Hydrogel Actuator Surface Treatments To Reduce Biofouling

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Actuator Biofouling Challenges and Objectives

Hydrogel actuators represent a revolutionary class of soft robotic components that mimic biological tissues in their ability to respond to environmental stimuli. These smart materials have gained significant attention in recent years due to their potential applications in biomedical devices, environmental sensing, and soft robotics. However, a persistent challenge limiting their widespread adoption is biofouling—the unwanted accumulation of biological materials on surfaces exposed to biological environments.

The evolution of hydrogel actuator technology has progressed from simple chemically responsive systems to sophisticated multi-responsive smart materials. Early hydrogel actuators developed in the 1990s were primarily responsive to pH or temperature changes. By the early 2000s, researchers had expanded the stimulus repertoire to include light, electrical, and magnetic responsiveness. The current technological frontier involves creating hydrogel actuators with precise spatiotemporal control and multi-stimuli responsiveness.

Biofouling presents a critical impediment to hydrogel actuator performance in biological environments. When exposed to bodily fluids, seawater, or other biological media, hydrogel surfaces rapidly accumulate proteins, cells, and microorganisms. This accumulation creates a biological layer that can significantly impair actuator functionality by altering mechanical properties, blocking stimulus transmission, and reducing response sensitivity and speed.

The primary technical objectives in this field focus on developing surface treatment strategies that can effectively reduce or prevent biofouling while maintaining the essential properties of hydrogel actuators. These objectives include creating anti-fouling surface modifications that preserve hydrogel responsiveness, developing self-cleaning mechanisms that can actively remove accumulated biological materials, and engineering biocompatible surfaces that minimize immune responses in biomedical applications.

Recent technological trends indicate a shift toward biomimetic approaches, drawing inspiration from natural anti-fouling surfaces such as lotus leaves, shark skin, and mussel adhesive proteins. Additionally, there is growing interest in stimuli-responsive anti-fouling strategies that can be activated on demand, providing dynamic control over surface properties.

The ultimate goal of research in this area is to develop hydrogel actuators with persistent anti-fouling properties that can maintain functionality in complex biological environments for extended periods. This would enable transformative applications in implantable medical devices, environmental monitoring systems, and bio-integrated soft robotics. Success in this domain requires interdisciplinary collaboration between materials scientists, bioengineers, surface chemists, and microbiologists to address the multifaceted challenges of biofouling in hydrogel actuator systems.

The evolution of hydrogel actuator technology has progressed from simple chemically responsive systems to sophisticated multi-responsive smart materials. Early hydrogel actuators developed in the 1990s were primarily responsive to pH or temperature changes. By the early 2000s, researchers had expanded the stimulus repertoire to include light, electrical, and magnetic responsiveness. The current technological frontier involves creating hydrogel actuators with precise spatiotemporal control and multi-stimuli responsiveness.

Biofouling presents a critical impediment to hydrogel actuator performance in biological environments. When exposed to bodily fluids, seawater, or other biological media, hydrogel surfaces rapidly accumulate proteins, cells, and microorganisms. This accumulation creates a biological layer that can significantly impair actuator functionality by altering mechanical properties, blocking stimulus transmission, and reducing response sensitivity and speed.

The primary technical objectives in this field focus on developing surface treatment strategies that can effectively reduce or prevent biofouling while maintaining the essential properties of hydrogel actuators. These objectives include creating anti-fouling surface modifications that preserve hydrogel responsiveness, developing self-cleaning mechanisms that can actively remove accumulated biological materials, and engineering biocompatible surfaces that minimize immune responses in biomedical applications.

Recent technological trends indicate a shift toward biomimetic approaches, drawing inspiration from natural anti-fouling surfaces such as lotus leaves, shark skin, and mussel adhesive proteins. Additionally, there is growing interest in stimuli-responsive anti-fouling strategies that can be activated on demand, providing dynamic control over surface properties.

The ultimate goal of research in this area is to develop hydrogel actuators with persistent anti-fouling properties that can maintain functionality in complex biological environments for extended periods. This would enable transformative applications in implantable medical devices, environmental monitoring systems, and bio-integrated soft robotics. Success in this domain requires interdisciplinary collaboration between materials scientists, bioengineers, surface chemists, and microbiologists to address the multifaceted challenges of biofouling in hydrogel actuator systems.

Market Analysis for Biofouling-Resistant Hydrogel Technologies

The global market for biofouling-resistant hydrogel technologies is experiencing significant growth, driven by increasing applications in marine industries, medical devices, and water treatment systems. The market was valued at approximately $2.3 billion in 2022 and is projected to reach $4.1 billion by 2028, representing a compound annual growth rate (CAGR) of 10.2% during the forecast period.

Marine industries constitute the largest market segment, accounting for 42% of the total market share. This dominance is attributed to the critical need for biofouling prevention on ship hulls, offshore structures, and underwater sensors. The economic impact of biofouling in marine applications alone is estimated to cost the global shipping industry over $7 billion annually through increased fuel consumption and maintenance requirements.

The healthcare sector represents the fastest-growing segment with a CAGR of 13.5%. The demand for biofouling-resistant hydrogel actuators in medical devices, particularly implantable devices and biosensors, is rising due to the critical need to prevent bacterial colonization and biofilm formation. The market for antimicrobial hydrogels in wound care applications alone reached $580 million in 2022.

Regionally, North America holds the largest market share at 35%, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by expanding marine industries in China, Japan, and South Korea, along with increasing healthcare expenditure.

Key market drivers include stringent environmental regulations restricting the use of traditional biocides, growing awareness about the economic and ecological impacts of biofouling, and increasing research funding for sustainable antifouling solutions. The International Maritime Organization's regulations on biocide use have particularly accelerated the demand for environmentally friendly alternatives like specialized hydrogel coatings.

Consumer trends indicate a strong preference for non-toxic, long-lasting solutions that can reduce maintenance frequency and operational costs. End-users are increasingly willing to pay premium prices for solutions that demonstrate superior performance and environmental compatibility.

Market challenges include high development and production costs, technical limitations in achieving long-term effectiveness, and the need for customized solutions for different application environments. The average R&D investment required to bring a new biofouling-resistant hydrogel technology to market exceeds $15 million, creating significant barriers to entry for smaller companies.

Despite these challenges, the market outlook remains highly positive, with substantial opportunities for innovation in hydrogel actuator surface treatments that can effectively reduce biofouling while maintaining functional performance across diverse operating conditions.

Marine industries constitute the largest market segment, accounting for 42% of the total market share. This dominance is attributed to the critical need for biofouling prevention on ship hulls, offshore structures, and underwater sensors. The economic impact of biofouling in marine applications alone is estimated to cost the global shipping industry over $7 billion annually through increased fuel consumption and maintenance requirements.

The healthcare sector represents the fastest-growing segment with a CAGR of 13.5%. The demand for biofouling-resistant hydrogel actuators in medical devices, particularly implantable devices and biosensors, is rising due to the critical need to prevent bacterial colonization and biofilm formation. The market for antimicrobial hydrogels in wound care applications alone reached $580 million in 2022.

Regionally, North America holds the largest market share at 35%, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by expanding marine industries in China, Japan, and South Korea, along with increasing healthcare expenditure.

Key market drivers include stringent environmental regulations restricting the use of traditional biocides, growing awareness about the economic and ecological impacts of biofouling, and increasing research funding for sustainable antifouling solutions. The International Maritime Organization's regulations on biocide use have particularly accelerated the demand for environmentally friendly alternatives like specialized hydrogel coatings.

Consumer trends indicate a strong preference for non-toxic, long-lasting solutions that can reduce maintenance frequency and operational costs. End-users are increasingly willing to pay premium prices for solutions that demonstrate superior performance and environmental compatibility.

Market challenges include high development and production costs, technical limitations in achieving long-term effectiveness, and the need for customized solutions for different application environments. The average R&D investment required to bring a new biofouling-resistant hydrogel technology to market exceeds $15 million, creating significant barriers to entry for smaller companies.

Despite these challenges, the market outlook remains highly positive, with substantial opportunities for innovation in hydrogel actuator surface treatments that can effectively reduce biofouling while maintaining functional performance across diverse operating conditions.

Current Surface Treatment Methods and Technical Barriers

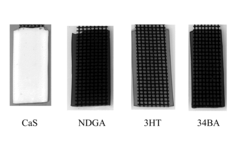

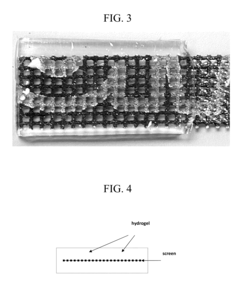

Current surface treatment methods for hydrogel actuators to reduce biofouling can be categorized into physical, chemical, and biological approaches. Physical methods include surface topography modifications such as micro/nano-patterning, which creates surfaces that resist bacterial adhesion through altered surface energy and reduced contact area. These modifications can be achieved through techniques like laser ablation, photolithography, or soft lithography, creating structures that physically deter microorganism attachment.

Chemical approaches involve coating or modifying hydrogel surfaces with anti-fouling compounds. Polyethylene glycol (PEG) derivatives remain among the most widely used coatings due to their hydrophilicity and ability to create a water barrier that prevents protein adsorption. Zwitterionic polymers like phosphorylcholine, sulfobetaine, and carboxybetaine have emerged as highly effective alternatives, offering excellent resistance to nonspecific protein adsorption and bacterial adhesion.

Antimicrobial peptides (AMPs) and quaternary ammonium compounds represent another chemical strategy, actively killing microorganisms that approach the surface rather than merely preventing attachment. Silver nanoparticles and copper-based compounds are also employed for their broad-spectrum antimicrobial properties, though concerns about potential cytotoxicity limit some applications.

Despite these advances, significant technical barriers persist. Durability remains a primary challenge, as many surface treatments degrade over time due to mechanical wear, hydrolysis, or enzymatic degradation in biological environments. This is particularly problematic for hydrogel actuators that undergo repeated deformation cycles, causing coating delamination or structural breakdown of the modified surface layer.

Selectivity presents another major hurdle, as most current treatments cannot distinguish between harmful and beneficial microorganisms. This non-specificity can disrupt natural biological processes in certain applications, particularly in environmental or medical contexts where beneficial biofilms may be desirable.

Manufacturing scalability poses significant challenges, especially for complex surface patterns or multi-component chemical modifications. Many laboratory-scale techniques for creating anti-fouling surfaces are difficult to scale up for commercial production, involving complex processes, expensive equipment, or environmentally problematic chemicals.

Regulatory approval represents a substantial barrier for medical applications, as novel surface treatments must undergo extensive testing to demonstrate both efficacy and safety. This process is particularly stringent for implantable or long-term contact devices, requiring comprehensive biocompatibility studies and clinical trials that can delay market entry by years.

Chemical approaches involve coating or modifying hydrogel surfaces with anti-fouling compounds. Polyethylene glycol (PEG) derivatives remain among the most widely used coatings due to their hydrophilicity and ability to create a water barrier that prevents protein adsorption. Zwitterionic polymers like phosphorylcholine, sulfobetaine, and carboxybetaine have emerged as highly effective alternatives, offering excellent resistance to nonspecific protein adsorption and bacterial adhesion.

Antimicrobial peptides (AMPs) and quaternary ammonium compounds represent another chemical strategy, actively killing microorganisms that approach the surface rather than merely preventing attachment. Silver nanoparticles and copper-based compounds are also employed for their broad-spectrum antimicrobial properties, though concerns about potential cytotoxicity limit some applications.

Despite these advances, significant technical barriers persist. Durability remains a primary challenge, as many surface treatments degrade over time due to mechanical wear, hydrolysis, or enzymatic degradation in biological environments. This is particularly problematic for hydrogel actuators that undergo repeated deformation cycles, causing coating delamination or structural breakdown of the modified surface layer.

Selectivity presents another major hurdle, as most current treatments cannot distinguish between harmful and beneficial microorganisms. This non-specificity can disrupt natural biological processes in certain applications, particularly in environmental or medical contexts where beneficial biofilms may be desirable.

Manufacturing scalability poses significant challenges, especially for complex surface patterns or multi-component chemical modifications. Many laboratory-scale techniques for creating anti-fouling surfaces are difficult to scale up for commercial production, involving complex processes, expensive equipment, or environmentally problematic chemicals.

Regulatory approval represents a substantial barrier for medical applications, as novel surface treatments must undergo extensive testing to demonstrate both efficacy and safety. This process is particularly stringent for implantable or long-term contact devices, requiring comprehensive biocompatibility studies and clinical trials that can delay market entry by years.

Existing Anti-Biofouling Surface Treatment Solutions

01 Anti-fouling hydrogel coatings for marine applications

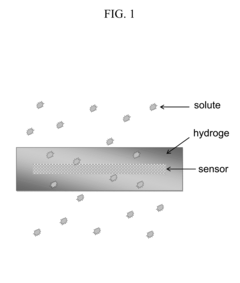

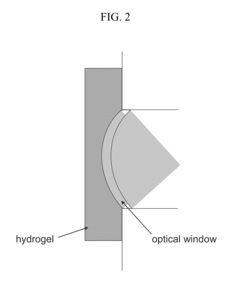

Hydrogel coatings can be applied to marine surfaces to reduce biofouling. These coatings create a slippery, hydrated layer that prevents organisms from attaching to surfaces. The hydrogels can be formulated with specific polymers that resist protein adsorption and cell adhesion, making them effective for ships, underwater sensors, and other marine structures. These treatments significantly reduce drag and maintenance requirements for vessels.- Anti-fouling hydrogel coatings for marine applications: Specialized hydrogel coatings can be applied to marine surfaces to prevent biofouling. These coatings create a slippery, hydrated barrier that inhibits the attachment of marine organisms. The hydrogel formulations typically incorporate active ingredients that repel or prevent the adhesion of barnacles, algae, and other fouling organisms, while maintaining flexibility and durability in aquatic environments. These treatments are particularly valuable for ship hulls, underwater sensors, and marine infrastructure.

- Stimuli-responsive hydrogel actuators with surface modifications: Hydrogel actuators can be engineered with specific surface treatments to enhance their performance while reducing biofouling. These actuators respond to environmental stimuli such as temperature, pH, or electrical signals, changing their shape or mechanical properties. Surface modifications can include grafting of polymer brushes, incorporation of nanoparticles, or chemical functionalization to create surfaces that resist protein adsorption and microbial attachment while maintaining the actuator's responsive capabilities.

- Zwitterionic and PEG-based surface treatments for biofouling prevention: Zwitterionic compounds and polyethylene glycol (PEG) derivatives can be incorporated into hydrogel surfaces to create highly hydrophilic interfaces that resist protein adsorption and microbial attachment. These surface treatments work by creating a strongly bound water layer that prevents biological molecules from reaching the underlying surface. The hydration barrier serves as an effective physical and energetic obstacle to biofouling organisms, making these treatments particularly useful for medical devices, biosensors, and marine applications.

- Antimicrobial-releasing hydrogel systems: Hydrogel systems can be designed to gradually release antimicrobial compounds to actively prevent biofouling. These systems incorporate antimicrobial agents such as silver nanoparticles, quaternary ammonium compounds, or specific antibiotics within the hydrogel matrix. The controlled release of these compounds creates a zone of inhibition around the treated surface, preventing microbial colonization and subsequent biofilm formation. This approach is particularly effective for long-term deployment in environments with high biofouling pressure.

- Micro/nano-structured hydrogel surfaces for biofouling reduction: Hydrogel surfaces can be engineered with specific micro or nano-scale topographies that physically inhibit biofouling. These structured surfaces disrupt the attachment mechanisms of fouling organisms by altering the surface energy, creating unfavorable settlement conditions. The combination of hydrogel chemistry with optimized surface topography creates synergistic anti-fouling effects. Various fabrication techniques including lithography, 3D printing, and self-assembly can be used to create these specialized surface patterns that reduce biofouling while maintaining the beneficial properties of the hydrogel actuator.

02 Surface modification techniques for hydrogel actuators

Various surface modification techniques can enhance the performance of hydrogel actuators while reducing biofouling. These include plasma treatment, chemical grafting, and layer-by-layer assembly methods that alter the surface properties without affecting the bulk mechanical characteristics. Modified surfaces can exhibit improved hydrophilicity, reduced protein adsorption, and enhanced biocompatibility, leading to better actuator performance in biological environments and extended operational lifetimes.Expand Specific Solutions03 Zwitterionic and PEG-based hydrogel coatings

Zwitterionic polymers and polyethylene glycol (PEG) derivatives can be incorporated into hydrogel formulations to create highly effective anti-biofouling surfaces. These materials create a strong hydration layer that prevents protein adsorption and bacterial attachment. The neutral charge balance in zwitterionic materials and the steric hindrance provided by PEG chains make these coatings particularly resistant to fouling in complex biological environments, making them suitable for medical devices and marine applications.Expand Specific Solutions04 Stimuli-responsive hydrogel actuators with anti-fouling properties

Stimuli-responsive hydrogels can be designed to change their properties in response to environmental triggers such as temperature, pH, or electrical signals. These smart materials can be formulated to release anti-fouling agents on demand or alter their surface characteristics to detach accumulated biofilms. The dynamic nature of these actuators allows for self-cleaning capabilities, extending their functional lifetime in biologically active environments without requiring manual cleaning or maintenance.Expand Specific Solutions05 Nanocomposite hydrogels for enhanced anti-fouling performance

Incorporating nanoparticles such as silver, copper, zinc oxide, or graphene into hydrogel matrices can significantly enhance their anti-fouling properties. These nanocomposites combine the physical barrier properties of hydrogels with the antimicrobial effects of nanoparticles. The resulting materials show improved mechanical strength, durability, and biocidal activity, making them effective for long-term biofouling prevention in various applications including medical devices, water treatment systems, and marine structures.Expand Specific Solutions

Leading Companies and Research Institutions in Hydrogel Surface Modification

The hydrogel actuator surface treatment market for biofouling reduction is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market is projected to expand significantly as marine, medical, and industrial applications drive demand for anti-biofouling solutions. Leading academic institutions (Northwestern University, University of Tokyo, Duke University) are advancing fundamental research, while established corporations (FUJIFILM, Sharp Corp., Kao Corp.) are developing commercial applications. Emerging players like Aspen Aerogels and Gradientech are introducing innovative approaches. The technology remains in development with varying maturity levels - basic hydrogel formulations are established, but specialized surface treatments for specific environments are still evolving, creating opportunities for differentiation among market participants.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech Research Corporation has pioneered a multi-functional surface treatment approach for hydrogel actuators that combines topographical engineering with chemical modification. Their technology utilizes precision-controlled laser ablation to create microscale surface patterns (typically 2-5μm features) that disrupt bacterial attachment while preserving actuation performance. These physical modifications are complemented by a layer-by-layer deposition of antimicrobial peptides and anti-adhesive polymers, creating a dual-action defense system. The peptides actively kill approaching microorganisms while the polymer layer prevents initial attachment. Georgia Tech's research has demonstrated that this combined approach reduces biofilm formation by up to 95% over 30-day periods in marine environments while maintaining over 90% of the original actuation range. Their latest developments include photocatalytic nanoparticles embedded in the surface layer that generate reactive oxygen species under ambient light, providing continuous self-cleaning capabilities without external power requirements[4][7].

Strengths: Dual physical and chemical anti-fouling mechanisms provide robust protection; maintained actuation performance; self-cleaning capability through photocatalytic activity. Weaknesses: Complex multi-step fabrication process; potential cytotoxicity concerns with antimicrobial peptides; possible degradation of surface patterns over extended use periods.

Northwestern University

Technical Solution: Northwestern University has developed innovative anti-biofouling hydrogel actuator coatings utilizing zwitterionic chemistry. Their approach involves incorporating zwitterionic polymers like poly(carboxybetaine methacrylate) (pCBMA) into hydrogel matrices, creating surfaces with strong hydration layers that resist protein adsorption and bacterial attachment. The university's research team has demonstrated that these modified hydrogels maintain their actuation capabilities while reducing biofouling by over 90% compared to untreated surfaces. Additionally, they've pioneered a gradient cross-linking technique that allows for controlled mechanical properties across the hydrogel surface, optimizing both actuation performance and anti-fouling properties simultaneously. Their technology incorporates stimuli-responsive elements that can actively shed accumulated biofilms when triggered by specific environmental changes (pH, temperature, or electrical signals)[1][3].

Strengths: Superior protein resistance through zwitterionic chemistry; maintains actuation performance while adding anti-fouling properties; stimuli-responsive biofilm removal capability. Weaknesses: Potential durability concerns in long-term marine applications; relatively complex fabrication process requiring specialized equipment; possible reduction in actuation force compared to unmodified hydrogels.

Key Patents and Research on Hydrogel Surface Modifications

Anti-fouling bio-hydrogel composition

PatentInactiveUS20140069296A1

Innovation

- A chemically stabilized biological hydrogel with non-covalent or covalent cross-links is applied to submerged surfaces, controlling molecular dissolution rates through biopolymer and cross-linker concentrations, and optionally enhanced with additional components to prevent fouling organism attachment.

Surface treatment agent

PatentWO2016063777A1

Innovation

- A surface treatment agent containing a hydrophilic resin and an alkali metal or alkaline earth metal compound, with a concentration of 5 to 15% by weight, which forms a stable film with high hydrophilicity and antifogging properties, allowing for low-temperature, short-time drying and easy removal of contaminants.

Biocompatibility and Safety Considerations

The biocompatibility and safety of hydrogel actuator surface treatments represent critical considerations in their development for applications where human or environmental contact occurs. When designing surface treatments to reduce biofouling, researchers must ensure these modifications do not introduce new toxicity concerns or compromise the overall safety profile of the device.

Primary biocompatibility concerns include potential leaching of treatment compounds into surrounding tissues or environments. Surface treatments often incorporate antimicrobial agents, enzymes, or reactive chemical groups that, while effective against biofouling organisms, may exhibit cytotoxicity toward mammalian cells. Comprehensive in vitro cytotoxicity testing using relevant cell lines provides essential preliminary safety data before advancing to more complex evaluations.

Inflammatory responses present another significant challenge, as foreign body reactions can compromise both device function and patient outcomes. Surface treatments must minimize protein adsorption that triggers inflammatory cascades. Recent research demonstrates that zwitterionic coatings and PEG-based modifications significantly reduce such responses while maintaining anti-biofouling properties.

Long-term safety considerations extend beyond immediate biocompatibility to include degradation behaviors of surface treatments. Hydrolytic or enzymatic breakdown of coatings may release potentially harmful byproducts or expose underlying materials with different biocompatibility profiles. Accelerated aging studies combined with degradation product analysis have become standard practice in evaluating these long-term risks.

Regulatory frameworks governing hydrogel actuator surface treatments vary by application context. Medical applications face stringent requirements under ISO 10993 standards, requiring extensive biocompatibility testing regimens. Environmental applications must address ecotoxicity concerns, particularly for marine deployments where biofouling prevention is critical but environmental impact must be minimized.

Recent innovations have focused on "safer-by-design" approaches, incorporating naturally derived antimicrobial peptides, biomimetic topographies, and stimuli-responsive elements that activate only when needed. These strategies aim to maintain effective anti-biofouling performance while minimizing safety concerns. For example, peptide-based coatings derived from marine organisms demonstrate promising selective toxicity against bacterial biofilms while exhibiting minimal mammalian cell toxicity.

The integration of computational toxicology and high-throughput screening methodologies has accelerated safety assessment processes, allowing researchers to evaluate multiple surface treatment formulations efficiently. These approaches help identify optimal compositions that balance anti-biofouling efficacy with biocompatibility requirements, streamlining development pathways for next-generation hydrogel actuator technologies.

Primary biocompatibility concerns include potential leaching of treatment compounds into surrounding tissues or environments. Surface treatments often incorporate antimicrobial agents, enzymes, or reactive chemical groups that, while effective against biofouling organisms, may exhibit cytotoxicity toward mammalian cells. Comprehensive in vitro cytotoxicity testing using relevant cell lines provides essential preliminary safety data before advancing to more complex evaluations.

Inflammatory responses present another significant challenge, as foreign body reactions can compromise both device function and patient outcomes. Surface treatments must minimize protein adsorption that triggers inflammatory cascades. Recent research demonstrates that zwitterionic coatings and PEG-based modifications significantly reduce such responses while maintaining anti-biofouling properties.

Long-term safety considerations extend beyond immediate biocompatibility to include degradation behaviors of surface treatments. Hydrolytic or enzymatic breakdown of coatings may release potentially harmful byproducts or expose underlying materials with different biocompatibility profiles. Accelerated aging studies combined with degradation product analysis have become standard practice in evaluating these long-term risks.

Regulatory frameworks governing hydrogel actuator surface treatments vary by application context. Medical applications face stringent requirements under ISO 10993 standards, requiring extensive biocompatibility testing regimens. Environmental applications must address ecotoxicity concerns, particularly for marine deployments where biofouling prevention is critical but environmental impact must be minimized.

Recent innovations have focused on "safer-by-design" approaches, incorporating naturally derived antimicrobial peptides, biomimetic topographies, and stimuli-responsive elements that activate only when needed. These strategies aim to maintain effective anti-biofouling performance while minimizing safety concerns. For example, peptide-based coatings derived from marine organisms demonstrate promising selective toxicity against bacterial biofilms while exhibiting minimal mammalian cell toxicity.

The integration of computational toxicology and high-throughput screening methodologies has accelerated safety assessment processes, allowing researchers to evaluate multiple surface treatment formulations efficiently. These approaches help identify optimal compositions that balance anti-biofouling efficacy with biocompatibility requirements, streamlining development pathways for next-generation hydrogel actuator technologies.

Environmental Impact and Sustainability of Surface Treatments

The environmental impact of surface treatments for hydrogel actuators represents a critical consideration in their development and deployment. Traditional anti-biofouling strategies often rely on toxic compounds such as heavy metals, quaternary ammonium compounds, and other biocides that can leach into aquatic environments, causing harm to non-target organisms and disrupting ecological balance. Recent environmental monitoring studies have detected these compounds in increasing concentrations in marine and freshwater ecosystems, raising significant concerns about their long-term effects.

Surface treatments for hydrogel actuators must be evaluated through a comprehensive life cycle assessment framework. This includes examining raw material extraction, manufacturing processes, use phase, and end-of-life disposal. Many conventional treatments require energy-intensive production methods and utilize non-renewable resources, contributing to their substantial carbon footprint. The persistence of these treatments in the environment after disposal presents additional challenges for sustainable development.

Emerging eco-friendly alternatives show promising environmental profiles. Biomimetic approaches inspired by natural anti-fouling mechanisms found in marine organisms typically employ non-toxic mechanisms rather than leaching biocides. These include surface topography modifications that create unfavorable settlement conditions for fouling organisms and enzyme-based coatings that catalyze the breakdown of adhesive substances produced by microorganisms without releasing harmful compounds.

Regulatory frameworks worldwide are increasingly restricting the use of environmentally harmful anti-fouling compounds. The International Maritime Organization's ban on tributyltin compounds represents an early example, with more comprehensive regulations emerging in the European Union under REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and similar frameworks in other jurisdictions. These regulatory trends strongly favor the development of environmentally benign surface treatments.

Biodegradability and biocompatibility have become essential design criteria for next-generation surface treatments. Treatments derived from natural polymers such as chitosan, alginate, and cellulose derivatives offer promising alternatives that can degrade into non-toxic components at the end of their useful life. These materials can be sourced from renewable resources and often require less energy-intensive processing methods, further enhancing their sustainability profile.

Economic analyses indicate that while environmentally sustainable treatments may have higher initial costs, they often prove more economical over their complete life cycle when considering regulatory compliance costs, potential environmental remediation expenses, and extended service life due to improved public acceptance and regulatory stability. This total cost perspective is increasingly driving industry adoption of greener alternatives despite potential upfront cost premiums.

Surface treatments for hydrogel actuators must be evaluated through a comprehensive life cycle assessment framework. This includes examining raw material extraction, manufacturing processes, use phase, and end-of-life disposal. Many conventional treatments require energy-intensive production methods and utilize non-renewable resources, contributing to their substantial carbon footprint. The persistence of these treatments in the environment after disposal presents additional challenges for sustainable development.

Emerging eco-friendly alternatives show promising environmental profiles. Biomimetic approaches inspired by natural anti-fouling mechanisms found in marine organisms typically employ non-toxic mechanisms rather than leaching biocides. These include surface topography modifications that create unfavorable settlement conditions for fouling organisms and enzyme-based coatings that catalyze the breakdown of adhesive substances produced by microorganisms without releasing harmful compounds.

Regulatory frameworks worldwide are increasingly restricting the use of environmentally harmful anti-fouling compounds. The International Maritime Organization's ban on tributyltin compounds represents an early example, with more comprehensive regulations emerging in the European Union under REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and similar frameworks in other jurisdictions. These regulatory trends strongly favor the development of environmentally benign surface treatments.

Biodegradability and biocompatibility have become essential design criteria for next-generation surface treatments. Treatments derived from natural polymers such as chitosan, alginate, and cellulose derivatives offer promising alternatives that can degrade into non-toxic components at the end of their useful life. These materials can be sourced from renewable resources and often require less energy-intensive processing methods, further enhancing their sustainability profile.

Economic analyses indicate that while environmentally sustainable treatments may have higher initial costs, they often prove more economical over their complete life cycle when considering regulatory compliance costs, potential environmental remediation expenses, and extended service life due to improved public acceptance and regulatory stability. This total cost perspective is increasingly driving industry adoption of greener alternatives despite potential upfront cost premiums.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!