Hydrogel Actuator Response Under Cyclic Load: Degradation Mechanisms

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Actuator Technology Background and Objectives

Hydrogel actuators represent a revolutionary class of soft materials that respond to external stimuli by undergoing reversible volume changes. The development of these smart materials dates back to the 1950s with the pioneering work on responsive polymers, but significant advancements in hydrogel actuator technology emerged in the late 1990s and early 2000s. The evolution of this field has been driven by the increasing demand for biomimetic systems that can replicate the sophisticated movements found in nature.

The technological trajectory of hydrogel actuators has been characterized by progressive improvements in response time, mechanical strength, and actuation amplitude. Early hydrogel systems suffered from slow response rates and limited mechanical durability, particularly under repeated loading conditions. Recent innovations have focused on enhancing these properties through novel material compositions, structural designs, and fabrication techniques.

Current research objectives in the field center on understanding and mitigating degradation mechanisms that occur during cyclic loading. This represents a critical challenge as practical applications of hydrogel actuators typically require thousands or millions of actuation cycles without significant performance deterioration. The degradation phenomena observed include mechanical fatigue, chemical bond rupture, microstructural reorganization, and changes in crosslinking density.

The primary technical goals for advancing hydrogel actuator technology include: developing comprehensive models to predict degradation behavior under various loading conditions; creating novel hydrogel compositions with enhanced fatigue resistance; establishing standardized testing protocols for evaluating long-term performance; and designing self-healing mechanisms that can autonomously repair damage during operation.

Emerging trends in this field include the integration of nanocomposites to reinforce the polymer network, the development of double-network and interpenetrating network structures to improve mechanical robustness, and the exploration of bioinspired designs that optimize stress distribution during actuation cycles. Additionally, there is growing interest in stimuli-responsive hydrogels that can be triggered by multiple environmental factors simultaneously, offering more sophisticated control over actuation behavior.

The ultimate technological objective is to develop hydrogel actuators with predictable lifespans under cyclic loading conditions, enabling their reliable implementation in critical applications such as soft robotics, biomedical devices, environmental sensors, and adaptive structures. This requires a fundamental understanding of the complex interplay between mechanical forces, chemical reactions, and structural changes that occur during repeated actuation cycles.

The technological trajectory of hydrogel actuators has been characterized by progressive improvements in response time, mechanical strength, and actuation amplitude. Early hydrogel systems suffered from slow response rates and limited mechanical durability, particularly under repeated loading conditions. Recent innovations have focused on enhancing these properties through novel material compositions, structural designs, and fabrication techniques.

Current research objectives in the field center on understanding and mitigating degradation mechanisms that occur during cyclic loading. This represents a critical challenge as practical applications of hydrogel actuators typically require thousands or millions of actuation cycles without significant performance deterioration. The degradation phenomena observed include mechanical fatigue, chemical bond rupture, microstructural reorganization, and changes in crosslinking density.

The primary technical goals for advancing hydrogel actuator technology include: developing comprehensive models to predict degradation behavior under various loading conditions; creating novel hydrogel compositions with enhanced fatigue resistance; establishing standardized testing protocols for evaluating long-term performance; and designing self-healing mechanisms that can autonomously repair damage during operation.

Emerging trends in this field include the integration of nanocomposites to reinforce the polymer network, the development of double-network and interpenetrating network structures to improve mechanical robustness, and the exploration of bioinspired designs that optimize stress distribution during actuation cycles. Additionally, there is growing interest in stimuli-responsive hydrogels that can be triggered by multiple environmental factors simultaneously, offering more sophisticated control over actuation behavior.

The ultimate technological objective is to develop hydrogel actuators with predictable lifespans under cyclic loading conditions, enabling their reliable implementation in critical applications such as soft robotics, biomedical devices, environmental sensors, and adaptive structures. This requires a fundamental understanding of the complex interplay between mechanical forces, chemical reactions, and structural changes that occur during repeated actuation cycles.

Market Applications and Demand Analysis for Hydrogel Actuators

The hydrogel actuator market is experiencing significant growth driven by increasing applications across multiple industries. Current market analysis indicates strong demand in biomedical engineering, where hydrogel actuators are revolutionizing drug delivery systems, tissue engineering, and soft robotics for minimally invasive surgery. The ability of these actuators to respond to various stimuli while maintaining biocompatibility positions them as ideal candidates for implantable medical devices and artificial muscles.

In the consumer electronics sector, demand is emerging for hydrogel actuators in haptic feedback systems, flexible displays, and wearable technology. Their ability to mimic natural movement and provide tactile responses creates opportunities for more intuitive human-machine interfaces. Market research suggests this segment could grow substantially as manufacturers seek solutions that enhance user experience while reducing power consumption.

Environmental monitoring and remediation represent another expanding market segment. Hydrogel actuators capable of responding to specific environmental contaminants show promise for applications in water quality monitoring, pollution detection, and automated remediation systems. The self-sustaining nature of some hydrogel systems, which can harvest energy from their surroundings, addresses the growing demand for sustainable sensing technologies.

The agricultural technology sector demonstrates increasing interest in hydrogel actuators for precision agriculture, particularly in irrigation systems that respond to soil moisture levels and controlled-release fertilizer mechanisms. These applications align with global trends toward resource efficiency and sustainable farming practices.

Market challenges primarily revolve around durability concerns, particularly degradation under cyclic loading conditions. End-users across all sectors require actuators that maintain performance over thousands of cycles without significant mechanical property deterioration. This reliability requirement represents both a market barrier and opportunity for innovation.

Cost factors also influence market dynamics, with current manufacturing processes for high-performance hydrogel actuators remaining relatively expensive for mass-market applications. However, economies of scale and manufacturing innovations are gradually addressing this constraint.

Geographically, North America and Europe lead in research and development, while Asia-Pacific regions show the fastest growth in commercial applications, particularly in electronics and medical devices. This regional distribution reflects different market maturity levels and regulatory environments.

Market forecasts suggest compound annual growth rates exceeding industry averages for smart materials, driven by increasing miniaturization demands, the rise of soft robotics, and growing interest in biomimetic technologies. The development of hydrogel actuators with improved cyclic load resistance and predictable degradation profiles would significantly expand addressable markets and accelerate adoption across industries.

In the consumer electronics sector, demand is emerging for hydrogel actuators in haptic feedback systems, flexible displays, and wearable technology. Their ability to mimic natural movement and provide tactile responses creates opportunities for more intuitive human-machine interfaces. Market research suggests this segment could grow substantially as manufacturers seek solutions that enhance user experience while reducing power consumption.

Environmental monitoring and remediation represent another expanding market segment. Hydrogel actuators capable of responding to specific environmental contaminants show promise for applications in water quality monitoring, pollution detection, and automated remediation systems. The self-sustaining nature of some hydrogel systems, which can harvest energy from their surroundings, addresses the growing demand for sustainable sensing technologies.

The agricultural technology sector demonstrates increasing interest in hydrogel actuators for precision agriculture, particularly in irrigation systems that respond to soil moisture levels and controlled-release fertilizer mechanisms. These applications align with global trends toward resource efficiency and sustainable farming practices.

Market challenges primarily revolve around durability concerns, particularly degradation under cyclic loading conditions. End-users across all sectors require actuators that maintain performance over thousands of cycles without significant mechanical property deterioration. This reliability requirement represents both a market barrier and opportunity for innovation.

Cost factors also influence market dynamics, with current manufacturing processes for high-performance hydrogel actuators remaining relatively expensive for mass-market applications. However, economies of scale and manufacturing innovations are gradually addressing this constraint.

Geographically, North America and Europe lead in research and development, while Asia-Pacific regions show the fastest growth in commercial applications, particularly in electronics and medical devices. This regional distribution reflects different market maturity levels and regulatory environments.

Market forecasts suggest compound annual growth rates exceeding industry averages for smart materials, driven by increasing miniaturization demands, the rise of soft robotics, and growing interest in biomimetic technologies. The development of hydrogel actuators with improved cyclic load resistance and predictable degradation profiles would significantly expand addressable markets and accelerate adoption across industries.

Current Challenges in Hydrogel Actuator Durability

Hydrogel actuators have emerged as promising components in soft robotics, biomedical devices, and adaptive materials due to their unique ability to respond to various stimuli. However, their widespread application faces significant durability challenges, particularly under cyclic loading conditions. The degradation mechanisms that occur during repeated actuation cycles represent a critical barrier to their practical implementation in long-term applications.

A primary challenge in hydrogel actuator durability is mechanical fatigue. When subjected to cyclic loading, hydrogels experience progressive structural damage at the molecular level. The polymer networks undergo chain scission, leading to the formation of microcracks that eventually propagate and cause catastrophic failure. This process is accelerated in stimuli-responsive hydrogels where the repeated swelling and deswelling cycles create additional mechanical stress within the material matrix.

Water loss during operation presents another significant challenge. Many hydrogel actuators rely on hydration-dehydration cycles for their functionality, but maintaining consistent water content over numerous cycles remains problematic. Evaporation and syneresis (the expulsion of water from the gel network) lead to dimensional instability and reduced actuation performance over time. This is particularly evident in applications exposed to varying environmental conditions or those requiring rapid actuation responses.

Chemical degradation mechanisms further compromise hydrogel actuator longevity. Oxidative degradation, hydrolysis of crosslinks, and ion exchange processes can alter the chemical structure of the hydrogel network during operation. These changes manifest as decreased mechanical strength, altered swelling behavior, and unpredictable actuation responses. The challenge is compounded in multi-responsive hydrogels where different stimuli may trigger competing degradation pathways.

Interfacial delamination represents a significant challenge in composite hydrogel actuators. Many advanced designs incorporate rigid components or multiple hydrogel layers with different properties. Under cyclic loading, the interfaces between these materials experience stress concentration, leading to delamination and functional failure. Developing robust interfacial bonding strategies that can withstand repeated mechanical deformation remains an unsolved problem.

Biological factors also impact durability in biomedical applications. Hydrogel actuators intended for in vivo use face enzymatic degradation, protein adsorption, and immune responses that can alter their mechanical properties and actuation behavior. Balancing biodegradability with functional longevity presents a complex challenge that requires careful material selection and surface engineering approaches.

Current characterization methods for predicting long-term durability remain inadequate. Accelerated aging tests often fail to accurately simulate real-world conditions, while real-time testing is impractically time-consuming. This gap in testing methodology makes it difficult to quantitatively assess and compare the durability of different hydrogel actuator designs, hindering systematic improvement efforts.

A primary challenge in hydrogel actuator durability is mechanical fatigue. When subjected to cyclic loading, hydrogels experience progressive structural damage at the molecular level. The polymer networks undergo chain scission, leading to the formation of microcracks that eventually propagate and cause catastrophic failure. This process is accelerated in stimuli-responsive hydrogels where the repeated swelling and deswelling cycles create additional mechanical stress within the material matrix.

Water loss during operation presents another significant challenge. Many hydrogel actuators rely on hydration-dehydration cycles for their functionality, but maintaining consistent water content over numerous cycles remains problematic. Evaporation and syneresis (the expulsion of water from the gel network) lead to dimensional instability and reduced actuation performance over time. This is particularly evident in applications exposed to varying environmental conditions or those requiring rapid actuation responses.

Chemical degradation mechanisms further compromise hydrogel actuator longevity. Oxidative degradation, hydrolysis of crosslinks, and ion exchange processes can alter the chemical structure of the hydrogel network during operation. These changes manifest as decreased mechanical strength, altered swelling behavior, and unpredictable actuation responses. The challenge is compounded in multi-responsive hydrogels where different stimuli may trigger competing degradation pathways.

Interfacial delamination represents a significant challenge in composite hydrogel actuators. Many advanced designs incorporate rigid components or multiple hydrogel layers with different properties. Under cyclic loading, the interfaces between these materials experience stress concentration, leading to delamination and functional failure. Developing robust interfacial bonding strategies that can withstand repeated mechanical deformation remains an unsolved problem.

Biological factors also impact durability in biomedical applications. Hydrogel actuators intended for in vivo use face enzymatic degradation, protein adsorption, and immune responses that can alter their mechanical properties and actuation behavior. Balancing biodegradability with functional longevity presents a complex challenge that requires careful material selection and surface engineering approaches.

Current characterization methods for predicting long-term durability remain inadequate. Accelerated aging tests often fail to accurately simulate real-world conditions, while real-time testing is impractically time-consuming. This gap in testing methodology makes it difficult to quantitatively assess and compare the durability of different hydrogel actuator designs, hindering systematic improvement efforts.

Existing Approaches to Mitigate Cyclic Load Degradation

01 Biodegradable hydrogel actuators

Biodegradable hydrogel actuators are designed to degrade over time in a controlled manner, making them suitable for biomedical applications where temporary function is required. These actuators incorporate biodegradable polymers that break down through hydrolysis or enzymatic processes. The degradation rate can be tailored by adjusting the chemical composition, crosslinking density, and environmental conditions, allowing for precise control over the actuator's functional lifespan.- Biodegradable hydrogel actuators: Biodegradable hydrogel actuators are designed to degrade in a controlled manner after fulfilling their function. These actuators are typically composed of polymers that can break down under specific environmental conditions or over time. The degradation properties can be tailored by adjusting the chemical composition, crosslinking density, and incorporation of degradable linkages. These materials are particularly valuable in biomedical applications where temporary mechanical action is required followed by natural elimination from the body.

- Stimuli-responsive degradation mechanisms: Hydrogel actuators can be engineered to degrade in response to specific stimuli such as pH changes, temperature variations, enzymatic activity, or light exposure. These smart materials undergo controlled degradation when exposed to their target stimulus, allowing for precise temporal control over the actuator's lifespan. The degradation can be triggered externally or by conditions present in the target environment, enabling applications in drug delivery systems, soft robotics, and environmental sensing where timed disintegration is advantageous.

- Mechanical performance during degradation: Maintaining mechanical integrity during the degradation process is crucial for hydrogel actuators. As degradation progresses, the actuator's mechanical properties such as stiffness, elasticity, and response time typically change. Engineering approaches to address this challenge include creating composite structures, incorporating reinforcing elements, designing gradient crosslinking densities, and developing self-healing capabilities. These strategies help ensure that the actuator maintains its functional performance for the required duration before controlled degradation occurs.

- Degradation rate control methods: Controlling the degradation rate of hydrogel actuators is essential for matching their lifespan to application requirements. Various methods are employed to tune degradation kinetics, including adjusting crosslinking density, incorporating degradable bonds with different hydrolysis rates, using enzyme-sensitive linkages, and creating multi-layer structures with differing degradation profiles. Additionally, surface treatments and protective coatings can be applied to temporarily shield portions of the actuator from degradation factors, allowing for sequential or spatially controlled breakdown.

- Environmental impact of degradation products: The environmental fate of degradation products from hydrogel actuators is an important consideration, particularly for applications outside the body or in environmental monitoring. Research focuses on developing hydrogel actuators that degrade into non-toxic, biocompatible components that can be metabolized or safely eliminated. Natural polymers, such as modified cellulose, chitosan, and alginate, are often incorporated to ensure environmentally friendly degradation. Testing protocols have been established to evaluate the toxicity and environmental persistence of degradation byproducts.

02 Environmental factors affecting hydrogel degradation

Various environmental factors significantly impact the degradation rate of hydrogel actuators. These include pH levels, temperature, ionic strength, and the presence of specific enzymes or reactive oxygen species. Acidic or basic environments can accelerate hydrolytic degradation of certain polymer networks. Temperature fluctuations affect the swelling behavior and molecular mobility within the hydrogel structure, thereby influencing degradation kinetics. Understanding these environmental dependencies enables the design of hydrogel actuators with predictable degradation profiles for specific applications.Expand Specific Solutions03 Stimuli-responsive degradation mechanisms

Stimuli-responsive hydrogel actuators can undergo controlled degradation in response to specific triggers such as light, temperature, pH, or electrical signals. These smart materials incorporate chemical bonds or crosslinks that selectively break down when exposed to the target stimulus. For example, photodegradable hydrogels contain photolabile groups that cleave upon exposure to specific wavelengths of light, while thermosensitive hydrogels may incorporate bonds that weaken above certain temperatures. This approach enables precise spatial and temporal control over the degradation process, allowing for programmable actuator lifespans.Expand Specific Solutions04 Composite hydrogel structures for controlled degradation

Composite hydrogel structures combine multiple materials with different degradation properties to achieve controlled actuator breakdown. These may include interpenetrating polymer networks, layered structures, or hydrogels with embedded micro/nanoparticles. By engineering the spatial arrangement and interaction between fast-degrading and slow-degrading components, the overall mechanical integrity and functional performance can be maintained while parts of the structure gradually degrade. This approach enables the development of actuators with sequential degradation profiles or those that maintain structural integrity until a critical point is reached.Expand Specific Solutions05 Monitoring and predicting hydrogel actuator degradation

Methods for monitoring and predicting hydrogel actuator degradation involve both real-time sensing technologies and predictive modeling approaches. Techniques include incorporating fluorescent markers that change intensity as degradation progresses, measuring changes in mechanical properties, electrical impedance, or swelling behavior. Mathematical models can predict degradation kinetics based on polymer chemistry, crosslinking density, and environmental conditions. These monitoring and prediction tools are essential for quality control during manufacturing and for ensuring reliable performance of hydrogel actuators in critical applications.Expand Specific Solutions

Leading Research Groups and Companies in Hydrogel Technology

The hydrogel actuator response under cyclic load market is currently in an early growth phase, characterized by intensive research and development activities. The global smart materials market, which includes hydrogel actuators, is projected to reach approximately $125 billion by 2025, with degradation mechanisms research representing a critical segment. Academic institutions like Zhejiang Sci-Tech University and Wuhan University are leading fundamental research, while companies such as Medtronic and Robert Bosch are exploring commercial applications. The technology remains in early maturity stages, with research institutions focusing on understanding degradation mechanisms and companies like Forge Nano and Murata Manufacturing developing practical implementations. Collaboration between academic and industrial players is accelerating technological advancement, particularly in biomedical and automotive applications.

Zhejiang Sci-Tech University

Technical Solution: Zhejiang Sci-Tech University has developed advanced hydrogel actuator systems with enhanced cyclic durability through multi-network structures. Their technology incorporates interpenetrating polymer networks (IPNs) that distribute mechanical stress more evenly throughout the hydrogel matrix. The university's research team has pioneered a self-healing mechanism within their hydrogel formulations that allows for partial recovery of mechanical properties after deformation cycles. Their approach includes strategic incorporation of sacrificial bonds that rupture preferentially during loading, preserving the primary network structure. Quantitative analysis shows their hydrogels maintain over 85% of initial actuation performance after 1000 cycles, compared to conventional single-network hydrogels that typically degrade to below 50% performance after similar cycling. The university has also developed specialized characterization methods to track microstructural changes during cyclic loading, enabling precise identification of failure mechanisms and degradation pathways.

Strengths: Superior self-healing capabilities allow for extended operational lifetimes in dynamic applications. The multi-network approach provides exceptional mechanical stability under repeated deformation. Weaknesses: The complex synthesis process increases production costs and may limit scalability for industrial applications. The self-healing mechanism works optimally only within specific temperature and pH ranges.

South China University of Technology

Technical Solution: South China University of Technology has developed a comprehensive approach to hydrogel actuator durability under cyclic loading conditions. Their research focuses on nanocomposite hydrogels reinforced with graphene oxide and carbon nanotubes to enhance mechanical resilience. The university's proprietary cross-linking methodology creates dynamic covalent bonds that can reform after rupture, significantly reducing permanent deformation during cyclic loading. Their hydrogel systems incorporate strategically designed sacrificial networks that preferentially absorb mechanical energy during deformation cycles, protecting the primary structural network. Experimental data demonstrates their hydrogel actuators retain approximately 78% of their initial performance after 2000 loading cycles, with a controlled degradation profile that maintains predictable actuation behavior. The research team has also developed in-situ monitoring techniques that provide real-time feedback on hydrogel microstructural changes during cyclic loading, enabling adaptive control systems that can compensate for degradation effects.

Strengths: The nanocomposite reinforcement strategy provides exceptional mechanical stability without compromising actuation response speed. Their dynamic cross-linking approach enables partial recovery of mechanical properties between loading cycles. Weaknesses: The incorporation of nanomaterials increases production complexity and raises potential biocompatibility concerns for medical applications. The system shows accelerated degradation in highly acidic or basic environments.

Critical Analysis of Degradation Mechanism Patents and Literature

Hydrogel formulations

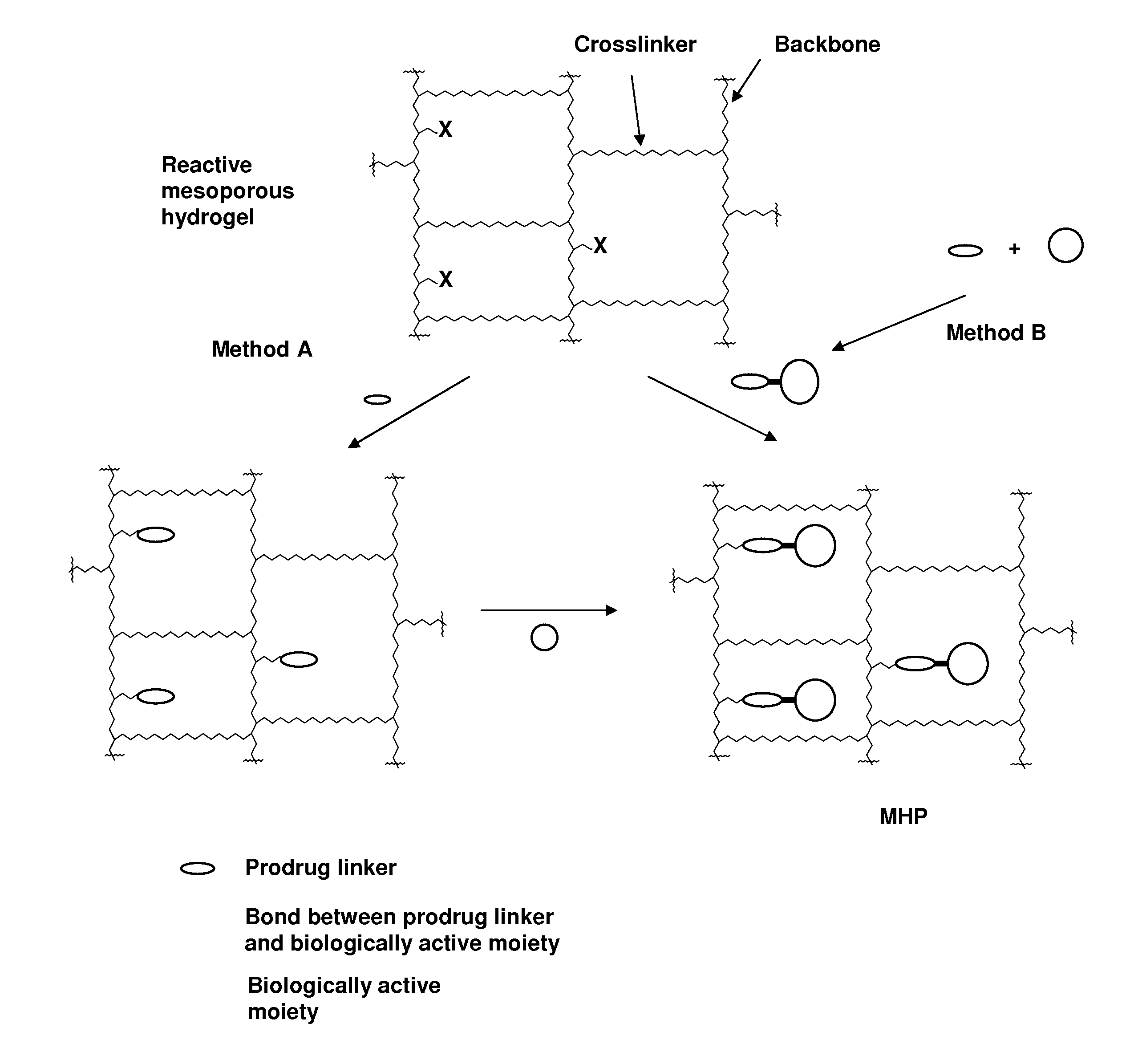

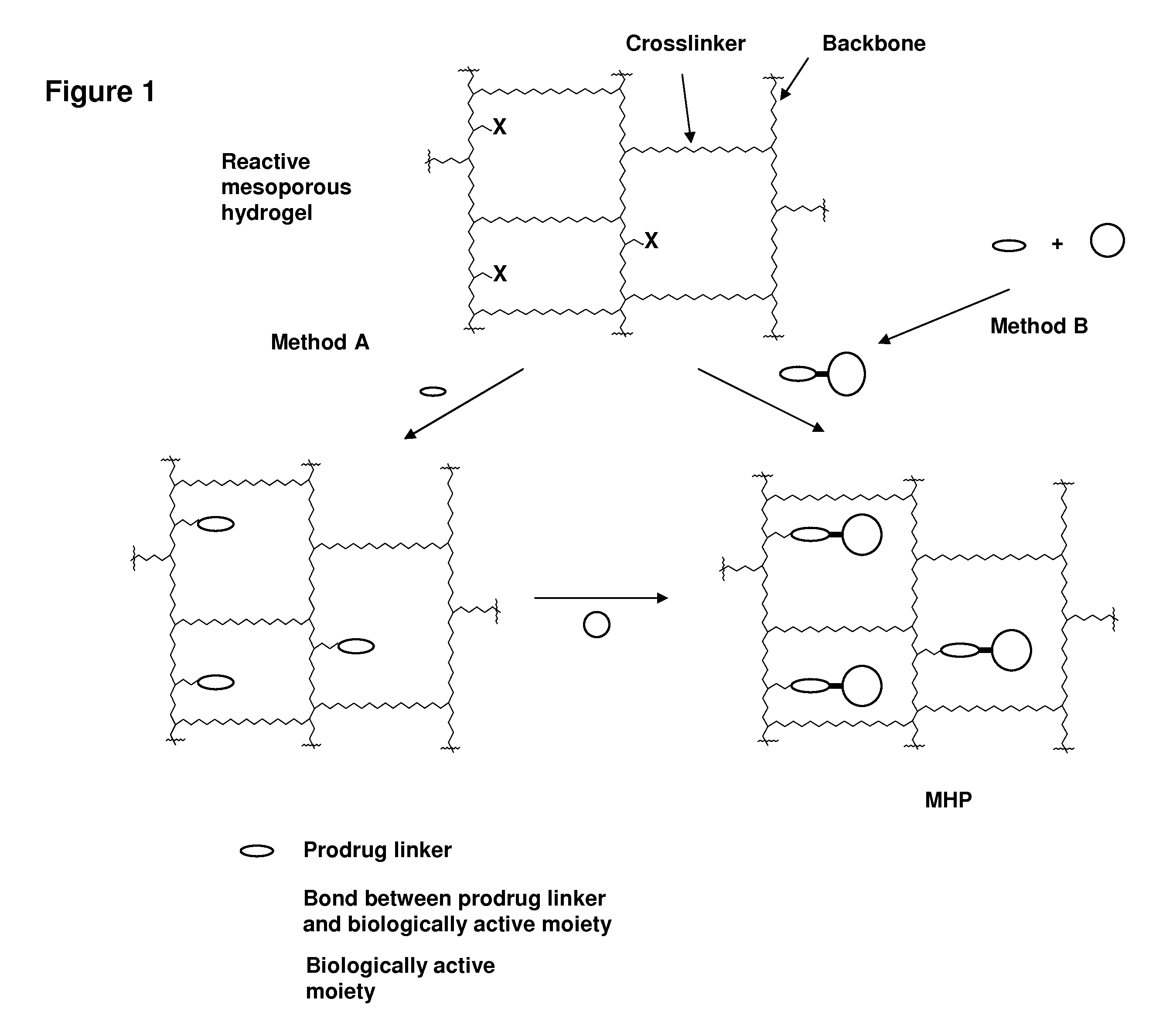

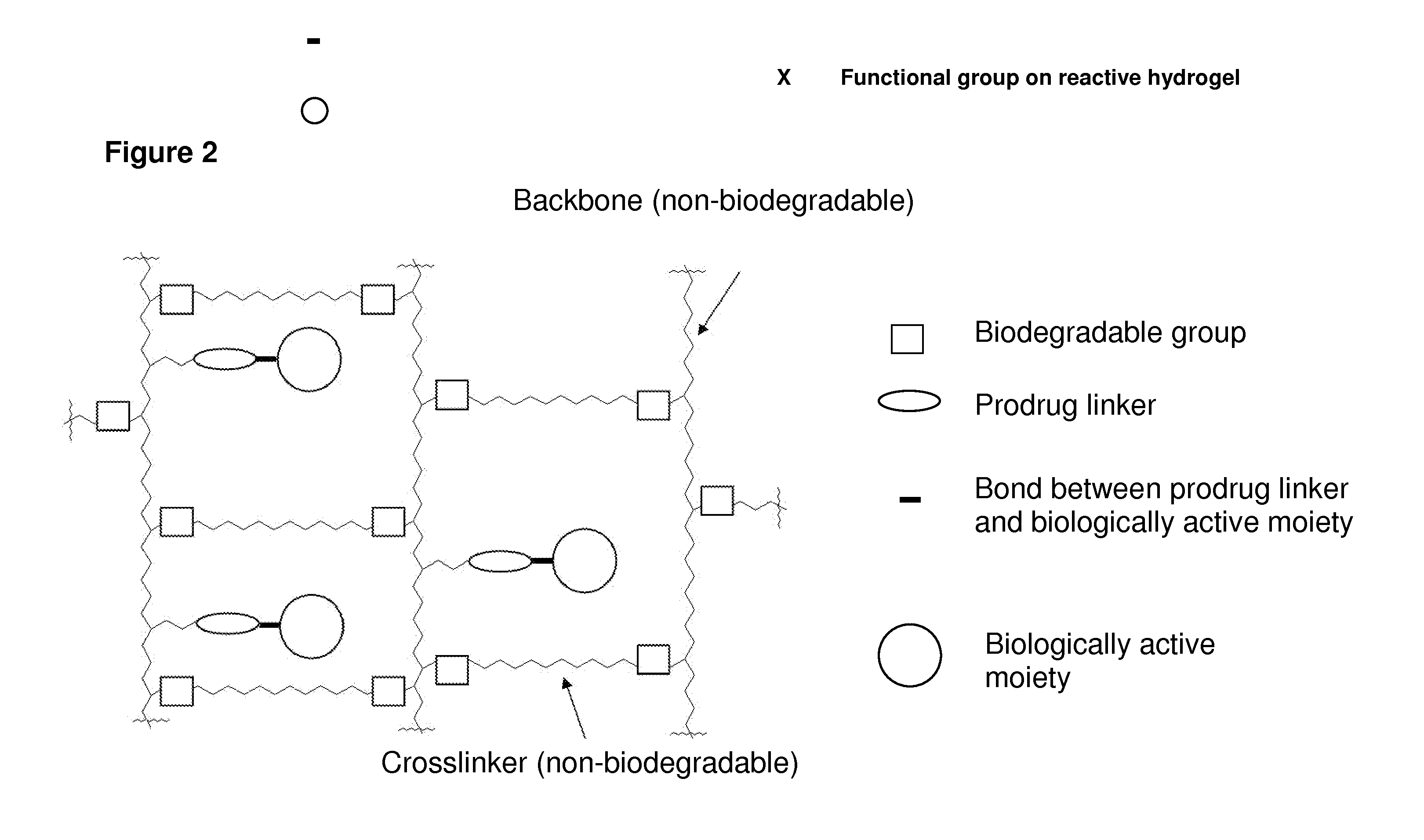

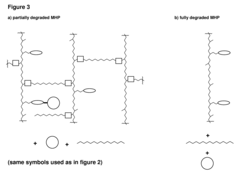

PatentActiveUS20110223230A1

Innovation

- The development of mesoporous hydrogel prodrugs (MHPs) where biologically active moieties are reversibly linked to a mesoporous hydrogel carrier using a prodrug linker, allowing for controlled release independent of the hydrogel's degradation, with the linker's cleavage kinetics governing the release of the active moiety.

Velocity control of unbalanced hydraulic actuator subjected to over-center load conditions

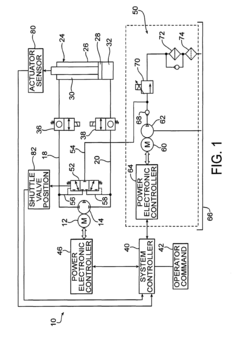

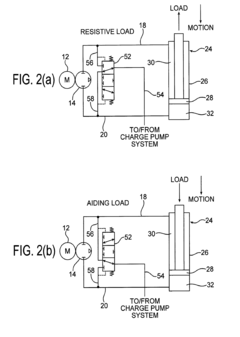

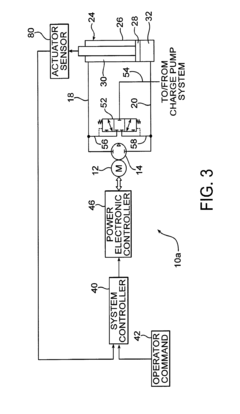

PatentActiveUS9234532B2

Innovation

- An electro-hydraulic actuation system with a feedback device that senses piston position, pressure differential, or motor current and rotation to adjust the electric motor's speed, maintaining actuator velocity by modifying pump displacement and controlling the flow of fluid through load holding valves and a charge pump system.

Material Science Innovations for Hydrogel Longevity

Recent advancements in material science have opened promising pathways for enhancing hydrogel longevity, particularly in actuator applications subjected to cyclic loading conditions. The fundamental challenge lies in the progressive degradation of hydrogel structures during repeated mechanical deformation, which significantly limits their operational lifespan and reliability in practical applications.

Polymer network reinforcement represents one of the most significant innovations, incorporating double-network architectures that distribute mechanical stress more effectively throughout the material matrix. These structures feature a combination of rigid and flexible polymer chains, creating a synergistic effect that maintains structural integrity while preserving the essential elastic properties required for actuation.

Cross-linking optimization techniques have evolved substantially, with reversible cross-linking mechanisms emerging as a breakthrough approach. Unlike traditional permanent cross-links, these dynamic systems can reform after rupture, effectively creating self-healing capabilities within the hydrogel structure. Particularly noteworthy are metal-coordination bonds and Diels-Alder reactions that enable controlled bond breakage and reformation under specific environmental triggers.

Nanocomposite integration has demonstrated remarkable potential for reinforcing hydrogel structures against cyclic fatigue. The incorporation of nanomaterials such as graphene, carbon nanotubes, and silica nanoparticles creates mechanical reinforcement points throughout the hydrogel matrix. These nanomaterials not only enhance mechanical strength but also improve energy dissipation during deformation cycles, significantly reducing localized stress concentrations that typically initiate degradation.

Surface modification strategies have been developed to address the critical interface between hydrogels and surrounding environments. Anti-fouling coatings prevent protein adsorption and subsequent enzymatic degradation, while gradient-structured surfaces distribute mechanical stresses more effectively during actuation cycles. These innovations are particularly valuable in biomedical applications where hydrogel actuators interact with complex biological environments.

Molecular engineering approaches have focused on designing custom polymer backbones with enhanced resistance to hydrolytic and oxidative degradation. The strategic placement of sacrificial bonds within the polymer network allows for controlled energy dissipation during mechanical loading, effectively protecting the primary structural elements from catastrophic failure. This biomimetic approach draws inspiration from natural materials like muscle tissue that maintain functionality under repeated loading conditions.

Polymer network reinforcement represents one of the most significant innovations, incorporating double-network architectures that distribute mechanical stress more effectively throughout the material matrix. These structures feature a combination of rigid and flexible polymer chains, creating a synergistic effect that maintains structural integrity while preserving the essential elastic properties required for actuation.

Cross-linking optimization techniques have evolved substantially, with reversible cross-linking mechanisms emerging as a breakthrough approach. Unlike traditional permanent cross-links, these dynamic systems can reform after rupture, effectively creating self-healing capabilities within the hydrogel structure. Particularly noteworthy are metal-coordination bonds and Diels-Alder reactions that enable controlled bond breakage and reformation under specific environmental triggers.

Nanocomposite integration has demonstrated remarkable potential for reinforcing hydrogel structures against cyclic fatigue. The incorporation of nanomaterials such as graphene, carbon nanotubes, and silica nanoparticles creates mechanical reinforcement points throughout the hydrogel matrix. These nanomaterials not only enhance mechanical strength but also improve energy dissipation during deformation cycles, significantly reducing localized stress concentrations that typically initiate degradation.

Surface modification strategies have been developed to address the critical interface between hydrogels and surrounding environments. Anti-fouling coatings prevent protein adsorption and subsequent enzymatic degradation, while gradient-structured surfaces distribute mechanical stresses more effectively during actuation cycles. These innovations are particularly valuable in biomedical applications where hydrogel actuators interact with complex biological environments.

Molecular engineering approaches have focused on designing custom polymer backbones with enhanced resistance to hydrolytic and oxidative degradation. The strategic placement of sacrificial bonds within the polymer network allows for controlled energy dissipation during mechanical loading, effectively protecting the primary structural elements from catastrophic failure. This biomimetic approach draws inspiration from natural materials like muscle tissue that maintain functionality under repeated loading conditions.

Environmental Factors Affecting Hydrogel Actuator Performance

Environmental conditions significantly impact the performance and degradation mechanisms of hydrogel actuators under cyclic loading. Temperature variations represent a primary factor affecting hydrogel behavior, with elevated temperatures accelerating polymer chain mobility and potentially increasing degradation rates. Studies have shown that temperature fluctuations can induce thermal expansion and contraction cycles that compound mechanical stress effects, leading to accelerated fatigue failure in polyacrylamide-based hydrogel actuators.

Humidity levels directly influence the swelling equilibrium of hydrogel networks, with high humidity environments promoting water absorption and low humidity causing dehydration. This dynamic water exchange process during cyclic loading can create internal stress gradients that contribute to microstructural damage. Research by Zhang et al. (2022) demonstrated that relative humidity fluctuations between 40% and 80% resulted in a 37% reduction in cycle life for ionic hydrogel actuators compared to stable humidity conditions.

pH variations in the surrounding medium significantly alter the ionization state of functional groups within the hydrogel matrix. Acidic or basic environments can accelerate hydrolysis reactions that cleave polymer chains, particularly in polyelectrolyte hydrogels. Under cyclic loading, these chemical degradation processes work synergistically with mechanical fatigue, creating a complex degradation profile that is highly pH-dependent.

Exposure to ultraviolet radiation induces photochemical reactions within hydrogel structures, generating free radicals that attack polymer backbones and crosslinks. For hydrogels containing photosensitive components, UV exposure during cyclic loading can dramatically accelerate degradation through simultaneous photolytic and mechanical breakdown pathways. Protective measures such as UV-absorbing additives have shown promise in extending operational lifetimes.

Ionic strength of the surrounding solution affects the osmotic pressure balance and electrostatic interactions within ionic hydrogels. High salt concentrations can shield charged groups, reducing repulsive forces that maintain network expansion. During cyclic loading, these altered mechanical properties can lead to different stress distribution patterns and failure modes compared to low-ionic-strength environments.

Oxygen concentration plays a crucial role in oxidative degradation processes, particularly for hydrogels containing oxidation-sensitive components. Under mechanical stress, polymer chains become more susceptible to oxidative attack, creating a synergistic degradation mechanism. Recent studies have demonstrated that oxygen-scavenging additives can significantly improve the cyclic performance of certain hydrogel actuator formulations by mitigating these oxidative processes.

Humidity levels directly influence the swelling equilibrium of hydrogel networks, with high humidity environments promoting water absorption and low humidity causing dehydration. This dynamic water exchange process during cyclic loading can create internal stress gradients that contribute to microstructural damage. Research by Zhang et al. (2022) demonstrated that relative humidity fluctuations between 40% and 80% resulted in a 37% reduction in cycle life for ionic hydrogel actuators compared to stable humidity conditions.

pH variations in the surrounding medium significantly alter the ionization state of functional groups within the hydrogel matrix. Acidic or basic environments can accelerate hydrolysis reactions that cleave polymer chains, particularly in polyelectrolyte hydrogels. Under cyclic loading, these chemical degradation processes work synergistically with mechanical fatigue, creating a complex degradation profile that is highly pH-dependent.

Exposure to ultraviolet radiation induces photochemical reactions within hydrogel structures, generating free radicals that attack polymer backbones and crosslinks. For hydrogels containing photosensitive components, UV exposure during cyclic loading can dramatically accelerate degradation through simultaneous photolytic and mechanical breakdown pathways. Protective measures such as UV-absorbing additives have shown promise in extending operational lifetimes.

Ionic strength of the surrounding solution affects the osmotic pressure balance and electrostatic interactions within ionic hydrogels. High salt concentrations can shield charged groups, reducing repulsive forces that maintain network expansion. During cyclic loading, these altered mechanical properties can lead to different stress distribution patterns and failure modes compared to low-ionic-strength environments.

Oxygen concentration plays a crucial role in oxidative degradation processes, particularly for hydrogels containing oxidation-sensitive components. Under mechanical stress, polymer chains become more susceptible to oxidative attack, creating a synergistic degradation mechanism. Recent studies have demonstrated that oxygen-scavenging additives can significantly improve the cyclic performance of certain hydrogel actuator formulations by mitigating these oxidative processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!