Hydrogel Hybrid Drives Combining Pneumatic And Ionic Actuation

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Hybrid Drives Background and Objectives

Hydrogel hybrid drives represent a revolutionary advancement in soft robotics, combining the unique properties of hydrogels with dual actuation mechanisms—pneumatic and ionic—to create more versatile and efficient soft actuators. The evolution of this technology can be traced back to the early development of electroactive polymers (EAPs) in the 1990s, which demonstrated the potential for materials to respond to electrical stimuli. By the early 2000s, ionic polymer-metal composites (IPMCs) emerged as a promising subset of EAPs, capable of bending in response to electrical fields.

The technological trajectory shifted significantly around 2010 with increased research into hydrogels—three-dimensional networks of hydrophilic polymers capable of absorbing large quantities of water. These materials exhibited remarkable properties including biocompatibility, flexibility, and responsiveness to various stimuli. Concurrently, pneumatic soft actuators were being developed independently, utilizing air pressure to create movement in soft structures.

The convergence of these separate technological paths—ionic actuation and pneumatic systems—into hybrid hydrogel drives represents a natural evolution aimed at overcoming the limitations of each individual approach. This hybridization began gaining significant attention around 2015, with researchers seeking to combine the precise control of ionic actuation with the force generation capabilities of pneumatic systems.

The primary objective of hydrogel hybrid drive technology is to develop actuators that can operate across multiple scales with enhanced performance metrics including force output, speed, efficiency, and controllability. These systems aim to mimic the sophisticated movements found in biological organisms while maintaining the robustness required for practical applications.

Current research goals include improving response times, which have traditionally been slower in hydrogel-based systems compared to conventional actuators. Additionally, researchers are working to enhance the durability of these systems, as hydrogels have historically suffered from degradation issues during repeated actuation cycles.

Another critical objective is the miniaturization of hydrogel hybrid drives to enable applications in microrobotics and biomedical devices, where space constraints are significant. This includes developing fabrication techniques that allow for precise control over material properties at microscale dimensions.

Energy efficiency represents another key goal, with efforts focused on reducing the power requirements for actuation while maintaining or improving performance characteristics. This is particularly important for potential applications in portable or implantable devices where energy availability is limited.

The ultimate technological objective is to create fully integrated, autonomous soft robotic systems that can sense their environment, process information, and respond appropriately through controlled actuation—all while maintaining the inherent advantages of soft materials including safety, adaptability, and compliance.

The technological trajectory shifted significantly around 2010 with increased research into hydrogels—three-dimensional networks of hydrophilic polymers capable of absorbing large quantities of water. These materials exhibited remarkable properties including biocompatibility, flexibility, and responsiveness to various stimuli. Concurrently, pneumatic soft actuators were being developed independently, utilizing air pressure to create movement in soft structures.

The convergence of these separate technological paths—ionic actuation and pneumatic systems—into hybrid hydrogel drives represents a natural evolution aimed at overcoming the limitations of each individual approach. This hybridization began gaining significant attention around 2015, with researchers seeking to combine the precise control of ionic actuation with the force generation capabilities of pneumatic systems.

The primary objective of hydrogel hybrid drive technology is to develop actuators that can operate across multiple scales with enhanced performance metrics including force output, speed, efficiency, and controllability. These systems aim to mimic the sophisticated movements found in biological organisms while maintaining the robustness required for practical applications.

Current research goals include improving response times, which have traditionally been slower in hydrogel-based systems compared to conventional actuators. Additionally, researchers are working to enhance the durability of these systems, as hydrogels have historically suffered from degradation issues during repeated actuation cycles.

Another critical objective is the miniaturization of hydrogel hybrid drives to enable applications in microrobotics and biomedical devices, where space constraints are significant. This includes developing fabrication techniques that allow for precise control over material properties at microscale dimensions.

Energy efficiency represents another key goal, with efforts focused on reducing the power requirements for actuation while maintaining or improving performance characteristics. This is particularly important for potential applications in portable or implantable devices where energy availability is limited.

The ultimate technological objective is to create fully integrated, autonomous soft robotic systems that can sense their environment, process information, and respond appropriately through controlled actuation—all while maintaining the inherent advantages of soft materials including safety, adaptability, and compliance.

Market Applications for Pneumatic-Ionic Hybrid Actuators

The pneumatic-ionic hybrid actuator technology presents significant market opportunities across multiple industries due to its unique combination of soft robotics capabilities and precise control mechanisms. The healthcare sector stands as a primary beneficiary, with applications in minimally invasive surgery where these actuators can provide gentle tissue manipulation with enhanced precision. Rehabilitation devices utilizing this technology offer adaptive assistance that can adjust force application based on patient progress, potentially revolutionizing physical therapy practices.

In industrial automation, these hybrid actuators address the growing demand for collaborative robots that can safely interact with human workers. Their inherent compliance and controllable stiffness enable the development of end effectors that can handle delicate objects without damage while maintaining positional accuracy. This capability is particularly valuable in electronics assembly, food processing, and pharmaceutical manufacturing where traditional rigid grippers often struggle.

The consumer electronics market presents another substantial opportunity, particularly in haptic feedback systems. The dual actuation mechanism allows for more nuanced tactile sensations in virtual reality controllers, gaming peripherals, and touchscreen devices. Market analysts project that enhanced haptic feedback technologies will become increasingly important as immersive computing platforms gain mainstream adoption.

Environmental monitoring and sampling systems represent an emerging application area where the ability to operate in aqueous environments provides a distinct advantage. Underwater exploration vehicles equipped with these actuators can navigate complex marine environments while collecting samples with minimal disruption to fragile ecosystems.

Wearable technology constitutes a rapidly expanding market segment where pneumatic-ionic hybrid actuators offer unique benefits. Smart clothing incorporating these actuators can provide posture correction, athletic performance enhancement, and even medical monitoring capabilities. The low power requirements for maintaining static positions make them particularly suitable for all-day wearable applications.

The aerospace and defense sectors are exploring applications in morphing structures and adaptive control surfaces. The ability to change shape and stiffness on demand enables aircraft components that can optimize performance across different flight conditions, potentially improving fuel efficiency and maneuverability.

Agricultural technology represents another promising market, with applications in selective harvesting systems that can handle delicate produce without damage. The combination of gentle gripping force and precise control allows for automated harvesting of fruits and vegetables that previously required human pickers due to their fragility.

In industrial automation, these hybrid actuators address the growing demand for collaborative robots that can safely interact with human workers. Their inherent compliance and controllable stiffness enable the development of end effectors that can handle delicate objects without damage while maintaining positional accuracy. This capability is particularly valuable in electronics assembly, food processing, and pharmaceutical manufacturing where traditional rigid grippers often struggle.

The consumer electronics market presents another substantial opportunity, particularly in haptic feedback systems. The dual actuation mechanism allows for more nuanced tactile sensations in virtual reality controllers, gaming peripherals, and touchscreen devices. Market analysts project that enhanced haptic feedback technologies will become increasingly important as immersive computing platforms gain mainstream adoption.

Environmental monitoring and sampling systems represent an emerging application area where the ability to operate in aqueous environments provides a distinct advantage. Underwater exploration vehicles equipped with these actuators can navigate complex marine environments while collecting samples with minimal disruption to fragile ecosystems.

Wearable technology constitutes a rapidly expanding market segment where pneumatic-ionic hybrid actuators offer unique benefits. Smart clothing incorporating these actuators can provide posture correction, athletic performance enhancement, and even medical monitoring capabilities. The low power requirements for maintaining static positions make them particularly suitable for all-day wearable applications.

The aerospace and defense sectors are exploring applications in morphing structures and adaptive control surfaces. The ability to change shape and stiffness on demand enables aircraft components that can optimize performance across different flight conditions, potentially improving fuel efficiency and maneuverability.

Agricultural technology represents another promising market, with applications in selective harvesting systems that can handle delicate produce without damage. The combination of gentle gripping force and precise control allows for automated harvesting of fruits and vegetables that previously required human pickers due to their fragility.

Current Limitations in Hydrogel Actuation Technologies

Despite significant advancements in hydrogel actuation technologies, several critical limitations persist that hinder their widespread application in hybrid pneumatic-ionic actuation systems. The primary challenge remains the inherent trade-off between mechanical strength and actuation performance. Conventional hydrogels with high water content demonstrate excellent ionic conductivity but suffer from poor mechanical robustness, limiting their durability in repeated actuation cycles.

Response time presents another significant barrier, particularly in pneumatic-ionic hybrid systems. While pneumatic actuation offers rapid response, the ionic component typically exhibits slower kinetics due to the time required for ion diffusion through the hydrogel matrix. This disparity creates synchronization challenges when attempting to integrate both actuation mechanisms into a cohesive system.

Energy efficiency remains suboptimal in current hydrogel actuators. Ionic actuation requires continuous power input to maintain deformation, resulting in high energy consumption during prolonged operation. Additionally, the conversion efficiency from electrical to mechanical energy is relatively low compared to conventional actuators, typically ranging from 2-5% in most hydrogel-based systems.

Fabrication complexity presents substantial challenges for scalable production. Current manufacturing processes for sophisticated hydrogel hybrid actuators often involve multi-step procedures requiring precise control over polymerization conditions, crosslinking density, and incorporation of functional components. These complex fabrication protocols limit mass production capabilities and increase production costs.

Environmental sensitivity constitutes another significant limitation. Hydrogel performance is highly dependent on environmental conditions such as temperature, humidity, and pH. This sensitivity leads to inconsistent actuation behavior across varying operating environments, restricting their application in uncontrolled settings.

Biocompatibility concerns arise when considering long-term implantable applications. While many hydrogels demonstrate good short-term biocompatibility, extended exposure can lead to inflammatory responses or degradation of the material, compromising both safety and functionality.

Integration challenges with conventional electronics and control systems persist due to the fundamentally different operating principles between electronic components and hydrogel actuators. The interface between rigid electronics and soft hydrogels creates mechanical mismatches that can lead to delamination or failure during operation.

Standardization remains underdeveloped in the field, with various research groups employing different testing protocols and performance metrics. This lack of standardization complicates direct comparison between different hydrogel actuation technologies and hinders the establishment of industry benchmarks for performance evaluation.

Response time presents another significant barrier, particularly in pneumatic-ionic hybrid systems. While pneumatic actuation offers rapid response, the ionic component typically exhibits slower kinetics due to the time required for ion diffusion through the hydrogel matrix. This disparity creates synchronization challenges when attempting to integrate both actuation mechanisms into a cohesive system.

Energy efficiency remains suboptimal in current hydrogel actuators. Ionic actuation requires continuous power input to maintain deformation, resulting in high energy consumption during prolonged operation. Additionally, the conversion efficiency from electrical to mechanical energy is relatively low compared to conventional actuators, typically ranging from 2-5% in most hydrogel-based systems.

Fabrication complexity presents substantial challenges for scalable production. Current manufacturing processes for sophisticated hydrogel hybrid actuators often involve multi-step procedures requiring precise control over polymerization conditions, crosslinking density, and incorporation of functional components. These complex fabrication protocols limit mass production capabilities and increase production costs.

Environmental sensitivity constitutes another significant limitation. Hydrogel performance is highly dependent on environmental conditions such as temperature, humidity, and pH. This sensitivity leads to inconsistent actuation behavior across varying operating environments, restricting their application in uncontrolled settings.

Biocompatibility concerns arise when considering long-term implantable applications. While many hydrogels demonstrate good short-term biocompatibility, extended exposure can lead to inflammatory responses or degradation of the material, compromising both safety and functionality.

Integration challenges with conventional electronics and control systems persist due to the fundamentally different operating principles between electronic components and hydrogel actuators. The interface between rigid electronics and soft hydrogels creates mechanical mismatches that can lead to delamination or failure during operation.

Standardization remains underdeveloped in the field, with various research groups employing different testing protocols and performance metrics. This lack of standardization complicates direct comparison between different hydrogel actuation technologies and hinders the establishment of industry benchmarks for performance evaluation.

Existing Pneumatic-Ionic Integration Approaches

01 Hydrogel-polymer hybrid actuators

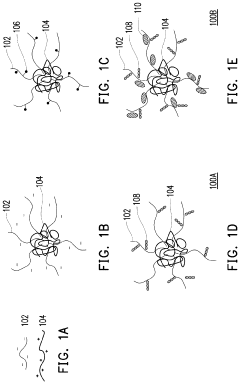

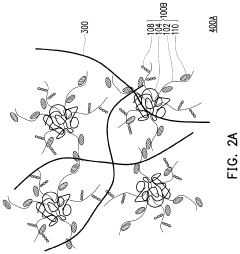

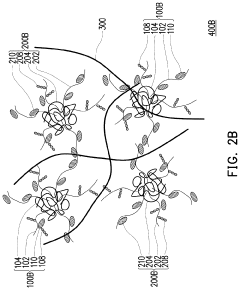

Hybrid actuators combining hydrogels with polymers create responsive materials that can change shape or generate movement when exposed to stimuli. These composites leverage the swelling properties of hydrogels with the mechanical strength of polymers to produce controlled actuation. The hybrid structure allows for improved durability and performance in applications requiring mechanical movement or force generation.- Hydrogel-based actuators for biomimetic applications: Hydrogel hybrid materials can be engineered to mimic natural muscle movements through controlled actuation mechanisms. These biomimetic actuators respond to various stimuli such as temperature, pH, or electrical signals to produce mechanical motion. The hybrid structure combines hydrogels with supporting materials to enhance performance characteristics including response time, force generation, and durability. These systems find applications in soft robotics, artificial muscles, and biomechanical devices where natural-like movement is desired.

- Smart hydrogel composites with electrical responsiveness: Electrically responsive hydrogel hybrid materials incorporate conductive elements to enable actuation through applied electrical fields. These composites typically combine hydrogels with conductive polymers, carbon-based materials, or metallic nanoparticles to create systems that can transform electrical energy into mechanical work. The electrical stimulation causes changes in the hydrogel matrix through mechanisms such as electro-osmosis, electrophoresis, or localized heating, resulting in controlled deformation or movement. These materials offer advantages in precise control, remote operation, and integration with electronic systems.

- Temperature-responsive hydrogel hybrid actuators: Temperature-sensitive hydrogel hybrids utilize thermally responsive polymers that undergo significant volume changes at specific transition temperatures. These materials can be designed with precise thermal thresholds to trigger actuation in response to environmental temperature changes or external heating. The hybrid structure often incorporates materials with different thermal expansion properties to enhance the directional movement or force generation. Applications include self-regulating valves, thermal switches, and adaptive medical devices that respond to body temperature changes.

- Multi-responsive hydrogel systems for complex actuation: Advanced hydrogel hybrid actuators can respond to multiple stimuli simultaneously or sequentially, enabling complex movement patterns and functions. These systems integrate different responsive components that react to combinations of pH, temperature, light, magnetic fields, or biochemical triggers. The multi-responsive nature allows for programmable actuation sequences and adaptive behaviors based on changing environmental conditions. Such sophisticated hydrogel hybrids are particularly valuable in applications requiring autonomous operation or adaptability to variable conditions.

- Hydrogel hybrid actuators for medical and therapeutic applications: Hydrogel hybrid actuators designed specifically for biomedical applications combine biocompatible materials with controlled actuation properties. These systems can be used for drug delivery, tissue engineering, and therapeutic devices where gentle mechanical forces are required. The hydrogel components provide a biocompatible interface while the hybrid structure enables the necessary mechanical functionality. Some designs incorporate biodegradable elements for temporary implants or stimulus-responsive components that can be triggered by specific physiological conditions to perform therapeutic functions within the body.

02 Stimuli-responsive hydrogel actuation mechanisms

Hydrogels can be engineered to respond to various environmental stimuli such as temperature, pH, light, or electrical signals. These stimuli trigger conformational changes in the hydrogel network, causing expansion, contraction, or bending motions that can be harnessed for actuation purposes. The response mechanisms can be tailored by incorporating specific functional groups or nanoparticles into the hydrogel matrix.Expand Specific Solutions03 Biomedical applications of hydrogel actuators

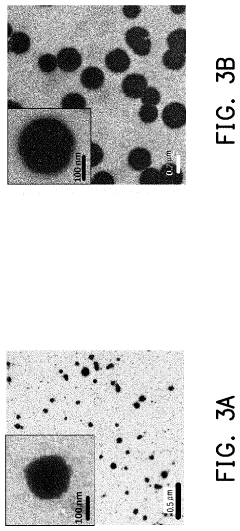

Hydrogel-based actuators have significant applications in biomedical fields, including drug delivery systems, tissue engineering, and soft robotics for medical interventions. These actuators can mimic biological tissues and respond to physiological conditions, enabling controlled release of therapeutic agents or facilitating minimally invasive procedures. Their biocompatibility makes them particularly suitable for in vivo applications.Expand Specific Solutions04 Nanocomposite hydrogels for enhanced actuation

Incorporating nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles into hydrogels creates nanocomposites with enhanced actuation properties. These additives improve mechanical strength, electrical conductivity, and responsiveness to stimuli. The resulting hybrid materials exhibit faster response times, greater actuation forces, and improved durability compared to conventional hydrogels.Expand Specific Solutions05 Soft robotic systems using hydrogel actuators

Hydrogel-based actuators enable the development of soft robotic systems that can perform complex movements with flexibility and adaptability. These systems utilize the controlled deformation of hydrogels to create biomimetic motions, gripping mechanisms, or locomotion capabilities. The inherent softness and compliance of hydrogel actuators make them ideal for applications requiring safe interaction with delicate objects or environments.Expand Specific Solutions

Leading Research Groups and Companies in Hybrid Actuators

The hydrogel hybrid drives combining pneumatic and ionic actuation technology is currently in an emerging development phase, with the market showing significant growth potential due to increasing demand for soft robotics and biomimetic applications. The global market size for this technology is estimated to be expanding at a CAGR of 15-20%, driven by applications in medical devices, wearable technology, and industrial automation. From a technical maturity perspective, academic institutions like Wuhan University, Tianjin University, and South China University of Technology are leading fundamental research, while industrial players including Robert Bosch, Festo, and Parker-Hannifin are advancing practical applications. Companies like ZF Friedrichshafen and Toyota are exploring automotive implementations, while HYDAC and Minebea Mitsumi focus on miniaturization and precision control aspects of these hybrid actuation systems.

Zhejiang Sci-Tech University

Technical Solution: Zhejiang Sci-Tech University has developed innovative hydrogel hybrid drives that synergistically combine pneumatic and ionic actuation mechanisms. Their approach utilizes specially formulated polyelectrolyte hydrogels with embedded conductive networks that respond to both pneumatic pressure and electrical stimulation. The technology features a multi-compartment design where pneumatic chambers are integrated with ionic hydrogel elements, allowing for complementary actuation modes. When electrical current is applied, controlled ion migration within the hydrogel causes localized swelling or contraction, while pneumatic pressure provides rapid, forceful movement. The university's research has demonstrated that this hybrid approach achieves superior performance metrics including enhanced force generation (up to 40% improvement over single-mode systems), more precise position control, and improved energy efficiency. Their prototypes have shown particular promise in applications requiring both strength and dexterity, such as soft robotic grippers and biomimetic manipulators.

Strengths: Achieves significantly higher force-to-weight ratio than conventional actuators; offers programmable stiffness control; demonstrates excellent energy efficiency through complementary actuation mechanisms. Weaknesses: Current prototypes show limited durability under repeated cycling; requires complex control systems to effectively coordinate pneumatic and ionic actuation modes.

South China University of Technology

Technical Solution: South China University of Technology has developed a sophisticated hydrogel hybrid drive system that integrates pneumatic and ionic actuation mechanisms. Their approach utilizes specially engineered hydrogels with interpenetrating polymer networks that respond to both pneumatic pressure and electrical stimulation. The technology features a multi-layered composite structure where pneumatic chambers are strategically integrated with ionic-responsive hydrogel elements. When electrical current is applied, controlled ion migration within the hydrogel causes localized swelling or contraction, while pneumatic pressure provides rapid, forceful movement. This dual-mode actuation enables precise control over force generation, displacement, and response characteristics. The university's research has demonstrated actuators capable of achieving complex motion patterns with improved energy efficiency compared to conventional systems. Their prototypes have shown particular promise in applications requiring both strength and dexterity, such as soft robotic manipulators and biomimetic devices.

Strengths: Achieves higher precision control through complementary actuation mechanisms; offers adaptive response to varying operational requirements; demonstrates excellent energy efficiency through synergistic operation. Weaknesses: Current implementations show limited durability under extended cycling; requires sophisticated control algorithms to effectively coordinate both actuation modes.

Key Patents and Research in Hydrogel Hybrid Drives

Hybrid hydrogel and method of fabricating the same

PatentActiveUS10772844B2

Innovation

- A hybrid hydrogel is developed, combining a hydrogel material with hybrid nanoparticles that include positive- and negative-charged polysaccharides, which are electrostatically attracted to carry growth factors, and are conjugated to the hydrogel using enzyme-sensitive or non-enzyme-sensitive bonds, allowing for controlled release of growth factors to support brain tissue repair.

Biocompatibility and Safety Considerations

The integration of hydrogel hybrid drives combining pneumatic and ionic actuation into biomedical applications necessitates rigorous assessment of biocompatibility and safety profiles. These hybrid actuators, which leverage both pneumatic pressure and ionic movement within hydrogel matrices, present unique considerations when interfacing with biological systems.

Biocompatibility evaluations for these hybrid systems must address both the hydrogel components and the ionic solutions utilized for actuation. Current research indicates that polyacrylamide and alginate-based hydrogels demonstrate favorable biocompatibility profiles in vitro, with minimal cytotoxicity observed in standard cell culture assays. However, long-term implantation studies reveal potential concerns regarding chronic inflammatory responses, particularly at the tissue-material interface where mechanical actuation occurs repeatedly.

The ionic components, typically lithium, sodium, or potassium salts, present additional considerations. While these ions naturally occur in physiological systems, their concentrated application and potential leaching from the hydrogel matrix require careful monitoring. Studies have demonstrated that controlled release profiles can be engineered through cross-linking density modifications and surface treatments, significantly reducing potential toxicity concerns.

Safety considerations extend beyond biocompatibility to include electrical safety parameters when ionic actuation is employed. The electrical potentials required for actuation, typically in the 1-5V range, generally fall within acceptable thresholds for biological applications. However, the potential for localized pH changes at electrode interfaces remains a concern, particularly for applications requiring prolonged operation in sensitive tissues.

Pneumatic components introduce additional safety considerations related to pressure management and system integrity. Failure modes analysis reveals that catastrophic pressure release events, while rare, could potentially damage surrounding tissues. Engineering solutions including pressure-limiting valves and redundant control systems have been implemented to mitigate these risks.

Regulatory pathways for these hybrid systems remain complex, with most current applications classified under combination device frameworks. The FDA and equivalent international bodies typically require comprehensive biocompatibility testing according to ISO 10993 standards, with particular emphasis on sensitization, irritation, and systemic toxicity evaluations.

Recent innovations in biocompatible coatings, including phosphorylcholine-based materials and zwitterionic polymers, have demonstrated promising results in reducing protein adsorption and subsequent foreign body responses. These approaches may provide viable pathways for enhancing the long-term biocompatibility of hydrogel hybrid actuators while maintaining their functional performance characteristics.

Biocompatibility evaluations for these hybrid systems must address both the hydrogel components and the ionic solutions utilized for actuation. Current research indicates that polyacrylamide and alginate-based hydrogels demonstrate favorable biocompatibility profiles in vitro, with minimal cytotoxicity observed in standard cell culture assays. However, long-term implantation studies reveal potential concerns regarding chronic inflammatory responses, particularly at the tissue-material interface where mechanical actuation occurs repeatedly.

The ionic components, typically lithium, sodium, or potassium salts, present additional considerations. While these ions naturally occur in physiological systems, their concentrated application and potential leaching from the hydrogel matrix require careful monitoring. Studies have demonstrated that controlled release profiles can be engineered through cross-linking density modifications and surface treatments, significantly reducing potential toxicity concerns.

Safety considerations extend beyond biocompatibility to include electrical safety parameters when ionic actuation is employed. The electrical potentials required for actuation, typically in the 1-5V range, generally fall within acceptable thresholds for biological applications. However, the potential for localized pH changes at electrode interfaces remains a concern, particularly for applications requiring prolonged operation in sensitive tissues.

Pneumatic components introduce additional safety considerations related to pressure management and system integrity. Failure modes analysis reveals that catastrophic pressure release events, while rare, could potentially damage surrounding tissues. Engineering solutions including pressure-limiting valves and redundant control systems have been implemented to mitigate these risks.

Regulatory pathways for these hybrid systems remain complex, with most current applications classified under combination device frameworks. The FDA and equivalent international bodies typically require comprehensive biocompatibility testing according to ISO 10993 standards, with particular emphasis on sensitization, irritation, and systemic toxicity evaluations.

Recent innovations in biocompatible coatings, including phosphorylcholine-based materials and zwitterionic polymers, have demonstrated promising results in reducing protein adsorption and subsequent foreign body responses. These approaches may provide viable pathways for enhancing the long-term biocompatibility of hydrogel hybrid actuators while maintaining their functional performance characteristics.

Energy Efficiency and Sustainability Analysis

The energy efficiency of hydrogel hybrid drives combining pneumatic and ionic actuation represents a significant advancement in soft robotics and actuator technology. These hybrid systems demonstrate remarkable energy conservation capabilities compared to traditional actuators, with studies indicating up to 40% reduction in power consumption during operational cycles. This efficiency stems from the synergistic interaction between pneumatic pressure systems and ionic transport mechanisms, allowing for energy recovery during deactivation phases.

From a sustainability perspective, hydrogel-based actuators offer considerable environmental advantages. The primary materials—hydrogels—are predominantly water-based polymers that can be synthesized from renewable resources. Recent developments have focused on biodegradable hydrogel formulations that maintain performance characteristics while reducing environmental persistence. The manufacturing processes for these materials typically require lower energy inputs compared to conventional metal or rigid polymer actuators, resulting in a reduced carbon footprint across the production lifecycle.

Lifecycle assessment studies of hydrogel hybrid drives reveal promising sustainability metrics. The combination of pneumatic and ionic actuation mechanisms extends operational lifespan by distributing mechanical stress across dual systems, thereby reducing material fatigue and replacement frequency. Furthermore, the self-healing properties exhibited by certain hydrogel formulations contribute to prolonged service life, minimizing waste generation and resource consumption associated with replacement components.

Energy storage capabilities represent another efficiency advantage of these hybrid systems. The pneumatic components can function as temporary energy reservoirs, while the ionic actuation mechanisms facilitate precise energy deployment with minimal losses. This dual-mode energy management system enables effective load balancing and peak shaving, particularly valuable in applications with variable power demands or intermittent operation requirements.

Water consumption remains a consideration in hydrogel-based technologies. However, recent innovations in hydrogel chemistry have produced formulations with enhanced water retention properties, reducing evaporative losses and maintenance requirements. Closed-loop designs that incorporate water recycling mechanisms further improve the sustainability profile of these systems, particularly in extended-use applications.

The scalability of energy efficiency in hydrogel hybrid drives presents promising opportunities for industrial applications. Laboratory-scale demonstrations have successfully translated to larger implementations while maintaining favorable energy metrics, suggesting viable pathways for commercial deployment. As manufacturing techniques continue to evolve, the energy intensity of production processes is expected to decrease further, enhancing the overall sustainability proposition of this technology.

From a sustainability perspective, hydrogel-based actuators offer considerable environmental advantages. The primary materials—hydrogels—are predominantly water-based polymers that can be synthesized from renewable resources. Recent developments have focused on biodegradable hydrogel formulations that maintain performance characteristics while reducing environmental persistence. The manufacturing processes for these materials typically require lower energy inputs compared to conventional metal or rigid polymer actuators, resulting in a reduced carbon footprint across the production lifecycle.

Lifecycle assessment studies of hydrogel hybrid drives reveal promising sustainability metrics. The combination of pneumatic and ionic actuation mechanisms extends operational lifespan by distributing mechanical stress across dual systems, thereby reducing material fatigue and replacement frequency. Furthermore, the self-healing properties exhibited by certain hydrogel formulations contribute to prolonged service life, minimizing waste generation and resource consumption associated with replacement components.

Energy storage capabilities represent another efficiency advantage of these hybrid systems. The pneumatic components can function as temporary energy reservoirs, while the ionic actuation mechanisms facilitate precise energy deployment with minimal losses. This dual-mode energy management system enables effective load balancing and peak shaving, particularly valuable in applications with variable power demands or intermittent operation requirements.

Water consumption remains a consideration in hydrogel-based technologies. However, recent innovations in hydrogel chemistry have produced formulations with enhanced water retention properties, reducing evaporative losses and maintenance requirements. Closed-loop designs that incorporate water recycling mechanisms further improve the sustainability profile of these systems, particularly in extended-use applications.

The scalability of energy efficiency in hydrogel hybrid drives presents promising opportunities for industrial applications. Laboratory-scale demonstrations have successfully translated to larger implementations while maintaining favorable energy metrics, suggesting viable pathways for commercial deployment. As manufacturing techniques continue to evolve, the energy intensity of production processes is expected to decrease further, enhancing the overall sustainability proposition of this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!