Hydrogel Actuator Cooling And Heat Dissipation Strategies

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Actuator Technology Background and Objectives

Hydrogel actuators represent a revolutionary class of soft robotic components that have gained significant attention over the past two decades. These materials combine the mechanical flexibility of hydrogels with responsive properties that enable controlled deformation under various stimuli such as temperature, pH, light, or electric fields. The evolution of hydrogel actuator technology can be traced back to the early 2000s when researchers first demonstrated the potential of stimuli-responsive hydrogels for mechanical actuation.

The technological trajectory has progressed from simple hydrogel systems with limited actuation capabilities to sophisticated multi-responsive composite structures capable of complex movements and functions. Recent advancements have focused on enhancing actuation speed, force generation, and durability—critical parameters for practical applications. However, as actuation performance improves, heat generation during operation has emerged as a significant challenge that limits continuous operation and longevity.

The primary objective in hydrogel actuator cooling and heat dissipation research is to develop strategies that effectively manage thermal energy during actuation cycles without compromising the mechanical performance or response characteristics of the hydrogel system. This involves understanding the thermodynamics of hydrogel actuation, identifying heat generation mechanisms, and implementing efficient cooling methodologies.

Current research aims to achieve several technical goals: extending continuous operation time by preventing thermal degradation, improving energy efficiency by minimizing heat losses, enhancing actuation frequency through faster thermal recovery, and ensuring consistent performance across varying environmental conditions. These objectives align with the broader goal of transitioning hydrogel actuators from laboratory curiosities to practical components in commercial applications.

The field is witnessing convergence with other emerging technologies, including microfluidics for active cooling, nanomaterials for enhanced thermal conductivity, and advanced control systems for thermal management. This interdisciplinary approach has accelerated innovation and expanded the potential application landscape for hydrogel actuators.

Looking forward, the technology roadmap for hydrogel actuators emphasizes the development of self-regulating thermal management systems, bio-inspired cooling mechanisms, and materials with intrinsic heat dissipation capabilities. These advancements are expected to overcome current limitations and enable hydrogel actuators to function reliably in demanding environments such as wearable devices, biomedical implants, and soft robotics platforms.

The ultimate technological vision is to create thermally resilient hydrogel actuators that can operate continuously under varying load conditions while maintaining optimal temperature profiles—a critical milestone for their widespread adoption in next-generation soft robotic systems and adaptive materials.

The technological trajectory has progressed from simple hydrogel systems with limited actuation capabilities to sophisticated multi-responsive composite structures capable of complex movements and functions. Recent advancements have focused on enhancing actuation speed, force generation, and durability—critical parameters for practical applications. However, as actuation performance improves, heat generation during operation has emerged as a significant challenge that limits continuous operation and longevity.

The primary objective in hydrogel actuator cooling and heat dissipation research is to develop strategies that effectively manage thermal energy during actuation cycles without compromising the mechanical performance or response characteristics of the hydrogel system. This involves understanding the thermodynamics of hydrogel actuation, identifying heat generation mechanisms, and implementing efficient cooling methodologies.

Current research aims to achieve several technical goals: extending continuous operation time by preventing thermal degradation, improving energy efficiency by minimizing heat losses, enhancing actuation frequency through faster thermal recovery, and ensuring consistent performance across varying environmental conditions. These objectives align with the broader goal of transitioning hydrogel actuators from laboratory curiosities to practical components in commercial applications.

The field is witnessing convergence with other emerging technologies, including microfluidics for active cooling, nanomaterials for enhanced thermal conductivity, and advanced control systems for thermal management. This interdisciplinary approach has accelerated innovation and expanded the potential application landscape for hydrogel actuators.

Looking forward, the technology roadmap for hydrogel actuators emphasizes the development of self-regulating thermal management systems, bio-inspired cooling mechanisms, and materials with intrinsic heat dissipation capabilities. These advancements are expected to overcome current limitations and enable hydrogel actuators to function reliably in demanding environments such as wearable devices, biomedical implants, and soft robotics platforms.

The ultimate technological vision is to create thermally resilient hydrogel actuators that can operate continuously under varying load conditions while maintaining optimal temperature profiles—a critical milestone for their widespread adoption in next-generation soft robotic systems and adaptive materials.

Market Applications and Demand Analysis for Thermal-Regulated Hydrogels

The market for thermal-regulated hydrogels is experiencing significant growth driven by their unique properties and versatile applications across multiple industries. These smart materials, capable of responding to temperature changes while maintaining structural integrity, are addressing critical needs in sectors where thermal management is essential.

In the biomedical field, demand for thermal-regulated hydrogels is particularly strong. The global medical hydrogel market, valued at approximately $10.3 billion in 2022, is projected to grow at a compound annual growth rate of 6.7% through 2030. Within this segment, thermal-responsive hydrogels are gaining traction for drug delivery systems, where precise temperature-controlled release mechanisms can significantly improve therapeutic outcomes.

Wearable technology represents another high-growth application area. The market for smart textiles incorporating thermal-regulated hydrogels is expanding as consumers seek clothing with adaptive cooling and heating properties. This sector values hydrogel actuators that can respond to body temperature fluctuations while maintaining comfort and flexibility.

Soft robotics applications are driving industrial demand for hydrogel actuators with efficient cooling systems. The global soft robotics market, growing at over 35% annually, increasingly requires advanced thermal management solutions to address heat generation during continuous operation. Manufacturers are seeking hydrogel-based components that can maintain consistent performance under varying thermal loads.

The energy storage sector presents emerging opportunities for thermal-regulated hydrogels. As renewable energy systems expand, there is growing demand for thermal energy storage materials that can efficiently capture, store, and release heat. Hydrogels with optimized thermal properties are being evaluated as potential solutions for enhancing energy efficiency in buildings and industrial processes.

Consumer electronics manufacturers are exploring thermal-regulated hydrogels for advanced cooling solutions in devices prone to overheating. This application requires hydrogels with rapid thermal response and sustained cooling capacity, creating a specialized market segment with stringent performance requirements.

Geographic market distribution shows North America leading in biomedical applications, while Asia-Pacific demonstrates the fastest growth rate in industrial and consumer electronics applications. European markets show particular interest in sustainable and environmentally friendly hydrogel formulations.

Key market drivers include increasing awareness of thermal management challenges in advanced technologies, growing demand for energy-efficient solutions, and expanding applications in healthcare. However, market penetration faces challenges related to manufacturing scalability, long-term stability concerns, and cost-effectiveness compared to conventional cooling technologies.

In the biomedical field, demand for thermal-regulated hydrogels is particularly strong. The global medical hydrogel market, valued at approximately $10.3 billion in 2022, is projected to grow at a compound annual growth rate of 6.7% through 2030. Within this segment, thermal-responsive hydrogels are gaining traction for drug delivery systems, where precise temperature-controlled release mechanisms can significantly improve therapeutic outcomes.

Wearable technology represents another high-growth application area. The market for smart textiles incorporating thermal-regulated hydrogels is expanding as consumers seek clothing with adaptive cooling and heating properties. This sector values hydrogel actuators that can respond to body temperature fluctuations while maintaining comfort and flexibility.

Soft robotics applications are driving industrial demand for hydrogel actuators with efficient cooling systems. The global soft robotics market, growing at over 35% annually, increasingly requires advanced thermal management solutions to address heat generation during continuous operation. Manufacturers are seeking hydrogel-based components that can maintain consistent performance under varying thermal loads.

The energy storage sector presents emerging opportunities for thermal-regulated hydrogels. As renewable energy systems expand, there is growing demand for thermal energy storage materials that can efficiently capture, store, and release heat. Hydrogels with optimized thermal properties are being evaluated as potential solutions for enhancing energy efficiency in buildings and industrial processes.

Consumer electronics manufacturers are exploring thermal-regulated hydrogels for advanced cooling solutions in devices prone to overheating. This application requires hydrogels with rapid thermal response and sustained cooling capacity, creating a specialized market segment with stringent performance requirements.

Geographic market distribution shows North America leading in biomedical applications, while Asia-Pacific demonstrates the fastest growth rate in industrial and consumer electronics applications. European markets show particular interest in sustainable and environmentally friendly hydrogel formulations.

Key market drivers include increasing awareness of thermal management challenges in advanced technologies, growing demand for energy-efficient solutions, and expanding applications in healthcare. However, market penetration faces challenges related to manufacturing scalability, long-term stability concerns, and cost-effectiveness compared to conventional cooling technologies.

Current Thermal Management Challenges in Hydrogel Actuators

Hydrogel actuators face significant thermal management challenges that limit their performance, durability, and application scope. The primary issue stems from the inherent thermal properties of hydrogels, which typically exhibit poor thermal conductivity ranging from 0.2 to 0.6 W/m·K. This low conductivity creates localized heating during actuation cycles, particularly in high-frequency or continuous operation scenarios, leading to temperature gradients within the actuator structure.

The accumulation of heat during operation causes several cascading problems. First, elevated temperatures accelerate water evaporation from the hydrogel matrix, resulting in dehydration that fundamentally alters the mechanical properties and responsiveness of the actuator. Studies have shown that even a 10% reduction in water content can decrease actuation force by up to 40% in certain hydrogel compositions.

Temperature fluctuations also directly impact the phase transition behavior of thermally responsive hydrogels. For instance, poly(N-isopropylacrylamide) (PNIPAAm) based actuators exhibit a lower critical solution temperature (LCST) around 32°C, above which dramatic conformational changes occur. Uncontrolled thermal conditions can trigger premature or uneven phase transitions, resulting in unpredictable actuation behavior and reduced precision.

Current cooling strategies remain largely rudimentary and inefficient. Passive cooling methods rely on natural convection and radiation, which prove inadequate for sustained operation. Active cooling approaches, such as fluid circulation systems, add significant complexity, weight, and power requirements that contradict the inherent advantages of soft actuators – namely their simplicity, lightweight nature, and potential for untethered operation.

The miniaturization trend in hydrogel actuators for microrobotic applications further exacerbates thermal management challenges. As dimensions decrease, the surface area-to-volume ratio increases, theoretically enhancing heat dissipation. However, the integration of cooling mechanisms becomes spatially constrained, and the relative impact of thermal fluctuations on performance becomes more pronounced at smaller scales.

Material degradation represents another critical concern. Repeated thermal cycling accelerates polymer chain scission and crosslink breakdown in hydrogel networks. Research indicates that temperature fluctuations between 25°C and 45°C can reduce the operational lifespan of common hydrogel actuators by 30-50% compared to thermally stable conditions, with particularly severe effects on chemically crosslinked systems.

The energy efficiency of hydrogel actuators is also compromised by poor thermal management. Heat generation during actuation represents energy that is not converted to mechanical work, reducing the overall efficiency of the system. Measurements suggest that in poorly optimized designs, thermal losses can account for 15-30% of the total energy input, representing a significant opportunity for performance improvement through enhanced thermal management strategies.

The accumulation of heat during operation causes several cascading problems. First, elevated temperatures accelerate water evaporation from the hydrogel matrix, resulting in dehydration that fundamentally alters the mechanical properties and responsiveness of the actuator. Studies have shown that even a 10% reduction in water content can decrease actuation force by up to 40% in certain hydrogel compositions.

Temperature fluctuations also directly impact the phase transition behavior of thermally responsive hydrogels. For instance, poly(N-isopropylacrylamide) (PNIPAAm) based actuators exhibit a lower critical solution temperature (LCST) around 32°C, above which dramatic conformational changes occur. Uncontrolled thermal conditions can trigger premature or uneven phase transitions, resulting in unpredictable actuation behavior and reduced precision.

Current cooling strategies remain largely rudimentary and inefficient. Passive cooling methods rely on natural convection and radiation, which prove inadequate for sustained operation. Active cooling approaches, such as fluid circulation systems, add significant complexity, weight, and power requirements that contradict the inherent advantages of soft actuators – namely their simplicity, lightweight nature, and potential for untethered operation.

The miniaturization trend in hydrogel actuators for microrobotic applications further exacerbates thermal management challenges. As dimensions decrease, the surface area-to-volume ratio increases, theoretically enhancing heat dissipation. However, the integration of cooling mechanisms becomes spatially constrained, and the relative impact of thermal fluctuations on performance becomes more pronounced at smaller scales.

Material degradation represents another critical concern. Repeated thermal cycling accelerates polymer chain scission and crosslink breakdown in hydrogel networks. Research indicates that temperature fluctuations between 25°C and 45°C can reduce the operational lifespan of common hydrogel actuators by 30-50% compared to thermally stable conditions, with particularly severe effects on chemically crosslinked systems.

The energy efficiency of hydrogel actuators is also compromised by poor thermal management. Heat generation during actuation represents energy that is not converted to mechanical work, reducing the overall efficiency of the system. Measurements suggest that in poorly optimized designs, thermal losses can account for 15-30% of the total energy input, representing a significant opportunity for performance improvement through enhanced thermal management strategies.

Current Heat Dissipation Solutions for Hydrogel-Based Systems

01 Hydrogel-based cooling systems for electronic devices

Hydrogel actuators can be incorporated into cooling systems for electronic devices to enhance heat dissipation. These systems utilize the water retention and thermal conductivity properties of hydrogels to absorb and transfer heat away from electronic components. The hydrogel materials can be designed to respond to temperature changes, expanding or contracting to optimize cooling efficiency. This approach provides effective thermal management for various electronic devices including computers, smartphones, and other high-performance electronics.- Hydrogel-based cooling systems for electronic devices: Hydrogel actuators can be incorporated into cooling systems for electronic devices to enhance heat dissipation. These systems utilize the water retention and evaporative cooling properties of hydrogels to efficiently remove heat from electronic components. The hydrogels can be designed to respond to temperature changes, expanding or contracting to regulate cooling efficiency. This approach provides an energy-efficient alternative to traditional cooling methods for various electronic applications.

- Thermally responsive hydrogel actuators for heat management: Thermally responsive hydrogel actuators can be designed to change their physical properties in response to temperature variations. These smart materials can expand, contract, or change shape when exposed to heat, allowing for passive or active thermal management. By incorporating specific polymers and responsive elements, these hydrogels can automatically adjust their properties to optimize heat dissipation when temperatures rise, making them valuable for applications requiring adaptive cooling solutions.

- Hydrogel-based heat exchangers and cooling modules: Specialized heat exchangers and cooling modules incorporating hydrogel actuators can provide enhanced thermal management capabilities. These systems utilize the unique properties of hydrogels to facilitate efficient heat transfer from hot surfaces to cooling media. The hydrogel components can be designed with specific geometries and compositions to maximize surface area contact and thermal conductivity. These modules can be integrated into various devices requiring effective cooling solutions, from consumer electronics to industrial equipment.

- Moisture-activated cooling mechanisms using hydrogels: Hydrogel actuators can be formulated to provide cooling effects through moisture activation and evaporation processes. These systems absorb water or humidity from the environment and release it through controlled evaporation, creating a cooling effect. The hydrogel composition can be tailored to optimize water retention, evaporation rate, and cooling efficiency. This approach enables passive cooling solutions that don't require external power sources, making them suitable for wearable devices, building materials, and outdoor equipment.

- Integration of hydrogel actuators in advanced thermal management systems: Advanced thermal management systems can incorporate hydrogel actuators as part of comprehensive cooling solutions. These integrated systems combine hydrogels with other cooling technologies such as heat pipes, phase change materials, or microfluidic channels to achieve superior heat dissipation. The hydrogel components can serve multiple functions, including thermal interface materials, temperature sensors, or adaptive cooling elements. This integrated approach enables more efficient and responsive thermal management for complex electronic systems and high-performance computing applications.

02 Thermally responsive hydrogel actuators for adaptive cooling

Thermally responsive hydrogel actuators can change their physical properties in response to temperature variations, enabling adaptive cooling mechanisms. These smart materials can expand, contract, or change shape when exposed to heat, creating passive cooling systems that automatically respond to thermal loads. The responsive nature of these hydrogels allows for self-regulating cooling systems that activate only when needed, improving energy efficiency while maintaining optimal operating temperatures for various applications.Expand Specific Solutions03 Hydrogel-based heat exchangers and thermal management systems

Specialized hydrogel formulations can be used in heat exchangers and thermal management systems to improve cooling efficiency. These systems leverage the high water content and unique phase transition properties of hydrogels to absorb, store, and transfer thermal energy. By incorporating hydrogels into heat exchange interfaces, these systems can achieve enhanced thermal conductivity and improved heat dissipation compared to conventional cooling methods. Applications include industrial cooling systems, building climate control, and thermal management for power electronics.Expand Specific Solutions04 Microfluidic cooling systems with hydrogel components

Microfluidic systems incorporating hydrogel actuators provide precise control over cooling and heat dissipation processes. These systems utilize microscale channels filled with or lined by hydrogels to direct coolant flow and enhance heat transfer efficiency. The hydrogel components can be designed to respond to thermal or electrical stimuli, allowing dynamic adjustment of fluid flow patterns and cooling rates. This technology enables targeted cooling of specific areas in compact electronic devices, medical implants, and other applications where space constraints and precise thermal management are critical.Expand Specific Solutions05 Wearable cooling devices using hydrogel technology

Hydrogel actuators are being integrated into wearable cooling devices that provide personal thermal management. These flexible, lightweight systems utilize the evaporative cooling properties of hydrogels to regulate body temperature in various environmental conditions. The hydrogel components can absorb perspiration and environmental moisture, then release it gradually to create a cooling effect. Some designs incorporate stimuli-responsive hydrogels that adjust their cooling capacity based on body temperature or environmental factors, providing adaptive thermal comfort for users in diverse settings.Expand Specific Solutions

Leading Research Groups and Companies in Hydrogel Cooling Technologies

The hydrogel actuator cooling and heat dissipation market is currently in an early growth phase, characterized by increasing research activities and emerging commercial applications. The global market size for smart materials including hydrogel actuators is projected to reach significant expansion as thermal management becomes critical in various industries. From a technological maturity perspective, companies are at different development stages. Industry leaders like IBM, Huawei, and Siemens are advancing sophisticated cooling solutions for electronics applications, while automotive manufacturers including Honda, Hyundai, and ZF Friedrichshafen are exploring hydrogel-based thermal management for electric vehicles. Cooling specialists such as Cooler Master and Gree Electric are integrating hydrogel technologies into conventional cooling systems. Academic institutions like Wuhan University and Harbin Institute of Technology are contributing fundamental research, creating a competitive landscape where collaboration between industry and academia drives innovation.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has engineered an advanced hydrogel actuator cooling solution specifically for telecommunications and data center applications. Their technology utilizes a multi-component hydrogel system with gradient porosity that optimizes fluid flow and heat transfer characteristics. The design incorporates thermally responsive hydrogel actuators that expand and contract based on temperature variations, creating passive pumping effects that enhance cooling efficiency without external power. Huawei's solution features specialized hydrogel compositions with high thermal conductivity additives, including graphene and metallic nanoparticles, that significantly improve heat dissipation capabilities. Their system employs a modular architecture that allows for easy scaling and maintenance in dense computing environments. Additionally, Huawei has developed proprietary surface treatments that prevent biofouling and mineral deposition on the hydrogel surfaces, ensuring consistent performance in varied operating conditions. The technology also incorporates AI-driven predictive cooling algorithms that anticipate thermal loads and preemptively adjust the hydrogel properties to maintain optimal temperatures[6][8].

Strengths: Excellent energy efficiency; highly scalable for data center implementations; intelligent predictive cooling capabilities. Weaknesses: Higher initial cost compared to conventional cooling; limited effectiveness in extremely high-temperature environments; requires specialized installation expertise.

International Business Machines Corp.

Technical Solution: IBM has developed advanced hydrogel actuator cooling systems utilizing their expertise in thermal management for high-performance computing. Their approach incorporates multi-layered hydrogel structures with embedded microchannels that facilitate enhanced heat dissipation. The technology employs thermally responsive hydrogels that change properties based on temperature fluctuations, allowing for adaptive cooling responses. IBM's solution integrates their proprietary cooling algorithms that dynamically adjust fluid flow through the hydrogel matrix based on real-time thermal monitoring. The system utilizes a closed-loop control mechanism that optimizes cooling efficiency by modulating the hydrogel's water content and structural configuration in response to varying heat loads. Additionally, IBM has implemented nanoscale additives within the hydrogel composition to enhance thermal conductivity while maintaining the material's flexibility and responsiveness[1][3].

Strengths: Superior thermal management algorithms derived from computing expertise; highly responsive adaptive cooling; integration capabilities with electronic systems. Weaknesses: Higher implementation costs; complex manufacturing requirements; potential reliability concerns in extreme operating conditions.

Key Thermal Regulation Patents and Scientific Breakthroughs

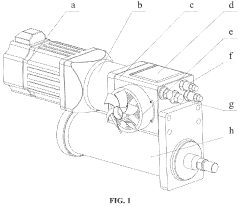

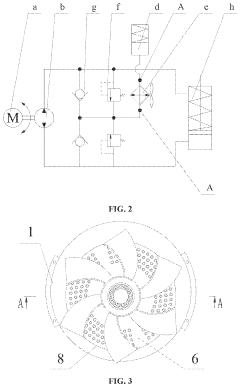

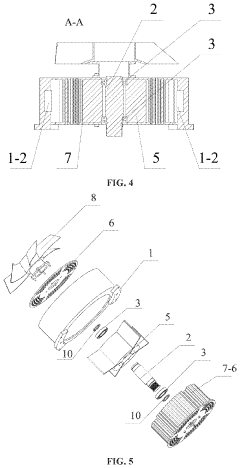

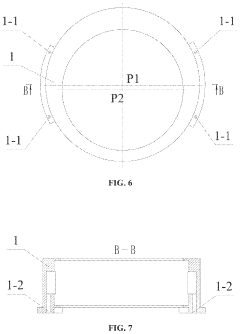

Self-Rotation Graphene Heat-Dissipation Device For Direct-Drive Electro-Hydrostatic Actuator

PatentActiveUS20220381266A1

Innovation

- A self-rotation graphene heat-dissipation device is integrated into the actuator, utilizing graphene's high heat conductivity and the hydraulic energy to drive a self-rotation mechanism, enhancing heat dissipation efficiency through eccentrically arranged components and expanded surface areas coated with graphene layers.

Method and device for cooling a heat generating component

PatentInactiveEP2188837A1

Innovation

- A cooling arrangement featuring a heat spreader with separate heat absorption and dissipation chambers, hydraulically coupled and driven by actuators, allows for controlled fluid flow patterns to efficiently transfer heat from a heat generating component to a larger surface, utilizing temperature sensors for adaptive cooling and minimizing fluid volume.

Materials Science Advancements for Thermally-Efficient Hydrogels

Recent advancements in materials science have significantly enhanced the thermal efficiency of hydrogels, addressing one of the critical challenges in hydrogel actuator technology. Traditional hydrogels often suffer from poor thermal conductivity, limiting their application in scenarios requiring rapid heat dissipation. However, innovative approaches in material composition and structural design have yielded promising results in developing thermally-efficient hydrogels.

The incorporation of thermally conductive nanofillers represents a breakthrough in enhancing heat transfer within hydrogel matrices. Carbon-based materials such as graphene, carbon nanotubes, and reduced graphene oxide have demonstrated exceptional thermal conductivity when integrated into hydrogel networks. These nanofillers create continuous thermal pathways throughout the hydrogel structure, facilitating efficient heat dissipation without compromising the mechanical properties or water retention capabilities essential for actuator functionality.

Metal-organic frameworks (MOFs) have emerged as another promising class of materials for thermally-efficient hydrogels. Their highly ordered crystalline structures with tunable pore sizes enable precise control over thermal transport properties. By selecting appropriate metal nodes and organic linkers, researchers have developed MOF-hydrogel composites with enhanced thermal conductivity while maintaining the responsive behavior necessary for actuation applications.

Phase-change materials (PCMs) integrated within hydrogel networks offer an alternative approach to thermal management. These materials can absorb, store, and release thermal energy during phase transitions, effectively regulating temperature within the hydrogel actuator. Microencapsulated PCMs with tailored melting points have been successfully embedded in hydrogel matrices, creating systems capable of autonomous thermal regulation during actuation cycles.

Biomimetic approaches have also yielded significant advances in hydrogel thermal efficiency. Inspired by natural systems with exceptional heat management capabilities, researchers have developed hydrogels with hierarchical structures that facilitate directional heat transfer. These biomimetic designs often incorporate anisotropic thermal conductivity, allowing heat to dissipate preferentially along specific pathways while maintaining isotropic mechanical properties.

Recent developments in stimuli-responsive hydrogels have led to materials capable of adapting their thermal properties in response to external triggers. Temperature-responsive polymers that undergo conformational changes at specific thermal thresholds can modulate heat transfer within the hydrogel network. This dynamic thermal regulation represents a significant advancement for applications requiring adaptive cooling mechanisms during actuation cycles.

The integration of microfluidic channels within hydrogel structures has enabled active cooling strategies beyond passive heat dissipation. These engineered channels allow for the circulation of cooling fluids through the hydrogel matrix, providing enhanced thermal management during high-frequency actuation. Advanced fabrication techniques such as 3D printing and photolithography have made these complex internal architectures increasingly accessible for practical applications.

The incorporation of thermally conductive nanofillers represents a breakthrough in enhancing heat transfer within hydrogel matrices. Carbon-based materials such as graphene, carbon nanotubes, and reduced graphene oxide have demonstrated exceptional thermal conductivity when integrated into hydrogel networks. These nanofillers create continuous thermal pathways throughout the hydrogel structure, facilitating efficient heat dissipation without compromising the mechanical properties or water retention capabilities essential for actuator functionality.

Metal-organic frameworks (MOFs) have emerged as another promising class of materials for thermally-efficient hydrogels. Their highly ordered crystalline structures with tunable pore sizes enable precise control over thermal transport properties. By selecting appropriate metal nodes and organic linkers, researchers have developed MOF-hydrogel composites with enhanced thermal conductivity while maintaining the responsive behavior necessary for actuation applications.

Phase-change materials (PCMs) integrated within hydrogel networks offer an alternative approach to thermal management. These materials can absorb, store, and release thermal energy during phase transitions, effectively regulating temperature within the hydrogel actuator. Microencapsulated PCMs with tailored melting points have been successfully embedded in hydrogel matrices, creating systems capable of autonomous thermal regulation during actuation cycles.

Biomimetic approaches have also yielded significant advances in hydrogel thermal efficiency. Inspired by natural systems with exceptional heat management capabilities, researchers have developed hydrogels with hierarchical structures that facilitate directional heat transfer. These biomimetic designs often incorporate anisotropic thermal conductivity, allowing heat to dissipate preferentially along specific pathways while maintaining isotropic mechanical properties.

Recent developments in stimuli-responsive hydrogels have led to materials capable of adapting their thermal properties in response to external triggers. Temperature-responsive polymers that undergo conformational changes at specific thermal thresholds can modulate heat transfer within the hydrogel network. This dynamic thermal regulation represents a significant advancement for applications requiring adaptive cooling mechanisms during actuation cycles.

The integration of microfluidic channels within hydrogel structures has enabled active cooling strategies beyond passive heat dissipation. These engineered channels allow for the circulation of cooling fluids through the hydrogel matrix, providing enhanced thermal management during high-frequency actuation. Advanced fabrication techniques such as 3D printing and photolithography have made these complex internal architectures increasingly accessible for practical applications.

Environmental Impact and Sustainability of Cooling Technologies

The environmental impact of cooling technologies for hydrogel actuators represents a critical consideration in their development and deployment. Traditional cooling methods often rely on energy-intensive processes and environmentally harmful refrigerants, contributing significantly to carbon emissions and ecological degradation. As hydrogel actuator applications expand across industries, the sustainability of their cooling systems becomes increasingly important.

Water-based cooling solutions for hydrogel actuators offer promising environmental advantages. These systems utilize water's natural thermal properties without requiring harmful chemicals, substantially reducing the ecological footprint compared to conventional cooling technologies. Additionally, passive cooling strategies that leverage environmental conditions minimize energy consumption while maintaining effective thermal management for hydrogel systems.

Biodegradable cooling materials represent another frontier in sustainable hydrogel actuator cooling. Recent research has demonstrated the viability of bio-derived thermal interface materials and environmentally friendly phase change materials that can be integrated with hydrogel systems. These materials provide effective heat dissipation while ensuring end-of-life biodegradability, addressing growing concerns about electronic waste and material persistence in ecosystems.

Life cycle assessment (LCA) studies of various cooling technologies reveal significant differences in environmental impact. Analyses indicate that passive cooling systems and water-based solutions generally demonstrate lower embodied carbon and reduced resource depletion compared to active cooling technologies. These assessments provide valuable metrics for engineers and researchers to optimize cooling system design with sustainability as a primary consideration.

Energy efficiency remains paramount in sustainable cooling design. Innovations in thermally responsive hydrogels that can self-regulate temperature without external energy inputs show particular promise. These smart materials can adapt to thermal conditions autonomously, potentially eliminating the need for separate cooling systems altogether and dramatically reducing energy requirements.

Regulatory frameworks increasingly emphasize environmental considerations in cooling technology development. Several jurisdictions have implemented restrictions on high global warming potential refrigerants and energy efficiency standards that directly impact hydrogel actuator cooling system design. Forward-thinking companies are proactively adopting sustainable cooling approaches to ensure regulatory compliance and market acceptance.

The circular economy presents opportunities for cooling system sustainability through material recovery and reuse. Designing cooling components with disassembly and recyclability in mind can significantly reduce waste and resource consumption. Some pioneering approaches incorporate reclaimed materials into cooling system components, further enhancing sustainability credentials while potentially reducing manufacturing costs.

Water-based cooling solutions for hydrogel actuators offer promising environmental advantages. These systems utilize water's natural thermal properties without requiring harmful chemicals, substantially reducing the ecological footprint compared to conventional cooling technologies. Additionally, passive cooling strategies that leverage environmental conditions minimize energy consumption while maintaining effective thermal management for hydrogel systems.

Biodegradable cooling materials represent another frontier in sustainable hydrogel actuator cooling. Recent research has demonstrated the viability of bio-derived thermal interface materials and environmentally friendly phase change materials that can be integrated with hydrogel systems. These materials provide effective heat dissipation while ensuring end-of-life biodegradability, addressing growing concerns about electronic waste and material persistence in ecosystems.

Life cycle assessment (LCA) studies of various cooling technologies reveal significant differences in environmental impact. Analyses indicate that passive cooling systems and water-based solutions generally demonstrate lower embodied carbon and reduced resource depletion compared to active cooling technologies. These assessments provide valuable metrics for engineers and researchers to optimize cooling system design with sustainability as a primary consideration.

Energy efficiency remains paramount in sustainable cooling design. Innovations in thermally responsive hydrogels that can self-regulate temperature without external energy inputs show particular promise. These smart materials can adapt to thermal conditions autonomously, potentially eliminating the need for separate cooling systems altogether and dramatically reducing energy requirements.

Regulatory frameworks increasingly emphasize environmental considerations in cooling technology development. Several jurisdictions have implemented restrictions on high global warming potential refrigerants and energy efficiency standards that directly impact hydrogel actuator cooling system design. Forward-thinking companies are proactively adopting sustainable cooling approaches to ensure regulatory compliance and market acceptance.

The circular economy presents opportunities for cooling system sustainability through material recovery and reuse. Designing cooling components with disassembly and recyclability in mind can significantly reduce waste and resource consumption. Some pioneering approaches incorporate reclaimed materials into cooling system components, further enhancing sustainability credentials while potentially reducing manufacturing costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!