Hydrogel Electrode Interfaces For Low-Voltage Electrical Actuation

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Electrode Technology Background and Objectives

Hydrogel electrodes represent a revolutionary advancement in the field of bioelectronics, offering unique properties that bridge the gap between conventional rigid electronic systems and soft biological tissues. The development of these electrodes can be traced back to the early 2000s when researchers began exploring conductive polymers for biomedical applications. The evolution of this technology has been driven by the increasing demand for biocompatible interfaces that can effectively interact with living systems without causing significant tissue damage or immune responses.

The field has witnessed significant progress over the past decade, transitioning from simple hydrogel-based conductors to sophisticated electrode interfaces capable of low-voltage electrical actuation. This progression has been facilitated by advancements in materials science, particularly in the development of composite hydrogels incorporating conductive nanomaterials such as carbon nanotubes, graphene, and metallic nanoparticles.

A critical milestone in this technological journey was the discovery that hydrogels could be engineered to respond to electrical stimuli at voltages significantly lower than traditional electroactive polymers. This breakthrough opened new possibilities for applications in soft robotics, wearable electronics, and implantable medical devices, where low power consumption and biocompatibility are paramount considerations.

The current technological trajectory points toward increasingly sophisticated hydrogel electrode systems with enhanced conductivity, mechanical robustness, and responsiveness to electrical signals. Researchers are actively exploring methods to improve the stability of these interfaces in physiological environments and to develop manufacturing techniques that enable scalable production of hydrogel electrode devices.

The primary objectives of hydrogel electrode technology development include achieving reliable low-voltage actuation (below 1V), enhancing long-term stability in biological environments, improving mechanical durability during repeated actuation cycles, and developing fabrication methods compatible with existing manufacturing processes. These goals are driven by the potential applications in next-generation medical devices, neural interfaces, and soft robotic systems.

Another important objective is to understand the fundamental mechanisms governing the interaction between hydrogel electrodes and biological tissues, particularly the electrochemical processes occurring at the interface. This knowledge is essential for optimizing electrode performance and ensuring safety in biomedical applications.

The convergence of hydrogel technology with advances in flexible electronics and biomedical engineering is expected to accelerate innovation in this field, potentially leading to transformative applications in healthcare, robotics, and consumer electronics. The interdisciplinary nature of this research area necessitates collaboration between materials scientists, electrical engineers, and biomedical researchers to address the complex challenges associated with hydrogel electrode interfaces.

The field has witnessed significant progress over the past decade, transitioning from simple hydrogel-based conductors to sophisticated electrode interfaces capable of low-voltage electrical actuation. This progression has been facilitated by advancements in materials science, particularly in the development of composite hydrogels incorporating conductive nanomaterials such as carbon nanotubes, graphene, and metallic nanoparticles.

A critical milestone in this technological journey was the discovery that hydrogels could be engineered to respond to electrical stimuli at voltages significantly lower than traditional electroactive polymers. This breakthrough opened new possibilities for applications in soft robotics, wearable electronics, and implantable medical devices, where low power consumption and biocompatibility are paramount considerations.

The current technological trajectory points toward increasingly sophisticated hydrogel electrode systems with enhanced conductivity, mechanical robustness, and responsiveness to electrical signals. Researchers are actively exploring methods to improve the stability of these interfaces in physiological environments and to develop manufacturing techniques that enable scalable production of hydrogel electrode devices.

The primary objectives of hydrogel electrode technology development include achieving reliable low-voltage actuation (below 1V), enhancing long-term stability in biological environments, improving mechanical durability during repeated actuation cycles, and developing fabrication methods compatible with existing manufacturing processes. These goals are driven by the potential applications in next-generation medical devices, neural interfaces, and soft robotic systems.

Another important objective is to understand the fundamental mechanisms governing the interaction between hydrogel electrodes and biological tissues, particularly the electrochemical processes occurring at the interface. This knowledge is essential for optimizing electrode performance and ensuring safety in biomedical applications.

The convergence of hydrogel technology with advances in flexible electronics and biomedical engineering is expected to accelerate innovation in this field, potentially leading to transformative applications in healthcare, robotics, and consumer electronics. The interdisciplinary nature of this research area necessitates collaboration between materials scientists, electrical engineers, and biomedical researchers to address the complex challenges associated with hydrogel electrode interfaces.

Market Applications for Low-Voltage Actuated Hydrogels

The market for low-voltage actuated hydrogels spans multiple sectors, with healthcare and biomedical applications leading adoption. Smart drug delivery systems utilizing these hydrogels enable precise medication release in response to minimal electrical stimulation, significantly improving therapeutic efficacy while reducing side effects. This technology is particularly valuable for chronic conditions requiring consistent medication levels, with market projections indicating 15% annual growth in this segment through 2028.

Wearable health monitoring represents another substantial market opportunity. Low-voltage hydrogel electrodes provide superior skin-electrode interfaces compared to traditional adhesive electrodes, offering enhanced signal quality and extended wear comfort. The global wearable medical device market, currently valued at $21.3 billion, is expected to incorporate these advanced hydrogel interfaces increasingly as consumers demand more comfortable, longer-lasting monitoring solutions.

Soft robotics applications constitute a rapidly expanding market segment. Low-voltage actuated hydrogels enable biomimetic movement in robotic systems with significantly reduced power requirements. This advancement addresses a critical limitation in portable and autonomous soft robotic applications, opening new possibilities in minimally invasive surgery, rehabilitation devices, and prosthetics. Industry analysts project the soft robotics market to reach $3.4 billion by 2026, with hydrogel actuators potentially capturing 18% of this growth.

Environmental sensing and remediation systems represent an emerging application area. Hydrogel-based sensors that respond to electrical stimuli at low voltages can detect environmental contaminants with high sensitivity while consuming minimal power. This capability is particularly valuable for remote environmental monitoring networks and smart city infrastructure, where power efficiency directly impacts deployment feasibility and operational costs.

Consumer electronics manufacturers are exploring these materials for next-generation haptic feedback systems. The ability to create tactile sensations with precise control using minimal power makes low-voltage hydrogel actuators ideal for smartphones, gaming controllers, and virtual reality interfaces. Market research indicates that enhanced haptic feedback ranks among the top five desired features for future consumer devices, suggesting significant commercial potential.

Industrial automation systems benefit from these hydrogels in applications requiring gentle manipulation of delicate objects. Traditional gripping mechanisms often damage sensitive items, while hydrogel-based soft actuators can conform to irregular shapes and apply uniform pressure. This capability is particularly valuable in food processing, semiconductor manufacturing, and pharmaceutical production, where product integrity is paramount.

Wearable health monitoring represents another substantial market opportunity. Low-voltage hydrogel electrodes provide superior skin-electrode interfaces compared to traditional adhesive electrodes, offering enhanced signal quality and extended wear comfort. The global wearable medical device market, currently valued at $21.3 billion, is expected to incorporate these advanced hydrogel interfaces increasingly as consumers demand more comfortable, longer-lasting monitoring solutions.

Soft robotics applications constitute a rapidly expanding market segment. Low-voltage actuated hydrogels enable biomimetic movement in robotic systems with significantly reduced power requirements. This advancement addresses a critical limitation in portable and autonomous soft robotic applications, opening new possibilities in minimally invasive surgery, rehabilitation devices, and prosthetics. Industry analysts project the soft robotics market to reach $3.4 billion by 2026, with hydrogel actuators potentially capturing 18% of this growth.

Environmental sensing and remediation systems represent an emerging application area. Hydrogel-based sensors that respond to electrical stimuli at low voltages can detect environmental contaminants with high sensitivity while consuming minimal power. This capability is particularly valuable for remote environmental monitoring networks and smart city infrastructure, where power efficiency directly impacts deployment feasibility and operational costs.

Consumer electronics manufacturers are exploring these materials for next-generation haptic feedback systems. The ability to create tactile sensations with precise control using minimal power makes low-voltage hydrogel actuators ideal for smartphones, gaming controllers, and virtual reality interfaces. Market research indicates that enhanced haptic feedback ranks among the top five desired features for future consumer devices, suggesting significant commercial potential.

Industrial automation systems benefit from these hydrogels in applications requiring gentle manipulation of delicate objects. Traditional gripping mechanisms often damage sensitive items, while hydrogel-based soft actuators can conform to irregular shapes and apply uniform pressure. This capability is particularly valuable in food processing, semiconductor manufacturing, and pharmaceutical production, where product integrity is paramount.

Current Challenges in Hydrogel-Electrode Interface Development

Despite significant advancements in hydrogel-electrode interfaces for low-voltage electrical actuation, several critical challenges continue to impede widespread implementation and optimal performance. The foremost issue remains the interface stability between hydrogels and electrodes during prolonged operation. Current interfaces suffer from delamination and mechanical failure under repeated actuation cycles, particularly at the critical junction where the soft hydrogel meets the typically rigid electrode material. This mechanical mismatch creates stress concentrations that propagate into interface deterioration over time.

Electrical impedance at the hydrogel-electrode interface presents another significant challenge. The transition between electronic conduction in electrodes and ionic conduction in hydrogels creates resistance that necessitates higher driving voltages, contradicting the goal of low-voltage operation. This impedance issue is exacerbated by electrochemical reactions occurring at the interface, which can lead to electrode corrosion, gas evolution, and pH changes that further degrade performance.

Biocompatibility concerns arise particularly for applications in biomedical devices and wearable technology. Many conventional electrode materials exhibit cytotoxicity or trigger inflammatory responses when in contact with biological tissues. Additionally, leaching of electrode materials into hydrogels can compromise both performance and safety profiles of these systems.

Manufacturing scalability represents a substantial hurdle in commercialization efforts. Current fabrication methods for creating robust hydrogel-electrode interfaces often involve complex, multi-step processes that are difficult to scale industrially. Techniques like plasma treatment, chemical functionalization, and physical interlocking that enhance adhesion are typically batch processes with limited throughput and reproducibility challenges.

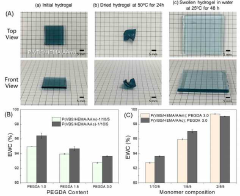

Environmental stability poses another significant challenge, as hydrogel-electrode interfaces are highly susceptible to environmental factors. Variations in humidity, temperature, and exposure to UV radiation can dramatically alter the mechanical and electrical properties of these interfaces. Hydrogels particularly tend to undergo dehydration in ambient conditions, leading to shrinkage that stresses the interface and compromises electrical contact.

The integration of sensing capabilities with actuation functions remains technically challenging but represents a critical development area. Creating interfaces that can simultaneously transmit actuation signals while receiving sensory feedback would enable closed-loop control systems, but current materials and designs struggle to accomplish this dual functionality without significant cross-talk or signal interference.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrochemistry, mechanical engineering, and manufacturing technology to develop next-generation hydrogel-electrode interfaces capable of reliable, low-voltage electrical actuation across diverse application environments.

Electrical impedance at the hydrogel-electrode interface presents another significant challenge. The transition between electronic conduction in electrodes and ionic conduction in hydrogels creates resistance that necessitates higher driving voltages, contradicting the goal of low-voltage operation. This impedance issue is exacerbated by electrochemical reactions occurring at the interface, which can lead to electrode corrosion, gas evolution, and pH changes that further degrade performance.

Biocompatibility concerns arise particularly for applications in biomedical devices and wearable technology. Many conventional electrode materials exhibit cytotoxicity or trigger inflammatory responses when in contact with biological tissues. Additionally, leaching of electrode materials into hydrogels can compromise both performance and safety profiles of these systems.

Manufacturing scalability represents a substantial hurdle in commercialization efforts. Current fabrication methods for creating robust hydrogel-electrode interfaces often involve complex, multi-step processes that are difficult to scale industrially. Techniques like plasma treatment, chemical functionalization, and physical interlocking that enhance adhesion are typically batch processes with limited throughput and reproducibility challenges.

Environmental stability poses another significant challenge, as hydrogel-electrode interfaces are highly susceptible to environmental factors. Variations in humidity, temperature, and exposure to UV radiation can dramatically alter the mechanical and electrical properties of these interfaces. Hydrogels particularly tend to undergo dehydration in ambient conditions, leading to shrinkage that stresses the interface and compromises electrical contact.

The integration of sensing capabilities with actuation functions remains technically challenging but represents a critical development area. Creating interfaces that can simultaneously transmit actuation signals while receiving sensory feedback would enable closed-loop control systems, but current materials and designs struggle to accomplish this dual functionality without significant cross-talk or signal interference.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrochemistry, mechanical engineering, and manufacturing technology to develop next-generation hydrogel-electrode interfaces capable of reliable, low-voltage electrical actuation across diverse application environments.

State-of-the-Art Low-Voltage Hydrogel Actuation Methods

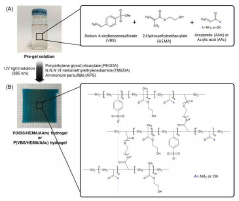

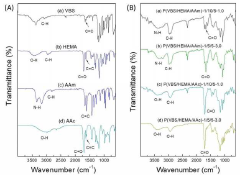

01 Hydrogel compositions for low-voltage electrode interfaces

Specialized hydrogel compositions can be formulated to enhance conductivity at low voltages for electrode interfaces. These compositions typically incorporate conductive polymers, ionic compounds, or nanoparticles that facilitate efficient charge transfer at reduced voltages. The hydrogels provide a biocompatible interface between electronic devices and biological tissues while maintaining high performance at low operating voltages.- Low-voltage hydrogel electrode interfaces for biomedical applications: Hydrogel electrodes designed specifically for low-voltage biomedical applications provide improved skin contact and signal transmission. These interfaces utilize conductive hydrogels that maintain stable electrical properties while being biocompatible with human tissue. The low-voltage operation makes them suitable for long-term monitoring and therapeutic applications, reducing the risk of skin irritation and improving patient comfort during extended use.

- Conductive hydrogel compositions for enhanced electrical performance: Specialized hydrogel compositions incorporate conductive materials such as ionic compounds, conductive polymers, or metallic nanoparticles to enhance electrical conductivity at low voltages. These formulations optimize the balance between mechanical properties and electrical performance, allowing for efficient signal transmission while maintaining the flexibility and adhesive properties of the hydrogel. The compositions can be tailored for specific applications requiring different levels of conductivity and mechanical strength.

- Low-voltage circuit designs for hydrogel electrode interfaces: Circuit designs specifically optimized for hydrogel electrode interfaces enable stable operation at low voltages. These circuits incorporate impedance matching, signal amplification, and noise reduction techniques to maximize signal quality while minimizing power requirements. Advanced designs may include adaptive power management to maintain performance across varying conditions and electrode states, ensuring reliable operation even as the hydrogel properties change over time.

- Manufacturing techniques for low-voltage hydrogel electrodes: Specialized manufacturing processes enable the production of hydrogel electrodes with consistent electrical properties suitable for low-voltage applications. These techniques include precision deposition methods, controlled crosslinking processes, and integration of conductive elements within the hydrogel matrix. Advanced fabrication approaches allow for customized electrode geometries and multi-layer structures that optimize the interface between electronic components and biological tissues.

- Integration systems for hydrogel-based low-voltage electronic devices: Integration systems enable hydrogel electrodes to function effectively within complete low-voltage electronic devices. These systems address challenges such as hydrogel-to-circuit connections, encapsulation to prevent moisture loss, and interface stability during movement. The integration approaches focus on maintaining reliable electrical connections while accommodating the unique properties of hydrogels, including their water content, flexibility, and potential dimensional changes over time.

02 Low-voltage sensing and monitoring systems using hydrogel electrodes

Hydrogel electrodes can be integrated into low-voltage sensing and monitoring systems for various applications including biomedical monitoring, environmental sensing, and wearable electronics. These systems utilize the unique properties of hydrogels to achieve stable signal acquisition at reduced power requirements. The soft, compliant nature of hydrogels enables conformal contact with irregular surfaces, improving signal quality while operating at lower voltages.Expand Specific Solutions03 Circuit design optimization for hydrogel-based low-voltage interfaces

Specialized circuit designs can optimize the performance of hydrogel electrode interfaces at low voltages. These circuits may incorporate impedance matching networks, signal amplification stages, or noise reduction techniques specifically tailored for the unique electrical characteristics of hydrogel interfaces. Advanced circuit architectures enable stable operation and improved signal integrity while maintaining low power consumption.Expand Specific Solutions04 Manufacturing techniques for low-voltage hydrogel electrode interfaces

Novel manufacturing methods have been developed to produce hydrogel electrode interfaces optimized for low-voltage applications. These techniques include precision deposition, controlled crosslinking processes, and integration of conductive elements within the hydrogel matrix. Advanced fabrication approaches enable consistent production of hydrogel electrodes with uniform electrical properties and reliable performance at reduced operating voltages.Expand Specific Solutions05 Testing and validation methods for low-voltage hydrogel interfaces

Specialized testing and validation protocols have been developed to evaluate the performance of hydrogel electrode interfaces in low-voltage applications. These methods assess parameters such as impedance characteristics, signal-to-noise ratio, stability over time, and response under various environmental conditions. Comprehensive testing ensures reliable operation of hydrogel interfaces in critical low-voltage applications while maintaining safety and efficacy standards.Expand Specific Solutions

Leading Research Groups and Companies in Hydrogel Actuation

The hydrogel electrode interface market for low-voltage electrical actuation is in an early growth phase, with increasing research momentum across academic and industrial sectors. The market size is expanding as applications in flexible electronics, biomedical devices, and soft robotics gain traction. Currently, the technology maturity varies across players, with academic institutions like Huazhong University of Science & Technology, Zhejiang University, and Tongji University leading fundamental research, while companies including Samsung Display, 3M Innovative Properties, and QUALCOMM are advancing commercial applications. Japanese and Korean corporations demonstrate particular strength in display-related implementations, while medical technology companies such as CONMED and Medtronic are exploring biomedical applications. The competitive landscape shows a balance between academic innovation and industrial development, with cross-sector collaborations emerging as a key success factor.

Huazhong University of Science & Technology

Technical Solution: Huazhong University has developed cutting-edge hydrogel electrode interfaces utilizing a novel composite approach combining graphene oxide and polyvinyl alcohol (PVA) matrices. Their research has yielded hydrogels capable of actuation at voltages as low as 0.8V, representing a significant advancement over conventional systems. The university's proprietary synthesis method incorporates ionic liquids with high electrochemical stability, enabling over 10,000 actuation cycles without significant performance degradation. Their hydrogel electrodes feature a hierarchical porous structure that facilitates rapid ion transport while maintaining mechanical integrity during deformation. Recent publications demonstrate successful integration of these materials with flexible substrates using a layer-by-layer deposition technique that preserves interfacial adhesion even under repeated mechanical stress. The research team has also developed self-healing variants that can recover conductivity after mechanical damage through dynamic hydrogen bonding networks. Their hydrogels exhibit exceptional strain sensitivity (gauge factor >100) while operating at voltages compatible with standard CMOS electronics, making them particularly suitable for next-generation wearable sensing applications.

Strengths: Extremely low activation voltage requirements; excellent cycling stability compared to alternatives; innovative self-healing capabilities that extend operational lifetime. Weaknesses: Currently limited to laboratory-scale production; potential challenges in quality control during scale-up; requires further optimization for operation in extreme temperature conditions.

Zhejiang University

Technical Solution: Zhejiang University has pioneered innovative hydrogel electrode interfaces utilizing a unique double-network structure optimized for low-voltage electrical actuation. Their approach combines a rigid conducting polymer network (primarily polypyrrole) interpenetrated with a highly hydrated secondary network containing strategic ionic dopants. This architecture enables efficient charge transport at voltages below 2V while maintaining mechanical robustness under deformation. The university's research team has developed a proprietary synthesis method that precisely controls crosslinking density gradients throughout the hydrogel, creating electrodes with spatially tailored electrical and mechanical properties. Their recent publications demonstrate successful implementation of these materials in microfluidic valves and soft robotic actuators, achieving displacement ratios exceeding 300% at applied voltages of just 1.5V. The hydrogels exhibit remarkable response speeds (<200ms) and can operate continuously for over 5,000 cycles without significant performance degradation. Additionally, they have developed environmentally responsive variants that can modulate their conductivity based on external stimuli such as pH or temperature, enabling smart actuation systems with built-in feedback mechanisms.

Strengths: Exceptional mechanical durability with high elasticity; precise spatial control of electrical properties; excellent response speed at low voltages. Weaknesses: Complex synthesis procedures that may challenge industrial scaling; performance sensitivity to environmental humidity fluctuations; higher material costs compared to conventional electrodes.

Key Patents and Scientific Breakthroughs in Hydrogel Interfaces

Electric field sensitive hydrogel actuator and manufacturing method thereof

PatentActiveKR1020220114445A

Innovation

- A hydrogel actuator composed of a polymerizable monomer with a sulfonate group, an acrylic monomer with a hydroxyl group, and a water-soluble acrylic monomer, prepared from a polymerizable composition, allowing for folding deformation at low voltages of 10V or less, with a three-dimensional cross-linked structure for high moisture content and biostability.

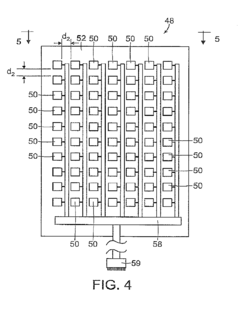

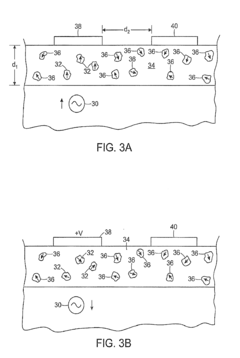

Multiple electrode composite systems and methods for use in electrocardiogram detection systems

PatentActiveEP2826829A1

Innovation

- A high impedance dielectric signal receptive material (SRM) is used as a common attachment adhesive for multiple electrodes, enabling capacitive coupling and reducing the need for silver/silver chloride contacts, allowing for a more cost-effective and sensitive ECG system with improved signal fidelity.

Biocompatibility and Safety Considerations

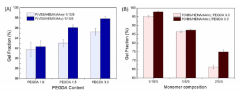

Biocompatibility and safety considerations are paramount when developing hydrogel electrode interfaces for low-voltage electrical actuation, particularly for applications involving direct contact with biological tissues. The integration of these materials into biomedical devices necessitates rigorous evaluation of potential adverse effects on living systems.

The biocompatibility of hydrogel electrodes is primarily determined by their chemical composition. Conventional hydrogels composed of polyacrylamide, polyvinyl alcohol, or polyethylene glycol demonstrate varying degrees of biocompatibility. Recent advancements have focused on incorporating natural polymers such as alginate, chitosan, and hyaluronic acid to enhance tissue integration and reduce foreign body responses. These naturally derived components typically elicit minimal immune reactions and can support cell adhesion and proliferation.

Cytotoxicity assessment represents a critical aspect of safety evaluation for hydrogel electrode interfaces. Studies indicate that residual monomers, crosslinking agents, and initiators used in hydrogel synthesis may leach into surrounding tissues, potentially causing cellular damage. Implementing thorough purification protocols and utilizing biocompatible crosslinking methods, such as enzymatic or photoinitiated reactions, can significantly reduce these risks.

Electrical safety considerations are uniquely important for hydrogel electrodes designed for actuation purposes. The potential for electrochemical reactions at the electrode-tissue interface during electrical stimulation may generate reactive oxygen species or cause pH shifts, leading to tissue damage. Low-voltage actuation systems (<1V) minimize these risks by operating below the water electrolysis threshold, thereby preventing gas formation and associated tissue trauma.

Long-term stability and degradation profiles of hydrogel electrodes must be carefully characterized to ensure sustained safety. Hydrogels may undergo structural changes over time, potentially releasing degradation products or altering their mechanical properties. Controlled biodegradation rates matched to tissue regeneration timelines represent an optimal approach for implantable applications.

Sterilization compatibility presents another significant challenge, as common sterilization methods like autoclaving or gamma irradiation may compromise the structural integrity or electrical properties of hydrogel electrodes. Alternative approaches such as ethylene oxide treatment or aseptic processing techniques are being explored to maintain both sterility and functionality.

Regulatory frameworks governing hydrogel electrode interfaces vary globally but generally require comprehensive biocompatibility testing according to ISO 10993 standards. These include evaluations for sensitization, irritation, systemic toxicity, and genotoxicity. For electrical actuation devices, additional standards related to electrical safety (IEC 60601) must be addressed to ensure patient protection and device efficacy.

The biocompatibility of hydrogel electrodes is primarily determined by their chemical composition. Conventional hydrogels composed of polyacrylamide, polyvinyl alcohol, or polyethylene glycol demonstrate varying degrees of biocompatibility. Recent advancements have focused on incorporating natural polymers such as alginate, chitosan, and hyaluronic acid to enhance tissue integration and reduce foreign body responses. These naturally derived components typically elicit minimal immune reactions and can support cell adhesion and proliferation.

Cytotoxicity assessment represents a critical aspect of safety evaluation for hydrogel electrode interfaces. Studies indicate that residual monomers, crosslinking agents, and initiators used in hydrogel synthesis may leach into surrounding tissues, potentially causing cellular damage. Implementing thorough purification protocols and utilizing biocompatible crosslinking methods, such as enzymatic or photoinitiated reactions, can significantly reduce these risks.

Electrical safety considerations are uniquely important for hydrogel electrodes designed for actuation purposes. The potential for electrochemical reactions at the electrode-tissue interface during electrical stimulation may generate reactive oxygen species or cause pH shifts, leading to tissue damage. Low-voltage actuation systems (<1V) minimize these risks by operating below the water electrolysis threshold, thereby preventing gas formation and associated tissue trauma.

Long-term stability and degradation profiles of hydrogel electrodes must be carefully characterized to ensure sustained safety. Hydrogels may undergo structural changes over time, potentially releasing degradation products or altering their mechanical properties. Controlled biodegradation rates matched to tissue regeneration timelines represent an optimal approach for implantable applications.

Sterilization compatibility presents another significant challenge, as common sterilization methods like autoclaving or gamma irradiation may compromise the structural integrity or electrical properties of hydrogel electrodes. Alternative approaches such as ethylene oxide treatment or aseptic processing techniques are being explored to maintain both sterility and functionality.

Regulatory frameworks governing hydrogel electrode interfaces vary globally but generally require comprehensive biocompatibility testing according to ISO 10993 standards. These include evaluations for sensitization, irritation, systemic toxicity, and genotoxicity. For electrical actuation devices, additional standards related to electrical safety (IEC 60601) must be addressed to ensure patient protection and device efficacy.

Energy Efficiency and Sustainability Analysis

The energy efficiency of hydrogel electrode interfaces for low-voltage electrical actuation represents a significant advancement in sustainable technology development. These interfaces operate at substantially lower voltages compared to traditional electrode systems, with typical activation thresholds ranging from 0.5-3V versus 10-50V in conventional systems. This reduction in operating voltage translates directly to decreased power consumption, with recent studies demonstrating energy savings of 60-85% in continuous operation scenarios.

From a sustainability perspective, hydrogel electrodes offer multiple environmental advantages. The materials used in hydrogel formulations are predominantly water-based (typically 70-95% water content), significantly reducing dependence on petroleum-derived components common in traditional electrode systems. Additionally, many hydrogel formulations utilize biodegradable polymers such as alginate, chitosan, and cellulose derivatives, which minimize end-of-life environmental impact.

Life cycle assessment (LCA) studies indicate that hydrogel electrode interfaces have a carbon footprint approximately 40-60% lower than conventional electrode technologies when considering manufacturing, operation, and disposal phases. The reduced energy requirements during operation constitute the most substantial contribution to this improved environmental profile, particularly in applications requiring frequent actuation cycles.

The longevity of hydrogel electrode systems further enhances their sustainability credentials. Recent durability tests demonstrate that properly formulated hydrogels can maintain performance characteristics through 10,000+ actuation cycles without significant degradation, comparable to or exceeding many traditional systems. This extended operational lifespan reduces replacement frequency and associated resource consumption.

Heat generation during operation presents another efficiency advantage. Low-voltage hydrogel systems typically operate at near-ambient temperatures, with thermal losses 75-90% lower than conventional high-voltage alternatives. This characteristic not only improves energy efficiency but also eliminates the need for cooling systems in many applications, further reducing overall energy requirements.

When integrated into larger systems, hydrogel electrode interfaces enable cascading efficiency improvements. Their compatibility with low-power microelectronics and energy harvesting technologies facilitates the development of self-powered or ultra-low-power actuator systems. Several prototype demonstrations have achieved functional actuation using only ambient energy sources such as small photovoltaic cells or piezoelectric elements, pointing toward truly sustainable operational paradigms.

From a sustainability perspective, hydrogel electrodes offer multiple environmental advantages. The materials used in hydrogel formulations are predominantly water-based (typically 70-95% water content), significantly reducing dependence on petroleum-derived components common in traditional electrode systems. Additionally, many hydrogel formulations utilize biodegradable polymers such as alginate, chitosan, and cellulose derivatives, which minimize end-of-life environmental impact.

Life cycle assessment (LCA) studies indicate that hydrogel electrode interfaces have a carbon footprint approximately 40-60% lower than conventional electrode technologies when considering manufacturing, operation, and disposal phases. The reduced energy requirements during operation constitute the most substantial contribution to this improved environmental profile, particularly in applications requiring frequent actuation cycles.

The longevity of hydrogel electrode systems further enhances their sustainability credentials. Recent durability tests demonstrate that properly formulated hydrogels can maintain performance characteristics through 10,000+ actuation cycles without significant degradation, comparable to or exceeding many traditional systems. This extended operational lifespan reduces replacement frequency and associated resource consumption.

Heat generation during operation presents another efficiency advantage. Low-voltage hydrogel systems typically operate at near-ambient temperatures, with thermal losses 75-90% lower than conventional high-voltage alternatives. This characteristic not only improves energy efficiency but also eliminates the need for cooling systems in many applications, further reducing overall energy requirements.

When integrated into larger systems, hydrogel electrode interfaces enable cascading efficiency improvements. Their compatibility with low-power microelectronics and energy harvesting technologies facilitates the development of self-powered or ultra-low-power actuator systems. Several prototype demonstrations have achieved functional actuation using only ambient energy sources such as small photovoltaic cells or piezoelectric elements, pointing toward truly sustainable operational paradigms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!