic demand surge has pushed lithium prices to historic highs, with spot prices reaching $78,000 per ton in 2022, though experiencing some correction in 2023.

Geographically, the market for hybrid lithium extraction technologies shows particular promise in the "Lithium Triangle" of South America (Argentina, Bolivia, and Chile), which holds approximately 58% of the world's lithium resources. North American markets are also rapidly developing, driven by supply chain security concerns and substantial government investments, including the $2.8 billion allocated through the U.S. Bipartisan Infrastructure Law for battery material processing.

Customer segments for hybrid extraction technologies include major mining corporations seeking to optimize existing operations, mid-tier lithium producers looking to enter the market with more sustainable technologies, and battery manufacturers pursuing vertical integration strategies. The latter category has grown significantly, with companies like Tesla, CATL, and LG Energy Solution making strategic investments in extraction technologies.

Market adoption barriers include high capital expenditure requirements, technological risk perception, and regulatory uncertainties regarding water usage and environmental impact. However, the economic advantages of hybrid systems—including 30-40% reduced production costs, 60-70% decreased water consumption, and production timelines shortened to 3-6 months—present compelling value propositions that are accelerating market acceptance.

Hybrid flowsheets combining evaporation and reverse osmosis (RO) for direct lithium extraction (DLE) are positioned at a critical intersection of market needs. Traditional evaporation pond methods, while established, face increasing scrutiny due to their extensive land requirements, water consumption, and lengthy production timelines of 18-24 months. These limitations have created a substantial market gap for more efficient extraction solutions.

The industrial battery sector represents the largest market segment for lithium, accounting for 71% of global lithium consumption. Automotive applications alone are expected to require over 2.7 million tons of lithium carbonate equivalent (LCE) by 2030, a nearly fivefold increase from 2022 levels. This dramatic demand surge has pushed lithium prices to historic highs, with spot prices reaching $78,000 per ton in 2022, though experiencing some correction in 2023.

Geographically, the market for hybrid lithium extraction technologies shows particular promise in the "Lithium Triangle" of South America (Argentina, Bolivia, and Chile), which holds approximately 58% of the world's lithium resources. North American markets are also rapidly developing, driven by supply chain security concerns and substantial government investments, including the $2.8 billion allocated through the U.S. Bipartisan Infrastructure Law for battery material processing.

Customer segments for hybrid extraction technologies include major mining corporations seeking to optimize existing operations, mid-tier lithium producers looking to enter the market with more sustainable technologies, and battery manufacturers pursuing vertical integration strategies. The latter category has grown significantly, with companies like Tesla, CATL, and LG Energy Solution making strategic investments in extraction technologies.

Market adoption barriers include high capital expenditure requirements, technological risk perception, and regulatory uncertainties regarding water usage and environmental impact. However, the economic advantages of hybrid systems—including 30-40% reduced production costs, 60-70% decreased water consumption, and production timelines shortened to 3-6 months—present compelling value propositions that are accelerating market acceptance.

Current Challenges in Evaporation-RO Combined Systems

Despite the promising potential of hybrid systems combining evaporation and reverse osmosis (RO) for direct lithium extraction (DLE), several significant technical challenges currently impede their widespread implementation and optimal performance. These challenges span across multiple dimensions of the integrated process.

Scale formation represents one of the most persistent issues in evaporation-RO hybrid systems. The high concentration of various salts in lithium-rich brines leads to severe scaling on heat transfer surfaces in evaporators and membrane fouling in RO units. Calcium sulfate, calcium carbonate, and silica deposits are particularly problematic, reducing thermal efficiency and increasing maintenance frequency. Current anti-scaling chemicals often prove inadequate for the complex chemistry of lithium brines.

Energy consumption remains prohibitively high for commercial viability in many cases. Evaporation processes require substantial thermal energy, while RO systems demand significant electrical power for maintaining high operating pressures. The integration of these energy-intensive processes creates challenges in optimizing the overall energy balance, particularly in remote locations where lithium resources are often found.

Membrane performance limitations severely constrain RO efficiency in lithium extraction applications. Existing membranes exhibit insufficient selectivity between lithium ions and competing ions such as sodium, potassium, and magnesium. Additionally, the harsh chemical environment of concentrated brines accelerates membrane degradation, reducing operational lifespan and increasing replacement costs.

Process control and integration difficulties arise from the dynamic nature of the hybrid system. Fluctuations in feed composition, temperature variations, and changing recovery rates create complex interdependencies between evaporation and RO units. Current control systems lack the sophistication to maintain optimal performance across these varying conditions.

Brine pre-treatment inadequacies further complicate operations. The diverse and variable composition of lithium-rich brines requires customized pre-treatment protocols that current standardized approaches fail to address effectively. Insufficient pre-treatment leads to accelerated equipment deterioration and reduced lithium recovery rates.

Environmental considerations pose additional challenges. Water recovery and waste management remain problematic, with concentrated reject streams requiring proper disposal. The substantial water footprint of evaporation processes conflicts with sustainability goals, particularly in water-scarce regions where many lithium resources are located.

Economic viability concerns persist due to high capital expenditure requirements and operational costs. The complex integration of evaporation and RO technologies demands specialized equipment and expertise, while maintenance costs remain elevated due to the harsh operating conditions and material limitations.

Scale formation represents one of the most persistent issues in evaporation-RO hybrid systems. The high concentration of various salts in lithium-rich brines leads to severe scaling on heat transfer surfaces in evaporators and membrane fouling in RO units. Calcium sulfate, calcium carbonate, and silica deposits are particularly problematic, reducing thermal efficiency and increasing maintenance frequency. Current anti-scaling chemicals often prove inadequate for the complex chemistry of lithium brines.

Energy consumption remains prohibitively high for commercial viability in many cases. Evaporation processes require substantial thermal energy, while RO systems demand significant electrical power for maintaining high operating pressures. The integration of these energy-intensive processes creates challenges in optimizing the overall energy balance, particularly in remote locations where lithium resources are often found.

Membrane performance limitations severely constrain RO efficiency in lithium extraction applications. Existing membranes exhibit insufficient selectivity between lithium ions and competing ions such as sodium, potassium, and magnesium. Additionally, the harsh chemical environment of concentrated brines accelerates membrane degradation, reducing operational lifespan and increasing replacement costs.

Process control and integration difficulties arise from the dynamic nature of the hybrid system. Fluctuations in feed composition, temperature variations, and changing recovery rates create complex interdependencies between evaporation and RO units. Current control systems lack the sophistication to maintain optimal performance across these varying conditions.

Brine pre-treatment inadequacies further complicate operations. The diverse and variable composition of lithium-rich brines requires customized pre-treatment protocols that current standardized approaches fail to address effectively. Insufficient pre-treatment leads to accelerated equipment deterioration and reduced lithium recovery rates.

Environmental considerations pose additional challenges. Water recovery and waste management remain problematic, with concentrated reject streams requiring proper disposal. The substantial water footprint of evaporation processes conflicts with sustainability goals, particularly in water-scarce regions where many lithium resources are located.

Economic viability concerns persist due to high capital expenditure requirements and operational costs. The complex integration of evaporation and RO technologies demands specialized equipment and expertise, while maintenance costs remain elevated due to the harsh operating conditions and material limitations.

Existing Hybrid Flowsheet Configurations and Performance

01 Hybrid evaporation-RO systems for lithium extraction efficiency

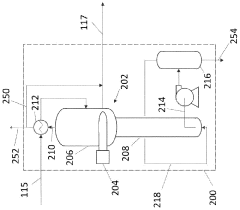

Hybrid systems combining evaporation and reverse osmosis technologies can significantly enhance lithium extraction efficiency. These integrated processes leverage the strengths of both methods, where evaporation concentrates the lithium-rich brine while reverse osmosis further purifies and concentrates the solution. This combination reduces energy consumption and processing time compared to traditional evaporation ponds alone, while achieving higher lithium recovery rates.- Hybrid evaporation-RO systems for lithium extraction efficiency: Hybrid systems combining evaporation and reverse osmosis technologies can significantly enhance lithium extraction efficiency from brine resources. These integrated processes leverage the strengths of both methods: evaporation concentrates the lithium solution while reverse osmosis removes impurities and further concentrates the lithium ions. This combination reduces processing time compared to traditional solar evaporation alone and improves overall recovery rates of lithium from various brine sources.

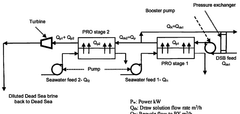

- Energy optimization in hybrid lithium extraction flowsheets: Energy consumption optimization is critical in hybrid lithium extraction processes. Advanced flowsheet designs incorporate energy recovery systems, such as pressure exchangers in RO units and heat recovery in evaporation stages. These optimizations reduce operational costs while maintaining extraction efficiency. Strategic sequencing of evaporation and RO stages can further minimize energy requirements by processing brine at optimal concentration levels for each technology, resulting in more sustainable lithium production processes.

- Selective membrane technologies for lithium concentration: Specialized membrane technologies play a crucial role in hybrid lithium extraction flowsheets. These membranes are designed with specific selectivity for lithium ions while rejecting competing ions such as sodium, magnesium, and calcium. When integrated with evaporation processes, these selective membranes can significantly increase lithium purity and concentration factors. The development of lithium-selective nanofiltration and RO membranes has enabled more efficient separation in the hybrid process, reducing the number of evaporation stages required.

- Pre-treatment and impurity management in hybrid systems: Effective pre-treatment processes are essential for maximizing the efficiency of hybrid evaporation-RO lithium extraction systems. These pre-treatment steps remove scaling compounds, organic matter, and other contaminants that could foul membranes or interfere with evaporation efficiency. Advanced impurity management techniques include selective precipitation, ion exchange, and adsorption processes that target specific interfering elements. These methods extend equipment lifespan and maintain consistent lithium recovery rates throughout the extraction process.

- Process control and optimization for lithium concentration: Sophisticated process control systems are implemented in hybrid lithium extraction flowsheets to dynamically adjust operating parameters based on feed composition variations. These systems monitor key parameters such as temperature, pressure, flow rates, and ion concentrations to optimize the performance of both evaporation and RO units. Advanced modeling and simulation tools enable predictive control strategies that can anticipate changes in brine composition and adjust process conditions accordingly, maximizing lithium recovery while minimizing reagent consumption and energy usage.

02 Energy optimization in combined evaporation-RO lithium extraction

Energy optimization strategies in hybrid flowsheets focus on heat recovery systems, pressure energy recovery devices, and staged processing. By utilizing waste heat from evaporation stages to power other parts of the process and implementing energy recovery devices in RO systems, these hybrid approaches can reduce overall energy consumption by up to 40%. Strategic sequencing of evaporation and RO stages based on brine composition further enhances energy efficiency while maintaining high lithium recovery rates.Expand Specific Solutions03 Membrane technology advancements for lithium selective extraction

Advanced membrane technologies specifically designed for lithium extraction improve the efficiency of hybrid systems. These specialized membranes feature lithium-selective properties that allow for preferential passage of lithium ions while rejecting competing ions like sodium, magnesium, and calcium. Innovations include composite membranes with lithium-specific channels, surface-modified membranes with lithium-binding functional groups, and thermally resistant membranes that can operate under the high-temperature conditions often present in hybrid systems.Expand Specific Solutions04 Brine pre-treatment methods for hybrid extraction systems

Effective pre-treatment of lithium-rich brines is crucial for the optimal performance of hybrid evaporation-RO systems. These pre-treatment methods include impurity removal through selective precipitation, adsorption techniques to eliminate interfering elements, and pH adjustment to optimize lithium solubility. Advanced filtration systems remove suspended solids and organic matter that could foul membranes, while anti-scaling agents prevent mineral deposits in both evaporation and RO units, thereby extending equipment lifespan and maintaining extraction efficiency.Expand Specific Solutions05 Process control and automation in hybrid lithium extraction

Sophisticated process control and automation systems enhance the efficiency of hybrid evaporation-RO lithium extraction operations. Real-time monitoring of key parameters such as temperature, pressure, flow rates, and ion concentrations allows for dynamic adjustments to optimize performance. Automated control systems can regulate the transition between evaporation and RO stages based on brine composition changes, while predictive algorithms anticipate maintenance needs and prevent system failures. These advanced control systems maximize lithium recovery while minimizing energy consumption and reagent use.Expand Specific Solutions

Leading Companies in Hybrid Lithium Extraction Industry

The direct lithium extraction (DLE) market using hybrid flowsheets combining evaporation and reverse osmosis is in an early growth phase, characterized by rapid technological innovation and increasing commercial applications. The global lithium market, valued at approximately $7 billion, is projected to grow significantly due to electric vehicle battery demand, creating opportunities for advanced extraction technologies. Companies like Lilac Solutions, EnergyX, and International Battery Metals are leading technological innovation with proprietary ion-exchange and membrane technologies, while established players such as Eramet and Schlumberger are leveraging their industrial expertise to scale operations. Research institutions including Qinghai Institute of Salt Lakes and Zhengzhou University are advancing fundamental science in this field, creating a competitive landscape where technological differentiation and process efficiency are key success factors.

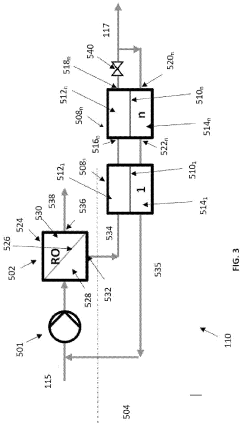

Lilac Solutions, Inc.

Technical Solution: Lilac Solutions has developed an innovative ion exchange technology for direct lithium extraction (DLE) that integrates with hybrid flowsheets combining evaporation and reverse osmosis (RO). Their approach uses proprietary ion exchange beads that selectively capture lithium ions from brine resources. The process begins with pre-treatment of brine using RO to concentrate lithium content, followed by their ion exchange system for extraction. Post-extraction, the lithium-rich solution undergoes evaporation to further concentrate before final processing. This hybrid approach significantly reduces water consumption by recycling RO permeate back into the process. Their system achieves lithium recovery rates of over 90% while reducing water usage by up to 70% compared to traditional evaporation ponds. The modular design allows for scalable implementation across various brine compositions and can be deployed in smaller footprints than conventional methods, making it suitable for diverse geographical locations.

Strengths: High selectivity for lithium over competing ions, significantly reduced water footprint, faster extraction time (hours vs. months), and modular scalability. Weaknesses: Higher upfront capital costs compared to traditional evaporation ponds, requires consistent energy supply for RO operations, and may face challenges with certain complex brine chemistries.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

Technical Solution: The Qinghai Institute of Salt Lakes has developed an advanced hybrid flowsheet for lithium extraction from salt lake brines that integrates selective adsorption, RO, and controlled evaporation. Their approach begins with a pre-treatment system to remove impurities, followed by their proprietary lithium-selective adsorption materials that can effectively separate lithium from complex brine matrices. The process incorporates multi-stage RO systems to concentrate lithium while minimizing water consumption. Their technology is particularly optimized for the unique high-magnesium, high-boron brines found in Chinese salt lakes, where traditional extraction methods face significant challenges. The institute has developed specialized membrane materials that resist scaling and fouling in these harsh environments. Their integrated system achieves lithium recovery rates of approximately 85-90% while reducing processing time from 18-24 months (traditional evaporation) to just 2-3 weeks. The technology has been successfully implemented at industrial scale in multiple Chinese salt lake operations, demonstrating consistent performance across seasonal variations. Their approach also incorporates comprehensive brine reinjection systems to minimize environmental impact on salt lake ecosystems.

Strengths: Specialized expertise with high-magnesium brines common in Chinese salt lakes, integrated approach addressing multiple extraction challenges, and proven industrial-scale implementation. Weaknesses: Technology optimization may be specific to certain brine chemistries, potentially higher energy requirements in cold climate operations, and possible challenges in technology transfer to significantly different brine compositions.

Critical Patents in Evaporation-RO Integration

Lithium recovery using aqueous sources

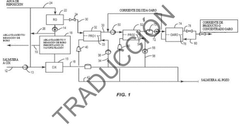

PatentWO2023215002A1

Innovation

- The method involves direct lithium extraction followed by multiple concentration stages using membrane separation operations, including counter-flow reverse osmosis and reverse osmosis, to produce a lithium concentrate with high TDS, while recycling low TDS streams for fresh water and reducing impurity levels, thereby enhancing lithium recovery from dilute sources.

energy efficient process for concentrating and recovering lithium from a brine containing lithium

PatentUndeterminedCL202200739A1

Innovation

- An energetically efficient system and process utilizing inverse osmosis, delayed osmosis modules with selective lithium membranes, and osmotic pressure differences to concentrate lithium compounds while generating energy through hydraulic turbines or isobaric recovery devices.

Environmental Impact Assessment of Hybrid DLE Systems

The environmental impact assessment of hybrid DLE systems combining evaporation and reverse osmosis (RO) reveals both significant advantages and challenges compared to traditional lithium extraction methods. These hybrid systems demonstrate reduced land footprint requirements, with approximately 30-50% less surface area needed compared to conventional evaporation ponds, thereby minimizing habitat disruption in sensitive brine-rich ecosystems.

Water consumption metrics show promising improvements, as hybrid systems can achieve up to 60% water recovery through RO integration, substantially reducing freshwater demands in water-stressed regions where lithium deposits are commonly found. This represents a critical advancement considering that traditional evaporation methods consume 500-2,000 liters of water per kilogram of lithium carbonate produced.

Carbon emissions analysis indicates that hybrid DLE systems generate 15-25% lower greenhouse gas emissions compared to conventional methods. The reduced evaporation time and energy-efficient RO processes contribute significantly to this improvement, though the precise carbon footprint varies based on energy sources powering the operations.

Chemical usage presents a notable environmental concern, as hybrid systems typically require specialized sorbents, ion exchange resins, and membrane cleaning chemicals. These introduce potential contamination risks if not properly managed. Studies indicate that approximately 2-5 kg of chemical additives may be required per ton of lithium produced, necessitating robust waste management protocols.

Brine reinjection impacts remain a critical consideration, as altered brine chemistry after lithium extraction can affect subsurface ecosystems. Research suggests that hybrid systems allow for more controlled reinjection with less chemical alteration than traditional methods, potentially reducing long-term hydrogeological impacts by 40-60%.

Waste stream characterization reveals that hybrid DLE systems produce concentrated brine streams containing elevated levels of calcium, magnesium, and boron. These require specialized treatment before disposal or reuse. However, emerging technologies within these hybrid systems are beginning to demonstrate potential for valuable by-product recovery, including magnesium compounds and potassium salts, which could transform waste streams into secondary resource streams.

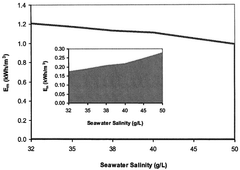

Energy efficiency assessments indicate that while RO components require significant electrical input (approximately 10-15 kWh per cubic meter of processed brine), the overall energy balance remains favorable compared to conventional thermal evaporation methods when considering total lithium yield and processing time.

Water consumption metrics show promising improvements, as hybrid systems can achieve up to 60% water recovery through RO integration, substantially reducing freshwater demands in water-stressed regions where lithium deposits are commonly found. This represents a critical advancement considering that traditional evaporation methods consume 500-2,000 liters of water per kilogram of lithium carbonate produced.

Carbon emissions analysis indicates that hybrid DLE systems generate 15-25% lower greenhouse gas emissions compared to conventional methods. The reduced evaporation time and energy-efficient RO processes contribute significantly to this improvement, though the precise carbon footprint varies based on energy sources powering the operations.

Chemical usage presents a notable environmental concern, as hybrid systems typically require specialized sorbents, ion exchange resins, and membrane cleaning chemicals. These introduce potential contamination risks if not properly managed. Studies indicate that approximately 2-5 kg of chemical additives may be required per ton of lithium produced, necessitating robust waste management protocols.

Brine reinjection impacts remain a critical consideration, as altered brine chemistry after lithium extraction can affect subsurface ecosystems. Research suggests that hybrid systems allow for more controlled reinjection with less chemical alteration than traditional methods, potentially reducing long-term hydrogeological impacts by 40-60%.

Waste stream characterization reveals that hybrid DLE systems produce concentrated brine streams containing elevated levels of calcium, magnesium, and boron. These require specialized treatment before disposal or reuse. However, emerging technologies within these hybrid systems are beginning to demonstrate potential for valuable by-product recovery, including magnesium compounds and potassium salts, which could transform waste streams into secondary resource streams.

Energy efficiency assessments indicate that while RO components require significant electrical input (approximately 10-15 kWh per cubic meter of processed brine), the overall energy balance remains favorable compared to conventional thermal evaporation methods when considering total lithium yield and processing time.

Resource Recovery Optimization in Hybrid Flowsheets

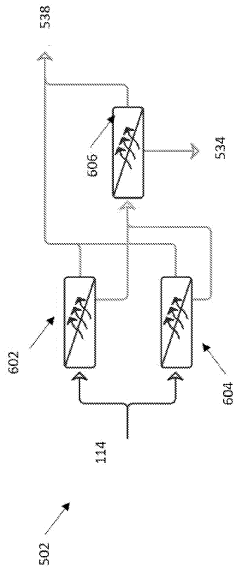

Resource recovery optimization in hybrid flowsheets represents a critical advancement in direct lithium extraction (DLE) technologies. The integration of evaporation and reverse osmosis (RO) processes creates significant opportunities to maximize resource utilization while minimizing waste and environmental impact. These hybrid systems enable more comprehensive recovery of lithium and valuable by-products from brine sources compared to traditional methods.

The optimization framework for these hybrid flowsheets typically involves multi-objective considerations including lithium recovery rates, energy consumption, water utilization efficiency, and by-product valorization. Mathematical modeling and simulation tools have become essential for predicting performance across various operational parameters and identifying optimal process configurations. Recent advancements in computational fluid dynamics and process simulation software have enhanced the accuracy of these optimization models.

Energy recovery systems play a pivotal role in hybrid flowsheet optimization. Pressure exchangers and energy recovery devices in RO systems can significantly reduce the overall energy footprint. Similarly, waste heat recovery from evaporation processes can be redirected to preheat feed streams, creating energy loops that improve system efficiency by 15-30% according to recent field studies.

Water management represents another crucial optimization target. Closed-loop water recycling systems within hybrid flowsheets can reduce freshwater consumption by up to 60% compared to conventional evaporation pond methods. Advanced membrane technologies with anti-fouling properties have extended operational cycles between maintenance, further improving resource efficiency and reducing downtime.

By-product recovery optimization has emerged as an economic driver for hybrid systems. Sequential extraction of magnesium, potassium, and boron compounds from concentrated brines can transform waste streams into valuable commercial products. Recent innovations in selective ion exchange materials have improved separation efficiency and product purity, enhancing the economic viability of comprehensive resource recovery approaches.

Process intensification techniques, including the use of advanced membrane contactors and crystallization technologies, have enabled more compact system designs with reduced footprint requirements. This spatial optimization is particularly valuable for operations in environmentally sensitive areas or regions with limited available land for industrial facilities.

Real-time monitoring and adaptive control systems represent the frontier of optimization efforts. Machine learning algorithms analyzing operational data can continuously adjust process parameters to maintain optimal performance despite variations in feed composition, ambient conditions, and product demand. These smart systems have demonstrated potential to increase lithium recovery rates by 5-12% while simultaneously reducing energy consumption.

The optimization framework for these hybrid flowsheets typically involves multi-objective considerations including lithium recovery rates, energy consumption, water utilization efficiency, and by-product valorization. Mathematical modeling and simulation tools have become essential for predicting performance across various operational parameters and identifying optimal process configurations. Recent advancements in computational fluid dynamics and process simulation software have enhanced the accuracy of these optimization models.

Energy recovery systems play a pivotal role in hybrid flowsheet optimization. Pressure exchangers and energy recovery devices in RO systems can significantly reduce the overall energy footprint. Similarly, waste heat recovery from evaporation processes can be redirected to preheat feed streams, creating energy loops that improve system efficiency by 15-30% according to recent field studies.

Water management represents another crucial optimization target. Closed-loop water recycling systems within hybrid flowsheets can reduce freshwater consumption by up to 60% compared to conventional evaporation pond methods. Advanced membrane technologies with anti-fouling properties have extended operational cycles between maintenance, further improving resource efficiency and reducing downtime.

By-product recovery optimization has emerged as an economic driver for hybrid systems. Sequential extraction of magnesium, potassium, and boron compounds from concentrated brines can transform waste streams into valuable commercial products. Recent innovations in selective ion exchange materials have improved separation efficiency and product purity, enhancing the economic viability of comprehensive resource recovery approaches.

Process intensification techniques, including the use of advanced membrane contactors and crystallization technologies, have enabled more compact system designs with reduced footprint requirements. This spatial optimization is particularly valuable for operations in environmentally sensitive areas or regions with limited available land for industrial facilities.

Real-time monitoring and adaptive control systems represent the frontier of optimization efforts. Machine learning algorithms analyzing operational data can continuously adjust process parameters to maintain optimal performance despite variations in feed composition, ambient conditions, and product demand. These smart systems have demonstrated potential to increase lithium recovery rates by 5-12% while simultaneously reducing energy consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!