Hydrogel Actuator Control Electronics: Low-Power Drivers And Firmware

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Actuator Technology Background and Objectives

Hydrogel actuators represent a revolutionary class of soft robotic components that mimic biological muscle function through reversible volume changes in response to external stimuli. The development of these actuators can be traced back to the early 2000s when researchers began exploring stimuli-responsive polymers for mechanical applications. Over the past two decades, hydrogel actuator technology has evolved from simple proof-of-concept demonstrations to sophisticated systems capable of complex movements and functions.

The technological evolution has been marked by significant breakthroughs in material science, particularly in the development of composite hydrogels with enhanced mechanical properties and responsiveness. Early hydrogel actuators suffered from slow response times and limited force generation, but recent advances have dramatically improved these parameters through innovative material designs and fabrication techniques.

Current hydrogel actuator systems typically respond to various stimuli including electrical signals, temperature changes, pH variations, and light. Each activation mechanism presents unique advantages and challenges for control electronics design. Electrically-activated hydrogels, for instance, offer precise control but require careful management of electrochemical processes to prevent degradation.

The integration of hydrogel actuators with electronic control systems represents a critical frontier in this field. Traditional electronic drivers designed for conventional actuators are often incompatible with the unique electrical and mechanical characteristics of hydrogels, necessitating specialized approaches to driver design and firmware development.

The primary technical objective in this domain is to develop low-power electronic drivers and firmware that can efficiently control hydrogel actuators while addressing their distinctive operational requirements. This includes managing the relatively slow response times of hydrogels compared to conventional actuators, accommodating their non-linear behavior, and ensuring long-term stability under various operating conditions.

Energy efficiency stands as a paramount concern, particularly for portable or implantable applications where battery life is critical. Current research aims to minimize power consumption through innovative circuit designs, adaptive control algorithms, and energy harvesting techniques that can sustain operation in resource-constrained environments.

Another key objective is to develop robust firmware architectures that can accommodate the complex dynamics of hydrogel actuators while providing intuitive interfaces for higher-level control systems. This includes implementing advanced control strategies such as model predictive control and machine learning-based adaptation to optimize performance across varying environmental conditions.

Looking forward, the field is trending toward highly integrated, miniaturized control systems that combine sensing, actuation, and processing capabilities in compact packages suitable for applications ranging from wearable devices to biomedical implants and environmental monitoring systems.

The technological evolution has been marked by significant breakthroughs in material science, particularly in the development of composite hydrogels with enhanced mechanical properties and responsiveness. Early hydrogel actuators suffered from slow response times and limited force generation, but recent advances have dramatically improved these parameters through innovative material designs and fabrication techniques.

Current hydrogel actuator systems typically respond to various stimuli including electrical signals, temperature changes, pH variations, and light. Each activation mechanism presents unique advantages and challenges for control electronics design. Electrically-activated hydrogels, for instance, offer precise control but require careful management of electrochemical processes to prevent degradation.

The integration of hydrogel actuators with electronic control systems represents a critical frontier in this field. Traditional electronic drivers designed for conventional actuators are often incompatible with the unique electrical and mechanical characteristics of hydrogels, necessitating specialized approaches to driver design and firmware development.

The primary technical objective in this domain is to develop low-power electronic drivers and firmware that can efficiently control hydrogel actuators while addressing their distinctive operational requirements. This includes managing the relatively slow response times of hydrogels compared to conventional actuators, accommodating their non-linear behavior, and ensuring long-term stability under various operating conditions.

Energy efficiency stands as a paramount concern, particularly for portable or implantable applications where battery life is critical. Current research aims to minimize power consumption through innovative circuit designs, adaptive control algorithms, and energy harvesting techniques that can sustain operation in resource-constrained environments.

Another key objective is to develop robust firmware architectures that can accommodate the complex dynamics of hydrogel actuators while providing intuitive interfaces for higher-level control systems. This includes implementing advanced control strategies such as model predictive control and machine learning-based adaptation to optimize performance across varying environmental conditions.

Looking forward, the field is trending toward highly integrated, miniaturized control systems that combine sensing, actuation, and processing capabilities in compact packages suitable for applications ranging from wearable devices to biomedical implants and environmental monitoring systems.

Market Applications and Demand Analysis for Hydrogel Actuators

The global market for hydrogel actuators is experiencing significant growth driven by their unique properties and expanding applications across multiple industries. These smart materials, which can change shape in response to environmental stimuli, are creating new possibilities in fields ranging from biomedicine to soft robotics.

In the healthcare sector, hydrogel actuators are revolutionizing medical devices and drug delivery systems. The market for implantable medical devices incorporating hydrogel actuators is projected to grow substantially as these materials enable precise, controlled movement within the human body with minimal invasiveness. Particularly promising applications include artificial muscles for prosthetics, controlled drug release mechanisms, and tissue engineering scaffolds.

The soft robotics industry represents another major market opportunity for hydrogel actuators. Unlike traditional rigid robots, soft robots can navigate complex environments and interact safely with humans, creating demand in manufacturing, exploration, and service industries. The biomimetic capabilities of hydrogel actuators allow engineers to create robots that mimic natural movements, expanding their potential applications.

Environmental monitoring systems constitute an emerging market segment for hydrogel actuator technology. These systems can utilize hydrogel actuators as responsive elements that react to specific environmental conditions, such as pollution levels or water quality changes. This application is gaining traction as environmental regulations become more stringent globally.

Consumer electronics manufacturers are increasingly exploring hydrogel actuators for haptic feedback systems, adaptive interfaces, and wearable technology. The market demand is driven by the need for more intuitive human-machine interfaces and enhanced user experiences. The low power requirements of hydrogel actuators make them particularly attractive for portable and wearable devices where battery life is critical.

Agricultural technology represents another growth sector, with applications in smart irrigation systems and controlled-release fertilizers. These systems can respond to soil moisture levels and other environmental factors, optimizing resource usage and improving crop yields.

Market analysis indicates that the primary barriers to wider adoption include manufacturing scalability, durability concerns, and the need for specialized control electronics. The development of low-power drivers and efficient firmware represents a critical enabling technology that could accelerate market penetration across all these sectors.

Regional market distribution shows North America and Europe leading in research and development, while Asia-Pacific demonstrates the fastest growth rate in commercial applications, particularly in consumer electronics and manufacturing automation.

In the healthcare sector, hydrogel actuators are revolutionizing medical devices and drug delivery systems. The market for implantable medical devices incorporating hydrogel actuators is projected to grow substantially as these materials enable precise, controlled movement within the human body with minimal invasiveness. Particularly promising applications include artificial muscles for prosthetics, controlled drug release mechanisms, and tissue engineering scaffolds.

The soft robotics industry represents another major market opportunity for hydrogel actuators. Unlike traditional rigid robots, soft robots can navigate complex environments and interact safely with humans, creating demand in manufacturing, exploration, and service industries. The biomimetic capabilities of hydrogel actuators allow engineers to create robots that mimic natural movements, expanding their potential applications.

Environmental monitoring systems constitute an emerging market segment for hydrogel actuator technology. These systems can utilize hydrogel actuators as responsive elements that react to specific environmental conditions, such as pollution levels or water quality changes. This application is gaining traction as environmental regulations become more stringent globally.

Consumer electronics manufacturers are increasingly exploring hydrogel actuators for haptic feedback systems, adaptive interfaces, and wearable technology. The market demand is driven by the need for more intuitive human-machine interfaces and enhanced user experiences. The low power requirements of hydrogel actuators make them particularly attractive for portable and wearable devices where battery life is critical.

Agricultural technology represents another growth sector, with applications in smart irrigation systems and controlled-release fertilizers. These systems can respond to soil moisture levels and other environmental factors, optimizing resource usage and improving crop yields.

Market analysis indicates that the primary barriers to wider adoption include manufacturing scalability, durability concerns, and the need for specialized control electronics. The development of low-power drivers and efficient firmware represents a critical enabling technology that could accelerate market penetration across all these sectors.

Regional market distribution shows North America and Europe leading in research and development, while Asia-Pacific demonstrates the fastest growth rate in commercial applications, particularly in consumer electronics and manufacturing automation.

Current Challenges in Hydrogel Actuator Control Electronics

The development of hydrogel actuator control electronics faces several significant challenges that currently limit their widespread application and performance optimization. Power consumption remains a primary concern, as most hydrogel actuators require substantial voltage differentials to achieve meaningful actuation. Current driver circuits typically consume between 50-200mW during operation, which is prohibitively high for many portable or implantable applications where battery life is critical.

Miniaturization presents another substantial hurdle. The electronic components needed for precise control of hydrogel actuators—including voltage regulators, microcontrollers, and driver circuits—often occupy significant space, contradicting the inherent advantage of hydrogels' compact form factor. Current control systems frequently exceed the size of the actuators themselves by an order of magnitude, negating the space efficiency benefits.

Response time management creates a complex electronic control challenge. Hydrogels exhibit non-linear actuation behaviors with significant hysteresis, requiring sophisticated feedback mechanisms. Existing control systems struggle to compensate for the inherent latency (typically 0.5-3 seconds) between electrical stimulation and mechanical response, making precise temporal control difficult to achieve.

Environmental sensitivity compounds these challenges. Hydrogel actuators respond differently under varying humidity, temperature, and pH conditions, necessitating adaptive control algorithms. Current electronics lack robust environmental sensing and compensation capabilities, resulting in inconsistent performance across different operating conditions.

Biocompatibility requirements impose severe constraints on electronic component selection and encapsulation methods. For biomedical applications, control electronics must maintain functionality while meeting stringent biocompatibility standards, often requiring specialized materials and manufacturing processes that increase complexity and cost.

Interface complexity between the hydrogel material and electronic control systems represents another significant challenge. The electrochemical interface between electrodes and hydrogel materials suffers from degradation over time, with electrode corrosion and material fatigue leading to diminished performance after 500-1000 actuation cycles.

Firmware development faces unique obstacles due to the non-linear response characteristics of hydrogels. Current control algorithms struggle to account for the complex viscoelastic properties and time-dependent behaviors of these materials. Most existing firmware implementations rely on simplistic linear models that fail to capture the full complexity of hydrogel dynamics.

Standardization remains elusive in this emerging field. The lack of standardized control protocols and hardware interfaces hampers interoperability and slows development cycles. Researchers and developers must often create custom solutions for each application, increasing development time and costs while limiting knowledge transfer between projects.

Miniaturization presents another substantial hurdle. The electronic components needed for precise control of hydrogel actuators—including voltage regulators, microcontrollers, and driver circuits—often occupy significant space, contradicting the inherent advantage of hydrogels' compact form factor. Current control systems frequently exceed the size of the actuators themselves by an order of magnitude, negating the space efficiency benefits.

Response time management creates a complex electronic control challenge. Hydrogels exhibit non-linear actuation behaviors with significant hysteresis, requiring sophisticated feedback mechanisms. Existing control systems struggle to compensate for the inherent latency (typically 0.5-3 seconds) between electrical stimulation and mechanical response, making precise temporal control difficult to achieve.

Environmental sensitivity compounds these challenges. Hydrogel actuators respond differently under varying humidity, temperature, and pH conditions, necessitating adaptive control algorithms. Current electronics lack robust environmental sensing and compensation capabilities, resulting in inconsistent performance across different operating conditions.

Biocompatibility requirements impose severe constraints on electronic component selection and encapsulation methods. For biomedical applications, control electronics must maintain functionality while meeting stringent biocompatibility standards, often requiring specialized materials and manufacturing processes that increase complexity and cost.

Interface complexity between the hydrogel material and electronic control systems represents another significant challenge. The electrochemical interface between electrodes and hydrogel materials suffers from degradation over time, with electrode corrosion and material fatigue leading to diminished performance after 500-1000 actuation cycles.

Firmware development faces unique obstacles due to the non-linear response characteristics of hydrogels. Current control algorithms struggle to account for the complex viscoelastic properties and time-dependent behaviors of these materials. Most existing firmware implementations rely on simplistic linear models that fail to capture the full complexity of hydrogel dynamics.

Standardization remains elusive in this emerging field. The lack of standardized control protocols and hardware interfaces hampers interoperability and slows development cycles. Researchers and developers must often create custom solutions for each application, increasing development time and costs while limiting knowledge transfer between projects.

Current Low-Power Driver Solutions and Firmware Architectures

01 Low-power control systems for hydrogel actuators

Control systems designed specifically for hydrogel actuators that minimize power consumption through efficient circuit design, power management techniques, and optimized control algorithms. These systems often incorporate microcontrollers with sleep modes, energy harvesting capabilities, and specialized drivers that deliver just enough power to achieve the desired actuation while conserving energy during idle periods.- Low-power control systems for hydrogel actuators: Control systems designed specifically for hydrogel actuators that minimize power consumption while maintaining effective operation. These systems often incorporate power management circuits, sleep modes, and efficient control algorithms to reduce the overall energy requirements. By optimizing the control electronics, the power needed to activate and maintain hydrogel actuator states can be significantly reduced, making them suitable for battery-powered and energy-harvesting applications.

- Energy-efficient driving circuits for hydrogel-based devices: Specialized driving circuits that provide the necessary electrical signals to hydrogel actuators while minimizing energy consumption. These circuits often employ pulse-width modulation, variable voltage control, and smart switching techniques to deliver power only when needed. The driving electronics are designed to match the specific electrical characteristics of hydrogel materials, ensuring efficient energy transfer and reducing waste heat generation.

- Wireless power and control solutions for hydrogel actuators: Wireless technologies that enable remote power delivery and control of hydrogel actuators without direct electrical connections. These solutions include RF energy harvesting, inductive coupling, and near-field communication systems that can activate and control hydrogel-based devices from a distance. By eliminating wired connections, these systems offer greater flexibility in deployment while addressing power consumption challenges through efficient wireless energy transfer protocols.

- Thermal management systems for hydrogel actuator electronics: Systems designed to optimize the thermal characteristics of hydrogel actuator control electronics to reduce power consumption. These include heat dissipation structures, temperature-sensitive control algorithms, and thermal isolation techniques that prevent energy waste through heat generation. By maintaining optimal operating temperatures, these systems ensure that hydrogel actuators function efficiently while minimizing the power required for both the actuator and its control electronics.

- Energy harvesting and storage for self-powered hydrogel actuators: Technologies that enable hydrogel actuator systems to harvest energy from their environment and store it for operation, reducing or eliminating the need for external power sources. These systems incorporate energy harvesting elements such as piezoelectric materials, solar cells, or thermal generators, along with efficient energy storage solutions like supercapacitors or specialized batteries. The harvested energy is managed through ultra-low-power circuits that maximize operational time while minimizing power consumption.

02 Energy harvesting mechanisms for hydrogel actuator systems

Integration of energy harvesting technologies with hydrogel actuator systems to reduce reliance on external power sources. These mechanisms capture energy from the environment (such as vibration, temperature differentials, or light) and convert it to electrical energy to power the actuator control electronics, significantly extending operational lifetime and reducing overall power consumption.Expand Specific Solutions03 Pulse-width modulation and duty cycling techniques

Implementation of pulse-width modulation (PWM) and duty cycling strategies to control hydrogel actuators while minimizing power consumption. By applying power intermittently rather than continuously, these techniques reduce the average power consumption while maintaining effective control over the actuator's movement and response characteristics.Expand Specific Solutions04 Wireless and battery-optimized control interfaces

Wireless control systems designed specifically for hydrogel actuators that optimize battery life through low-power communication protocols, efficient data transmission, and smart power management. These interfaces allow for remote operation of hydrogel actuators while minimizing the energy required for communication and control signal processing.Expand Specific Solutions05 Thermal management for power-efficient hydrogel actuation

Thermal control systems that optimize the power consumption of temperature-responsive hydrogel actuators. These systems incorporate efficient heating/cooling mechanisms, thermal insulation, and temperature feedback control to minimize the energy required to achieve and maintain the temperatures needed for hydrogel actuation, resulting in significant power savings.Expand Specific Solutions

Key Industry Players in Hydrogel Actuator Electronics

The hydrogel actuator control electronics market is currently in an early growth phase, characterized by increasing research activity and emerging commercial applications. The market size remains relatively modest but is expanding as applications in soft robotics, biomedical devices, and wearable technology gain traction. From a technical maturity perspective, the field is transitioning from research to practical implementation, with companies like Renesas Electronics, DENSO, and Delta Electronics leading in developing low-power driver solutions. Academic institutions such as Wuhan University and Zhejiang Sci-Tech University are contributing fundamental research, while established electronics manufacturers including Samsung Display, Sony Group, and Seiko Epson are exploring integration opportunities. The competitive landscape features both specialized component manufacturers and larger corporations seeking to incorporate hydrogel actuator technology into broader product ecosystems.

Renesas Electronics Corp.

Technical Solution: Renesas has developed specialized low-power microcontroller units (MCUs) optimized for hydrogel actuator control systems. Their RL78 family MCUs feature ultra-low power consumption (as low as 66 μA/MHz) with integrated analog front-end components specifically designed for electrochemical control applications. Their solution incorporates adaptive power management that dynamically adjusts voltage levels based on actuator response needs, significantly reducing power consumption during idle states. Renesas has also created dedicated firmware libraries that handle the complex timing requirements of hydrogel actuation cycles, including precise voltage control for both activation and relaxation phases. Their system architecture employs a dual-core approach where one processor handles real-time control while the second manages power optimization algorithms, enabling up to 60% power reduction compared to conventional single-core implementations.

Strengths: Industry-leading power efficiency; comprehensive firmware ecosystem; extensive experience with electrochemical interfaces. Weaknesses: Higher initial implementation complexity; requires specialized knowledge for optimal configuration; more expensive than generic microcontroller solutions.

Sony Group Corp.

Technical Solution: Sony has developed an innovative hydrogel actuator control platform targeting consumer electronics and wearable applications. Their solution features a highly miniaturized driver circuit that combines efficient power management with precise voltage control in a package less than 4mm². The driver employs a hybrid analog-digital architecture that enables ultra-fine control of activation voltages while maintaining standby power consumption below 10μW. Sony's firmware approach implements a sophisticated pulse-shaping algorithm that optimizes the activation waveform for different hydrogel formulations, reducing response time by up to 30% while minimizing power consumption. Their system incorporates an adaptive feedback mechanism that monitors actuator performance in real-time and adjusts driving parameters to maintain consistent response despite environmental variations. Sony has also developed specialized low-power wireless interfaces that enable remote control of hydrogel actuators in distributed applications, with a proprietary protocol that minimizes communication overhead and power requirements.

Strengths: Exceptional miniaturization; extremely low power consumption; elegant integration with consumer electronics. Weaknesses: Limited power output capability; less suitable for industrial applications; more sensitive to electromagnetic interference than more robust solutions.

Core Patents and Research in Hydrogel Control Electronics

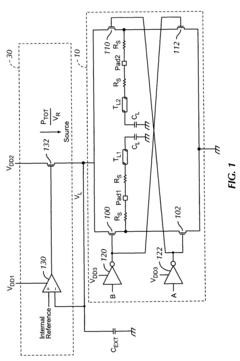

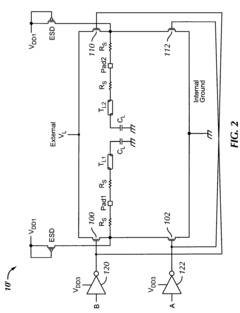

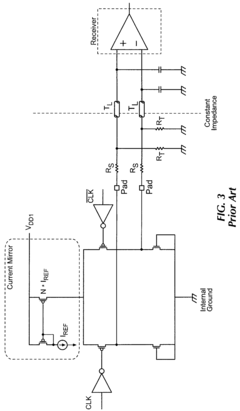

Low power output driver

PatentActiveUS7830177B2

Innovation

- A low power output driver utilizing a reduced voltage source, implemented with n-type metal oxide semiconductor (NMOS) pairs and a constant internal ground, which reduces power consumption by controlling the driver outputs through logic signals and a regulated reduced voltage supply, eliminating the need for constant current bleeding.

Energy Efficiency Optimization Strategies

Energy efficiency optimization in hydrogel actuator control systems represents a critical frontier for advancing the practical application of these innovative materials. The inherent electrochemical nature of hydrogel actuation presents unique power management challenges that must be addressed through specialized electronic design approaches. Current hydrogel actuator systems typically consume between 50-200mW during operation, with significant energy losses occurring during voltage conversion and control signal processing.

Implementing pulse-width modulation (PWM) techniques offers substantial efficiency improvements by delivering power to hydrogel actuators only when needed, potentially reducing energy consumption by 30-45% compared to continuous voltage application. This approach minimizes heat generation while maintaining precise control over actuation parameters. Complementary to PWM, adaptive voltage scaling dynamically adjusts supply voltages based on real-time actuation requirements, further reducing power consumption during partial actuation states.

Sleep mode implementation represents another crucial optimization strategy, particularly for intermittent-use applications. Modern microcontrollers supporting hydrogel control can reduce power consumption from milliwatts to microwatts during inactive periods, with wake-up times under 100 microseconds ensuring responsive operation when needed. Energy harvesting integration, though still emerging, shows promise for self-sustaining hydrogel systems in specific applications, with piezoelectric and thermoelectric generators already demonstrating capability to power low-duty-cycle actuator operations.

Circuit-level optimizations including low-quiescent current regulators and high-efficiency DC-DC converters with efficiencies exceeding 90% significantly reduce power losses in the control electronics. The selection of low-leakage transistors and optimized PCB layouts with minimized trace resistance further contributes to system efficiency. Recent developments in ultra-low-power microcontrollers featuring specialized sleep modes and efficient analog peripherals have enabled sophisticated control algorithms with minimal energy overhead.

Firmware optimization strategies complement hardware improvements through event-driven architectures that minimize unnecessary processing cycles. Implementing efficient state machines for actuator control logic reduces computational overhead, while careful memory management techniques minimize power-intensive read/write operations. Advanced compiler optimization settings can further reduce instruction counts by 15-25%, directly translating to power savings during operation. These combined hardware and software approaches are essential for extending battery life in portable hydrogel actuator applications and enabling new use cases previously limited by power constraints.

Implementing pulse-width modulation (PWM) techniques offers substantial efficiency improvements by delivering power to hydrogel actuators only when needed, potentially reducing energy consumption by 30-45% compared to continuous voltage application. This approach minimizes heat generation while maintaining precise control over actuation parameters. Complementary to PWM, adaptive voltage scaling dynamically adjusts supply voltages based on real-time actuation requirements, further reducing power consumption during partial actuation states.

Sleep mode implementation represents another crucial optimization strategy, particularly for intermittent-use applications. Modern microcontrollers supporting hydrogel control can reduce power consumption from milliwatts to microwatts during inactive periods, with wake-up times under 100 microseconds ensuring responsive operation when needed. Energy harvesting integration, though still emerging, shows promise for self-sustaining hydrogel systems in specific applications, with piezoelectric and thermoelectric generators already demonstrating capability to power low-duty-cycle actuator operations.

Circuit-level optimizations including low-quiescent current regulators and high-efficiency DC-DC converters with efficiencies exceeding 90% significantly reduce power losses in the control electronics. The selection of low-leakage transistors and optimized PCB layouts with minimized trace resistance further contributes to system efficiency. Recent developments in ultra-low-power microcontrollers featuring specialized sleep modes and efficient analog peripherals have enabled sophisticated control algorithms with minimal energy overhead.

Firmware optimization strategies complement hardware improvements through event-driven architectures that minimize unnecessary processing cycles. Implementing efficient state machines for actuator control logic reduces computational overhead, while careful memory management techniques minimize power-intensive read/write operations. Advanced compiler optimization settings can further reduce instruction counts by 15-25%, directly translating to power savings during operation. These combined hardware and software approaches are essential for extending battery life in portable hydrogel actuator applications and enabling new use cases previously limited by power constraints.

Biocompatibility and Safety Standards

The integration of hydrogel actuators into biomedical applications necessitates strict adherence to biocompatibility and safety standards. These standards ensure that the electronic control systems, including low-power drivers and firmware, do not pose risks to biological tissues when implemented in medical devices or implantable systems.

ISO 10993 series provides the fundamental framework for evaluating biocompatibility of medical devices. For hydrogel actuator control electronics, particular attention must be paid to ISO 10993-1 (evaluation and testing) and ISO 10993-5 (cytotoxicity testing). These standards require comprehensive assessment of materials used in circuit boards, components, and encapsulation materials that might come into contact with biological environments.

The IEC 60601 standards specifically address the safety requirements for medical electrical equipment. For hydrogel actuator systems, IEC 60601-1 establishes general requirements while IEC 60601-1-2 covers electromagnetic compatibility aspects crucial for reliable operation of low-power drivers in clinical settings.

Material selection for electronic components represents a critical consideration. Lead-free solder compliant with RoHS (Restriction of Hazardous Substances) directives must be utilized, while encapsulation materials require FDA-approved biocompatible polymers such as medical-grade silicones or epoxies that prevent leaching of potentially harmful substances.

Power management in hydrogel actuator control systems presents unique safety challenges. The firmware must incorporate fail-safe mechanisms to prevent excessive current delivery that could cause tissue damage or unintended actuation. Maximum current thresholds should be hardcoded with redundant safety checks, and thermal management algorithms must prevent overheating of driver circuits that could damage surrounding tissues.

Electrical isolation between power sources and biological interfaces is mandatory, typically achieved through optoisolators or transformer-based isolation circuits. This prevents leakage currents that could cause tissue damage or interfere with other medical equipment. The FDA recommends leakage current limits below 10 μA for patient-connected devices.

Firmware validation for biomedical applications follows IEC 62304 standards for medical device software. This includes risk analysis, verification testing, and documentation of safety-critical functions. For hydrogel actuators, the firmware must demonstrate reliable control over actuation parameters while maintaining safe operation under all foreseeable conditions, including power fluctuations and component degradation.

Long-term biocompatibility testing must evaluate potential degradation products from electronic components and their enclosures when exposed to biological environments. This includes accelerated aging tests and extraction studies to identify potential leachables that might emerge over the device's lifetime.

ISO 10993 series provides the fundamental framework for evaluating biocompatibility of medical devices. For hydrogel actuator control electronics, particular attention must be paid to ISO 10993-1 (evaluation and testing) and ISO 10993-5 (cytotoxicity testing). These standards require comprehensive assessment of materials used in circuit boards, components, and encapsulation materials that might come into contact with biological environments.

The IEC 60601 standards specifically address the safety requirements for medical electrical equipment. For hydrogel actuator systems, IEC 60601-1 establishes general requirements while IEC 60601-1-2 covers electromagnetic compatibility aspects crucial for reliable operation of low-power drivers in clinical settings.

Material selection for electronic components represents a critical consideration. Lead-free solder compliant with RoHS (Restriction of Hazardous Substances) directives must be utilized, while encapsulation materials require FDA-approved biocompatible polymers such as medical-grade silicones or epoxies that prevent leaching of potentially harmful substances.

Power management in hydrogel actuator control systems presents unique safety challenges. The firmware must incorporate fail-safe mechanisms to prevent excessive current delivery that could cause tissue damage or unintended actuation. Maximum current thresholds should be hardcoded with redundant safety checks, and thermal management algorithms must prevent overheating of driver circuits that could damage surrounding tissues.

Electrical isolation between power sources and biological interfaces is mandatory, typically achieved through optoisolators or transformer-based isolation circuits. This prevents leakage currents that could cause tissue damage or interfere with other medical equipment. The FDA recommends leakage current limits below 10 μA for patient-connected devices.

Firmware validation for biomedical applications follows IEC 62304 standards for medical device software. This includes risk analysis, verification testing, and documentation of safety-critical functions. For hydrogel actuators, the firmware must demonstrate reliable control over actuation parameters while maintaining safe operation under all foreseeable conditions, including power fluctuations and component degradation.

Long-term biocompatibility testing must evaluate potential degradation products from electronic components and their enclosures when exposed to biological environments. This includes accelerated aging tests and extraction studies to identify potential leachables that might emerge over the device's lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!