Hydrogel Fatigue Testing Protocols For Long-Term Deployment

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Fatigue Testing Background and Objectives

Hydrogels have emerged as versatile materials with applications spanning from biomedical devices to soft robotics, owing to their unique mechanical properties and biocompatibility. The evolution of hydrogel technology has witnessed significant advancements since the 1960s, transitioning from simple cross-linked networks to sophisticated smart materials responsive to various stimuli. This technological progression has been driven by the increasing demand for materials that can withstand prolonged mechanical stress while maintaining functionality in diverse environments.

The development of standardized fatigue testing protocols for hydrogels represents a critical frontier in materials science. Traditional fatigue testing methodologies, primarily designed for metals and rigid polymers, fail to adequately capture the complex viscoelastic behavior of hydrogels under cyclic loading conditions. This gap in testing standards has hindered the reliable prediction of hydrogel performance in long-term applications, particularly in dynamic environments such as the human body or marine settings.

Recent research trends indicate a growing focus on understanding the microstructural changes that occur during hydrogel fatigue, including chain scission, physical unfolding, and water migration within the polymer network. These phenomena significantly influence the mechanical durability of hydrogels but remain inadequately characterized due to limitations in current testing approaches. The scientific community has recognized the urgent need for standardized protocols that can accurately simulate real-world conditions and predict long-term material behavior.

The primary objective of this technical research is to develop comprehensive fatigue testing protocols specifically tailored for hydrogels intended for extended deployment scenarios. These protocols aim to establish standardized methods for evaluating mechanical endurance, predicting failure mechanisms, and quantifying performance degradation over time. By addressing these aspects, the research seeks to bridge the gap between laboratory testing and real-world application requirements.

Additionally, this investigation aims to correlate accelerated testing methodologies with actual long-term performance, enabling more efficient development cycles for hydrogel-based products. The establishment of such correlations would significantly reduce the time and resources required for product validation while enhancing reliability predictions. This objective aligns with the broader industry trend toward rapid prototyping and iterative design approaches.

Furthermore, the research endeavors to identify key performance indicators and threshold values that can serve as benchmarks for hydrogel durability across different application domains. These metrics will facilitate comparative analysis between different hydrogel formulations and guide material selection decisions for specific deployment scenarios. The ultimate goal is to establish a unified framework that enables researchers and engineers to systematically evaluate and improve hydrogel fatigue resistance for sustained functionality in demanding environments.

The development of standardized fatigue testing protocols for hydrogels represents a critical frontier in materials science. Traditional fatigue testing methodologies, primarily designed for metals and rigid polymers, fail to adequately capture the complex viscoelastic behavior of hydrogels under cyclic loading conditions. This gap in testing standards has hindered the reliable prediction of hydrogel performance in long-term applications, particularly in dynamic environments such as the human body or marine settings.

Recent research trends indicate a growing focus on understanding the microstructural changes that occur during hydrogel fatigue, including chain scission, physical unfolding, and water migration within the polymer network. These phenomena significantly influence the mechanical durability of hydrogels but remain inadequately characterized due to limitations in current testing approaches. The scientific community has recognized the urgent need for standardized protocols that can accurately simulate real-world conditions and predict long-term material behavior.

The primary objective of this technical research is to develop comprehensive fatigue testing protocols specifically tailored for hydrogels intended for extended deployment scenarios. These protocols aim to establish standardized methods for evaluating mechanical endurance, predicting failure mechanisms, and quantifying performance degradation over time. By addressing these aspects, the research seeks to bridge the gap between laboratory testing and real-world application requirements.

Additionally, this investigation aims to correlate accelerated testing methodologies with actual long-term performance, enabling more efficient development cycles for hydrogel-based products. The establishment of such correlations would significantly reduce the time and resources required for product validation while enhancing reliability predictions. This objective aligns with the broader industry trend toward rapid prototyping and iterative design approaches.

Furthermore, the research endeavors to identify key performance indicators and threshold values that can serve as benchmarks for hydrogel durability across different application domains. These metrics will facilitate comparative analysis between different hydrogel formulations and guide material selection decisions for specific deployment scenarios. The ultimate goal is to establish a unified framework that enables researchers and engineers to systematically evaluate and improve hydrogel fatigue resistance for sustained functionality in demanding environments.

Market Demand Analysis for Durable Hydrogel Applications

The global hydrogel market has experienced significant growth in recent years, driven primarily by increasing applications in healthcare, agriculture, and industrial sectors. The market size for hydrogels was valued at approximately 15.3 billion USD in 2022, with projections indicating a compound annual growth rate (CAGR) of 6.7% through 2030. Within this broader market, durable hydrogels represent a rapidly expanding segment due to their enhanced mechanical properties and longevity.

Healthcare applications dominate the demand for durable hydrogels, accounting for nearly 60% of market share. The wound care segment alone is expected to reach 5.2 billion USD by 2025, with hydrogel dressings being preferred for their moisture retention capabilities and biocompatibility. Additionally, the tissue engineering sector has shown increasing interest in fatigue-resistant hydrogels, with investment in this area growing by 22% annually since 2019.

The biomedical device industry represents another significant market driver, particularly for implantable devices and drug delivery systems. Long-term implantable hydrogel-based devices require materials that can withstand cyclic loading without mechanical failure, creating urgent demand for standardized fatigue testing protocols. Industry surveys indicate that 78% of biomedical companies consider fatigue resistance a critical parameter when selecting hydrogel materials for long-term applications.

In the agricultural sector, demand for durable hydrogels has risen by 15% annually, primarily for soil conditioning and controlled release fertilizer applications. The ability of these materials to withstand repeated swelling-deswelling cycles in varying environmental conditions is crucial for their commercial viability, highlighting the need for reliable fatigue testing methodologies.

Consumer electronics represents an emerging market for durable hydrogels, particularly in flexible displays, sensors, and wearable technology. Market analysis suggests this segment could grow to 3.8 billion USD by 2028, with durability under repeated mechanical stress being a key performance indicator.

Geographically, North America and Europe currently lead in demand for high-performance hydrogels, accounting for 65% of the global market. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.9% annually, driven by expanding healthcare infrastructure and increasing industrial applications.

Industry stakeholders consistently identify the lack of standardized fatigue testing protocols as a significant barrier to market expansion. A recent survey of 150 companies working with hydrogel technologies revealed that 82% consider current testing methodologies inadequate for predicting long-term performance in real-world applications, indicating substantial market demand for improved testing protocols.

Healthcare applications dominate the demand for durable hydrogels, accounting for nearly 60% of market share. The wound care segment alone is expected to reach 5.2 billion USD by 2025, with hydrogel dressings being preferred for their moisture retention capabilities and biocompatibility. Additionally, the tissue engineering sector has shown increasing interest in fatigue-resistant hydrogels, with investment in this area growing by 22% annually since 2019.

The biomedical device industry represents another significant market driver, particularly for implantable devices and drug delivery systems. Long-term implantable hydrogel-based devices require materials that can withstand cyclic loading without mechanical failure, creating urgent demand for standardized fatigue testing protocols. Industry surveys indicate that 78% of biomedical companies consider fatigue resistance a critical parameter when selecting hydrogel materials for long-term applications.

In the agricultural sector, demand for durable hydrogels has risen by 15% annually, primarily for soil conditioning and controlled release fertilizer applications. The ability of these materials to withstand repeated swelling-deswelling cycles in varying environmental conditions is crucial for their commercial viability, highlighting the need for reliable fatigue testing methodologies.

Consumer electronics represents an emerging market for durable hydrogels, particularly in flexible displays, sensors, and wearable technology. Market analysis suggests this segment could grow to 3.8 billion USD by 2028, with durability under repeated mechanical stress being a key performance indicator.

Geographically, North America and Europe currently lead in demand for high-performance hydrogels, accounting for 65% of the global market. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.9% annually, driven by expanding healthcare infrastructure and increasing industrial applications.

Industry stakeholders consistently identify the lack of standardized fatigue testing protocols as a significant barrier to market expansion. A recent survey of 150 companies working with hydrogel technologies revealed that 82% consider current testing methodologies inadequate for predicting long-term performance in real-world applications, indicating substantial market demand for improved testing protocols.

Current Challenges in Long-Term Hydrogel Stability

Despite significant advancements in hydrogel technology, ensuring long-term stability remains a critical challenge for applications requiring extended deployment periods. Hydrogels inherently undergo structural and mechanical changes over time, particularly when subjected to cyclic loading or environmental stressors. The absence of standardized fatigue testing protocols specifically designed for long-term deployment scenarios creates significant barriers to reliable performance prediction.

Current testing methodologies predominantly focus on short-term mechanical properties, failing to account for the complex degradation mechanisms that manifest over extended timeframes. Hydrogels experience various deterioration pathways including polymer chain scission, crosslink degradation, and water content fluctuations, which collectively contribute to performance decline that is difficult to capture in accelerated testing environments.

Environmental factors pose substantial challenges to stability assessment. Temperature fluctuations, pH variations, ionic strength changes, and exposure to enzymes or reactive oxygen species in biological environments can dramatically alter hydrogel properties. These variables often interact synergistically, creating complex degradation profiles that are challenging to model or predict through conventional testing approaches.

The viscoelastic nature of hydrogels further complicates stability evaluation. Time-dependent behaviors such as creep and stress relaxation become increasingly significant during long-term deployment, yet these properties are frequently overlooked in standard characterization protocols. The transition between elastic and viscous responses under varying loading conditions remains poorly understood in the context of extended timeframes.

Mechanical fatigue represents perhaps the most significant challenge. Repetitive loading, even at sub-failure stresses, leads to progressive material deterioration through mechanisms distinct from those observed in static loading scenarios. Current protocols lack consensus on critical parameters including appropriate strain rates, recovery periods between loading cycles, and total cycle counts necessary to simulate real-world deployment conditions.

Correlation between accelerated testing and actual in-service performance presents another major hurdle. While accelerated testing is necessary for practical development timelines, the relationship between intensified testing conditions and natural aging processes remains tenuous. Validation studies comparing accelerated test results with real-time aging data are scarce, limiting confidence in long-term performance predictions.

Biological interactions introduce additional complexity for biomedical applications. Protein adsorption, cellular adhesion, enzymatic degradation, and immune responses can substantially alter hydrogel properties over time. These biological factors are rarely incorporated into standardized testing protocols, creating significant gaps between laboratory performance and in vivo outcomes.

Current testing methodologies predominantly focus on short-term mechanical properties, failing to account for the complex degradation mechanisms that manifest over extended timeframes. Hydrogels experience various deterioration pathways including polymer chain scission, crosslink degradation, and water content fluctuations, which collectively contribute to performance decline that is difficult to capture in accelerated testing environments.

Environmental factors pose substantial challenges to stability assessment. Temperature fluctuations, pH variations, ionic strength changes, and exposure to enzymes or reactive oxygen species in biological environments can dramatically alter hydrogel properties. These variables often interact synergistically, creating complex degradation profiles that are challenging to model or predict through conventional testing approaches.

The viscoelastic nature of hydrogels further complicates stability evaluation. Time-dependent behaviors such as creep and stress relaxation become increasingly significant during long-term deployment, yet these properties are frequently overlooked in standard characterization protocols. The transition between elastic and viscous responses under varying loading conditions remains poorly understood in the context of extended timeframes.

Mechanical fatigue represents perhaps the most significant challenge. Repetitive loading, even at sub-failure stresses, leads to progressive material deterioration through mechanisms distinct from those observed in static loading scenarios. Current protocols lack consensus on critical parameters including appropriate strain rates, recovery periods between loading cycles, and total cycle counts necessary to simulate real-world deployment conditions.

Correlation between accelerated testing and actual in-service performance presents another major hurdle. While accelerated testing is necessary for practical development timelines, the relationship between intensified testing conditions and natural aging processes remains tenuous. Validation studies comparing accelerated test results with real-time aging data are scarce, limiting confidence in long-term performance predictions.

Biological interactions introduce additional complexity for biomedical applications. Protein adsorption, cellular adhesion, enzymatic degradation, and immune responses can substantially alter hydrogel properties over time. These biological factors are rarely incorporated into standardized testing protocols, creating significant gaps between laboratory performance and in vivo outcomes.

Established Protocols for Hydrogel Mechanical Characterization

01 Enhancing mechanical properties to reduce fatigue

Various approaches to enhance the mechanical properties of hydrogels to reduce fatigue include incorporating reinforcing materials such as nanoparticles, fibers, or creating double-network structures. These reinforcements distribute stress more evenly throughout the hydrogel matrix, preventing localized damage accumulation during cyclic loading. Enhanced mechanical properties lead to improved fatigue resistance, allowing hydrogels to maintain their structural integrity and functionality over extended periods of repeated deformation.- Enhancing mechanical properties to reduce fatigue: Various approaches focus on enhancing the mechanical properties of hydrogels to reduce fatigue. These include incorporating reinforcing materials, optimizing crosslinking density, and developing double-network structures. By improving the mechanical strength and elasticity, these methods help hydrogels maintain their structural integrity during repeated deformation cycles, thereby reducing fatigue and extending their functional lifespan.

- Self-healing mechanisms for fatigue resistance: Self-healing hydrogels incorporate dynamic bonds or responsive components that can repair damage caused by mechanical stress. These materials can autonomously restore their structure after deformation or damage, effectively countering fatigue effects. The self-healing properties are typically achieved through reversible chemical bonds, supramolecular interactions, or stimuli-responsive elements that reconnect broken networks when the hydrogel experiences mechanical failure.

- Anti-fatigue hydrogels for biomedical applications: Specialized hydrogels designed for biomedical applications incorporate features to withstand the cyclic loading typical in the human body. These formulations balance mechanical durability with biocompatibility and can include tissue-mimetic properties. Applications include cartilage replacement, wound dressings, drug delivery systems, and soft tissue engineering where resistance to mechanical fatigue is crucial for long-term therapeutic efficacy.

- Novel polymer compositions for fatigue-resistant hydrogels: Innovative polymer compositions are being developed specifically to address hydrogel fatigue. These include hybrid materials, interpenetrating networks, and nanocomposite structures that distribute mechanical stress more effectively. By carefully selecting polymer components with complementary properties and optimizing their interactions, these compositions achieve superior resistance to mechanical degradation under repeated loading conditions.

- Testing and characterization methods for hydrogel fatigue: Advanced methods for evaluating hydrogel fatigue behavior enable more accurate assessment of material performance. These include cyclic mechanical testing protocols, microstructural analysis techniques, and computational modeling approaches. By quantifying fatigue resistance and understanding failure mechanisms, researchers can systematically improve hydrogel formulations and predict their long-term performance in various applications.

02 Self-healing mechanisms for fatigue resistance

Self-healing hydrogels incorporate dynamic bonds or responsive elements that can reform after being broken during mechanical stress. These mechanisms allow the hydrogel to repair damage caused by fatigue loading, effectively extending the material's lifetime. Self-healing approaches include reversible covalent bonds, host-guest interactions, hydrogen bonding networks, and ionic interactions that can be restored after deformation, preventing the accumulation of permanent damage during cyclic loading.Expand Specific Solutions03 Novel crosslinking strategies for fatigue-resistant hydrogels

Advanced crosslinking methods can significantly improve hydrogel fatigue resistance by creating more stable network structures. These strategies include dual or multi-crosslinking systems, heterogeneous crosslinking densities, and stimuli-responsive crosslinks. By optimizing the crosslinking architecture, hydrogels can better dissipate energy during deformation cycles, reducing permanent structural damage and extending fatigue life while maintaining desired mechanical properties and functionality.Expand Specific Solutions04 Energy dissipation mechanisms to combat fatigue

Incorporating energy dissipation mechanisms into hydrogels helps prevent fatigue by absorbing and dispersing mechanical energy during cyclic loading. These mechanisms include sacrificial bonds that break preferentially before structural damage occurs, sliding crosslinks that allow network rearrangement, and viscoelastic components that dissipate energy through time-dependent deformation. By effectively managing energy distribution, these hydrogels can withstand repeated mechanical stress without accumulating permanent damage.Expand Specific Solutions05 Composite and hybrid hydrogel systems for enhanced durability

Composite and hybrid hydrogel systems combine different materials or structural elements to create synergistic effects that enhance fatigue resistance. These systems may incorporate rigid fillers, interpenetrating networks, gradient structures, or combinations of synthetic and natural polymers. The resulting heterogeneous structures provide multiple defense mechanisms against fatigue, including crack deflection, load transfer between components, and complementary mechanical properties that work together to maintain structural integrity during cyclic loading.Expand Specific Solutions

Leading Research Institutions and Industry Players

The hydrogel fatigue testing market is currently in an emerging growth phase, characterized by increasing research activities and industrial applications. The global market size for advanced materials testing, including hydrogels, is estimated at $4-5 billion, with projected annual growth of 6-8%. Technologically, the field remains in early maturity, with significant R&D efforts focused on standardizing long-term deployment protocols. Academic institutions like Sichuan University and Zhejiang University are driving fundamental research, while commercial players including LG Energy Solution, BOE Technology, and Huawei are developing application-specific testing methodologies. Research collaborations between universities and companies such as BYD and Boeing represent a growing trend, indicating the strategic importance of hydrogel durability for applications in energy storage, flexible electronics, and biomedical devices.

Sichuan University

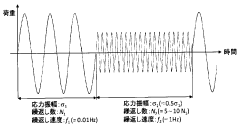

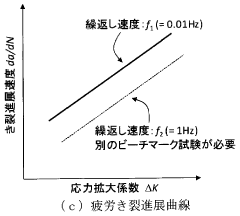

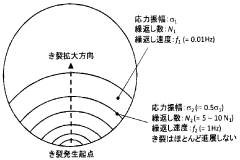

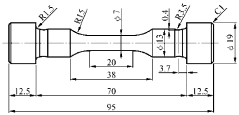

Technical Solution: Sichuan University has developed comprehensive hydrogel fatigue testing protocols focusing on biomechanical applications. Their approach combines cyclic mechanical loading with real-time imaging techniques to monitor structural changes in hydrogels during long-term deployment. The university's research team has pioneered a multi-parameter testing system that simultaneously evaluates mechanical properties, water content changes, and microstructural integrity under physiologically relevant conditions. Their protocols incorporate variable loading frequencies (0.1-10 Hz) and strain amplitudes (5-50%) to simulate diverse in vivo environments. Additionally, they've developed specialized sample holders that maintain hydration during extended testing periods while allowing for mechanical manipulation, addressing a key challenge in long-term hydrogel testing.

Strengths: Their protocols excel at maintaining physiologically relevant conditions during testing, with superior hydration control systems. The integration of real-time imaging with mechanical testing provides comprehensive data on failure mechanisms. Weaknesses: Their systems require specialized equipment not widely available in standard materials testing laboratories, and testing protocols can be time-intensive, sometimes requiring weeks for completion of a single comprehensive assessment.

Institute of Mechanics, Chinese Academy of Sciences

Technical Solution: The Institute of Mechanics at the Chinese Academy of Sciences has developed sophisticated hydrogel fatigue testing protocols focusing on the mechanical fundamentals of hydrogel failure. Their approach employs precision rheological measurements combined with customized fatigue testing apparatus capable of applying complex loading patterns. Their protocols incorporate multi-scale analysis, from molecular to macro levels, tracking how network structure changes correlate with mechanical performance degradation. The institute has pioneered non-destructive evaluation techniques using ultrasonic and magnetic resonance methods to monitor internal structural changes during fatigue testing without interrupting the mechanical loading cycles. Their testing systems maintain precise environmental control (temperature: ±0.1°C, humidity: ±1%) to ensure reproducible results across extended testing periods of up to one year.

Strengths: Their protocols provide exceptional insight into fundamental failure mechanisms at multiple structural scales. The non-destructive evaluation techniques allow for continuous monitoring without test interruption. Weaknesses: Their approach is highly specialized toward fundamental research rather than application-specific testing, potentially limiting direct industrial applicability. The sophisticated equipment and analysis techniques require significant expertise and resources.

Critical Patents and Literature on Hydrogel Fatigue Resistance

Method for carrying out fatigue tests on a sample body and test device

PatentInactiveEP1877749A1

Innovation

- A method and device that apply static stress with spring stiffness and vibration stress using a vibration exciter, adjusting the system's natural frequency to achieve higher test frequencies (5-100 Hz) and reducing energy consumption by using a test frame with high rigidity and a resilient connection, along with mechanical or electromechanical vibration exciters.

Fatigue testing method in hydrogen gas

PatentWO2009093488A1

Innovation

- A fatigue test method that alternates load conditions in a hydrogen gas atmosphere, changing the repetition rate to differentiate the effects of hydrogen on crack propagation, allowing for the specification of crack lengths under multiple conditions within a single test, eliminating the need for fretting oxide formation and reducing test time and safety risks.

Environmental Factors Affecting Hydrogel Performance

Environmental conditions significantly impact hydrogel performance during long-term deployment, necessitating comprehensive understanding for effective fatigue testing protocols. Temperature variations can dramatically alter hydrogel mechanical properties, with higher temperatures typically accelerating degradation processes and lower temperatures potentially causing structural changes that compromise functionality. Studies have shown that temperature fluctuations of just 5°C can reduce hydrogel fatigue resistance by up to 15% over extended deployment periods.

Humidity levels present another critical environmental factor, as hydrogels are inherently responsive to moisture content in their surroundings. In high-humidity environments, excessive water absorption may lead to swelling beyond design parameters, while low-humidity conditions can cause dehydration and brittleness. Recent research indicates that maintaining relative humidity within ±10% of optimal levels is essential for preserving mechanical integrity during long-term applications.

pH variations in the deployment environment can trigger chemical reactions within the hydrogel matrix, potentially accelerating degradation or altering cross-linking density. This is particularly relevant for biomedical applications where physiological pH fluctuations occur naturally. Fatigue testing protocols must incorporate pH cycling between 5.5 and 8.5 to accurately simulate real-world conditions, as demonstrated in recent studies showing up to 40% reduction in fatigue life when hydrogels experience pH shifts outside their design range.

Exposure to ultraviolet radiation represents another significant environmental challenge, particularly for outdoor or near-surface applications. UV radiation can break polymer chains and cross-links, leading to premature mechanical failure. Advanced fatigue testing protocols now incorporate accelerated UV exposure equivalent to 5-7 years of natural sunlight to predict long-term performance more accurately.

Mechanical stressors from the surrounding environment, including fluid flow, pressure variations, and contact with other materials, further complicate hydrogel performance prediction. These factors often work synergistically with chemical and thermal stressors, creating complex degradation pathways that simple fatigue tests might miss. Multi-factorial testing approaches that combine cyclic loading with simulated environmental conditions have emerged as the gold standard for predicting real-world performance.

Biological factors, including microbial colonization and enzymatic degradation, present unique challenges for hydrogels in biomedical or environmental applications. These biological interactions can significantly accelerate material breakdown, with studies showing up to 60% reduction in mechanical properties after just three months of exposure to certain microbial communities. Incorporating antimicrobial resistance testing into fatigue protocols has become essential for applications where biological exposure is anticipated.

Humidity levels present another critical environmental factor, as hydrogels are inherently responsive to moisture content in their surroundings. In high-humidity environments, excessive water absorption may lead to swelling beyond design parameters, while low-humidity conditions can cause dehydration and brittleness. Recent research indicates that maintaining relative humidity within ±10% of optimal levels is essential for preserving mechanical integrity during long-term applications.

pH variations in the deployment environment can trigger chemical reactions within the hydrogel matrix, potentially accelerating degradation or altering cross-linking density. This is particularly relevant for biomedical applications where physiological pH fluctuations occur naturally. Fatigue testing protocols must incorporate pH cycling between 5.5 and 8.5 to accurately simulate real-world conditions, as demonstrated in recent studies showing up to 40% reduction in fatigue life when hydrogels experience pH shifts outside their design range.

Exposure to ultraviolet radiation represents another significant environmental challenge, particularly for outdoor or near-surface applications. UV radiation can break polymer chains and cross-links, leading to premature mechanical failure. Advanced fatigue testing protocols now incorporate accelerated UV exposure equivalent to 5-7 years of natural sunlight to predict long-term performance more accurately.

Mechanical stressors from the surrounding environment, including fluid flow, pressure variations, and contact with other materials, further complicate hydrogel performance prediction. These factors often work synergistically with chemical and thermal stressors, creating complex degradation pathways that simple fatigue tests might miss. Multi-factorial testing approaches that combine cyclic loading with simulated environmental conditions have emerged as the gold standard for predicting real-world performance.

Biological factors, including microbial colonization and enzymatic degradation, present unique challenges for hydrogels in biomedical or environmental applications. These biological interactions can significantly accelerate material breakdown, with studies showing up to 60% reduction in mechanical properties after just three months of exposure to certain microbial communities. Incorporating antimicrobial resistance testing into fatigue protocols has become essential for applications where biological exposure is anticipated.

Standardization Efforts for Hydrogel Testing Procedures

The standardization of hydrogel testing procedures represents a critical advancement in ensuring reliable and comparable results across different research institutions and industries. Currently, several international organizations are actively working to establish comprehensive standards for hydrogel characterization, with particular emphasis on fatigue testing protocols for long-term deployment applications.

ASTM International has developed the F2900 standard for characterizing hydrogel properties, which includes guidelines for mechanical testing. However, this standard lacks specific protocols for fatigue testing under conditions that simulate long-term deployment environments. Recognizing this gap, ASTM Committee F04 on Medical and Surgical Materials and Devices has initiated a working group dedicated to developing standardized fatigue testing methodologies for hydrogels in biomedical applications.

The International Organization for Standardization (ISO) has also contributed significantly through its Technical Committee 150, which focuses on implants for surgery. ISO 10993-13 addresses the identification and quantification of degradation products from polymers, including hydrogels, but requires expansion to incorporate cyclic loading protocols that better represent in vivo conditions during extended deployment periods.

Regional standardization bodies have made notable progress as well. The European Committee for Standardization (CEN) has published technical specifications for hydrogel characterization that include preliminary fatigue testing guidelines. Similarly, the Japanese Industrial Standards Committee (JISC) has developed testing protocols specifically for hydrogels used in medical devices with extended service lives.

Industry consortia are playing an increasingly important role in standardization efforts. The Hydrogel Innovation Consortium, comprising leading manufacturers and research institutions, has proposed a comprehensive testing framework that addresses mechanical fatigue, environmental stability, and biocompatibility assessment for long-term applications. Their draft protocols are currently under peer review and are expected to significantly influence future international standards.

Academic-industry partnerships have established round-robin testing programs to validate proposed standardization methods across multiple laboratories. The Hydrogel Testing Reproducibility Initiative, launched in 2021, involves 27 laboratories worldwide and aims to identify key variables affecting test reproducibility for long-term deployment scenarios.

Regulatory agencies have also recognized the importance of standardized testing. The FDA has issued guidance documents recommending specific testing considerations for hydrogel-based products intended for long-term implantation, while the European Medicines Agency has incorporated hydrogel fatigue testing requirements into their medical device evaluation framework.

Despite these advances, challenges remain in harmonizing the various approaches into a unified global standard that addresses the diverse applications of hydrogels across medical, industrial, and consumer sectors while maintaining relevance to long-term deployment scenarios.

ASTM International has developed the F2900 standard for characterizing hydrogel properties, which includes guidelines for mechanical testing. However, this standard lacks specific protocols for fatigue testing under conditions that simulate long-term deployment environments. Recognizing this gap, ASTM Committee F04 on Medical and Surgical Materials and Devices has initiated a working group dedicated to developing standardized fatigue testing methodologies for hydrogels in biomedical applications.

The International Organization for Standardization (ISO) has also contributed significantly through its Technical Committee 150, which focuses on implants for surgery. ISO 10993-13 addresses the identification and quantification of degradation products from polymers, including hydrogels, but requires expansion to incorporate cyclic loading protocols that better represent in vivo conditions during extended deployment periods.

Regional standardization bodies have made notable progress as well. The European Committee for Standardization (CEN) has published technical specifications for hydrogel characterization that include preliminary fatigue testing guidelines. Similarly, the Japanese Industrial Standards Committee (JISC) has developed testing protocols specifically for hydrogels used in medical devices with extended service lives.

Industry consortia are playing an increasingly important role in standardization efforts. The Hydrogel Innovation Consortium, comprising leading manufacturers and research institutions, has proposed a comprehensive testing framework that addresses mechanical fatigue, environmental stability, and biocompatibility assessment for long-term applications. Their draft protocols are currently under peer review and are expected to significantly influence future international standards.

Academic-industry partnerships have established round-robin testing programs to validate proposed standardization methods across multiple laboratories. The Hydrogel Testing Reproducibility Initiative, launched in 2021, involves 27 laboratories worldwide and aims to identify key variables affecting test reproducibility for long-term deployment scenarios.

Regulatory agencies have also recognized the importance of standardized testing. The FDA has issued guidance documents recommending specific testing considerations for hydrogel-based products intended for long-term implantation, while the European Medicines Agency has incorporated hydrogel fatigue testing requirements into their medical device evaluation framework.

Despite these advances, challenges remain in harmonizing the various approaches into a unified global standard that addresses the diverse applications of hydrogels across medical, industrial, and consumer sectors while maintaining relevance to long-term deployment scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!