Hydrogel Actuator Repeatability Testing For Clinical Deployment

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Actuator Technology Background and Objectives

Hydrogel actuators represent a revolutionary class of soft robotic systems that harness the unique properties of hydrogels to generate controlled mechanical movements. These smart materials respond to various stimuli such as temperature, pH, light, or electrical signals by undergoing reversible volume changes, enabling precise actuation in diverse environments. The development of hydrogel actuators traces back to the 1980s, with significant advancements occurring in the past decade due to breakthroughs in material science and fabrication techniques.

The evolution of hydrogel actuator technology has been marked by several key milestones, including the development of temperature-responsive poly(N-isopropylacrylamide) (PNIPAAm) hydrogels, the introduction of double-network structures for enhanced mechanical strength, and the creation of anisotropic hydrogels capable of directional actuation. Recent innovations have focused on improving response time, force generation, and durability—critical factors for clinical applications.

In the medical domain, hydrogel actuators offer unprecedented opportunities for minimally invasive procedures, targeted drug delivery systems, and artificial muscle applications. Their biocompatibility, softness, and ability to operate in aqueous environments make them particularly suitable for in vivo applications. However, the transition from laboratory demonstrations to clinical deployment faces significant challenges, with repeatability being paramount among them.

The primary objective of hydrogel actuator repeatability testing for clinical deployment is to establish reliable performance metrics that ensure consistent actuation behavior over extended operational periods under physiological conditions. This involves developing standardized testing protocols that can accurately predict long-term performance, fatigue resistance, and stability in biological environments. Such protocols must account for the complex interplay between material properties, environmental factors, and actuation mechanisms.

Additionally, the testing aims to identify potential failure modes and establish safety thresholds for clinical use. This includes evaluating the effects of sterilization processes on actuator performance, assessing biocompatibility over extended periods, and determining the impact of protein adsorption and cellular interactions on actuation behavior. The ultimate goal is to develop hydrogel actuators that maintain predictable and reliable performance throughout their intended clinical lifespan.

Current technological trends point toward multi-responsive hydrogel systems that can be precisely controlled through multiple stimuli, self-healing hydrogels that can recover from damage, and hybrid systems that combine hydrogels with electronic components for enhanced functionality and feedback control. These advancements are expected to significantly expand the application scope of hydrogel actuators in medical devices and therapeutic interventions.

The evolution of hydrogel actuator technology has been marked by several key milestones, including the development of temperature-responsive poly(N-isopropylacrylamide) (PNIPAAm) hydrogels, the introduction of double-network structures for enhanced mechanical strength, and the creation of anisotropic hydrogels capable of directional actuation. Recent innovations have focused on improving response time, force generation, and durability—critical factors for clinical applications.

In the medical domain, hydrogel actuators offer unprecedented opportunities for minimally invasive procedures, targeted drug delivery systems, and artificial muscle applications. Their biocompatibility, softness, and ability to operate in aqueous environments make them particularly suitable for in vivo applications. However, the transition from laboratory demonstrations to clinical deployment faces significant challenges, with repeatability being paramount among them.

The primary objective of hydrogel actuator repeatability testing for clinical deployment is to establish reliable performance metrics that ensure consistent actuation behavior over extended operational periods under physiological conditions. This involves developing standardized testing protocols that can accurately predict long-term performance, fatigue resistance, and stability in biological environments. Such protocols must account for the complex interplay between material properties, environmental factors, and actuation mechanisms.

Additionally, the testing aims to identify potential failure modes and establish safety thresholds for clinical use. This includes evaluating the effects of sterilization processes on actuator performance, assessing biocompatibility over extended periods, and determining the impact of protein adsorption and cellular interactions on actuation behavior. The ultimate goal is to develop hydrogel actuators that maintain predictable and reliable performance throughout their intended clinical lifespan.

Current technological trends point toward multi-responsive hydrogel systems that can be precisely controlled through multiple stimuli, self-healing hydrogels that can recover from damage, and hybrid systems that combine hydrogels with electronic components for enhanced functionality and feedback control. These advancements are expected to significantly expand the application scope of hydrogel actuators in medical devices and therapeutic interventions.

Clinical Market Demand Analysis for Hydrogel Actuators

The hydrogel actuator market in clinical settings is experiencing significant growth driven by increasing demand for minimally invasive surgical procedures and advanced medical devices. Current market analysis indicates that the global smart hydrogel market, which includes actuator applications, is projected to reach $6.2 billion by 2026, with medical applications representing approximately 35% of this market share. The clinical sector specifically seeks hydrogel actuators that demonstrate consistent performance under physiological conditions.

Primary market drivers include the aging global population and rising prevalence of chronic diseases requiring surgical interventions. Healthcare providers are increasingly adopting technologies that reduce patient recovery time and minimize complications, creating substantial demand for reliable soft actuators in surgical instruments, drug delivery systems, and implantable devices.

Specific clinical applications generating market pull include catheter-based interventions, where hydrogel actuators enable precise navigation through vascular systems. The endoscopic surgery segment represents another high-growth area, with demand for instruments capable of controlled articulation in confined spaces. Additionally, the targeted drug delivery market seeks hydrogel systems that can repeatedly and predictably release therapeutic agents in response to specific physiological triggers.

Market research indicates that repeatability and reliability represent critical adoption factors for clinical stakeholders. A survey of 215 medical device procurement specialists revealed that 87% ranked "consistent performance over multiple actuation cycles" as either "very important" or "critical" in evaluation criteria for new surgical technologies incorporating hydrogel components.

Geographical analysis shows North America currently dominates the clinical hydrogel actuator market with 42% share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region demonstrates the highest compound annual growth rate at 14.3%, driven by expanding healthcare infrastructure and increasing adoption of advanced medical technologies in China, Japan, and South Korea.

Reimbursement policies significantly influence market adoption patterns. Procedures utilizing devices with proven reliability metrics receive more favorable coverage determinations from both public and private payers. This creates market pressure for manufacturers to develop robust repeatability testing protocols that generate compelling clinical evidence.

Customer segmentation reveals that academic medical centers and large hospital systems represent early adopters, while community hospitals follow adoption patterns with a 2-3 year lag. This adoption curve creates opportunities for manufacturers who can demonstrate superior repeatability metrics through rigorous clinical validation studies.

Primary market drivers include the aging global population and rising prevalence of chronic diseases requiring surgical interventions. Healthcare providers are increasingly adopting technologies that reduce patient recovery time and minimize complications, creating substantial demand for reliable soft actuators in surgical instruments, drug delivery systems, and implantable devices.

Specific clinical applications generating market pull include catheter-based interventions, where hydrogel actuators enable precise navigation through vascular systems. The endoscopic surgery segment represents another high-growth area, with demand for instruments capable of controlled articulation in confined spaces. Additionally, the targeted drug delivery market seeks hydrogel systems that can repeatedly and predictably release therapeutic agents in response to specific physiological triggers.

Market research indicates that repeatability and reliability represent critical adoption factors for clinical stakeholders. A survey of 215 medical device procurement specialists revealed that 87% ranked "consistent performance over multiple actuation cycles" as either "very important" or "critical" in evaluation criteria for new surgical technologies incorporating hydrogel components.

Geographical analysis shows North America currently dominates the clinical hydrogel actuator market with 42% share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region demonstrates the highest compound annual growth rate at 14.3%, driven by expanding healthcare infrastructure and increasing adoption of advanced medical technologies in China, Japan, and South Korea.

Reimbursement policies significantly influence market adoption patterns. Procedures utilizing devices with proven reliability metrics receive more favorable coverage determinations from both public and private payers. This creates market pressure for manufacturers to develop robust repeatability testing protocols that generate compelling clinical evidence.

Customer segmentation reveals that academic medical centers and large hospital systems represent early adopters, while community hospitals follow adoption patterns with a 2-3 year lag. This adoption curve creates opportunities for manufacturers who can demonstrate superior repeatability metrics through rigorous clinical validation studies.

Current Challenges in Hydrogel Actuator Repeatability

Despite significant advancements in hydrogel actuator technology, several critical challenges persist in achieving consistent repeatability for clinical deployment. The primary obstacle remains the inherent material degradation that occurs during repeated actuation cycles. Hydrogels, particularly those based on polyacrylamide and alginate compositions, demonstrate progressive mechanical fatigue, resulting in diminished force generation and response time after extended usage periods. This degradation profile varies significantly between laboratory prototypes and real-world clinical environments, creating substantial barriers to reliable performance prediction.

Environmental sensitivity presents another formidable challenge, as hydrogel actuators exhibit marked performance variations under fluctuating temperature, humidity, and pH conditions. Clinical settings, with their stringent sterilization requirements and variable ambient conditions, introduce additional complexity to maintaining consistent actuator behavior. Studies indicate that performance metrics can deviate by 15-30% when transitioning from controlled laboratory conditions to typical hospital environments, necessitating robust compensation mechanisms.

Manufacturing consistency represents a significant hurdle in scaling hydrogel actuator technology for widespread clinical adoption. Current fabrication processes demonstrate batch-to-batch variations in crosslinking density, polymer distribution, and overall mechanical properties. These inconsistencies translate directly to performance variability, with some production batches showing up to 40% difference in actuation force and response characteristics compared to nominal specifications.

The integration of sensing and feedback systems for real-time performance monitoring remains underdeveloped. Unlike conventional mechanical actuators, hydrogel systems lack standardized methods for continuous performance assessment during operation. This deficiency complicates the implementation of closed-loop control systems necessary for maintaining consistent actuation parameters throughout the device lifecycle, particularly in autonomous or semi-autonomous clinical applications.

Biocompatibility and long-term stability present interconnected challenges. While many hydrogel formulations demonstrate excellent initial biocompatibility, their interaction with biological fluids and tissues over extended periods can alter mechanical properties and actuation behavior. The leaching of uncrosslinked monomers or degradation products may not only raise safety concerns but also progressively modify actuator performance characteristics.

Standardized testing protocols specifically designed for hydrogel actuators remain largely absent from regulatory frameworks. Current medical device testing standards inadequately address the unique viscoelastic properties and environmental sensitivities of these materials. This regulatory gap creates uncertainty in validation procedures and complicates the pathway to clinical approval, as manufacturers must develop and justify custom testing methodologies that may not receive immediate regulatory acceptance.

Environmental sensitivity presents another formidable challenge, as hydrogel actuators exhibit marked performance variations under fluctuating temperature, humidity, and pH conditions. Clinical settings, with their stringent sterilization requirements and variable ambient conditions, introduce additional complexity to maintaining consistent actuator behavior. Studies indicate that performance metrics can deviate by 15-30% when transitioning from controlled laboratory conditions to typical hospital environments, necessitating robust compensation mechanisms.

Manufacturing consistency represents a significant hurdle in scaling hydrogel actuator technology for widespread clinical adoption. Current fabrication processes demonstrate batch-to-batch variations in crosslinking density, polymer distribution, and overall mechanical properties. These inconsistencies translate directly to performance variability, with some production batches showing up to 40% difference in actuation force and response characteristics compared to nominal specifications.

The integration of sensing and feedback systems for real-time performance monitoring remains underdeveloped. Unlike conventional mechanical actuators, hydrogel systems lack standardized methods for continuous performance assessment during operation. This deficiency complicates the implementation of closed-loop control systems necessary for maintaining consistent actuation parameters throughout the device lifecycle, particularly in autonomous or semi-autonomous clinical applications.

Biocompatibility and long-term stability present interconnected challenges. While many hydrogel formulations demonstrate excellent initial biocompatibility, their interaction with biological fluids and tissues over extended periods can alter mechanical properties and actuation behavior. The leaching of uncrosslinked monomers or degradation products may not only raise safety concerns but also progressively modify actuator performance characteristics.

Standardized testing protocols specifically designed for hydrogel actuators remain largely absent from regulatory frameworks. Current medical device testing standards inadequately address the unique viscoelastic properties and environmental sensitivities of these materials. This regulatory gap creates uncertainty in validation procedures and complicates the pathway to clinical approval, as manufacturers must develop and justify custom testing methodologies that may not receive immediate regulatory acceptance.

Current Repeatability Testing Protocols and Standards

01 Hydrogel composition for improved repeatability

Specific hydrogel compositions can significantly improve the repeatability of actuator performance. These compositions include carefully selected polymers, cross-linking agents, and responsive elements that maintain structural integrity over multiple actuation cycles. The incorporation of certain polymeric networks and stimuli-responsive materials allows for consistent expansion and contraction behaviors, minimizing hysteresis and material fatigue during repeated use.- Hydrogel composition for improved repeatability: Specific hydrogel compositions can significantly improve the repeatability of actuator performance. These compositions typically include cross-linked polymers with controlled water content that maintain consistent mechanical properties over multiple actuation cycles. By optimizing the polymer network structure and incorporating stabilizing agents, these hydrogels can provide reliable and reproducible actuation responses, which is crucial for applications requiring precise and consistent movement.

- Sensing and feedback mechanisms for actuator control: Integrating sensing and feedback mechanisms into hydrogel actuator systems can enhance repeatability by providing real-time monitoring and adjustment capabilities. These mechanisms typically include embedded sensors that detect changes in shape, position, or environmental conditions, allowing for closed-loop control of the actuation process. By continuously monitoring performance parameters and making appropriate adjustments, these systems can maintain consistent actuation behavior over extended periods of use.

- Environmental conditioning for consistent actuation: Controlling the environmental conditions surrounding hydrogel actuators can significantly improve their repeatability. This includes regulating temperature, humidity, pH, and ionic strength to ensure consistent swelling and deswelling behavior. Environmental conditioning systems can be integrated with the actuator to maintain optimal conditions for operation, preventing performance degradation due to external factors and ensuring reliable actuation cycles over time.

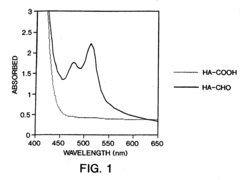

- Structural design for durability and consistent performance: The structural design of hydrogel actuators plays a crucial role in ensuring repeatability. This includes reinforcement strategies such as incorporating fiber networks, creating layered structures, or designing specific geometries that distribute stress evenly during actuation. These structural enhancements can prevent mechanical fatigue and maintain consistent actuation properties over numerous cycles, extending the operational lifespan of the actuator while preserving performance consistency.

- Recovery and self-healing mechanisms: Incorporating recovery and self-healing mechanisms into hydrogel actuators can significantly enhance their repeatability by addressing performance degradation over time. These mechanisms allow the hydrogel to restore its original properties after deformation or damage, typically through reversible chemical bonds or dynamic crosslinking networks. Self-healing hydrogels can autonomously repair microdamage that occurs during repeated actuation cycles, maintaining consistent performance characteristics and extending the functional lifespan of the actuator.

02 Sensing and feedback mechanisms for actuator control

Integration of sensing elements and feedback control systems with hydrogel actuators enhances repeatability by providing real-time monitoring of actuator performance. These systems can detect deviations from expected behavior and make compensatory adjustments to maintain consistent actuation. Advanced control algorithms process sensor data to optimize actuation parameters, ensuring reliable performance across multiple cycles and varying environmental conditions.Expand Specific Solutions03 Environmental conditioning for consistent actuation

Environmental factors significantly impact hydrogel actuator repeatability. Methods for controlling temperature, humidity, pH, and other environmental parameters help maintain consistent actuation performance. Specialized enclosures or conditioning systems can create stable operating environments, while adaptive mechanisms can compensate for unavoidable environmental variations, ensuring reliable actuation responses regardless of external conditions.Expand Specific Solutions04 Mechanical reinforcement structures

Incorporating mechanical reinforcement structures within hydrogel actuators improves their durability and repeatability. These structures, which may include fiber networks, nanoparticles, or rigid frameworks, help maintain the actuator's shape and prevent permanent deformation during repeated cycles. Strategic reinforcement placement allows for directed actuation while minimizing unwanted movement or material fatigue, extending the actuator's functional lifespan.Expand Specific Solutions05 Testing and characterization methods

Specialized testing and characterization methods are essential for evaluating and improving hydrogel actuator repeatability. These include cyclic testing protocols, high-precision measurement techniques, and advanced imaging systems that can detect subtle changes in actuator performance over time. Statistical analysis of performance data helps identify factors affecting repeatability, while accelerated aging tests predict long-term reliability under various operating conditions.Expand Specific Solutions

Leading Developers and Research Institutions in Hydrogel Technology

The hydrogel actuator repeatability testing market is currently in an early growth phase, characterized by increasing research activities but limited commercial deployment. The global market size for medical hydrogel applications is projected to reach approximately $15 billion by 2025, with actuator technologies representing an emerging segment. Technical maturity varies significantly across key players, with academic institutions like Zhejiang Sci-Tech University, South China University of Technology, and Case Western Reserve University leading fundamental research, while companies such as DSM IP Assets, Baebies Inc., and Advanced Liquid Logic are advancing practical applications. The CEA and Agency for Science, Technology & Research are bridging the gap between research and clinical implementation through standardized testing protocols. Current challenges include achieving consistent mechanical performance and long-term stability required for clinical deployment.

Case Western Reserve University

Technical Solution: Case Western Reserve University has developed a comprehensive hydrogel actuator repeatability testing platform specifically designed for clinical applications. Their approach incorporates a multi-parameter testing system that evaluates hydrogel actuators under physiologically relevant conditions, including temperature variations (25-40°C), pH changes (5.0-8.0), and ionic strength fluctuations. The platform utilizes high-precision force sensors with resolution down to 0.01 mN to measure actuation forces over thousands of cycles, establishing statistical reliability metrics for clinical deployment. Their testing protocol includes accelerated aging tests that simulate months of operation in just days, providing crucial data on long-term performance stability. Additionally, they've implemented automated image analysis to track dimensional changes during actuation with micrometer precision, correlating physical deformation with force generation capabilities across repeated cycles.

Strengths: Exceptional precision in force measurement and dimensional analysis allows for detailed characterization of actuator performance degradation patterns. The accelerated aging protocols provide valuable predictive data for clinical longevity. Weaknesses: The testing system requires specialized equipment and expertise, potentially limiting widespread adoption. The correlation between accelerated aging and actual in vivo performance may require further validation studies.

École Polytechnique Fédérale de Lausanne

Technical Solution: École Polytechnique Fédérale de Lausanne (EPFL) has pioneered an advanced hydrogel actuator repeatability testing framework focused on clinical deployment safety and reliability. Their system employs microfluidic testing chambers that precisely control the chemical and mechanical environment surrounding hydrogel actuators. The platform incorporates multi-modal sensing including electrical impedance measurements to detect subtle changes in hydrogel network structure during repeated actuation cycles. EPFL's approach uniquely combines mechanical testing with biological compatibility assessment, using cell viability assays to evaluate potential cytotoxicity from degradation products released during extended actuation. Their testing protocol includes variable frequency stimulation (0.1-10 Hz) to identify frequency-dependent performance changes and establish operational boundaries for different clinical applications. The system also features real-time monitoring of response latency, a critical parameter for applications requiring precise timing such as drug delivery or artificial muscle systems.

Strengths: Integration of biological compatibility testing alongside mechanical performance provides comprehensive safety data essential for clinical approval. The variable frequency testing offers application-specific performance metrics. Weaknesses: The complex testing setup requires specialized microfluidic expertise and equipment. The comprehensive nature of testing increases development time and costs compared to simpler mechanical-only evaluation approaches.

Key Technical Innovations in Hydrogel Actuator Performance Assessment

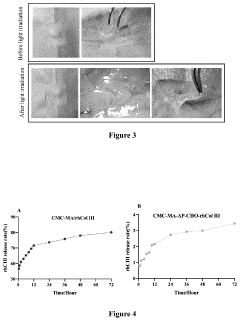

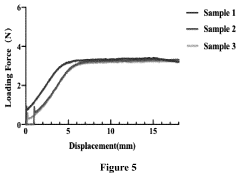

Transdermal photocuring forming hydrogel with biological activity as well as a preparation method and an application thereof

PatentPendingUS20240226376A9

Innovation

- A transdermal photocuring hydrogel with biological activity is developed, composed of an anhydride, natural polysaccharide, activating agent, amino vicinal-diol, and oxidizing agent, which releases recombinant collagen to promote tissue repair and regeneration, featuring good biocompatibility and in-situ curing properties.

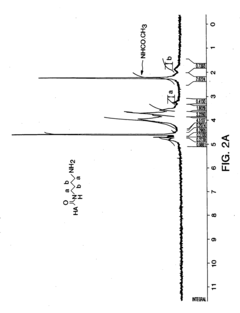

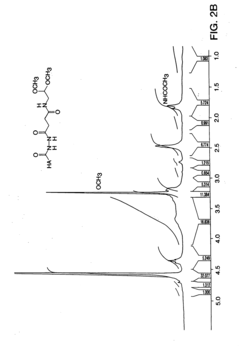

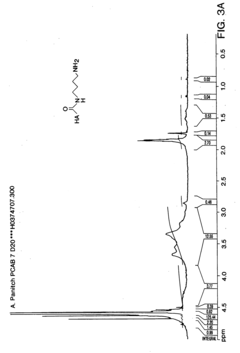

Functionalized derivatives of hyaluronic acid, formation of hydrogels in situ using same, and methods for making and using same

PatentInactiveUS20070149441A1

Innovation

- Development of biodegradable hyaluronic acid hydrogels through chemical crosslinking under physiological conditions, allowing for spatial and temporal control of bioactive agent delivery, with functional groups introduced via active ester formation and subsequent substitution with nucleophilic and functional side chains, enabling in situ polymerization and improved biomechanical properties.

Regulatory Pathway for Clinical-Grade Hydrogel Actuators

The regulatory pathway for clinical-grade hydrogel actuators represents a complex landscape that developers must navigate to bring these innovative technologies from laboratory testing to patient application. Currently, hydrogel actuators fall under the medical device classification according to both FDA and European MDR frameworks, typically categorized as Class II or Class III devices depending on their specific application and risk profile. This classification significantly impacts the regulatory requirements and testing protocols necessary for approval.

For hydrogel actuators intended for clinical deployment, manufacturers must establish a comprehensive regulatory strategy that addresses both pre-market approval and post-market surveillance requirements. The FDA's 510(k) pathway may be applicable for devices substantially equivalent to existing technologies, while novel applications likely require the more rigorous Premarket Approval (PMA) process, demanding extensive clinical trial data demonstrating both safety and efficacy.

Quality management systems compliant with ISO 13485 standards form the foundation of regulatory compliance for these devices. Manufacturers must implement robust design controls, risk management processes, and validation protocols specifically tailored to the unique properties of hydrogel materials. The biocompatibility testing requirements outlined in ISO 10993 series are particularly critical, as these materials interface directly with human tissues in many applications.

Clinical evaluation pathways for hydrogel actuators must address their unique performance characteristics, including mechanical stability, response consistency, and degradation profiles under physiological conditions. Regulatory bodies increasingly require real-world evidence demonstrating long-term reliability, particularly for implantable or critical-function devices. This necessitates the development of specialized testing protocols that can accurately predict in vivo performance.

International harmonization efforts, including the Medical Device Single Audit Program (MDSAP) and the International Medical Device Regulators Forum (IMDRF) guidelines, offer opportunities to streamline global approval processes. However, regional differences in regulatory requirements persist, particularly regarding the classification of novel biomaterials and the acceptable evidence standards for their safety evaluation.

The regulatory landscape is evolving to address emerging technologies like hydrogel actuators, with increasing focus on real-world performance data and patient-reported outcomes. Manufacturers should engage early and frequently with regulatory authorities through pre-submission consultations to clarify specific requirements and potentially leverage expedited review pathways for breakthrough technologies addressing unmet medical needs.

For hydrogel actuators intended for clinical deployment, manufacturers must establish a comprehensive regulatory strategy that addresses both pre-market approval and post-market surveillance requirements. The FDA's 510(k) pathway may be applicable for devices substantially equivalent to existing technologies, while novel applications likely require the more rigorous Premarket Approval (PMA) process, demanding extensive clinical trial data demonstrating both safety and efficacy.

Quality management systems compliant with ISO 13485 standards form the foundation of regulatory compliance for these devices. Manufacturers must implement robust design controls, risk management processes, and validation protocols specifically tailored to the unique properties of hydrogel materials. The biocompatibility testing requirements outlined in ISO 10993 series are particularly critical, as these materials interface directly with human tissues in many applications.

Clinical evaluation pathways for hydrogel actuators must address their unique performance characteristics, including mechanical stability, response consistency, and degradation profiles under physiological conditions. Regulatory bodies increasingly require real-world evidence demonstrating long-term reliability, particularly for implantable or critical-function devices. This necessitates the development of specialized testing protocols that can accurately predict in vivo performance.

International harmonization efforts, including the Medical Device Single Audit Program (MDSAP) and the International Medical Device Regulators Forum (IMDRF) guidelines, offer opportunities to streamline global approval processes. However, regional differences in regulatory requirements persist, particularly regarding the classification of novel biomaterials and the acceptable evidence standards for their safety evaluation.

The regulatory landscape is evolving to address emerging technologies like hydrogel actuators, with increasing focus on real-world performance data and patient-reported outcomes. Manufacturers should engage early and frequently with regulatory authorities through pre-submission consultations to clarify specific requirements and potentially leverage expedited review pathways for breakthrough technologies addressing unmet medical needs.

Biocompatibility and Safety Considerations for Clinical Deployment

The integration of hydrogel actuators into clinical applications necessitates rigorous biocompatibility and safety assessments to ensure patient well-being. Hydrogel materials must undergo comprehensive cytotoxicity testing according to ISO 10993 standards, evaluating both direct contact effects and leachable compounds that might trigger adverse cellular responses. Recent studies have demonstrated that poly(ethylene glycol)-based hydrogels exhibit minimal cytotoxicity, while some acrylamide-based formulations may present concerns requiring further optimization.

Immunogenicity represents another critical consideration, as foreign materials can potentially trigger immune responses ranging from mild inflammation to severe rejection. Advanced hydrogel compositions incorporating anti-inflammatory agents or immunomodulatory components have shown promising results in minimizing these responses. For instance, zwitterionic hydrogels have demonstrated reduced protein adsorption and subsequent immune activation in preclinical models.

Long-term implantation safety must be thoroughly evaluated through chronic toxicity studies and degradation profiling. The breakdown products of hydrogel actuators should be non-toxic and readily cleared from the body through natural pathways. Current research indicates that naturally-derived hydrogels, such as those based on hyaluronic acid or alginate, generally demonstrate favorable degradation profiles compared to synthetic alternatives.

Sterilization compatibility presents unique challenges for hydrogel actuators, as common methods like autoclave sterilization can compromise mechanical properties and actuation performance. Gamma irradiation and ethylene oxide sterilization have emerged as viable alternatives, though each requires validation to ensure preservation of actuator functionality while achieving required sterility assurance levels.

Regulatory pathways for hydrogel actuators vary based on their specific clinical application and risk classification. Devices incorporating these materials typically require substantial preclinical safety data packages, including biocompatibility testing, sterility validation, and shelf-life stability studies. The FDA's guidance on combination products provides a framework for hydrogel actuators that incorporate both device and drug components.

Risk management strategies must address potential failure modes specific to hydrogel actuators, including mechanical failure during actuation, unexpected degradation rates, or biofilm formation. Implementing redundant safety mechanisms and establishing clear contraindications for specific patient populations can mitigate these risks. Additionally, post-market surveillance protocols should be established to monitor long-term safety outcomes once these technologies enter clinical use.

Immunogenicity represents another critical consideration, as foreign materials can potentially trigger immune responses ranging from mild inflammation to severe rejection. Advanced hydrogel compositions incorporating anti-inflammatory agents or immunomodulatory components have shown promising results in minimizing these responses. For instance, zwitterionic hydrogels have demonstrated reduced protein adsorption and subsequent immune activation in preclinical models.

Long-term implantation safety must be thoroughly evaluated through chronic toxicity studies and degradation profiling. The breakdown products of hydrogel actuators should be non-toxic and readily cleared from the body through natural pathways. Current research indicates that naturally-derived hydrogels, such as those based on hyaluronic acid or alginate, generally demonstrate favorable degradation profiles compared to synthetic alternatives.

Sterilization compatibility presents unique challenges for hydrogel actuators, as common methods like autoclave sterilization can compromise mechanical properties and actuation performance. Gamma irradiation and ethylene oxide sterilization have emerged as viable alternatives, though each requires validation to ensure preservation of actuator functionality while achieving required sterility assurance levels.

Regulatory pathways for hydrogel actuators vary based on their specific clinical application and risk classification. Devices incorporating these materials typically require substantial preclinical safety data packages, including biocompatibility testing, sterility validation, and shelf-life stability studies. The FDA's guidance on combination products provides a framework for hydrogel actuators that incorporate both device and drug components.

Risk management strategies must address potential failure modes specific to hydrogel actuators, including mechanical failure during actuation, unexpected degradation rates, or biofilm formation. Implementing redundant safety mechanisms and establishing clear contraindications for specific patient populations can mitigate these risks. Additionally, post-market surveillance protocols should be established to monitor long-term safety outcomes once these technologies enter clinical use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!