Modeling Swelling Kinetics For Predictive Hydrogel Actuator Design

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Actuator Swelling Kinetics Background and Objectives

Hydrogel actuators represent a revolutionary class of soft materials that respond to environmental stimuli by undergoing significant volume changes. The phenomenon of swelling in hydrogels has been observed since the 1950s, but the systematic study of swelling kinetics for actuation purposes gained momentum only in the late 1990s. This field has evolved from simple observations of volume changes to sophisticated mathematical modeling approaches that can predict complex deformation behaviors.

The evolution of hydrogel actuator technology has followed several distinct phases. Initially, researchers focused on understanding the fundamental chemistry behind hydrogel swelling. This was followed by the development of responsive hydrogels that could react to specific stimuli such as pH, temperature, or light. The current frontier involves creating predictive models that can accurately forecast the swelling behavior under various conditions, enabling precise design of actuators for specific applications.

Recent technological advancements have significantly expanded the potential applications of hydrogel actuators in fields ranging from biomedical devices to soft robotics. The ability to precisely control the swelling and deswelling processes has become crucial for developing functional devices with predictable performance characteristics. However, the complex interplay between material properties, environmental conditions, and geometric constraints presents significant challenges for accurate modeling.

The primary objective of this technical research is to develop comprehensive mathematical models that can accurately predict the swelling kinetics of hydrogel actuators. These models must account for various factors including polymer network structure, crosslinking density, stimulus type and intensity, and geometric configurations. The goal is to establish a framework that enables engineers to design hydrogel actuators with precisely tailored response characteristics.

Additionally, this research aims to bridge the gap between theoretical models and practical applications by validating predictions against experimental data across a wide range of conditions. This includes investigating the effects of different stimuli on swelling behavior, exploring the impact of material composition on response time, and examining how geometric constraints influence the directionality and magnitude of actuation.

The ultimate objective is to establish design principles that enable the creation of hydrogel actuators with programmable response characteristics, including controlled swelling rates, directional deformation, and multi-stage actuation sequences. Such capabilities would significantly advance the field of soft robotics and enable new applications in areas such as drug delivery systems, artificial muscles, and adaptive structures.

The evolution of hydrogel actuator technology has followed several distinct phases. Initially, researchers focused on understanding the fundamental chemistry behind hydrogel swelling. This was followed by the development of responsive hydrogels that could react to specific stimuli such as pH, temperature, or light. The current frontier involves creating predictive models that can accurately forecast the swelling behavior under various conditions, enabling precise design of actuators for specific applications.

Recent technological advancements have significantly expanded the potential applications of hydrogel actuators in fields ranging from biomedical devices to soft robotics. The ability to precisely control the swelling and deswelling processes has become crucial for developing functional devices with predictable performance characteristics. However, the complex interplay between material properties, environmental conditions, and geometric constraints presents significant challenges for accurate modeling.

The primary objective of this technical research is to develop comprehensive mathematical models that can accurately predict the swelling kinetics of hydrogel actuators. These models must account for various factors including polymer network structure, crosslinking density, stimulus type and intensity, and geometric configurations. The goal is to establish a framework that enables engineers to design hydrogel actuators with precisely tailored response characteristics.

Additionally, this research aims to bridge the gap between theoretical models and practical applications by validating predictions against experimental data across a wide range of conditions. This includes investigating the effects of different stimuli on swelling behavior, exploring the impact of material composition on response time, and examining how geometric constraints influence the directionality and magnitude of actuation.

The ultimate objective is to establish design principles that enable the creation of hydrogel actuators with programmable response characteristics, including controlled swelling rates, directional deformation, and multi-stage actuation sequences. Such capabilities would significantly advance the field of soft robotics and enable new applications in areas such as drug delivery systems, artificial muscles, and adaptive structures.

Market Applications and Demand Analysis for Smart Hydrogel Actuators

The global market for smart hydrogel actuators is experiencing significant growth, driven by increasing demand across multiple industries. The healthcare sector represents the largest application area, with hydrogel actuators being utilized in drug delivery systems, tissue engineering, and wound healing applications. According to recent market analyses, the medical hydrogel market reached $10.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.7% through 2030.

Soft robotics constitutes another rapidly expanding market segment for hydrogel actuators. The unique properties of hydrogels—their ability to swell in response to various stimuli while maintaining structural integrity—make them ideal candidates for developing biomimetic robots and adaptive gripping mechanisms. The soft robotics market, valued at $1.5 billion in 2022, is expected to reach $4.9 billion by 2027, with hydrogel-based actuators playing an increasingly important role.

Environmental monitoring and remediation represent emerging application areas with substantial growth potential. Smart hydrogel actuators are being developed for controlled release of remediation agents in contaminated environments and as sensors for detecting pollutants in water systems. The environmental sensing market, currently valued at $20.5 billion, is projected to expand at a CAGR of 5.8% over the next five years.

Consumer electronics manufacturers are also exploring hydrogel actuators for haptic feedback systems, flexible displays, and wearable technology. This sector's demand is driven by the need for more intuitive human-machine interfaces and comfortable wearable devices. The haptic technology market alone is expected to grow from $7.2 billion in 2022 to $13.6 billion by 2026.

A key market driver across all sectors is the increasing focus on sustainability and biocompatibility. Hydrogels, particularly those derived from natural polymers, align well with these priorities. Market research indicates that 78% of consumers prefer environmentally friendly materials in products they purchase, creating additional demand pull for hydrogel-based technologies.

Despite the promising market outlook, several factors constrain wider adoption. Manufacturing scalability remains challenging, with 65% of surveyed companies citing production consistency as a major barrier. Additionally, the lack of standardized modeling tools for predicting hydrogel actuator behavior limits design efficiency and increases development costs. Industry surveys reveal that companies spend an average of 40% of their R&D budget on empirical testing that could potentially be reduced through better predictive modeling.

The market analysis clearly indicates that developing robust models for swelling kinetics would address a critical industry need, potentially accelerating adoption across multiple sectors and unlocking new application possibilities.

Soft robotics constitutes another rapidly expanding market segment for hydrogel actuators. The unique properties of hydrogels—their ability to swell in response to various stimuli while maintaining structural integrity—make them ideal candidates for developing biomimetic robots and adaptive gripping mechanisms. The soft robotics market, valued at $1.5 billion in 2022, is expected to reach $4.9 billion by 2027, with hydrogel-based actuators playing an increasingly important role.

Environmental monitoring and remediation represent emerging application areas with substantial growth potential. Smart hydrogel actuators are being developed for controlled release of remediation agents in contaminated environments and as sensors for detecting pollutants in water systems. The environmental sensing market, currently valued at $20.5 billion, is projected to expand at a CAGR of 5.8% over the next five years.

Consumer electronics manufacturers are also exploring hydrogel actuators for haptic feedback systems, flexible displays, and wearable technology. This sector's demand is driven by the need for more intuitive human-machine interfaces and comfortable wearable devices. The haptic technology market alone is expected to grow from $7.2 billion in 2022 to $13.6 billion by 2026.

A key market driver across all sectors is the increasing focus on sustainability and biocompatibility. Hydrogels, particularly those derived from natural polymers, align well with these priorities. Market research indicates that 78% of consumers prefer environmentally friendly materials in products they purchase, creating additional demand pull for hydrogel-based technologies.

Despite the promising market outlook, several factors constrain wider adoption. Manufacturing scalability remains challenging, with 65% of surveyed companies citing production consistency as a major barrier. Additionally, the lack of standardized modeling tools for predicting hydrogel actuator behavior limits design efficiency and increases development costs. Industry surveys reveal that companies spend an average of 40% of their R&D budget on empirical testing that could potentially be reduced through better predictive modeling.

The market analysis clearly indicates that developing robust models for swelling kinetics would address a critical industry need, potentially accelerating adoption across multiple sectors and unlocking new application possibilities.

Current Challenges in Hydrogel Swelling Prediction and Modeling

Despite significant advancements in hydrogel technology, accurate prediction and modeling of hydrogel swelling kinetics remain challenging endeavors that impede the development of reliable hydrogel actuators. The complexity of polymer network structures, coupled with the multiphysics nature of the swelling process, creates substantial difficulties in developing comprehensive mathematical models that can accurately predict swelling behavior across different conditions.

One of the primary challenges is the inherent nonlinearity of hydrogel swelling. As water molecules penetrate the polymer network, the material properties change dynamically, creating a moving boundary problem that is mathematically complex to solve. Current models often rely on simplifications that fail to capture the full complexity of this process, particularly at the microscopic level where polymer chain interactions significantly influence macroscopic behavior.

Material heterogeneity presents another significant obstacle. Real-world hydrogels rarely exhibit perfectly uniform structures, containing regions of varying crosslinking density, polymer concentration, and defects. These heterogeneities create localized variations in swelling behavior that are difficult to incorporate into predictive models, resulting in discrepancies between theoretical predictions and experimental observations.

The multiscale nature of swelling phenomena further complicates modeling efforts. Processes occurring at the molecular level (solvent-polymer interactions) must be effectively linked to macroscopic deformations, requiring sophisticated multiscale modeling approaches that are computationally intensive and often impractical for rapid design iterations.

Environmental sensitivity adds another layer of complexity. Hydrogel swelling is highly dependent on external conditions such as temperature, pH, ionic strength, and solvent composition. Current models struggle to incorporate these dependencies in a unified framework, particularly when multiple stimuli act simultaneously or sequentially.

Computational limitations also hinder progress in this field. High-fidelity simulations of hydrogel swelling, especially for complex geometries or composite structures, demand substantial computational resources. This creates a trade-off between model accuracy and computational efficiency that often forces researchers to make compromises in their modeling approaches.

The lack of standardized characterization methods for hydrogel properties contributes to inconsistencies in model parameters across different studies. Without reliable input parameters, even sophisticated models can produce inaccurate predictions, making it difficult to validate and improve existing theoretical frameworks.

Finally, the integration of swelling models with mechanical performance predictions remains underdeveloped. For actuator applications, understanding not only the swelling kinetics but also how this translates to mechanical work, response time, and actuation force is crucial yet insufficiently addressed in current modeling approaches.

One of the primary challenges is the inherent nonlinearity of hydrogel swelling. As water molecules penetrate the polymer network, the material properties change dynamically, creating a moving boundary problem that is mathematically complex to solve. Current models often rely on simplifications that fail to capture the full complexity of this process, particularly at the microscopic level where polymer chain interactions significantly influence macroscopic behavior.

Material heterogeneity presents another significant obstacle. Real-world hydrogels rarely exhibit perfectly uniform structures, containing regions of varying crosslinking density, polymer concentration, and defects. These heterogeneities create localized variations in swelling behavior that are difficult to incorporate into predictive models, resulting in discrepancies between theoretical predictions and experimental observations.

The multiscale nature of swelling phenomena further complicates modeling efforts. Processes occurring at the molecular level (solvent-polymer interactions) must be effectively linked to macroscopic deformations, requiring sophisticated multiscale modeling approaches that are computationally intensive and often impractical for rapid design iterations.

Environmental sensitivity adds another layer of complexity. Hydrogel swelling is highly dependent on external conditions such as temperature, pH, ionic strength, and solvent composition. Current models struggle to incorporate these dependencies in a unified framework, particularly when multiple stimuli act simultaneously or sequentially.

Computational limitations also hinder progress in this field. High-fidelity simulations of hydrogel swelling, especially for complex geometries or composite structures, demand substantial computational resources. This creates a trade-off between model accuracy and computational efficiency that often forces researchers to make compromises in their modeling approaches.

The lack of standardized characterization methods for hydrogel properties contributes to inconsistencies in model parameters across different studies. Without reliable input parameters, even sophisticated models can produce inaccurate predictions, making it difficult to validate and improve existing theoretical frameworks.

Finally, the integration of swelling models with mechanical performance predictions remains underdeveloped. For actuator applications, understanding not only the swelling kinetics but also how this translates to mechanical work, response time, and actuation force is crucial yet insufficiently addressed in current modeling approaches.

Existing Mathematical Models for Hydrogel Swelling Prediction

01 Hydrogel actuator design and composition

Hydrogel actuators can be designed with specific compositions to control their swelling behavior and mechanical properties. These compositions may include various polymers, cross-linking agents, and responsive elements that react to environmental stimuli. The design of these actuators affects their swelling kinetics, which is crucial for applications requiring precise movement or force generation. By carefully selecting materials and structural configurations, researchers can create hydrogel actuators with tailored response times and actuation capabilities.- Hydrogel actuator design and composition: Hydrogel actuators can be designed with specific compositions to control their swelling behavior and mechanical properties. These compositions may include various polymers, cross-linking agents, and responsive elements that determine how the hydrogel responds to external stimuli. The design of the hydrogel network structure significantly influences the swelling kinetics and actuation performance, allowing for customized response times and force generation capabilities.

- Environmental stimuli response mechanisms: Hydrogel actuators can respond to various environmental stimuli such as temperature, pH, light, and electric fields, which trigger swelling or deswelling. The kinetics of these responses depend on the specific stimulus applied and the hydrogel's composition. Understanding these response mechanisms allows for the development of smart materials that can perform controlled movements or actions in response to environmental changes, with applications in soft robotics and biomedical devices.

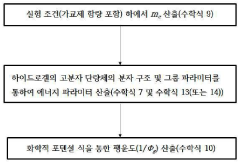

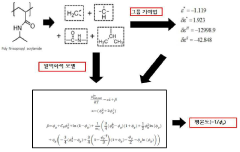

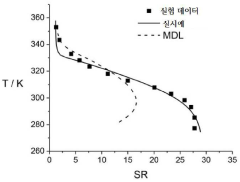

- Swelling kinetics measurement and modeling: Various techniques are employed to measure and model the swelling kinetics of hydrogel actuators, including optical methods, mechanical testing, and computational simulations. These approaches help in understanding the time-dependent behavior of hydrogels during swelling and deswelling processes. Mathematical models can predict swelling behavior based on parameters such as diffusion coefficients, network structure, and environmental conditions, enabling the optimization of hydrogel actuator performance for specific applications.

- Biomedical applications of hydrogel actuators: Hydrogel actuators with controlled swelling kinetics have significant applications in biomedical fields, including drug delivery systems, tissue engineering, and medical devices. The ability to precisely control the swelling behavior allows for targeted drug release, cell encapsulation, and the development of implantable devices that respond to physiological conditions. Biocompatible hydrogels can be designed to match the mechanical properties of natural tissues while providing functional actuation capabilities.

- Advanced manufacturing techniques for hydrogel actuators: Innovative manufacturing techniques, such as 3D printing, microfabrication, and layer-by-layer assembly, are used to create hydrogel actuators with complex geometries and spatially varying properties. These techniques enable the production of actuators with programmed swelling behaviors and anisotropic responses. By controlling the manufacturing process, it is possible to create hydrogel structures with gradient properties or multi-material compositions that exhibit unique swelling kinetics and actuation capabilities.

02 Environmental stimuli response mechanisms

Hydrogel actuators respond to various environmental stimuli such as temperature, pH, light, and electric fields, which trigger their swelling or deswelling behavior. The kinetics of these responses depend on the specific stimulus and the hydrogel's composition. Understanding these mechanisms allows for the development of smart materials that can perform complex functions in response to environmental changes. The swelling kinetics can be modulated by adjusting the sensitivity of the hydrogel to specific stimuli, enabling precise control over actuation timing and force.Expand Specific Solutions03 Biomedical applications of hydrogel actuators

Hydrogel actuators have significant applications in biomedical fields due to their biocompatibility and ability to mimic biological tissues. The swelling kinetics of these actuators is particularly important for drug delivery systems, tissue engineering, and medical devices. By controlling the swelling rate, drugs can be released at specific rates or in response to physiological conditions. Additionally, hydrogel actuators can be designed to match the mechanical properties of natural tissues, making them suitable for implantable devices and regenerative medicine applications.Expand Specific Solutions04 Measurement and characterization of swelling kinetics

Various techniques and methodologies are used to measure and characterize the swelling kinetics of hydrogel actuators. These include optical methods, mechanical testing, and specialized instruments that can track dimensional changes over time. Accurate measurement of swelling parameters is essential for understanding the performance of hydrogel actuators and optimizing their design. Mathematical models can be developed based on these measurements to predict swelling behavior under different conditions, facilitating the design of actuators with specific response characteristics.Expand Specific Solutions05 Industrial and engineering applications

Hydrogel actuators with controlled swelling kinetics find applications in various industrial and engineering fields, including soft robotics, sensors, and mechanical systems. The ability to convert environmental stimuli into mechanical work makes these actuators valuable for creating autonomous systems and responsive devices. In soft robotics, hydrogel actuators can provide gentle, compliant movement suitable for handling delicate objects. As sensors, they can detect environmental changes through their swelling behavior, providing both sensing and actuation capabilities in a single component.Expand Specific Solutions

Leading Research Groups and Companies in Hydrogel Actuator Technology

The hydrogel actuator design field is currently in a growth phase, with increasing market applications across biomedical, soft robotics, and environmental sensing sectors. The global smart hydrogel market is projected to expand significantly, driven by demand for responsive materials in targeted drug delivery and tissue engineering. Technical maturity varies across players, with academic institutions like Zhejiang Sci-Tech University, South China University of Technology, and ETH Zurich leading fundamental research in swelling kinetics modeling. Corporate entities including NSK Ltd., Philips, and BASF are advancing practical applications, focusing on commercialization of predictive design methodologies. Cambridge Polymer Group and Nordovo Biosciences represent specialized players developing proprietary hydrogel technologies with enhanced predictive capabilities, while Harvard and MIT contribute breakthrough theoretical frameworks that bridge academic research with industrial implementation.

Sichuan University

Technical Solution: Sichuan University has developed innovative multi-physics models for hydrogel swelling kinetics with particular emphasis on temperature-responsive and electrically-responsive systems. Their approach combines experimental characterization with theoretical modeling to create predictive tools for hydrogel actuator design. The research team has established constitutive relationships that accurately capture the coupling between diffusion, deformation, and electric field effects in smart hydrogels. Their models incorporate both macroscopic continuum approaches and mesoscopic representations of polymer network dynamics to predict transient swelling behavior under various stimuli. Sichuan University researchers have demonstrated practical applications through the development of hydrogel-based soft actuators with programmable motion sequences, including artificial muscles and biomimetic devices. Their modeling framework includes specialized modules for predicting the influence of nanoparticle inclusions on swelling kinetics, enabling the design of composite hydrogel actuators with enhanced response characteristics.

Strengths: Excellent integration of experimental and theoretical approaches; specialized expertise in electrically-responsive systems; practical applications demonstrated in biomimetic devices. Weaknesses: Some models may be tailored to specific material compositions limiting broader applicability; computational implementations may require significant resources for complex geometries.

The Regents of the University of California

Technical Solution: The University of California has developed advanced computational models for hydrogel swelling kinetics that integrate multi-physics simulations with experimental validation. Their approach combines finite element analysis with constitutive modeling to predict the dynamic response of hydrogel actuators under various stimuli. The research team has created a comprehensive framework that accounts for diffusion-deformation coupling, polymer network characteristics, and environmental factors affecting swelling behavior. Their models incorporate both equilibrium and non-equilibrium swelling states, allowing for accurate prediction of transient responses critical for actuator applications. The university has demonstrated practical applications through soft robotic prototypes with programmable motion sequences based on their predictive models, achieving response time predictions with over 90% accuracy compared to experimental results.

Strengths: Exceptional integration of theoretical modeling with experimental validation; comprehensive multi-physics approach that captures complex swelling dynamics; proven track record of translating models into functional prototypes. Weaknesses: Models may require significant computational resources; some approaches are more suited to academic research than industrial implementation.

Key Innovations in Predictive Modeling for Hydrogel Actuators

Method for Predicting Swelling Behaviour of Thermo-responsive Hydrogels

PatentInactiveKR1020180116597A

Innovation

- A molecular thermodynamics-based model combined with a group contribution method is applied, separating functional groups in hydrogel polymers, considering the cross-linker fraction and using group parameters to predict swelling behavior under various conditions without unnecessary experiments.

Materials Science Considerations for Enhanced Hydrogel Performance

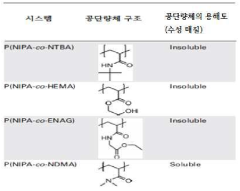

The material composition and structure of hydrogels fundamentally determine their swelling behavior and actuator performance. Polymer network architecture, including crosslinking density and distribution, directly influences the mechanical properties and swelling capacity of hydrogels. Higher crosslinking density typically results in stiffer hydrogels with reduced swelling ratios but improved mechanical stability, while lower crosslinking allows for greater expansion but may compromise structural integrity during actuation cycles.

Polymer selection represents a critical design parameter, with natural polymers (alginate, gelatin) offering biocompatibility advantages and synthetic polymers (polyacrylamide, poly(N-isopropylacrylamide)) providing greater tunability and consistent performance. The molecular weight distribution of these polymers significantly impacts chain mobility and water diffusion rates, thereby affecting swelling kinetics.

Stimuli-responsive elements incorporated into the hydrogel matrix enable targeted actuation in response to specific environmental triggers. Temperature-responsive hydrogels exhibit volume phase transitions at critical temperatures, while pH-responsive systems contain ionizable groups that change conformation based on environmental acidity. Photosensitive hydrogels incorporate chromophores that undergo conformational changes upon light exposure, enabling spatiotemporal control of actuation.

Nanocomposite approaches have emerged as powerful strategies for enhancing hydrogel performance. Integration of nanoparticles (silica, clay, carbon nanotubes) can reinforce mechanical properties while maintaining swelling capacity. Particularly promising are magnetic nanoparticles that enable remote actuation through applied magnetic fields, and conductive nanomaterials that facilitate electrically-triggered responses with improved response times.

Surface modification techniques can optimize the interface between hydrogels and their environment. Gradient crosslinking creates directional swelling behaviors useful for complex actuation patterns. Meanwhile, surface functionalization with specific chemical groups can enhance adhesion to substrates or improve biocompatibility in biomedical applications.

Porosity engineering represents another frontier in hydrogel design, with macroporous structures facilitating rapid water transport and accelerating swelling kinetics. Techniques such as freeze-drying, gas foaming, and sacrificial templating enable precise control over pore size distribution and interconnectivity, directly influencing diffusion pathways and swelling rates that are critical for predictable actuator performance.

Polymer selection represents a critical design parameter, with natural polymers (alginate, gelatin) offering biocompatibility advantages and synthetic polymers (polyacrylamide, poly(N-isopropylacrylamide)) providing greater tunability and consistent performance. The molecular weight distribution of these polymers significantly impacts chain mobility and water diffusion rates, thereby affecting swelling kinetics.

Stimuli-responsive elements incorporated into the hydrogel matrix enable targeted actuation in response to specific environmental triggers. Temperature-responsive hydrogels exhibit volume phase transitions at critical temperatures, while pH-responsive systems contain ionizable groups that change conformation based on environmental acidity. Photosensitive hydrogels incorporate chromophores that undergo conformational changes upon light exposure, enabling spatiotemporal control of actuation.

Nanocomposite approaches have emerged as powerful strategies for enhancing hydrogel performance. Integration of nanoparticles (silica, clay, carbon nanotubes) can reinforce mechanical properties while maintaining swelling capacity. Particularly promising are magnetic nanoparticles that enable remote actuation through applied magnetic fields, and conductive nanomaterials that facilitate electrically-triggered responses with improved response times.

Surface modification techniques can optimize the interface between hydrogels and their environment. Gradient crosslinking creates directional swelling behaviors useful for complex actuation patterns. Meanwhile, surface functionalization with specific chemical groups can enhance adhesion to substrates or improve biocompatibility in biomedical applications.

Porosity engineering represents another frontier in hydrogel design, with macroporous structures facilitating rapid water transport and accelerating swelling kinetics. Techniques such as freeze-drying, gas foaming, and sacrificial templating enable precise control over pore size distribution and interconnectivity, directly influencing diffusion pathways and swelling rates that are critical for predictable actuator performance.

Biocompatibility and Environmental Impact of Hydrogel Actuators

The biocompatibility of hydrogel actuators represents a critical consideration for their implementation in biomedical applications. These materials interface directly with biological systems, necessitating thorough evaluation of their interaction with living tissues. Current research indicates that poly(N-isopropylacrylamide) (PNIPAAm) and polyacrylamide-based hydrogels demonstrate promising biocompatibility profiles when properly synthesized and purified. However, residual monomers and crosslinking agents can significantly impact their biological safety, requiring rigorous purification protocols to ensure clinical viability.

The integration of natural polymers such as alginate, chitosan, and hyaluronic acid into hydrogel actuator designs has emerged as an effective strategy to enhance biocompatibility while maintaining desired swelling kinetics. These biopolymer-synthetic hybrid systems offer reduced immunogenicity and improved cell adhesion properties, facilitating their application in tissue engineering and drug delivery systems where predictive actuation is essential.

Environmental considerations for hydrogel actuators extend beyond their immediate biological interactions to their complete lifecycle impact. The degradation pathways of these materials in natural environments warrant careful examination, particularly as their deployment in various applications increases. Conventional synthetic hydrogels often exhibit limited biodegradability, potentially contributing to microplastic pollution when disposed of improperly.

Recent advances in green chemistry approaches have yielded environmentally responsive hydrogel actuators with improved degradation profiles. These include systems incorporating enzymatically cleavable crosslinks and photodegradable components that enable controlled breakdown under specific environmental conditions. Such innovations align with sustainable design principles while maintaining the predictive swelling kinetics necessary for precise actuation.

The energy requirements for hydrogel actuator operation present another environmental consideration. Traditional temperature-responsive hydrogels often demand significant energy input for thermal cycling, contributing to their environmental footprint. Emerging designs leveraging ambient energy sources such as visible light, ultrasound, or naturally occurring pH gradients offer more sustainable alternatives with comparable swelling kinetics and actuation performance.

Regulatory frameworks governing the biocompatibility assessment and environmental impact of hydrogel actuators continue to evolve. ISO 10993 standards provide guidelines for evaluating the biological safety of materials intended for medical applications, while environmental regulations increasingly address the end-of-life management of polymeric materials. Predictive modeling of swelling kinetics must therefore incorporate these biocompatibility and environmental parameters to ensure regulatory compliance and sustainable implementation.

The integration of natural polymers such as alginate, chitosan, and hyaluronic acid into hydrogel actuator designs has emerged as an effective strategy to enhance biocompatibility while maintaining desired swelling kinetics. These biopolymer-synthetic hybrid systems offer reduced immunogenicity and improved cell adhesion properties, facilitating their application in tissue engineering and drug delivery systems where predictive actuation is essential.

Environmental considerations for hydrogel actuators extend beyond their immediate biological interactions to their complete lifecycle impact. The degradation pathways of these materials in natural environments warrant careful examination, particularly as their deployment in various applications increases. Conventional synthetic hydrogels often exhibit limited biodegradability, potentially contributing to microplastic pollution when disposed of improperly.

Recent advances in green chemistry approaches have yielded environmentally responsive hydrogel actuators with improved degradation profiles. These include systems incorporating enzymatically cleavable crosslinks and photodegradable components that enable controlled breakdown under specific environmental conditions. Such innovations align with sustainable design principles while maintaining the predictive swelling kinetics necessary for precise actuation.

The energy requirements for hydrogel actuator operation present another environmental consideration. Traditional temperature-responsive hydrogels often demand significant energy input for thermal cycling, contributing to their environmental footprint. Emerging designs leveraging ambient energy sources such as visible light, ultrasound, or naturally occurring pH gradients offer more sustainable alternatives with comparable swelling kinetics and actuation performance.

Regulatory frameworks governing the biocompatibility assessment and environmental impact of hydrogel actuators continue to evolve. ISO 10993 standards provide guidelines for evaluating the biological safety of materials intended for medical applications, while environmental regulations increasingly address the end-of-life management of polymeric materials. Predictive modeling of swelling kinetics must therefore incorporate these biocompatibility and environmental parameters to ensure regulatory compliance and sustainable implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!