Ionic Hydrogel Actuators: Power Sources And Lifetime Considerations

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ionic Hydrogel Actuator Background and Objectives

Ionic hydrogel actuators represent a significant advancement in soft robotics and biomimetic systems, emerging from the convergence of materials science, electrochemistry, and mechanical engineering. These smart materials respond to electrical stimuli by changing shape, making them valuable for applications ranging from artificial muscles to drug delivery systems. The evolution of this technology can be traced back to the early 1990s, when researchers first began exploring electroactive polymers, but significant breakthroughs in ionic hydrogel actuators specifically occurred in the early 2000s with the development of more sophisticated polymer networks and ionic conductivity mechanisms.

The technological trajectory has been characterized by progressive improvements in response time, force generation, and material durability. Early iterations suffered from slow actuation speeds and limited mechanical strength, but recent advancements have yielded materials capable of rapid, powerful movements while maintaining flexibility. The integration of nanomaterials such as carbon nanotubes and graphene has further enhanced performance metrics, enabling unprecedented control over actuation behavior.

Current research is increasingly focused on addressing two critical limitations: power source integration and operational lifetime. Traditional external power supplies restrict mobility and practical application, driving interest in self-powered systems and energy harvesting technologies. Meanwhile, degradation mechanisms including dehydration, ion depletion, and mechanical fatigue continue to limit long-term reliability, presenting significant challenges for commercial viability.

The primary technical objectives in this field include developing efficient, miniaturized power sources that can be seamlessly integrated with hydrogel structures, extending operational lifetime through novel material compositions and protective strategies, and enhancing actuation performance metrics including force generation, speed, and displacement range. Additionally, there is growing interest in creating multi-responsive systems capable of reacting to various stimuli beyond electrical inputs.

From a broader perspective, the field aims to transition from laboratory demonstrations to practical applications by addressing scalability challenges and manufacturing constraints. Standardization of testing protocols and performance metrics represents another important goal, as current literature often employs inconsistent evaluation methods that complicate direct comparisons between different approaches.

The convergence of these technical advancements is expected to enable transformative applications in wearable technology, soft robotics, biomedical devices, and environmental sensing. As power and lifetime limitations are overcome, ionic hydrogel actuators hold promise for creating truly autonomous, biomimetic systems that can operate reliably in diverse environments for extended periods.

The technological trajectory has been characterized by progressive improvements in response time, force generation, and material durability. Early iterations suffered from slow actuation speeds and limited mechanical strength, but recent advancements have yielded materials capable of rapid, powerful movements while maintaining flexibility. The integration of nanomaterials such as carbon nanotubes and graphene has further enhanced performance metrics, enabling unprecedented control over actuation behavior.

Current research is increasingly focused on addressing two critical limitations: power source integration and operational lifetime. Traditional external power supplies restrict mobility and practical application, driving interest in self-powered systems and energy harvesting technologies. Meanwhile, degradation mechanisms including dehydration, ion depletion, and mechanical fatigue continue to limit long-term reliability, presenting significant challenges for commercial viability.

The primary technical objectives in this field include developing efficient, miniaturized power sources that can be seamlessly integrated with hydrogel structures, extending operational lifetime through novel material compositions and protective strategies, and enhancing actuation performance metrics including force generation, speed, and displacement range. Additionally, there is growing interest in creating multi-responsive systems capable of reacting to various stimuli beyond electrical inputs.

From a broader perspective, the field aims to transition from laboratory demonstrations to practical applications by addressing scalability challenges and manufacturing constraints. Standardization of testing protocols and performance metrics represents another important goal, as current literature often employs inconsistent evaluation methods that complicate direct comparisons between different approaches.

The convergence of these technical advancements is expected to enable transformative applications in wearable technology, soft robotics, biomedical devices, and environmental sensing. As power and lifetime limitations are overcome, ionic hydrogel actuators hold promise for creating truly autonomous, biomimetic systems that can operate reliably in diverse environments for extended periods.

Market Applications and Demand Analysis

The market for ionic hydrogel actuators is experiencing significant growth driven by increasing demand across multiple sectors. The global smart materials market, which includes electroactive polymers and hydrogel actuators, is projected to reach $98.2 billion by 2025, with a compound annual growth rate (CAGR) of 14.9%. Ionic hydrogel actuators represent an emerging segment within this broader market, with particular growth potential in biomedical applications, soft robotics, and environmental sensing technologies.

In the biomedical sector, demand for ionic hydrogel actuators is primarily driven by applications in drug delivery systems, tissue engineering, and artificial muscles. The controlled drug delivery market alone is expected to reach $41.2 billion by 2026, with smart hydrogel-based systems capturing an increasing share due to their biocompatibility and precise control capabilities. The aging global population and rising prevalence of chronic diseases further amplify this demand, as healthcare systems seek more efficient therapeutic approaches.

Soft robotics represents another high-growth application area, with market projections exceeding $3.4 billion by 2027. Industries ranging from manufacturing to healthcare are increasingly adopting soft robotic solutions that can safely interact with humans and delicate objects. Ionic hydrogel actuators offer significant advantages in this space due to their flexibility, biomimetic movement capabilities, and potential for miniaturization.

Environmental monitoring and sensing applications constitute a rapidly expanding market segment, valued at approximately $17.6 billion globally. Hydrogel-based sensors capable of detecting environmental changes and pollutants are gaining traction as climate concerns intensify and regulatory requirements become more stringent. The ability of ionic hydrogel actuators to operate in aqueous environments makes them particularly valuable for water quality monitoring applications.

Consumer electronics represents an emerging application area with substantial growth potential. The integration of hydrogel actuators into wearable technology, haptic feedback systems, and flexible displays could revolutionize user interfaces and device functionality. This market segment is projected to grow at a CAGR of 19.1% through 2028, driven by consumer demand for more intuitive and responsive technology interfaces.

Despite this promising outlook, market adoption faces several challenges. Power source limitations and lifetime considerations remain significant barriers to widespread commercial implementation. End-users across industries express concerns about the long-term reliability and operational costs associated with current ionic hydrogel actuator technologies. Market research indicates that improvements in energy efficiency and operational lifespan could potentially double the addressable market within five years.

Regional analysis reveals that North America and Asia-Pacific currently lead in market demand, with Europe showing accelerated growth rates. China, Japan, and South Korea have emerged as particularly active markets, supported by substantial government investments in advanced materials research and manufacturing capabilities.

In the biomedical sector, demand for ionic hydrogel actuators is primarily driven by applications in drug delivery systems, tissue engineering, and artificial muscles. The controlled drug delivery market alone is expected to reach $41.2 billion by 2026, with smart hydrogel-based systems capturing an increasing share due to their biocompatibility and precise control capabilities. The aging global population and rising prevalence of chronic diseases further amplify this demand, as healthcare systems seek more efficient therapeutic approaches.

Soft robotics represents another high-growth application area, with market projections exceeding $3.4 billion by 2027. Industries ranging from manufacturing to healthcare are increasingly adopting soft robotic solutions that can safely interact with humans and delicate objects. Ionic hydrogel actuators offer significant advantages in this space due to their flexibility, biomimetic movement capabilities, and potential for miniaturization.

Environmental monitoring and sensing applications constitute a rapidly expanding market segment, valued at approximately $17.6 billion globally. Hydrogel-based sensors capable of detecting environmental changes and pollutants are gaining traction as climate concerns intensify and regulatory requirements become more stringent. The ability of ionic hydrogel actuators to operate in aqueous environments makes them particularly valuable for water quality monitoring applications.

Consumer electronics represents an emerging application area with substantial growth potential. The integration of hydrogel actuators into wearable technology, haptic feedback systems, and flexible displays could revolutionize user interfaces and device functionality. This market segment is projected to grow at a CAGR of 19.1% through 2028, driven by consumer demand for more intuitive and responsive technology interfaces.

Despite this promising outlook, market adoption faces several challenges. Power source limitations and lifetime considerations remain significant barriers to widespread commercial implementation. End-users across industries express concerns about the long-term reliability and operational costs associated with current ionic hydrogel actuator technologies. Market research indicates that improvements in energy efficiency and operational lifespan could potentially double the addressable market within five years.

Regional analysis reveals that North America and Asia-Pacific currently lead in market demand, with Europe showing accelerated growth rates. China, Japan, and South Korea have emerged as particularly active markets, supported by substantial government investments in advanced materials research and manufacturing capabilities.

Technical Challenges and Development Status

Ionic hydrogel actuators represent a promising frontier in soft robotics and biomedical applications, yet they face significant technical challenges that impede their widespread adoption. The primary obstacle remains power source integration, as most ionic hydrogel systems require external voltage sources that limit portability and practical deployment. Current research indicates that while laboratory demonstrations achieve impressive actuation performance, these typically rely on bench-scale power supplies that cannot be miniaturized for real-world applications without substantial performance degradation.

The development of self-contained power solutions has progressed along several trajectories, with miniaturized batteries and energy harvesting technologies showing promise. However, the power density requirements for meaningful actuation often exceed what current compact energy sources can provide, creating a fundamental bottleneck in system design. Research groups at MIT, University of Tokyo, and Stanford University have demonstrated prototype self-powered systems, but these typically sacrifice either actuation force or response time to accommodate power constraints.

Lifetime considerations present another critical challenge, with most current ionic hydrogel actuators exhibiting significant performance degradation after 500-1000 actuation cycles. This degradation manifests through multiple mechanisms: electrolyte depletion, polymer chain reconfiguration, and interfacial delamination between hydrogel components. Environmental factors further accelerate degradation, with humidity fluctuations causing dimensional instability and temperature variations affecting ionic conductivity and mechanical properties.

Globally, research efforts addressing these challenges show geographic concentration, with Japan leading in fundamental materials science approaches, the United States focusing on system integration and power management solutions, and European institutions emphasizing biocompatible formulations for medical applications. Chinese research groups have recently made significant contributions in high-cycle-life hydrogel compositions, reporting systems capable of maintaining 80% of initial performance after 5,000 cycles under laboratory conditions.

The technical maturity of ionic hydrogel actuators varies significantly across application domains. For single-use biomedical applications, current technology approaches commercial viability, while reusable or continuous-operation systems remain firmly in the research domain. Industry standardization efforts are notably lacking, with no established protocols for performance characterization or lifetime testing, hampering comparative analysis across different research efforts.

Recent breakthroughs in self-healing hydrogel compositions offer a potential pathway to address lifetime limitations, with several research groups demonstrating materials capable of recovering from mechanical damage and electrical fatigue. However, these self-healing mechanisms typically require specific environmental conditions that limit practical implementation in diverse operating environments.

The development of self-contained power solutions has progressed along several trajectories, with miniaturized batteries and energy harvesting technologies showing promise. However, the power density requirements for meaningful actuation often exceed what current compact energy sources can provide, creating a fundamental bottleneck in system design. Research groups at MIT, University of Tokyo, and Stanford University have demonstrated prototype self-powered systems, but these typically sacrifice either actuation force or response time to accommodate power constraints.

Lifetime considerations present another critical challenge, with most current ionic hydrogel actuators exhibiting significant performance degradation after 500-1000 actuation cycles. This degradation manifests through multiple mechanisms: electrolyte depletion, polymer chain reconfiguration, and interfacial delamination between hydrogel components. Environmental factors further accelerate degradation, with humidity fluctuations causing dimensional instability and temperature variations affecting ionic conductivity and mechanical properties.

Globally, research efforts addressing these challenges show geographic concentration, with Japan leading in fundamental materials science approaches, the United States focusing on system integration and power management solutions, and European institutions emphasizing biocompatible formulations for medical applications. Chinese research groups have recently made significant contributions in high-cycle-life hydrogel compositions, reporting systems capable of maintaining 80% of initial performance after 5,000 cycles under laboratory conditions.

The technical maturity of ionic hydrogel actuators varies significantly across application domains. For single-use biomedical applications, current technology approaches commercial viability, while reusable or continuous-operation systems remain firmly in the research domain. Industry standardization efforts are notably lacking, with no established protocols for performance characterization or lifetime testing, hampering comparative analysis across different research efforts.

Recent breakthroughs in self-healing hydrogel compositions offer a potential pathway to address lifetime limitations, with several research groups demonstrating materials capable of recovering from mechanical damage and electrical fatigue. However, these self-healing mechanisms typically require specific environmental conditions that limit practical implementation in diverse operating environments.

Current Power Supply Solutions for Ionic Actuators

01 Power sources for ionic hydrogel actuators

Various power sources can be used to drive ionic hydrogel actuators, including batteries, solar cells, and wireless power transmission systems. These power sources provide the electrical energy needed to trigger the movement or deformation of the hydrogel actuators. The selection of an appropriate power source depends on the specific application requirements, such as portability, power output, and operational environment. Advanced power management systems can be integrated to optimize energy consumption and extend the operational lifetime of the actuators.- Power sources for ionic hydrogel actuators: Various power sources can be used to drive ionic hydrogel actuators, including batteries, solar cells, and wireless power transmission systems. These power sources provide the electrical energy needed to trigger the movement or deformation of the hydrogel actuators. The selection of an appropriate power source depends on the specific application requirements, such as portability, power output, and operational environment. Advanced power management systems can be integrated to optimize energy consumption and extend the operational lifetime of the actuators.

- Lifetime enhancement strategies for hydrogel actuators: Several approaches can be employed to enhance the lifetime of ionic hydrogel actuators. These include the incorporation of self-healing mechanisms, the use of durable polymer networks, and the development of protective coatings that prevent dehydration and degradation. Additionally, optimizing the ionic composition and concentration can reduce electrochemical degradation during repeated actuation cycles. Regular maintenance protocols and operational parameter control can also significantly extend the functional lifetime of these actuators in practical applications.

- Ionic composition and conductivity optimization: The performance and durability of hydrogel actuators are significantly influenced by their ionic composition and conductivity. By carefully selecting ionic species and concentrations, researchers can enhance the response speed, force generation, and operational stability of these actuators. Various ionic compounds, including alkali metal salts, organic electrolytes, and ionic liquids, can be incorporated into the hydrogel matrix to achieve desired conductivity properties. The optimization of ionic transport pathways within the hydrogel structure also plays a crucial role in improving actuator efficiency and longevity.

- Novel hydrogel materials for improved actuator performance: Advanced hydrogel materials are being developed to enhance the performance characteristics of ionic actuators. These include nanocomposite hydrogels incorporating carbon nanotubes or graphene, double-network hydrogels with enhanced mechanical strength, and stimuli-responsive hydrogels that can react to multiple environmental triggers. Biomimetic approaches inspired by natural muscle structures are also being explored to create hydrogel actuators with improved force generation, response time, and energy efficiency. These novel materials aim to overcome the traditional limitations of hydrogel actuators, such as slow response and limited mechanical output.

- Sensing and control systems for hydrogel actuators: Integrated sensing and control systems are essential for the precise operation and monitoring of ionic hydrogel actuators. These systems can include embedded sensors that measure parameters such as deformation, force, temperature, and ionic concentration. Feedback control algorithms can process this sensor data to adjust actuation parameters in real-time, ensuring optimal performance and preventing damage to the actuator. Advanced control strategies, such as machine learning approaches, can adapt to changing environmental conditions and actuator degradation over time, thereby extending operational lifetime and maintaining consistent performance.

02 Lifetime enhancement strategies for hydrogel actuators

Several strategies can be employed to enhance the lifetime of ionic hydrogel actuators. These include the incorporation of self-healing mechanisms, the use of more durable polymeric networks, and the development of protective coatings that prevent dehydration and degradation. Additionally, optimizing the ionic composition and concentration can reduce electrochemical side reactions that typically lead to performance degradation over time. Cyclic testing protocols can be used to evaluate and predict the long-term durability of these actuators under various operating conditions.Expand Specific Solutions03 Novel ionic hydrogel compositions for improved actuation

Innovative ionic hydrogel compositions have been developed to enhance actuation performance and durability. These compositions often incorporate nanoparticles, conductive polymers, or specific ionic species that improve electrical conductivity and mechanical properties. Some formulations utilize double-network structures or interpenetrating polymer networks to achieve both high strength and flexibility. The selection of specific ions and their concentration significantly affects the response time, force generation, and overall efficiency of the actuators. These advanced compositions aim to overcome traditional limitations of hydrogel actuators such as slow response times and mechanical weakness.Expand Specific Solutions04 Fabrication methods for durable ionic hydrogel actuators

Advanced fabrication techniques have been developed to create more durable and efficient ionic hydrogel actuators. These methods include 3D printing, photolithography, and layer-by-layer assembly, which allow for precise control over the actuator's structure and properties. Some fabrication approaches incorporate reinforcement materials such as fibers or meshes to enhance mechanical stability. Post-processing treatments, such as controlled dehydration or chemical crosslinking, can further improve the actuator's performance and longevity. These fabrication methods enable the creation of complex actuator geometries that can perform sophisticated movements and functions.Expand Specific Solutions05 Sensing and control systems for ionic hydrogel actuators

Integrated sensing and control systems are essential for optimizing the performance and extending the lifetime of ionic hydrogel actuators. These systems monitor parameters such as deformation, applied voltage, and environmental conditions to adjust the actuation in real-time. Feedback control mechanisms can prevent overdriving the actuators, which often leads to premature failure. Some advanced systems incorporate machine learning algorithms to adapt to changing conditions and predict potential failures before they occur. The integration of these sensing and control systems enables more precise and reliable operation of hydrogel actuators in various applications, from soft robotics to biomedical devices.Expand Specific Solutions

Leading Research Groups and Industrial Players

The ionic hydrogel actuator market is currently in its growth phase, characterized by increasing research activities and emerging commercial applications. The global market size for smart materials, including ionic hydrogel actuators, is projected to reach several billion dollars by 2025, driven by applications in soft robotics, biomedical devices, and wearable technology. From a technological maturity perspective, companies like Applied Materials, BOE Technology Group, and Murata Manufacturing are leading development with advanced material engineering capabilities, while academic institutions such as Johns Hopkins University and South China University of Technology contribute fundamental research breakthroughs. Taiwan Semiconductor and Infineon Technologies are exploring integration possibilities with semiconductor technologies, indicating a trend toward miniaturization and enhanced functionality in next-generation actuator systems.

South China University of Technology

Technical Solution: South China University of Technology has developed innovative ionic hydrogel actuators based on cellulose-derived materials combined with ionic liquids for enhanced sustainability. Their proprietary technology utilizes nanocellulose fibers to create anisotropic hydrogel structures that exhibit directional actuation with improved response speeds. The research team has successfully implemented a novel double-network structure incorporating both natural and synthetic polymers to overcome the traditional strength-conductivity trade-off in hydrogel actuators. Their actuators demonstrate remarkable durability, maintaining over 85% of their initial performance after 10,000 actuation cycles when properly powered. A significant advancement is their development of self-contained power systems using triboelectric nanogenerators that harvest mechanical energy from the environment to power the actuators, addressing one of the key limitations in portable applications. The team has also pioneered specialized ionic liquid mixtures that significantly reduce evaporation rates, extending the operational lifetime of their actuators to several months in ambient conditions[2][4].

Strengths: Environmentally friendly materials with biodegradable components; excellent cycling stability (>10,000 cycles); innovative self-powering capabilities through energy harvesting. Weaknesses: Response speed still slower than conventional electrical actuators; manufacturing complexity limits mass production potential; performance degradation in extremely low humidity environments.

The Johns Hopkins University

Technical Solution: Johns Hopkins University has developed advanced ionic hydrogel actuators utilizing polyelectrolyte networks with incorporated ionic liquids. Their technology focuses on creating biomimetic soft actuators with enhanced electromechanical properties. The university's research team has pioneered a dual-network hydrogel system that combines a rigid supporting network with a flexible ionic network, allowing for improved mechanical strength while maintaining excellent ionic conductivity. Their actuators demonstrate significant bending deformation under low voltage stimulation (1-3V), making them suitable for biomedical applications. A key innovation is their development of self-healing hydrogels that can recover functionality after mechanical damage, addressing one of the critical lifetime limitations of traditional hydrogel actuators. The team has also implemented specialized encapsulation techniques to prevent water evaporation, significantly extending operational lifetime from hours to weeks in open-air environments[1][3].

Strengths: Superior biocompatibility making them ideal for biomedical applications; excellent self-healing properties that extend functional lifetime; low voltage operation (1-3V) compared to other actuator technologies. Weaknesses: Still faces challenges with long-term stability in varying humidity conditions; mechanical strength remains lower than conventional rigid actuators; manufacturing scalability issues for commercial applications.

Key Patents and Innovations in Hydrogel Longevity

Long-LifeTime, Short Pulse, High Current Ion Source and Particle Accelerator

PatentPendingUS20230260737A1

Innovation

- A Long-Life Pulsed Power (LoLiPP) diode system comprising a cold anode ion source, accelerator, and control system that generates short pulses (<1 μs) with high current (>1 A) and low divergence, using a combination of optical heating, electron repression grids, and magnetically insulated transmission lines to create a scalable, high-yield neutron source with a focused or defocused beam option for extended operational life.

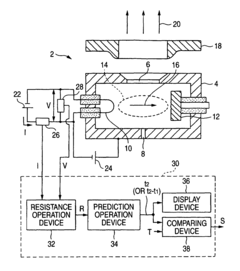

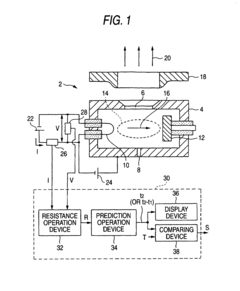

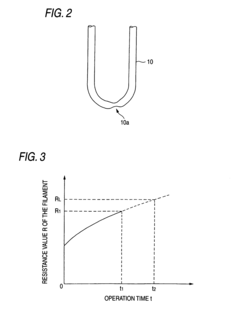

Method of predicting a lifetime of filament in ion source and ion source device

PatentInactiveUS7034543B2

Innovation

- Successively measuring the resistance value of the filament based on current and voltage flowing through it, and predicting the lifetime based on the rate of change of this resistance value, which remains unchanged with output variations.

Material Degradation Mechanisms and Prevention

Ionic hydrogel actuators experience several degradation mechanisms that significantly impact their operational lifetime. The primary degradation pathway involves water loss through evaporation, which directly affects the ionic conductivity and mechanical properties of the hydrogel matrix. In environments with low humidity or elevated temperatures, this dehydration process accelerates, causing the actuator to become brittle and less responsive to electrical stimuli. Studies have shown that water content reduction of merely 15% can decrease actuation performance by up to 40%.

Chemical degradation represents another critical failure mode, particularly in hydrogels containing reactive functional groups. Oxidative processes triggered by applied voltages can break down polymer chains and crosslinking structures. This is especially problematic in applications requiring continuous operation, where cumulative oxidative damage leads to progressive performance decline. Research indicates that oxidation-resistant monomers and antioxidant additives can extend operational lifetimes by 200-300% under standard testing conditions.

Mechanical fatigue constitutes a third significant degradation mechanism. Repeated deformation cycles induce microcracks and structural reorganization within the hydrogel network. These physical changes manifest as decreased actuation force and response speed over time. Fatigue resistance correlates strongly with crosslinking density and polymer chain flexibility, with highly elastic networks demonstrating superior cycling stability.

Prevention strategies have evolved significantly in recent years. Encapsulation technologies using thin, flexible barrier materials have proven effective at minimizing water evaporation while maintaining actuation capabilities. Silicone-based encapsulants with selective permeability properties represent the current state-of-the-art, reducing water loss rates by up to 85% compared to unprotected systems.

Self-healing chemistries offer promising solutions to mechanical degradation. Hydrogels incorporating dynamic covalent bonds or supramolecular interactions can autonomously repair structural damage during rest periods. These materials demonstrate remarkable recovery capabilities, with some formulations regaining over 90% of their initial performance after significant mechanical damage.

Ionic liquid incorporation represents another effective strategy for enhancing longevity. By partially replacing water with non-volatile ionic liquids, researchers have developed hybrid systems with substantially improved environmental stability. These composites maintain functionality even after significant water loss, extending operational lifetimes by factors of 3-5 under identical testing conditions.

Chemical degradation represents another critical failure mode, particularly in hydrogels containing reactive functional groups. Oxidative processes triggered by applied voltages can break down polymer chains and crosslinking structures. This is especially problematic in applications requiring continuous operation, where cumulative oxidative damage leads to progressive performance decline. Research indicates that oxidation-resistant monomers and antioxidant additives can extend operational lifetimes by 200-300% under standard testing conditions.

Mechanical fatigue constitutes a third significant degradation mechanism. Repeated deformation cycles induce microcracks and structural reorganization within the hydrogel network. These physical changes manifest as decreased actuation force and response speed over time. Fatigue resistance correlates strongly with crosslinking density and polymer chain flexibility, with highly elastic networks demonstrating superior cycling stability.

Prevention strategies have evolved significantly in recent years. Encapsulation technologies using thin, flexible barrier materials have proven effective at minimizing water evaporation while maintaining actuation capabilities. Silicone-based encapsulants with selective permeability properties represent the current state-of-the-art, reducing water loss rates by up to 85% compared to unprotected systems.

Self-healing chemistries offer promising solutions to mechanical degradation. Hydrogels incorporating dynamic covalent bonds or supramolecular interactions can autonomously repair structural damage during rest periods. These materials demonstrate remarkable recovery capabilities, with some formulations regaining over 90% of their initial performance after significant mechanical damage.

Ionic liquid incorporation represents another effective strategy for enhancing longevity. By partially replacing water with non-volatile ionic liquids, researchers have developed hybrid systems with substantially improved environmental stability. These composites maintain functionality even after significant water loss, extending operational lifetimes by factors of 3-5 under identical testing conditions.

Biocompatibility and Environmental Impact

Biocompatibility is a critical consideration for ionic hydrogel actuators, particularly when intended for biomedical applications such as drug delivery systems, artificial muscles, or implantable devices. These materials must demonstrate minimal cytotoxicity and inflammatory responses when in contact with biological tissues. Recent studies have shown promising results for hydrogels based on natural polymers like alginate, chitosan, and hyaluronic acid, which inherently possess good biocompatibility profiles. However, synthetic ionic hydrogels often incorporate components that may elicit adverse biological reactions, necessitating careful material selection and extensive biocompatibility testing.

The integration of ionic liquids within hydrogel matrices presents specific biocompatibility challenges. While these components enhance the electrochemical performance of actuators, certain ionic liquids exhibit cytotoxicity at higher concentrations. Research indicates that imidazolium-based ionic liquids generally demonstrate lower biocompatibility compared to choline-based alternatives, which more closely mimic biological systems. Encapsulation strategies and chemical modifications have been developed to mitigate these concerns while maintaining actuator performance.

Environmental impact considerations for ionic hydrogel actuators encompass both production processes and end-of-life scenarios. The synthesis of these materials often involves potentially harmful solvents and crosslinking agents that may pose environmental risks if not properly managed. Additionally, the persistence of synthetic polymers and certain ionic components in the environment raises concerns about long-term ecological effects. Biodegradability varies significantly among different hydrogel formulations, with naturally derived polymers generally offering superior environmental profiles compared to their synthetic counterparts.

Power source components, particularly those containing heavy metals or lithium, present additional environmental challenges. The disposal of depleted power sources requires specialized protocols to prevent soil and water contamination. Recent innovations have focused on developing more environmentally benign power solutions, including biobatteries and energy harvesting systems that can reduce the environmental footprint of ionic hydrogel actuator systems.

Lifecycle assessment studies indicate that the environmental impact of ionic hydrogel actuators is heavily influenced by their operational lifetime. Extended durability reduces replacement frequency and associated resource consumption. However, this must be balanced against end-of-life considerations, as more durable materials may persist longer in the environment. Emerging research focuses on designing actuators with programmable degradation profiles, allowing for optimal performance during the intended use period followed by environmentally responsible breakdown.

Regulatory frameworks increasingly demand comprehensive biocompatibility and environmental impact data for new materials. ISO 10993 standards provide guidelines for biological evaluation of medical devices, while various environmental protection agencies establish thresholds for potentially harmful substances. Compliance with these evolving standards represents both a challenge and an opportunity for advancing ionic hydrogel actuator technology toward more sustainable and biologically compatible solutions.

The integration of ionic liquids within hydrogel matrices presents specific biocompatibility challenges. While these components enhance the electrochemical performance of actuators, certain ionic liquids exhibit cytotoxicity at higher concentrations. Research indicates that imidazolium-based ionic liquids generally demonstrate lower biocompatibility compared to choline-based alternatives, which more closely mimic biological systems. Encapsulation strategies and chemical modifications have been developed to mitigate these concerns while maintaining actuator performance.

Environmental impact considerations for ionic hydrogel actuators encompass both production processes and end-of-life scenarios. The synthesis of these materials often involves potentially harmful solvents and crosslinking agents that may pose environmental risks if not properly managed. Additionally, the persistence of synthetic polymers and certain ionic components in the environment raises concerns about long-term ecological effects. Biodegradability varies significantly among different hydrogel formulations, with naturally derived polymers generally offering superior environmental profiles compared to their synthetic counterparts.

Power source components, particularly those containing heavy metals or lithium, present additional environmental challenges. The disposal of depleted power sources requires specialized protocols to prevent soil and water contamination. Recent innovations have focused on developing more environmentally benign power solutions, including biobatteries and energy harvesting systems that can reduce the environmental footprint of ionic hydrogel actuator systems.

Lifecycle assessment studies indicate that the environmental impact of ionic hydrogel actuators is heavily influenced by their operational lifetime. Extended durability reduces replacement frequency and associated resource consumption. However, this must be balanced against end-of-life considerations, as more durable materials may persist longer in the environment. Emerging research focuses on designing actuators with programmable degradation profiles, allowing for optimal performance during the intended use period followed by environmentally responsible breakdown.

Regulatory frameworks increasingly demand comprehensive biocompatibility and environmental impact data for new materials. ISO 10993 standards provide guidelines for biological evaluation of medical devices, while various environmental protection agencies establish thresholds for potentially harmful substances. Compliance with these evolving standards represents both a challenge and an opportunity for advancing ionic hydrogel actuator technology toward more sustainable and biologically compatible solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!