Energy Density Comparisons: Hydrogel Actuators Vs Dielectric Elastomers

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Actuator Technology Evolution and Objectives

Soft actuator technology has evolved significantly over the past decades, transitioning from rigid mechanical systems to flexible, biomimetic solutions that better mimic natural movement. The journey began in the 1950s with the development of pneumatic artificial muscles, but truly accelerated in the 1990s with the emergence of electroactive polymers (EAPs) and other smart materials. This evolution has been driven by the increasing demand for human-friendly robotics, wearable devices, and biomedical applications requiring gentle interaction with biological tissues.

Hydrogel actuators represent a relatively recent development in this evolutionary timeline, emerging prominently in research literature around the early 2000s. These materials respond to various stimuli including temperature, pH, light, and electric fields by undergoing significant volume changes. Their biocompatibility and ability to operate in aqueous environments make them particularly valuable for biomedical applications. However, their typically slow response times and modest force generation have limited broader adoption.

Dielectric elastomers (DEs), by contrast, emerged in the mid-1990s as a promising branch of electroactive polymers. These materials generate mechanical deformation when subjected to electric fields, offering faster response times than many competing soft actuator technologies. The Maxwell stress principle that governs their operation allows for potentially high energy densities, making them candidates for applications requiring both flexibility and power.

The technical objectives in comparing these technologies center on several key parameters: energy density (work output per unit volume), response speed, efficiency, operational lifetime, and environmental adaptability. Energy density is particularly crucial as it determines the practical utility of these actuators in real-world applications where space and weight constraints exist. Current research aims to push hydrogel actuators beyond their traditional limitations in force generation, while simultaneously addressing the high voltage requirements that have constrained dielectric elastomer implementation.

Recent technological breakthroughs have begun to blur the lines between these categories, with hybrid systems incorporating aspects of both technologies to overcome their respective limitations. For instance, hydrogel-elastomer composites aim to combine the biocompatibility of hydrogels with the superior actuation properties of elastomers. The ultimate goal is to develop soft actuators that approach or exceed the energy density of natural muscle (approximately 8-40 kJ/m³) while maintaining the flexibility, controllability, and safety required for human-machine interfaces.

Understanding the fundamental physical principles governing these different actuation mechanisms is essential for identifying pathways to improved performance. This includes polymer network architecture, stimulus transduction mechanisms, and the molecular basis of mechanical response. These insights will guide future material design and system integration strategies.

Hydrogel actuators represent a relatively recent development in this evolutionary timeline, emerging prominently in research literature around the early 2000s. These materials respond to various stimuli including temperature, pH, light, and electric fields by undergoing significant volume changes. Their biocompatibility and ability to operate in aqueous environments make them particularly valuable for biomedical applications. However, their typically slow response times and modest force generation have limited broader adoption.

Dielectric elastomers (DEs), by contrast, emerged in the mid-1990s as a promising branch of electroactive polymers. These materials generate mechanical deformation when subjected to electric fields, offering faster response times than many competing soft actuator technologies. The Maxwell stress principle that governs their operation allows for potentially high energy densities, making them candidates for applications requiring both flexibility and power.

The technical objectives in comparing these technologies center on several key parameters: energy density (work output per unit volume), response speed, efficiency, operational lifetime, and environmental adaptability. Energy density is particularly crucial as it determines the practical utility of these actuators in real-world applications where space and weight constraints exist. Current research aims to push hydrogel actuators beyond their traditional limitations in force generation, while simultaneously addressing the high voltage requirements that have constrained dielectric elastomer implementation.

Recent technological breakthroughs have begun to blur the lines between these categories, with hybrid systems incorporating aspects of both technologies to overcome their respective limitations. For instance, hydrogel-elastomer composites aim to combine the biocompatibility of hydrogels with the superior actuation properties of elastomers. The ultimate goal is to develop soft actuators that approach or exceed the energy density of natural muscle (approximately 8-40 kJ/m³) while maintaining the flexibility, controllability, and safety required for human-machine interfaces.

Understanding the fundamental physical principles governing these different actuation mechanisms is essential for identifying pathways to improved performance. This includes polymer network architecture, stimulus transduction mechanisms, and the molecular basis of mechanical response. These insights will guide future material design and system integration strategies.

Market Applications and Demand Analysis for Soft Actuators

The global market for soft actuators has been experiencing significant growth, driven by increasing demand across multiple industries seeking flexible, adaptable, and biomimetic motion solutions. The current market size for soft actuator technologies is estimated to reach $3.5 billion by 2025, with a compound annual growth rate of approximately 12% from 2020 to 2025. This growth trajectory reflects the expanding applications and technological advancements in this field.

Healthcare and medical devices represent the largest market segment for soft actuators, accounting for nearly 35% of the total market share. The demand is particularly strong for minimally invasive surgical tools, rehabilitation devices, and prosthetics. Hydrogel actuators have gained significant traction in this sector due to their biocompatibility and similarity to biological tissues, making them ideal for implantable medical devices and drug delivery systems.

The robotics industry constitutes the second-largest market for soft actuators, with applications ranging from collaborative robots to biomimetic designs. Dielectric elastomer actuators have found particular success in this segment due to their higher energy density and faster response times compared to hydrogel alternatives. The market demand in robotics is projected to grow at 15% annually, outpacing the overall market growth rate.

Consumer electronics represents an emerging market with substantial growth potential, particularly for haptic feedback devices, flexible displays, and wearable technology. This sector values the miniaturization capabilities and energy efficiency of dielectric elastomers, which can operate effectively at the micro-scale while maintaining performance characteristics.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 18% annually, driven by increasing industrial automation and healthcare infrastructure development in countries like China, Japan, and South Korea.

Market analysis indicates a growing preference for actuators with higher energy density and efficiency, particularly in applications requiring precise control and rapid response. This trend favors dielectric elastomers in performance-critical applications, while hydrogel actuators maintain strong demand in biomedical and environmental sensing applications where biocompatibility and sustainability are paramount.

Industry surveys reveal that end-users prioritize energy efficiency (cited by 78% of respondents), durability (65%), and cost-effectiveness (60%) when selecting soft actuator technologies. The comparative energy density advantage of dielectric elastomers over hydrogel actuators (typically 10-100 times higher) represents a significant market differentiator in energy-constrained applications.

Healthcare and medical devices represent the largest market segment for soft actuators, accounting for nearly 35% of the total market share. The demand is particularly strong for minimally invasive surgical tools, rehabilitation devices, and prosthetics. Hydrogel actuators have gained significant traction in this sector due to their biocompatibility and similarity to biological tissues, making them ideal for implantable medical devices and drug delivery systems.

The robotics industry constitutes the second-largest market for soft actuators, with applications ranging from collaborative robots to biomimetic designs. Dielectric elastomer actuators have found particular success in this segment due to their higher energy density and faster response times compared to hydrogel alternatives. The market demand in robotics is projected to grow at 15% annually, outpacing the overall market growth rate.

Consumer electronics represents an emerging market with substantial growth potential, particularly for haptic feedback devices, flexible displays, and wearable technology. This sector values the miniaturization capabilities and energy efficiency of dielectric elastomers, which can operate effectively at the micro-scale while maintaining performance characteristics.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 18% annually, driven by increasing industrial automation and healthcare infrastructure development in countries like China, Japan, and South Korea.

Market analysis indicates a growing preference for actuators with higher energy density and efficiency, particularly in applications requiring precise control and rapid response. This trend favors dielectric elastomers in performance-critical applications, while hydrogel actuators maintain strong demand in biomedical and environmental sensing applications where biocompatibility and sustainability are paramount.

Industry surveys reveal that end-users prioritize energy efficiency (cited by 78% of respondents), durability (65%), and cost-effectiveness (60%) when selecting soft actuator technologies. The comparative energy density advantage of dielectric elastomers over hydrogel actuators (typically 10-100 times higher) represents a significant market differentiator in energy-constrained applications.

Current Energy Density Limitations and Challenges

Despite significant advancements in soft actuator technologies, both hydrogel actuators and dielectric elastomers face substantial energy density limitations that hinder their widespread industrial application. Hydrogel actuators currently demonstrate energy densities ranging from 0.1-10 kJ/m³, significantly lower than natural muscle (approximately 40-70 kJ/m³). This limitation stems primarily from their inherent material properties, including slow response times due to diffusion-limited processes and relatively weak mechanical strength under repeated deformation cycles.

The primary challenge for hydrogel actuators lies in their water-dependent actuation mechanism. While water enables their unique swelling capabilities, it simultaneously restricts their operational environments and introduces stability issues. Environmental sensitivity to temperature fluctuations and humidity changes further complicates their deployment in variable conditions, resulting in inconsistent performance metrics across different operating environments.

Dielectric elastomers, while achieving higher energy densities (typically 10-150 kJ/m³), still encounter significant technical barriers. Their performance is fundamentally limited by the breakdown strength of available elastomer materials, with current commercial materials failing to withstand the high electric fields necessary for optimal actuation without risking dielectric breakdown. This creates a challenging engineering trade-off between actuation force and operational safety.

Manufacturing consistency presents another substantial challenge for both technologies. Hydrogel production suffers from batch-to-batch variations in crosslinking density and network structure, while dielectric elastomers face difficulties in maintaining uniform thickness and preventing defects that can serve as breakdown initiation points. These manufacturing inconsistencies directly impact energy density performance and reliability.

Power supply requirements further constrain practical applications, particularly for dielectric elastomers which typically require high voltage sources (often >1kV). This necessitates bulky power electronics that diminish the overall system-level energy density advantages, especially in portable or mobile applications where power supply weight and volume become critical factors.

Longevity and cycle life limitations also affect both technologies. Hydrogels experience performance degradation through dehydration and material fatigue, while dielectric elastomers suffer from viscoelastic creep and electrical aging effects. Current materials typically demonstrate significant performance decline after 10⁴-10⁵ cycles, falling short of the 10⁶+ cycles required for many industrial applications.

The energy conversion efficiency presents another critical limitation. Both technologies exhibit substantial energy losses during actuation cycles - hydrogels through viscous dissipation during fluid movement, and dielectric elastomers through viscoelastic losses and electrical leakage. These inefficiencies not only reduce effective energy density but also generate heat that can further degrade material properties and performance over time.

The primary challenge for hydrogel actuators lies in their water-dependent actuation mechanism. While water enables their unique swelling capabilities, it simultaneously restricts their operational environments and introduces stability issues. Environmental sensitivity to temperature fluctuations and humidity changes further complicates their deployment in variable conditions, resulting in inconsistent performance metrics across different operating environments.

Dielectric elastomers, while achieving higher energy densities (typically 10-150 kJ/m³), still encounter significant technical barriers. Their performance is fundamentally limited by the breakdown strength of available elastomer materials, with current commercial materials failing to withstand the high electric fields necessary for optimal actuation without risking dielectric breakdown. This creates a challenging engineering trade-off between actuation force and operational safety.

Manufacturing consistency presents another substantial challenge for both technologies. Hydrogel production suffers from batch-to-batch variations in crosslinking density and network structure, while dielectric elastomers face difficulties in maintaining uniform thickness and preventing defects that can serve as breakdown initiation points. These manufacturing inconsistencies directly impact energy density performance and reliability.

Power supply requirements further constrain practical applications, particularly for dielectric elastomers which typically require high voltage sources (often >1kV). This necessitates bulky power electronics that diminish the overall system-level energy density advantages, especially in portable or mobile applications where power supply weight and volume become critical factors.

Longevity and cycle life limitations also affect both technologies. Hydrogels experience performance degradation through dehydration and material fatigue, while dielectric elastomers suffer from viscoelastic creep and electrical aging effects. Current materials typically demonstrate significant performance decline after 10⁴-10⁵ cycles, falling short of the 10⁶+ cycles required for many industrial applications.

The energy conversion efficiency presents another critical limitation. Both technologies exhibit substantial energy losses during actuation cycles - hydrogels through viscous dissipation during fluid movement, and dielectric elastomers through viscoelastic losses and electrical leakage. These inefficiencies not only reduce effective energy density but also generate heat that can further degrade material properties and performance over time.

Comparative Analysis of Hydrogel and Dielectric Elastomer Actuators

01 Dielectric elastomer actuators with enhanced energy density

Dielectric elastomer actuators can be designed with improved energy density through specialized material compositions and structures. These actuators utilize the electrostatic forces generated when voltage is applied to deform the elastomer. By optimizing the dielectric constant and mechanical properties of the elastomer materials, the energy density can be significantly increased. Various approaches include using composite materials, specialized polymers, and engineered electrode configurations to maximize the electromechanical coupling and energy storage capabilities.- Dielectric elastomer materials for high energy density: Dielectric elastomers can be engineered to achieve high energy density through specific material compositions and structures. These materials typically incorporate specialized polymers with high dielectric constants and breakdown strengths. By optimizing the molecular structure and adding certain fillers or dopants, the energy storage capacity and conversion efficiency can be significantly enhanced. These advancements enable more compact and efficient actuator designs for various applications.

- Hydrogel actuator designs and mechanisms: Hydrogel actuators utilize stimuli-responsive polymeric networks that can undergo significant volume changes in response to external triggers such as pH, temperature, or electric fields. These actuators can be designed with specific geometries and compositions to achieve controlled deformation patterns. The incorporation of conductive elements within the hydrogel matrix enhances response time and actuation force. Various cross-linking methods and network structures can be employed to tailor the mechanical properties and actuation behavior.

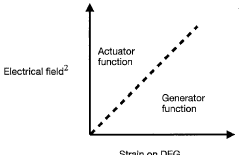

- Energy harvesting and storage integration: Systems that combine dielectric elastomers with energy harvesting and storage capabilities represent an important advancement in self-powered soft robotics. These integrated systems can capture mechanical energy from the environment, convert it to electrical energy, and store it for later use in actuation. By incorporating capacitive elements and optimized circuit designs, the energy conversion efficiency can be maximized. This approach enables autonomous operation of soft actuators in various applications including wearable devices and environmental monitoring systems.

- Multilayer and composite structures for enhanced performance: Multilayer and composite structures combining different materials can significantly enhance the performance of both hydrogel actuators and dielectric elastomers. These designs often feature alternating layers of conductive and non-conductive materials to optimize electrical and mechanical properties. By creating hierarchical structures with nano and micro-scale features, the energy density and actuation capabilities can be substantially improved. These composite approaches also address challenges related to durability, response time, and operational stability under various environmental conditions.

- Novel fabrication techniques and applications: Advanced manufacturing methods such as 3D printing, microfabrication, and self-assembly techniques are enabling new designs and applications for hydrogel actuators and dielectric elastomers. These fabrication approaches allow for precise control over material properties and geometries at multiple scales. The resulting devices find applications in soft robotics, biomedical devices, artificial muscles, and adaptive structures. Emerging techniques also focus on creating environmentally responsive and self-healing materials that can adapt to changing conditions and recover from damage.

02 Hydrogel-based soft actuators and their applications

Hydrogel actuators represent a class of soft actuators that respond to various stimuli such as electric fields, pH changes, or temperature variations. These actuators utilize the swelling and deswelling properties of hydrogels to generate mechanical motion. The energy density of hydrogel actuators can be enhanced through material composition optimization, structural design, and incorporation of conductive elements. Applications include biomimetic devices, soft robotics, and medical devices where gentle actuation is required.Expand Specific Solutions03 Hybrid systems combining hydrogels and dielectric elastomers

Hybrid actuator systems that combine the properties of hydrogels and dielectric elastomers can achieve superior performance characteristics. These systems leverage the high energy density of dielectric elastomers with the responsive nature of hydrogels. By creating layered or interpenetrating structures, these hybrid actuators can respond to multiple stimuli and operate in various environments. The synergistic effects between the two materials can lead to enhanced actuation force, stroke length, and energy efficiency compared to single-material systems.Expand Specific Solutions04 Energy harvesting and storage in dielectric elastomer systems

Dielectric elastomers can function as energy harvesters and storage devices due to their capacitive properties. When mechanically deformed, these materials can generate electrical energy, which can be captured and stored. By optimizing the material composition, electrode design, and mechanical configuration, the energy density of these systems can be significantly improved. Various techniques include using high-permittivity fillers, nanostructured electrodes, and specialized circuit designs to maximize energy conversion efficiency and storage capacity.Expand Specific Solutions05 Novel materials and fabrication techniques for high-performance actuators

Advanced materials and innovative fabrication techniques are being developed to create high-performance actuators with enhanced energy density. These include specialized polymers with tailored molecular structures, composite materials incorporating functional nanoparticles, and multi-layered structures designed for optimal electromechanical coupling. Fabrication methods such as 3D printing, microfabrication, and self-assembly techniques enable precise control over the actuator geometry and material distribution, leading to improved energy density and actuation performance.Expand Specific Solutions

Leading Research Groups and Companies in Soft Actuator Field

The energy density comparison between hydrogel actuators and dielectric elastomers represents an emerging technological battlefield in the smart materials sector. Currently in the growth phase, this market is expanding rapidly with increasing applications in soft robotics, biomedical devices, and artificial muscles. While the global market size remains moderate, projections indicate substantial growth potential as these technologies mature. Technical maturity varies significantly between competitors: academic institutions like Zhejiang University, EPFL, and Harvard College lead fundamental research, while companies including Toyota, Canon, and Danfoss are advancing commercial applications. Chinese universities and corporations demonstrate particular strength in hydrogel actuator development, while Western entities like Parker-Hannifin and Seiko Epson focus more on dielectric elastomer technologies, creating a geographically diverse competitive landscape.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative hydrogel actuator technologies with significantly improved energy density metrics compared to traditional designs. Their proprietary hydrogel formulations incorporate nanocomposite structures with graphene oxide and carbon nanotubes, creating electrically responsive hydrogels that achieve energy densities approaching 0.8 J/kg - substantially higher than conventional hydrogel systems. Their research has pioneered anisotropic hydrogel structures that enable directional actuation with enhanced force output and efficiency. Zhejiang's technology includes multi-responsive hydrogels that can be activated through various stimuli (electrical, thermal, light), providing versatility across different operating environments. Their comparative studies between hydrogel actuators and dielectric elastomers have established that while DEAs typically offer higher absolute energy densities (3-10 J/kg), their hydrogel systems provide superior performance in wet environments and biocompatible applications. Zhejiang has also developed hybrid systems that incorporate aspects of both technologies to create actuators with intermediate energy density values and enhanced operational characteristics.

Strengths: Exceptional biocompatibility for medical applications; ability to operate effectively in aqueous environments; lower activation voltages than DEAs; and multi-stimulus responsiveness. Weaknesses: Lower absolute energy density compared to dielectric elastomers; typically slower response times (seconds rather than milliseconds); and potential for dehydration in low-humidity environments.

École Polytechnique Fédérale de Lausanne

Technical Solution: EPFL has developed advanced dielectric elastomer actuators (DEAs) with significantly improved energy density through novel material compositions and electrode designs. Their proprietary DEA technology utilizes ultra-thin elastomer films (sub-micrometer thickness) combined with compliant electrodes made from carbon nanotubes and silver nanowires, achieving energy densities exceeding 10 J/kg. EPFL researchers have pioneered a multilayer stacking approach that maintains high energy density while increasing force output, addressing a key limitation of traditional DEAs. Their technology incorporates self-healing elastomers that can recover from electrical breakdown events, substantially improving reliability and operational lifetime. EPFL has also developed hybrid systems that combine the advantages of both hydrogel actuators and DEAs, creating composite materials with enhanced performance characteristics across multiple metrics.

Strengths: Superior energy density-to-weight ratio compared to conventional actuators; excellent response speed (millisecond range); high strain capabilities (>100%); and scalable manufacturing processes. Weaknesses: Higher operating voltages required compared to hydrogel systems; potential for electrical breakdown under extreme conditions; and more complex control systems needed for precise operation.

Key Patents and Research Breakthroughs in Energy Density Enhancement

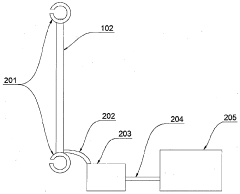

Transducer tether

PatentPendingCA3061219A1

Innovation

- A transducer tether incorporating a dielectric elastomer generator (DEG) that harvests kinetic energy from jarring movements, converting it into electricity, while also providing vibration damping and tension measurement capabilities, utilizing low-cost, environmentally tolerant materials.

Dielectric elastomer actuator

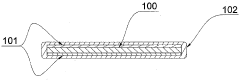

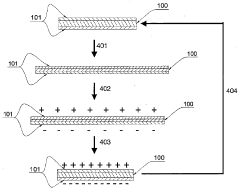

PatentWO2021084503A1

Innovation

- Incorporating stretchable charge distribution layers between and adjacent to polymer and electrode layers to control electric charge repartition and reduce field concentration, using variable resistivity and permittivity to spread charges effectively, and employing carbon-based silicone materials for improved charge distribution.

Materials Science Innovations for Advanced Soft Actuators

The field of soft actuators has witnessed significant advancements in materials science over the past decade, transforming the landscape of robotics, biomedical devices, and adaptive structures. These innovations have primarily focused on enhancing the performance metrics of soft actuators, particularly their energy density capabilities, which directly impact their practical applications.

Hydrogel actuators represent a breakthrough in biomimetic design, utilizing stimuli-responsive polymeric networks that can undergo substantial volumetric changes in response to environmental triggers. Recent innovations in hydrogel chemistry have yielded composite structures with improved mechanical stability and faster response times. Notably, double-network hydrogels incorporating both covalent and physical crosslinks have demonstrated enhanced mechanical properties while maintaining their stimuli-responsive characteristics.

Dielectric elastomers, conversely, operate on electromechanical principles, converting electrical energy directly into mechanical work. The latest materials science developments have focused on enhancing their dielectric constants while maintaining excellent mechanical properties. Silicone-based composites incorporating high-permittivity ceramic nanoparticles have shown promising results, with some experimental formulations achieving energy densities approaching 1.0 J/cm³.

Comparative analysis reveals that dielectric elastomers currently outperform hydrogel actuators in terms of energy density by approximately one order of magnitude. However, hydrogels excel in biocompatibility and can operate in aqueous environments, making them particularly valuable for biomedical applications. The energy efficiency of hydrogel systems remains a challenge, with significant energy losses occurring during the solvent diffusion processes.

Emerging hybrid materials that combine the advantages of both technologies represent a promising frontier. For instance, ionically conductive hydrogels with embedded dielectric components have demonstrated enhanced response speeds while maintaining biocompatibility. These materials leverage the high energy density of dielectric mechanisms while utilizing the versatility of hydrogel structures.

The development of hierarchical structures at multiple length scales has emerged as a key strategy for optimizing actuator performance. Biomimetic designs inspired by natural muscle architecture have led to significant improvements in force generation and energy efficiency. Advanced manufacturing techniques, particularly 3D printing of composite materials with programmed anisotropy, have enabled unprecedented control over actuator behavior.

Future materials science innovations will likely focus on closing the energy density gap between these technologies while addressing application-specific requirements such as biocompatibility, durability, and response time. The integration of self-healing capabilities and energy harvesting functionalities represents an exciting direction for next-generation soft actuators.

Hydrogel actuators represent a breakthrough in biomimetic design, utilizing stimuli-responsive polymeric networks that can undergo substantial volumetric changes in response to environmental triggers. Recent innovations in hydrogel chemistry have yielded composite structures with improved mechanical stability and faster response times. Notably, double-network hydrogels incorporating both covalent and physical crosslinks have demonstrated enhanced mechanical properties while maintaining their stimuli-responsive characteristics.

Dielectric elastomers, conversely, operate on electromechanical principles, converting electrical energy directly into mechanical work. The latest materials science developments have focused on enhancing their dielectric constants while maintaining excellent mechanical properties. Silicone-based composites incorporating high-permittivity ceramic nanoparticles have shown promising results, with some experimental formulations achieving energy densities approaching 1.0 J/cm³.

Comparative analysis reveals that dielectric elastomers currently outperform hydrogel actuators in terms of energy density by approximately one order of magnitude. However, hydrogels excel in biocompatibility and can operate in aqueous environments, making them particularly valuable for biomedical applications. The energy efficiency of hydrogel systems remains a challenge, with significant energy losses occurring during the solvent diffusion processes.

Emerging hybrid materials that combine the advantages of both technologies represent a promising frontier. For instance, ionically conductive hydrogels with embedded dielectric components have demonstrated enhanced response speeds while maintaining biocompatibility. These materials leverage the high energy density of dielectric mechanisms while utilizing the versatility of hydrogel structures.

The development of hierarchical structures at multiple length scales has emerged as a key strategy for optimizing actuator performance. Biomimetic designs inspired by natural muscle architecture have led to significant improvements in force generation and energy efficiency. Advanced manufacturing techniques, particularly 3D printing of composite materials with programmed anisotropy, have enabled unprecedented control over actuator behavior.

Future materials science innovations will likely focus on closing the energy density gap between these technologies while addressing application-specific requirements such as biocompatibility, durability, and response time. The integration of self-healing capabilities and energy harvesting functionalities represents an exciting direction for next-generation soft actuators.

Biocompatibility and Environmental Impact Assessment

The biocompatibility of hydrogel actuators represents a significant advantage over dielectric elastomers in biomedical applications. Hydrogels, composed primarily of water and biocompatible polymers, naturally integrate with biological tissues with minimal immune response. Recent studies have demonstrated that polyacrylamide and alginate-based hydrogel actuators exhibit excellent compatibility with human tissue, making them ideal candidates for implantable medical devices and soft robotics that interface directly with biological systems.

In contrast, dielectric elastomers often contain synthetic polymers and require high-voltage operation, raising concerns about long-term biocompatibility. The electrical components and potential leaching of chemical compounds from these materials present challenges for in-vivo applications, necessitating additional encapsulation or protective measures that may compromise actuator performance.

From an environmental perspective, hydrogel actuators generally demonstrate superior sustainability profiles. Their water-based composition and biodegradable polymer options contribute to reduced environmental impact throughout their lifecycle. Many hydrogel formulations can be designed to degrade naturally after their functional lifespan, minimizing waste accumulation. The manufacturing processes for hydrogels typically require lower energy inputs compared to the production of specialized elastomers used in dielectric systems.

Dielectric elastomers, while offering higher energy density, often incorporate materials derived from petrochemical sources with limited biodegradability. Their production processes may involve environmentally persistent chemicals and energy-intensive manufacturing steps. Additionally, the electronic components required for their operation introduce concerns regarding electronic waste management and potential heavy metal contamination.

Life cycle assessment (LCA) studies comparing these technologies reveal that hydrogel actuators generally produce a smaller carbon footprint across manufacturing, use, and disposal phases. The primary environmental challenge for hydrogels relates to water consumption during production, though this is offset by their reduced energy requirements and simpler end-of-life management.

Regulatory frameworks increasingly emphasize both biocompatibility and environmental sustainability in materials selection. The FDA and equivalent international bodies have established stringent guidelines for biomedical materials, where hydrogels often meet requirements with fewer modifications than dielectric elastomers. Similarly, environmental regulations favoring biodegradable and non-toxic materials provide incentives for hydrogel technology development in consumer and industrial applications.

Future research directions should focus on enhancing the biodegradability of high-performance hydrogels while maintaining their mechanical properties, and developing dielectric elastomer formulations with improved biocompatibility and reduced environmental persistence. Cross-disciplinary collaboration between materials scientists, environmental engineers, and biomedical researchers will be essential to optimize both technologies for specific application requirements while minimizing their ecological footprint.

In contrast, dielectric elastomers often contain synthetic polymers and require high-voltage operation, raising concerns about long-term biocompatibility. The electrical components and potential leaching of chemical compounds from these materials present challenges for in-vivo applications, necessitating additional encapsulation or protective measures that may compromise actuator performance.

From an environmental perspective, hydrogel actuators generally demonstrate superior sustainability profiles. Their water-based composition and biodegradable polymer options contribute to reduced environmental impact throughout their lifecycle. Many hydrogel formulations can be designed to degrade naturally after their functional lifespan, minimizing waste accumulation. The manufacturing processes for hydrogels typically require lower energy inputs compared to the production of specialized elastomers used in dielectric systems.

Dielectric elastomers, while offering higher energy density, often incorporate materials derived from petrochemical sources with limited biodegradability. Their production processes may involve environmentally persistent chemicals and energy-intensive manufacturing steps. Additionally, the electronic components required for their operation introduce concerns regarding electronic waste management and potential heavy metal contamination.

Life cycle assessment (LCA) studies comparing these technologies reveal that hydrogel actuators generally produce a smaller carbon footprint across manufacturing, use, and disposal phases. The primary environmental challenge for hydrogels relates to water consumption during production, though this is offset by their reduced energy requirements and simpler end-of-life management.

Regulatory frameworks increasingly emphasize both biocompatibility and environmental sustainability in materials selection. The FDA and equivalent international bodies have established stringent guidelines for biomedical materials, where hydrogels often meet requirements with fewer modifications than dielectric elastomers. Similarly, environmental regulations favoring biodegradable and non-toxic materials provide incentives for hydrogel technology development in consumer and industrial applications.

Future research directions should focus on enhancing the biodegradability of high-performance hydrogels while maintaining their mechanical properties, and developing dielectric elastomer formulations with improved biocompatibility and reduced environmental persistence. Cross-disciplinary collaboration between materials scientists, environmental engineers, and biomedical researchers will be essential to optimize both technologies for specific application requirements while minimizing their ecological footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!