Hydrogel Based Soft Robots For Environmental Sensing Deployments

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Soft Robotics Background and Objectives

Hydrogel-based soft robotics represents a revolutionary frontier in environmental sensing technology, merging the adaptability of soft materials with advanced sensing capabilities. The evolution of this field traces back to the early 2000s when researchers began exploring biomimetic approaches to create robots that could safely interact with delicate environments. Traditional rigid robots, while effective in controlled settings, face significant limitations when deployed in complex, dynamic natural environments where adaptability and resilience are paramount.

The technological trajectory has accelerated dramatically in the past decade, with hydrogels emerging as particularly promising materials due to their unique properties. These water-containing polymer networks offer exceptional biocompatibility, stimuli-responsiveness, and tunable mechanical characteristics that closely mimic biological tissues. The integration of hydrogels into soft robotics has enabled the development of systems capable of autonomous movement, shape transformation, and environmental sensing without the constraints of rigid components.

Current research objectives in hydrogel-based soft robotics for environmental sensing focus on several key areas. First, enhancing the durability and longevity of hydrogel materials when exposed to harsh environmental conditions, including extreme temperatures, pH variations, and prolonged submersion. Second, improving the sensitivity and specificity of embedded sensing mechanisms to detect multiple environmental parameters simultaneously, such as pollutants, temperature gradients, and biological agents.

Another critical objective involves developing energy-efficient actuation mechanisms that enable sustained operation in remote environments with minimal external power requirements. This includes exploring self-powering capabilities through environmental energy harvesting techniques. Additionally, researchers aim to create seamless integration systems between the soft robotic structure and data processing units to enable real-time analysis and response to environmental stimuli.

The field is increasingly moving toward multi-functional hydrogel composites that combine sensing, actuation, and communication capabilities within a single platform. These advanced materials incorporate nanomaterials, conductive elements, and responsive polymers to create truly autonomous environmental monitoring systems. The ultimate goal is to develop deployable networks of hydrogel-based soft robots capable of collaborative environmental sensing across diverse ecosystems.

Technical objectives also extend to addressing scalability challenges, as current laboratory prototypes must transition to field-deployable systems capable of withstanding real-world conditions. This includes developing standardized fabrication methods that ensure consistency and reliability while maintaining the adaptability that makes these systems valuable for environmental applications.

The technological trajectory has accelerated dramatically in the past decade, with hydrogels emerging as particularly promising materials due to their unique properties. These water-containing polymer networks offer exceptional biocompatibility, stimuli-responsiveness, and tunable mechanical characteristics that closely mimic biological tissues. The integration of hydrogels into soft robotics has enabled the development of systems capable of autonomous movement, shape transformation, and environmental sensing without the constraints of rigid components.

Current research objectives in hydrogel-based soft robotics for environmental sensing focus on several key areas. First, enhancing the durability and longevity of hydrogel materials when exposed to harsh environmental conditions, including extreme temperatures, pH variations, and prolonged submersion. Second, improving the sensitivity and specificity of embedded sensing mechanisms to detect multiple environmental parameters simultaneously, such as pollutants, temperature gradients, and biological agents.

Another critical objective involves developing energy-efficient actuation mechanisms that enable sustained operation in remote environments with minimal external power requirements. This includes exploring self-powering capabilities through environmental energy harvesting techniques. Additionally, researchers aim to create seamless integration systems between the soft robotic structure and data processing units to enable real-time analysis and response to environmental stimuli.

The field is increasingly moving toward multi-functional hydrogel composites that combine sensing, actuation, and communication capabilities within a single platform. These advanced materials incorporate nanomaterials, conductive elements, and responsive polymers to create truly autonomous environmental monitoring systems. The ultimate goal is to develop deployable networks of hydrogel-based soft robots capable of collaborative environmental sensing across diverse ecosystems.

Technical objectives also extend to addressing scalability challenges, as current laboratory prototypes must transition to field-deployable systems capable of withstanding real-world conditions. This includes developing standardized fabrication methods that ensure consistency and reliability while maintaining the adaptability that makes these systems valuable for environmental applications.

Environmental Sensing Market Demand Analysis

The environmental sensing market is experiencing robust growth driven by increasing awareness of environmental issues and the need for real-time monitoring solutions. According to recent market research, the global environmental sensing market was valued at approximately 14.2 billion USD in 2022 and is projected to reach 21.5 billion USD by 2027, growing at a CAGR of 8.6% during the forecast period. This growth is primarily fueled by stringent environmental regulations, rising pollution levels, and growing public health concerns.

Water quality monitoring represents the largest segment within environmental sensing, accounting for nearly 32% of the market share. This is particularly relevant for hydrogel-based soft robots, which excel in aquatic environments due to their inherent compatibility with water and ability to operate without contaminating sensitive ecosystems. The demand for continuous, real-time water quality monitoring in natural bodies of water, drinking water systems, and wastewater treatment facilities presents a significant opportunity for this technology.

Air quality monitoring follows closely, comprising approximately 28% of the market. While traditional air quality sensors are well-established, there is growing interest in mobile and adaptive sensing platforms that can navigate complex environments and provide spatially distributed measurements, an area where soft robots could offer unique advantages.

Soil quality monitoring, representing about 18% of the market, is gaining importance with the rise of precision agriculture and environmental remediation efforts. Hydrogel-based robots could potentially revolutionize this segment by enabling minimally invasive soil sampling and in-situ analysis.

From an end-user perspective, government agencies and environmental regulatory bodies constitute the largest customer segment (41%), followed by industrial users (27%), research institutions (19%), and commercial entities (13%). The increasing adoption of IoT and AI technologies in environmental monitoring is creating demand for more sophisticated sensing platforms that can integrate with these systems.

Geographically, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

Key market drivers include the growing need for disaster prediction and management systems, increasing deployment of environmental sensing networks in smart cities, and rising demand for wearable environmental sensors. Additionally, there is significant interest in developing sensing solutions for extreme environments where traditional rigid sensors fail, presenting a unique opportunity for hydrogel-based soft robots that can withstand harsh conditions while maintaining functionality.

Water quality monitoring represents the largest segment within environmental sensing, accounting for nearly 32% of the market share. This is particularly relevant for hydrogel-based soft robots, which excel in aquatic environments due to their inherent compatibility with water and ability to operate without contaminating sensitive ecosystems. The demand for continuous, real-time water quality monitoring in natural bodies of water, drinking water systems, and wastewater treatment facilities presents a significant opportunity for this technology.

Air quality monitoring follows closely, comprising approximately 28% of the market. While traditional air quality sensors are well-established, there is growing interest in mobile and adaptive sensing platforms that can navigate complex environments and provide spatially distributed measurements, an area where soft robots could offer unique advantages.

Soil quality monitoring, representing about 18% of the market, is gaining importance with the rise of precision agriculture and environmental remediation efforts. Hydrogel-based robots could potentially revolutionize this segment by enabling minimally invasive soil sampling and in-situ analysis.

From an end-user perspective, government agencies and environmental regulatory bodies constitute the largest customer segment (41%), followed by industrial users (27%), research institutions (19%), and commercial entities (13%). The increasing adoption of IoT and AI technologies in environmental monitoring is creating demand for more sophisticated sensing platforms that can integrate with these systems.

Geographically, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

Key market drivers include the growing need for disaster prediction and management systems, increasing deployment of environmental sensing networks in smart cities, and rising demand for wearable environmental sensors. Additionally, there is significant interest in developing sensing solutions for extreme environments where traditional rigid sensors fail, presenting a unique opportunity for hydrogel-based soft robots that can withstand harsh conditions while maintaining functionality.

Current Hydrogel Technology Challenges

Despite significant advancements in hydrogel-based soft robotics for environmental sensing, several critical technical challenges persist that limit their widespread deployment and effectiveness. The mechanical durability of hydrogels remains a primary concern, as these materials often exhibit poor tear resistance and mechanical strength when subjected to repeated deformation cycles in variable environmental conditions. This fragility significantly restricts their operational lifespan in real-world environmental monitoring scenarios, particularly in harsh settings such as marine environments or industrial waste sites.

Water management presents another substantial challenge, as hydrogels inherently experience dehydration in dry environments and excessive swelling in aqueous settings. This dynamic water content fluctuation directly impacts sensor performance, mechanical properties, and overall functionality. Current hydrogel formulations struggle to maintain consistent water content equilibrium across diverse deployment environments, resulting in unpredictable sensing behaviors and mechanical responses.

Biocompatibility and biodegradation issues further complicate environmental applications. While biodegradability can be advantageous for reducing environmental impact, uncontrolled degradation compromises long-term monitoring capabilities. Conversely, non-degradable hydrogels may introduce microplastic pollution when deployed in natural ecosystems. Striking the optimal balance between environmental persistence and ecological safety remains unresolved.

Response time limitations represent another significant technical barrier. Many hydrogel-based sensing mechanisms rely on diffusion-controlled processes, resulting in delayed responses to environmental stimuli. This inherent latency restricts their utility in applications requiring real-time monitoring of rapidly changing environmental conditions, such as chemical spill detection or early warning systems for environmental hazards.

Integration challenges between hydrogels and electronic components persist despite advances in flexible electronics. Creating robust, waterproof interfaces between hydrated polymers and electronic sensing elements remains problematic. Signal transduction from hydrogel physical or chemical changes to measurable electronic outputs often suffers from interference, drift, and calibration difficulties in field conditions.

Manufacturing scalability presents additional obstacles, as current fabrication techniques for complex hydrogel-based soft robots typically involve laboratory-scale processes that are difficult to scale industrially. Techniques such as 3D bioprinting offer promising approaches but remain limited in terms of production volume, consistency, and cost-effectiveness for mass deployment scenarios.

Energy autonomy represents a final critical challenge, as environmental sensing deployments often require long-term operation in remote locations. Current power solutions for hydrogel-based soft robots are inadequate, with limited progress in developing self-powering mechanisms or ultra-efficient energy harvesting systems compatible with hydrogel materials and environmental monitoring requirements.

Water management presents another substantial challenge, as hydrogels inherently experience dehydration in dry environments and excessive swelling in aqueous settings. This dynamic water content fluctuation directly impacts sensor performance, mechanical properties, and overall functionality. Current hydrogel formulations struggle to maintain consistent water content equilibrium across diverse deployment environments, resulting in unpredictable sensing behaviors and mechanical responses.

Biocompatibility and biodegradation issues further complicate environmental applications. While biodegradability can be advantageous for reducing environmental impact, uncontrolled degradation compromises long-term monitoring capabilities. Conversely, non-degradable hydrogels may introduce microplastic pollution when deployed in natural ecosystems. Striking the optimal balance between environmental persistence and ecological safety remains unresolved.

Response time limitations represent another significant technical barrier. Many hydrogel-based sensing mechanisms rely on diffusion-controlled processes, resulting in delayed responses to environmental stimuli. This inherent latency restricts their utility in applications requiring real-time monitoring of rapidly changing environmental conditions, such as chemical spill detection or early warning systems for environmental hazards.

Integration challenges between hydrogels and electronic components persist despite advances in flexible electronics. Creating robust, waterproof interfaces between hydrated polymers and electronic sensing elements remains problematic. Signal transduction from hydrogel physical or chemical changes to measurable electronic outputs often suffers from interference, drift, and calibration difficulties in field conditions.

Manufacturing scalability presents additional obstacles, as current fabrication techniques for complex hydrogel-based soft robots typically involve laboratory-scale processes that are difficult to scale industrially. Techniques such as 3D bioprinting offer promising approaches but remain limited in terms of production volume, consistency, and cost-effectiveness for mass deployment scenarios.

Energy autonomy represents a final critical challenge, as environmental sensing deployments often require long-term operation in remote locations. Current power solutions for hydrogel-based soft robots are inadequate, with limited progress in developing self-powering mechanisms or ultra-efficient energy harvesting systems compatible with hydrogel materials and environmental monitoring requirements.

Current Hydrogel-Based Sensing Solutions

01 Hydrogel-based soft robots with environmental sensing capabilities

Hydrogel-based soft robots can be designed with integrated environmental sensing capabilities, allowing them to detect and respond to changes in their surroundings. These robots utilize hydrogels that can change their properties in response to environmental stimuli such as temperature, pH, light, or chemical presence. The sensing capabilities enable autonomous operation and adaptive behavior in various environments, making them suitable for applications in environmental monitoring and smart systems.- Hydrogel-based soft robots with environmental sensing capabilities: Hydrogel-based soft robots can be designed with integrated environmental sensing capabilities, allowing them to detect and respond to changes in their surroundings. These robots utilize hydrogels that can change their properties in response to environmental stimuli such as temperature, pH, light, or chemical presence. The sensing capabilities enable autonomous operation and adaptive behavior in various environments, making them suitable for applications in environmental monitoring and smart systems.

- Multi-responsive hydrogel actuators for soft robotics: Multi-responsive hydrogel actuators can be formulated to respond to multiple environmental stimuli simultaneously or sequentially. These actuators can change shape, stiffness, or volume in response to specific environmental conditions, enabling complex movements and functions in soft robots. By incorporating different responsive elements, these hydrogels can be tailored for specific sensing and actuation requirements, enhancing the versatility and functionality of soft robotic systems in environmental applications.

- Biomimetic hydrogel sensors for environmental monitoring: Biomimetic hydrogel sensors mimic natural biological systems to detect environmental parameters with high sensitivity and specificity. These sensors can be integrated into soft robotic platforms to monitor water quality, air pollution, soil conditions, or the presence of specific chemicals. The biomimetic approach allows for more natural interaction with the environment and can provide real-time data on environmental conditions, making these systems valuable for ecological research and environmental protection applications.

- Self-healing hydrogels for durable environmental sensing robots: Self-healing hydrogels can repair damage autonomously, extending the operational lifespan of soft robots in harsh environmental conditions. These materials can recover their structural integrity and functionality after mechanical damage, making them ideal for long-term environmental monitoring applications. The self-healing properties ensure consistent sensing performance over time and reduce maintenance requirements, enabling deployment in remote or difficult-to-access locations for continuous environmental data collection.

- Wireless communication systems for hydrogel-based environmental sensors: Wireless communication systems can be integrated with hydrogel-based soft robots to transmit environmental sensing data remotely. These systems enable real-time monitoring and data collection without physical connections, expanding the operational range and applications of soft robotic sensors. The wireless capabilities allow for deployment in distributed sensor networks for comprehensive environmental monitoring across large areas, with applications in disaster response, climate research, and pollution tracking.

02 Temperature-responsive hydrogel actuators for soft robotics

Temperature-responsive hydrogels can be incorporated into soft robotic systems to create actuators that respond to thermal changes in the environment. These hydrogels undergo significant volume or stiffness changes when exposed to temperature variations, enabling movement and shape transformation. The temperature sensitivity allows for the development of soft robots that can operate autonomously in environments with temperature gradients or can be controlled through external thermal stimulation.Expand Specific Solutions03 pH and chemical sensing in hydrogel-based soft robots

Hydrogel-based soft robots can be engineered to detect changes in pH levels and chemical compositions in their environment. These robots incorporate hydrogels that swell, shrink, or change color in response to specific chemical stimuli or pH variations. This capability enables applications in environmental monitoring, water quality assessment, and chemical detection in hard-to-reach areas. The chemical sensing properties can be tuned by modifying the hydrogel composition or incorporating specific receptor molecules.Expand Specific Solutions04 Multi-responsive hydrogel systems for enhanced environmental interaction

Multi-responsive hydrogel systems can be designed to respond to multiple environmental stimuli simultaneously or sequentially. These advanced systems combine sensitivity to various factors such as light, temperature, pH, and mechanical stress, enabling more complex interactions with the environment. The integration of multiple sensing capabilities allows for more sophisticated decision-making algorithms in soft robots, enhancing their adaptability and functionality in diverse and changing environments.Expand Specific Solutions05 Biomimetic hydrogel sensors for environmental monitoring

Biomimetic approaches can be applied to develop hydrogel-based soft robots with sensing capabilities inspired by natural organisms. These bio-inspired designs mimic the sensing mechanisms found in plants and animals, such as mechanoreception, chemoreception, and photoreception. By incorporating biomimetic principles, these soft robots can achieve more efficient and effective environmental sensing, enabling applications in ecological monitoring, disaster response, and exploration of fragile ecosystems.Expand Specific Solutions

Leading Hydrogel Soft Robotics Developers

Hydrogel-based soft robots for environmental sensing deployments are emerging at the intersection of materials science and robotics, currently in an early growth phase. The market is expanding rapidly, projected to reach significant scale as applications in environmental monitoring gain traction. Technologically, academic institutions lead research advancement, with Zhejiang University, MIT, and Carnegie Mellon University pioneering fundamental innovations in hydrogel formulations and sensing capabilities. Commercial development is gradually accelerating, with companies like Philips exploring practical applications. The technology remains in early maturity, with significant research focusing on improving flexibility, durability, and sensing precision in aquatic environments. Cross-institutional collaboration between universities and industry partners is driving progress toward field-deployable systems that can operate autonomously in diverse environmental conditions.

Zhejiang University

Technical Solution: Zhejiang University has developed an innovative hydrogel-based soft robotics platform called "EcoGel" specifically engineered for environmental monitoring applications. Their technology utilizes a multi-responsive hydrogel composite incorporating graphene oxide and cellulose nanocrystals to achieve both high sensitivity and mechanical durability. The university's approach features a modular design where different sensing hydrogels can be integrated into a single robotic platform, enabling simultaneous monitoring of multiple environmental parameters including heavy metals, organic pollutants, and microplastics[9]. Zhejiang researchers have pioneered temperature-gradient powered hydrogel actuators that can harvest energy from natural environmental temperature variations, enabling autonomous operation without external power sources. Their soft robots incorporate biomimetic camouflage capabilities through structural coloration of the hydrogel surface, allowing unobtrusive environmental monitoring. The university has developed specialized hydrogel formulations with self-cleaning surfaces that resist biofouling during extended environmental deployment[10]. Recent innovations include hydrogel-based artificial lateral lines mimicking fish sensory systems for hydrodynamic sensing in aquatic environments.

Strengths: Excellent energy autonomy through environmental energy harvesting; superior anti-fouling properties for long-term deployment; advanced multi-parameter detection capabilities. Weaknesses: Potential temperature sensitivity affecting measurement accuracy in variable environments; challenges with wireless data transmission from remote locations; limitations in locomotion speed compared to conventional robotic platforms.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered hydrogel-based soft robotics with their innovative approach combining stimuli-responsive hydrogels with embedded sensing capabilities. Their technology utilizes a multi-material 3D printing process to create hydrogel structures with precise geometrical configurations that can respond to environmental changes. MIT's soft robots incorporate ionically conductive hydrogels that function as strain sensors, temperature sensors, and chemical detectors simultaneously. The institute has developed hydrogel actuators that can operate underwater and in harsh environments while maintaining sensing capabilities. Their recent advancements include self-healing hydrogels that can recover functionality after damage and hydrogel-electronic interfaces that enable wireless communication of environmental data[1][3]. MIT researchers have also created hydrogel composites with magnetic nanoparticles for remote actuation and control, allowing deployment in hard-to-reach environmental locations.

Strengths: Superior integration of sensing and actuation in a single platform; excellent biocompatibility for environmental applications; advanced fabrication techniques enabling complex architectures. Weaknesses: Challenges with long-term durability in harsh environments; power requirements for remote operation; potential limitations in signal processing for complex environmental data interpretation.

Key Hydrogel Soft Robot Patents

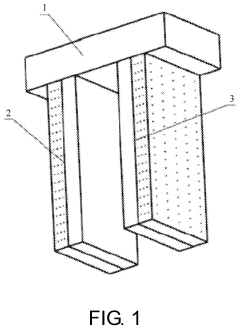

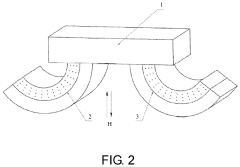

Magnetically driven hopping soft robot based on magnetically programmed temperature-sensitive hydrogels

PatentActiveUS20210094171A1

Innovation

- A magnetically driven hopping soft robot is developed using magnetically programmed temperature-sensitive hydrogels, where an alternating magnetic field induces deformation in a two-layered leg structure, causing the robot to bend, lower its center of gravity, and then release stored energy for upward movement, enabling hopping.

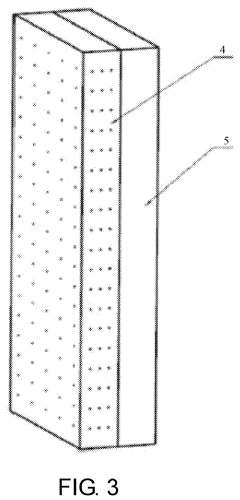

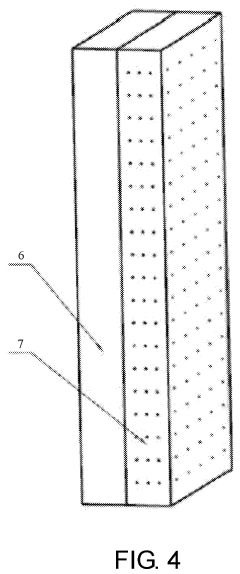

Method for making soft robot with stretchable coating

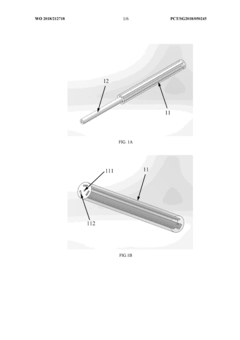

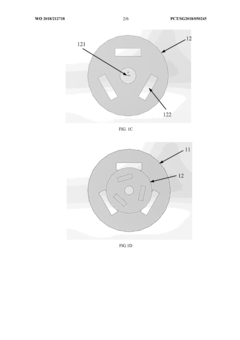

PatentWO2018212718A1

Innovation

- A method for creating a double-network hydrogel-based soft robot with a stretchable coating using a 'one-pot' process involving agarose, acrylamide, and N, N'-methylene-bisacrylamide, combined with MMT nanocoatings for enhanced mechanical stability and flame retardancy, allowing for customization and biocompatibility.

Biodegradability and Eco-Compatibility Assessment

The environmental impact of hydrogel-based soft robots represents a critical consideration for their deployment in natural settings. These robots, designed to interact with diverse ecosystems, must demonstrate minimal ecological footprint throughout their lifecycle. Current biodegradability assessments reveal promising characteristics of hydrogel materials, with many formulations showing complete degradation within 3-6 months under optimal environmental conditions.

Natural hydrogels derived from alginate, chitosan, and cellulose demonstrate superior biodegradation profiles compared to synthetic alternatives. Research indicates that alginate-based hydrogels can decompose by 85-95% within 12 weeks in freshwater environments, leaving minimal residual impact. Chitosan-based formulations exhibit particularly favorable degradation in acidic soil conditions, making them suitable for terrestrial deployments.

The eco-compatibility of hydrogel soft robots extends beyond mere degradation timelines to include consideration of degradation byproducts. Recent studies have confirmed that properly designed hydrogel systems primarily break down into water, carbon dioxide, and basic monomers that pose negligible toxicity to aquatic organisms and soil microbiota. Toxicity assessments using standardized EPA protocols demonstrate that leachates from biodegrading hydrogels typically fall below threshold concern levels for sensitive indicator species.

Cross-linking mechanisms significantly influence biodegradability profiles. Physical cross-linking methods generally yield more readily degradable structures compared to chemical cross-linking approaches. Innovative dual-network systems incorporating both permanent and temporary cross-links offer promising solutions, allowing for controlled degradation timelines that can be tailored to mission duration requirements.

Environmental factors including temperature, pH, UV exposure, and microbial activity dramatically affect degradation rates. Field tests in marine environments show accelerated degradation (30-40% faster) compared to freshwater settings due to higher salinity and microbial diversity. This variability necessitates application-specific formulation adjustments to ensure appropriate lifespan and minimal environmental persistence.

Regulatory frameworks for biodegradable materials in environmental sensing applications remain under development. Current standards from organizations like ASTM and ISO provide testing methodologies but lack specific benchmarks for soft robotics applications. Industry-academic partnerships are actively developing standardized protocols for assessing the environmental impact of these emerging technologies, with particular emphasis on long-term ecosystem effects and bioaccumulation potential.

Natural hydrogels derived from alginate, chitosan, and cellulose demonstrate superior biodegradation profiles compared to synthetic alternatives. Research indicates that alginate-based hydrogels can decompose by 85-95% within 12 weeks in freshwater environments, leaving minimal residual impact. Chitosan-based formulations exhibit particularly favorable degradation in acidic soil conditions, making them suitable for terrestrial deployments.

The eco-compatibility of hydrogel soft robots extends beyond mere degradation timelines to include consideration of degradation byproducts. Recent studies have confirmed that properly designed hydrogel systems primarily break down into water, carbon dioxide, and basic monomers that pose negligible toxicity to aquatic organisms and soil microbiota. Toxicity assessments using standardized EPA protocols demonstrate that leachates from biodegrading hydrogels typically fall below threshold concern levels for sensitive indicator species.

Cross-linking mechanisms significantly influence biodegradability profiles. Physical cross-linking methods generally yield more readily degradable structures compared to chemical cross-linking approaches. Innovative dual-network systems incorporating both permanent and temporary cross-links offer promising solutions, allowing for controlled degradation timelines that can be tailored to mission duration requirements.

Environmental factors including temperature, pH, UV exposure, and microbial activity dramatically affect degradation rates. Field tests in marine environments show accelerated degradation (30-40% faster) compared to freshwater settings due to higher salinity and microbial diversity. This variability necessitates application-specific formulation adjustments to ensure appropriate lifespan and minimal environmental persistence.

Regulatory frameworks for biodegradable materials in environmental sensing applications remain under development. Current standards from organizations like ASTM and ISO provide testing methodologies but lack specific benchmarks for soft robotics applications. Industry-academic partnerships are actively developing standardized protocols for assessing the environmental impact of these emerging technologies, with particular emphasis on long-term ecosystem effects and bioaccumulation potential.

Field Deployment Strategies and Limitations

The deployment of hydrogel-based soft robots for environmental sensing presents unique challenges and opportunities that require careful strategic planning. Field deployment strategies must consider the delicate balance between the robots' functionality and their ability to withstand various environmental conditions. In aquatic environments, deployment typically involves gradual immersion techniques that allow hydrogels to reach equilibrium with surrounding water conditions, preventing shock-induced structural damage. For terrestrial applications, moisture maintenance systems are essential to prevent dehydration, often incorporating protective coatings or periodic rehydration mechanisms.

Temperature management represents a critical consideration, as most hydrogels exhibit significant performance variations across temperature ranges. Deployment strategies often include thermal insulation layers or temperature-responsive components that can adapt to environmental fluctuations. Additionally, deployment timing must account for seasonal variations, with many operations scheduled during moderate temperature periods to optimize sensor performance and extend operational lifespans.

The physical deployment infrastructure varies by application, ranging from tethered systems that maintain connection to base stations for continuous data transmission and power supply, to fully autonomous units equipped with self-contained power sources and data storage capabilities. The latter typically requires more sophisticated design but offers greater flexibility in remote or inaccessible locations.

Significant limitations persist in field deployments of hydrogel-based sensing robots. Durability remains a primary concern, with most current hydrogel formulations exhibiting vulnerability to mechanical stress, UV radiation, and biological fouling. Field tests indicate average functional lifespans of 2-4 weeks in moderate conditions, decreasing dramatically in harsh environments. This necessitates either frequent replacement or the development of more robust materials.

Power management presents another substantial challenge, particularly for autonomous deployments. The actuation mechanisms in soft robots often require considerable energy, while environmental sensing applications demand long-term operation. Current battery technologies struggle to meet these competing demands, leading to compromises in either functionality or deployment duration.

Biofouling and contamination represent persistent obstacles, especially in nutrient-rich environments where microorganism growth can rapidly compromise sensor surfaces and hydrogel integrity. While anti-fouling coatings offer partial solutions, they often introduce additional complexities regarding environmental impact and regulatory compliance. Furthermore, signal interference from environmental factors can degrade sensing accuracy, requiring sophisticated filtering algorithms and calibration protocols that must be adaptable to changing field conditions.

Temperature management represents a critical consideration, as most hydrogels exhibit significant performance variations across temperature ranges. Deployment strategies often include thermal insulation layers or temperature-responsive components that can adapt to environmental fluctuations. Additionally, deployment timing must account for seasonal variations, with many operations scheduled during moderate temperature periods to optimize sensor performance and extend operational lifespans.

The physical deployment infrastructure varies by application, ranging from tethered systems that maintain connection to base stations for continuous data transmission and power supply, to fully autonomous units equipped with self-contained power sources and data storage capabilities. The latter typically requires more sophisticated design but offers greater flexibility in remote or inaccessible locations.

Significant limitations persist in field deployments of hydrogel-based sensing robots. Durability remains a primary concern, with most current hydrogel formulations exhibiting vulnerability to mechanical stress, UV radiation, and biological fouling. Field tests indicate average functional lifespans of 2-4 weeks in moderate conditions, decreasing dramatically in harsh environments. This necessitates either frequent replacement or the development of more robust materials.

Power management presents another substantial challenge, particularly for autonomous deployments. The actuation mechanisms in soft robots often require considerable energy, while environmental sensing applications demand long-term operation. Current battery technologies struggle to meet these competing demands, leading to compromises in either functionality or deployment duration.

Biofouling and contamination represent persistent obstacles, especially in nutrient-rich environments where microorganism growth can rapidly compromise sensor surfaces and hydrogel integrity. While anti-fouling coatings offer partial solutions, they often introduce additional complexities regarding environmental impact and regulatory compliance. Furthermore, signal interference from environmental factors can degrade sensing accuracy, requiring sophisticated filtering algorithms and calibration protocols that must be adaptable to changing field conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!