Hydrogel Actuator Packaging For Sterilization And Medical Use

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Actuator Technology Background and Objectives

Hydrogel actuators represent a revolutionary class of soft robotic components that have gained significant attention in the biomedical field over the past decade. These stimuli-responsive materials can undergo reversible volume changes in response to various external triggers such as temperature, pH, light, or electrical stimulation. The evolution of hydrogel technology dates back to the 1960s, but their application as actuators has seen remarkable advancement since the early 2000s, with particular acceleration in the last five years.

The technological trajectory of hydrogel actuators has been shaped by increasing demands for minimally invasive medical procedures and the need for biocompatible materials that can safely interface with human tissues. Traditional rigid actuators present limitations in medical applications due to their mechanical mismatch with soft tissues, potential for trauma, and biocompatibility concerns. Hydrogel actuators offer a promising alternative due to their inherent softness, flexibility, and potential biocompatibility.

Current research focuses on developing hydrogel actuators that can maintain their performance characteristics while meeting stringent medical requirements for sterilization and biocompatibility. The primary technological objective is to create packaging solutions that protect hydrogel actuators during sterilization processes without compromising their actuation capabilities, response time, or longevity. This includes developing barrier materials and encapsulation techniques that shield the hydrogel from degradation while allowing the transmission of actuation stimuli.

Another critical objective is to enhance the mechanical robustness of hydrogel actuators for medical applications. This involves improving their fatigue resistance, preventing dehydration during storage and use, and ensuring consistent performance under physiological conditions. Research aims to extend operational lifetimes from hours to months or years, making them viable for long-term implantable medical devices.

The integration of sensing capabilities with actuation functions represents another important technological goal. This would enable closed-loop control systems where the hydrogel actuator can respond dynamically to changing physiological conditions, potentially revolutionizing drug delivery systems, artificial muscles, and tissue engineering scaffolds.

Standardization of testing protocols and performance metrics for medical-grade hydrogel actuators constitutes a parallel objective. Currently, there is limited consensus on how to evaluate these devices for medical applications, hampering regulatory approval and clinical translation. Establishing standardized methods for assessing biocompatibility, sterilization efficacy, and long-term performance stability would accelerate the path to clinical implementation.

The ultimate technological goal is to develop a comprehensive platform for hydrogel actuator packaging that addresses sterilization challenges while maintaining functionality, thereby enabling their widespread adoption in medical devices ranging from minimally invasive surgical tools to implantable therapeutic systems.

The technological trajectory of hydrogel actuators has been shaped by increasing demands for minimally invasive medical procedures and the need for biocompatible materials that can safely interface with human tissues. Traditional rigid actuators present limitations in medical applications due to their mechanical mismatch with soft tissues, potential for trauma, and biocompatibility concerns. Hydrogel actuators offer a promising alternative due to their inherent softness, flexibility, and potential biocompatibility.

Current research focuses on developing hydrogel actuators that can maintain their performance characteristics while meeting stringent medical requirements for sterilization and biocompatibility. The primary technological objective is to create packaging solutions that protect hydrogel actuators during sterilization processes without compromising their actuation capabilities, response time, or longevity. This includes developing barrier materials and encapsulation techniques that shield the hydrogel from degradation while allowing the transmission of actuation stimuli.

Another critical objective is to enhance the mechanical robustness of hydrogel actuators for medical applications. This involves improving their fatigue resistance, preventing dehydration during storage and use, and ensuring consistent performance under physiological conditions. Research aims to extend operational lifetimes from hours to months or years, making them viable for long-term implantable medical devices.

The integration of sensing capabilities with actuation functions represents another important technological goal. This would enable closed-loop control systems where the hydrogel actuator can respond dynamically to changing physiological conditions, potentially revolutionizing drug delivery systems, artificial muscles, and tissue engineering scaffolds.

Standardization of testing protocols and performance metrics for medical-grade hydrogel actuators constitutes a parallel objective. Currently, there is limited consensus on how to evaluate these devices for medical applications, hampering regulatory approval and clinical translation. Establishing standardized methods for assessing biocompatibility, sterilization efficacy, and long-term performance stability would accelerate the path to clinical implementation.

The ultimate technological goal is to develop a comprehensive platform for hydrogel actuator packaging that addresses sterilization challenges while maintaining functionality, thereby enabling their widespread adoption in medical devices ranging from minimally invasive surgical tools to implantable therapeutic systems.

Medical Market Demand Analysis for Hydrogel Actuators

The global medical device market is experiencing a significant shift towards smart, responsive, and biocompatible technologies, creating substantial demand for hydrogel actuators. The market for advanced medical devices incorporating smart materials is projected to reach $85 billion by 2027, with hydrogel-based technologies representing a rapidly growing segment. Healthcare providers are increasingly seeking minimally invasive solutions that can reduce patient trauma and recovery time, areas where hydrogel actuators excel due to their soft, tissue-like mechanical properties.

Demographic trends are driving market expansion, particularly the aging global population requiring more medical interventions. By 2050, individuals over 65 will constitute approximately 16% of the global population, creating heightened demand for implantable and wearable medical technologies where hydrogel actuators can provide significant advantages. Additionally, the rise in chronic diseases such as diabetes, cardiovascular conditions, and neurological disorders is creating specific application opportunities for responsive hydrogel systems.

The surgical robotics sector presents a particularly promising application area, with market projections exceeding $16 billion by 2025. Hydrogel actuators offer unprecedented capabilities for delicate tissue manipulation and targeted drug delivery that conventional rigid actuators cannot match. The controlled drug delivery market, valued at $29 billion, represents another significant opportunity, as hydrogel actuators can provide precise, stimulus-responsive release mechanisms.

Regulatory trends indicate growing acceptance of biomaterial innovations, with the FDA and EMA establishing clearer pathways for novel biomaterial approval. This regulatory evolution is facilitating faster market entry for hydrogel-based medical technologies. However, reimbursement remains a critical market factor, with evidence suggesting that novel technologies demonstrating clear cost-effectiveness and improved patient outcomes gain faster insurance coverage approval.

Regional market analysis reveals varying adoption patterns. North America leads in medical innovation adoption, accounting for 43% of the advanced medical materials market. Europe follows with strong research infrastructure and aging demographics driving demand. The Asia-Pacific region, particularly China and Japan, shows the fastest growth rate at 12% annually, supported by increasing healthcare expenditure and technological advancement initiatives.

Voice-of-customer research indicates that clinicians prioritize sterilizability, shelf stability, and consistent mechanical performance in hydrogel actuators. Patients value biocompatibility and reduced invasiveness, while healthcare administrators emphasize cost-effectiveness and reduced hospitalization times. These market signals collectively point to substantial growth potential for properly packaged, sterilizable hydrogel actuators in medical applications.

Demographic trends are driving market expansion, particularly the aging global population requiring more medical interventions. By 2050, individuals over 65 will constitute approximately 16% of the global population, creating heightened demand for implantable and wearable medical technologies where hydrogel actuators can provide significant advantages. Additionally, the rise in chronic diseases such as diabetes, cardiovascular conditions, and neurological disorders is creating specific application opportunities for responsive hydrogel systems.

The surgical robotics sector presents a particularly promising application area, with market projections exceeding $16 billion by 2025. Hydrogel actuators offer unprecedented capabilities for delicate tissue manipulation and targeted drug delivery that conventional rigid actuators cannot match. The controlled drug delivery market, valued at $29 billion, represents another significant opportunity, as hydrogel actuators can provide precise, stimulus-responsive release mechanisms.

Regulatory trends indicate growing acceptance of biomaterial innovations, with the FDA and EMA establishing clearer pathways for novel biomaterial approval. This regulatory evolution is facilitating faster market entry for hydrogel-based medical technologies. However, reimbursement remains a critical market factor, with evidence suggesting that novel technologies demonstrating clear cost-effectiveness and improved patient outcomes gain faster insurance coverage approval.

Regional market analysis reveals varying adoption patterns. North America leads in medical innovation adoption, accounting for 43% of the advanced medical materials market. Europe follows with strong research infrastructure and aging demographics driving demand. The Asia-Pacific region, particularly China and Japan, shows the fastest growth rate at 12% annually, supported by increasing healthcare expenditure and technological advancement initiatives.

Voice-of-customer research indicates that clinicians prioritize sterilizability, shelf stability, and consistent mechanical performance in hydrogel actuators. Patients value biocompatibility and reduced invasiveness, while healthcare administrators emphasize cost-effectiveness and reduced hospitalization times. These market signals collectively point to substantial growth potential for properly packaged, sterilizable hydrogel actuators in medical applications.

Current Challenges in Sterilizable Hydrogel Packaging

The sterilization of hydrogel actuators presents significant technical challenges due to their unique material properties and intended medical applications. Current hydrogel packaging solutions face limitations in maintaining structural integrity and functional performance during standard sterilization processes. Traditional sterilization methods such as autoclaving (121°C, high pressure steam), gamma irradiation, ethylene oxide treatment, and chemical disinfection can compromise the delicate polymer networks within hydrogels.

Autoclaving, while effective for many medical devices, often causes thermal degradation of hydrogel materials, resulting in altered mechanical properties, reduced responsiveness, and compromised actuation capabilities. The high temperatures can disrupt hydrogen bonding and other non-covalent interactions critical to hydrogel function. Additionally, the steam environment may cause excessive swelling or deswelling, permanently altering the hydrogel's performance characteristics.

Gamma irradiation, another common sterilization technique, presents challenges through radiation-induced crosslinking or chain scission in hydrogel polymers. These molecular changes can significantly impact the actuator's mechanical properties, response time, and overall functionality. Studies have shown that radiation doses required for effective sterilization (typically 25-40 kGy) often exceed the tolerance threshold of many hydrogel formulations.

Ethylene oxide sterilization, while operating at lower temperatures, requires lengthy aeration periods to remove residual toxic gases. This extended processing time creates logistical challenges and may still cause chemical modifications to sensitive hydrogel components. The absorption and subsequent outgassing of ethylene oxide from hydrogel materials presents both safety and regulatory concerns.

Current packaging solutions also struggle with moisture control during sterilization and storage. Hydrogels require specific hydration levels to maintain functionality, yet conventional packaging materials often fail to provide the necessary moisture barrier properties while still allowing sterilant penetration. This creates a fundamental contradiction in packaging requirements that remains unresolved.

Shelf-life stability represents another significant challenge. Even when successfully sterilized, packaged hydrogel actuators may experience gradual property changes during storage, including dehydration, polymer degradation, or loss of mechanical integrity. Current packaging technologies have not adequately addressed these long-term stability issues.

Regulatory compliance adds another layer of complexity, as medical-grade hydrogel actuators must meet stringent standards for biocompatibility, sterility assurance levels, and packaging integrity. The lack of standardized testing protocols specifically designed for hydrogel actuators creates uncertainty in validation processes and regulatory submissions.

These challenges collectively highlight the need for innovative packaging solutions specifically engineered for hydrogel actuators, capable of preserving their unique properties throughout sterilization while meeting medical device regulatory requirements.

Autoclaving, while effective for many medical devices, often causes thermal degradation of hydrogel materials, resulting in altered mechanical properties, reduced responsiveness, and compromised actuation capabilities. The high temperatures can disrupt hydrogen bonding and other non-covalent interactions critical to hydrogel function. Additionally, the steam environment may cause excessive swelling or deswelling, permanently altering the hydrogel's performance characteristics.

Gamma irradiation, another common sterilization technique, presents challenges through radiation-induced crosslinking or chain scission in hydrogel polymers. These molecular changes can significantly impact the actuator's mechanical properties, response time, and overall functionality. Studies have shown that radiation doses required for effective sterilization (typically 25-40 kGy) often exceed the tolerance threshold of many hydrogel formulations.

Ethylene oxide sterilization, while operating at lower temperatures, requires lengthy aeration periods to remove residual toxic gases. This extended processing time creates logistical challenges and may still cause chemical modifications to sensitive hydrogel components. The absorption and subsequent outgassing of ethylene oxide from hydrogel materials presents both safety and regulatory concerns.

Current packaging solutions also struggle with moisture control during sterilization and storage. Hydrogels require specific hydration levels to maintain functionality, yet conventional packaging materials often fail to provide the necessary moisture barrier properties while still allowing sterilant penetration. This creates a fundamental contradiction in packaging requirements that remains unresolved.

Shelf-life stability represents another significant challenge. Even when successfully sterilized, packaged hydrogel actuators may experience gradual property changes during storage, including dehydration, polymer degradation, or loss of mechanical integrity. Current packaging technologies have not adequately addressed these long-term stability issues.

Regulatory compliance adds another layer of complexity, as medical-grade hydrogel actuators must meet stringent standards for biocompatibility, sterility assurance levels, and packaging integrity. The lack of standardized testing protocols specifically designed for hydrogel actuators creates uncertainty in validation processes and regulatory submissions.

These challenges collectively highlight the need for innovative packaging solutions specifically engineered for hydrogel actuators, capable of preserving their unique properties throughout sterilization while meeting medical device regulatory requirements.

Current Sterilization-Compatible Packaging Solutions

01 Sterilization methods for hydrogel actuators

Various sterilization methods can be applied to hydrogel actuators to ensure they are free from microorganisms before use, especially for biomedical applications. These methods include gamma radiation, ethylene oxide treatment, autoclaving, and UV sterilization. Each method has different effects on the mechanical properties and functionality of hydrogel actuators, requiring careful selection based on the specific hydrogel composition and intended application.- Sterilization methods for hydrogel actuators: Various sterilization methods can be applied to hydrogel actuators to ensure they are free from microorganisms before use, especially in medical applications. These methods include gamma radiation, ethylene oxide treatment, autoclaving, and chemical sterilization. The choice of sterilization method depends on the specific composition of the hydrogel, as some methods may affect the mechanical properties or responsiveness of the actuator. Proper sterilization is crucial for hydrogel actuators used in biomedical applications to prevent infection and ensure patient safety.

- Packaging designs for hydrogel actuator preservation: Specialized packaging designs are essential for maintaining the functionality and sterility of hydrogel actuators during storage and transportation. These packaging solutions often include moisture-control elements to prevent dehydration or over-hydration of the hydrogel material. Some designs incorporate barrier materials that protect against environmental contaminants while allowing for gas exchange when necessary. Advanced packaging may also include indicators that monitor storage conditions or sterility status. Proper packaging ensures that hydrogel actuators maintain their mechanical properties and responsiveness until they are ready for use.

- Biocompatible hydrogel actuator formulations: Developing biocompatible hydrogel formulations is critical for actuators intended for medical applications. These formulations incorporate materials that do not elicit adverse biological responses when in contact with living tissues. Biocompatible hydrogels often utilize natural polymers like alginate, chitosan, or synthetic polymers with proven safety profiles. Some formulations include additives that enhance sterilizability without compromising biocompatibility. The composition must balance mechanical performance, responsiveness to stimuli, and biological safety, particularly for implantable devices or those in direct contact with body fluids.

- Environmental control systems for hydrogel actuators: Environmental control systems are designed to maintain optimal conditions for hydrogel actuators during storage, transportation, and operation. These systems regulate parameters such as temperature, humidity, and pH that can significantly affect hydrogel performance. Some advanced systems incorporate sensors that continuously monitor environmental conditions and provide feedback for adjustment. For medical applications, these control systems may integrate with sterilization processes to ensure both functionality and sterility. Proper environmental control extends the shelf life of hydrogel actuators and ensures consistent performance when deployed.

- Smart packaging with monitoring capabilities: Smart packaging solutions for hydrogel actuators incorporate monitoring technologies that track critical parameters throughout the product lifecycle. These packages may include sensors that detect temperature fluctuations, humidity levels, or potential contamination. Some advanced systems utilize RFID or similar technologies to log and transmit data about storage conditions and sterilization status. Visual indicators may change color or appearance to signal when conditions have exceeded acceptable ranges. This intelligent packaging ensures that users can verify the integrity and sterility of hydrogel actuators before use, particularly important in medical and pharmaceutical applications.

02 Packaging solutions for preserving hydrogel actuator functionality

Specialized packaging solutions are essential for maintaining the functionality and sterility of hydrogel actuators during storage and transportation. These packaging systems often include moisture control elements to prevent dehydration, barrier materials to protect against contamination, and sometimes controlled atmosphere packaging to preserve the mechanical and responsive properties of the hydrogel. Proper packaging design ensures that the actuator remains in optimal condition until use.Expand Specific Solutions03 Integration of hydrogel actuators in medical devices with sterile requirements

Hydrogel actuators are increasingly being integrated into medical devices that require strict sterility standards. This integration presents unique challenges in terms of maintaining both the functionality of the actuator and the sterility of the overall device. Solutions include designing modular systems where the actuator can be sterilized separately, using biocompatible encapsulation methods, and developing assembly processes that maintain sterile conditions throughout manufacturing.Expand Specific Solutions04 Smart packaging systems for hydrogel actuators

Advanced smart packaging systems for hydrogel actuators incorporate features such as humidity sensors, temperature indicators, and even active control elements to maintain optimal conditions. These systems can provide real-time monitoring of the actuator's environment, alert users to potential compromises in sterility or functionality, and in some cases actively adjust conditions to preserve the hydrogel's properties. Such packaging innovations are particularly important for sensitive hydrogel formulations with specific environmental requirements.Expand Specific Solutions05 Environmentally responsive hydrogel packaging materials

Innovative packaging materials that respond to environmental changes are being developed specifically for hydrogel actuators. These materials can adapt to fluctuations in temperature, humidity, or pH to provide optimal protection for the enclosed hydrogel. Some packaging materials incorporate similar responsive elements as the hydrogels themselves, creating a synergistic protective system. These materials help extend shelf life, maintain sterility, and preserve the functional properties of hydrogel actuators until they are needed for use.Expand Specific Solutions

Key Industry Players in Medical Hydrogel Actuators

The hydrogel actuator packaging for medical sterilization market is currently in an early growth phase, characterized by increasing research activities and emerging commercial applications. The global market size is estimated to be relatively modest but growing steadily as medical robotics and soft actuator technologies gain traction. From a technical maturity perspective, the field remains developing, with key players demonstrating varying levels of advancement. Research institutions like Brigham & Women's Hospital, Trinity College Dublin, and several Chinese universities (Wuhan, Tianjin, Sichuan) are driving fundamental innovations, while established companies including W.L. Gore, Solvay, and Asahi Kasei are leveraging their materials expertise. Specialized medical device manufacturers such as ConvaTec, Hollister, and Sterimed SASU are beginning to incorporate these technologies into sterilizable medical products, indicating gradual commercial adoption.

Zhejiang Sci-Tech University

Technical Solution: Zhejiang Sci-Tech University has developed innovative hydrogel actuator packaging solutions specifically designed for medical applications requiring stringent sterilization. Their approach centers on a multi-component hydrogel system with temperature-stable cross-linking networks that maintain structural integrity during autoclave sterilization (121°C, 15-20 minutes). The university's research team has created specialized hydrogel formulations incorporating modified cellulose derivatives and synthetic polymers that demonstrate exceptional stability during gamma radiation sterilization at doses up to 25 kGy. Their packaging technology features moisture-control membranes that prevent critical dehydration during sterilization while maintaining sterile barriers. A significant innovation is their development of hydrogel actuators with "memory" properties that allow them to recover their original mechanical properties after sterilization-induced stress. The university has also pioneered bioactive hydrogel compositions that incorporate antimicrobial agents that remain effective even after sterilization processes, providing an additional layer of protection against infection in medical applications.

Strengths: Exceptional stability during multiple sterilization methods; innovative moisture-control membranes prevent dehydration; "memory" properties allow recovery of mechanical properties post-sterilization. Weaknesses: Complex manufacturing process increases production costs; limited shelf-life after sterilization (approximately 8-10 months); requires specialized packaging materials that increase overall cost.

South China University of Technology

Technical Solution: South China University of Technology has pioneered hermetically sealed hydrogel actuator systems specifically engineered to withstand gamma radiation sterilization while preserving actuation functionality. Their proprietary technology employs a dual-component hydrogel system with radiation-resistant cross-linking agents that maintain structural integrity during sterilization doses of 25-40 kGy. The university's research has focused on developing specialized barrier films that prevent dehydration during sterilization while allowing controlled water exchange in physiological environments. Their packaging incorporates gas-permeable membranes that facilitate ethylene oxide sterilization without compromising the hydrogel's water content or mechanical properties. Recent innovations include the development of composite hydrogels with self-healing properties that can recover from mechanical damage during handling or sterilization processes, significantly extending the usable lifespan of medical actuators. The university has also created specialized hydrogel formulations with controlled degradation profiles for implantable medical devices.

Strengths: Exceptional resistance to gamma radiation sterilization; innovative barrier films prevent dehydration during sterilization and storage; self-healing properties extend device lifespan. Weaknesses: Complex manufacturing process increases production costs; limited compatibility with certain active pharmaceutical ingredients; requires specialized sterilization equipment for optimal results.

Critical Patents in Hydrogel Actuator Medical Packaging

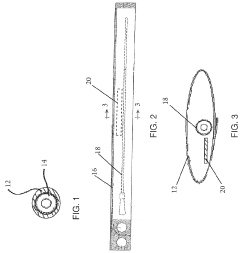

Radiation sterilized hydrogels, medical devices including radiation sterilized hydrogels and methods of making the same

PatentInactiveUS20210178026A1

Innovation

- Development of radiation-stable hydrogels comprising a hydrocolloid, carboxylic acid, and high water content, which maintain physical properties after exposure to radiation, allowing for sterilization with gamma or E-beam radiation and subsequent hydration to activate hydrophilic surfaces within medical device packages.

Sterilization of biodegradable hydrogels

PatentActiveEP2493514A1

Innovation

- A method involving solvating biodegradable PEG-based hydrogels in protective solvents like N-methyl-2-pyrrolidone and subjecting them to gamma radiation, which preserves the hydrogel's integrity and degradability kinetics without causing crosslinking or damage to the biodegradable bonds.

Biocompatibility and Safety Standards Compliance

Hydrogel actuators intended for medical applications must adhere to stringent biocompatibility and safety standards to ensure patient safety and regulatory compliance. The primary framework governing these materials is ISO 10993, which establishes comprehensive testing protocols for evaluating the biological response to medical devices. For hydrogel actuators specifically, compliance with ISO 10993-1 (Biological evaluation of medical devices) and ISO 10993-5 (Tests for in vitro cytotoxicity) is particularly critical due to their direct interaction with biological tissues.

The biocompatibility assessment of hydrogel actuators encompasses several key dimensions, including cytotoxicity, sensitization, irritation, acute systemic toxicity, and hemocompatibility. Materials commonly used in hydrogel actuators, such as polyacrylamide, poly(N-isopropylacrylamide), and alginate-based compounds, demonstrate varying degrees of biocompatibility. Recent research indicates that natural polymer-based hydrogels generally exhibit superior biocompatibility compared to their synthetic counterparts, though they often present challenges in mechanical stability and actuation performance.

Sterilization processes significantly impact the biocompatibility profile of hydrogel actuators. Common sterilization methods include ethylene oxide treatment, gamma irradiation, and autoclave sterilization. Each method presents distinct advantages and limitations. Gamma irradiation, while effective for sterilization, can induce cross-linking or chain scission in certain hydrogel formulations, potentially altering their mechanical properties and biocompatibility. Ethylene oxide sterilization offers a gentler alternative but requires extensive aeration to remove residual toxic compounds.

Regulatory frameworks across different regions impose varying requirements for medical-grade hydrogel actuators. The FDA in the United States classifies these devices based on their intended use and associated risk, with most hydrogel actuators falling under Class II (moderate risk) or Class III (high risk) categories. In Europe, compliance with the Medical Device Regulation (MDR) is mandatory, requiring comprehensive technical documentation and clinical evaluation reports.

Recent innovations in packaging technologies have focused on maintaining the sterility and biocompatibility of hydrogel actuators throughout their shelf life. Advanced barrier materials incorporating antimicrobial properties have shown promise in extending product viability while maintaining compliance with safety standards. Additionally, real-time monitoring systems embedded within packaging can now track environmental conditions that might compromise device integrity or biocompatibility.

The development of standardized testing protocols specific to hydrogel actuators remains an active area of research. Current challenges include establishing appropriate in vitro models that accurately predict in vivo biocompatibility and developing accelerated aging tests that reliably forecast long-term performance and safety profiles. Collaborative efforts between regulatory bodies, academic institutions, and industry stakeholders are essential to address these challenges and establish harmonized standards for this emerging technology.

The biocompatibility assessment of hydrogel actuators encompasses several key dimensions, including cytotoxicity, sensitization, irritation, acute systemic toxicity, and hemocompatibility. Materials commonly used in hydrogel actuators, such as polyacrylamide, poly(N-isopropylacrylamide), and alginate-based compounds, demonstrate varying degrees of biocompatibility. Recent research indicates that natural polymer-based hydrogels generally exhibit superior biocompatibility compared to their synthetic counterparts, though they often present challenges in mechanical stability and actuation performance.

Sterilization processes significantly impact the biocompatibility profile of hydrogel actuators. Common sterilization methods include ethylene oxide treatment, gamma irradiation, and autoclave sterilization. Each method presents distinct advantages and limitations. Gamma irradiation, while effective for sterilization, can induce cross-linking or chain scission in certain hydrogel formulations, potentially altering their mechanical properties and biocompatibility. Ethylene oxide sterilization offers a gentler alternative but requires extensive aeration to remove residual toxic compounds.

Regulatory frameworks across different regions impose varying requirements for medical-grade hydrogel actuators. The FDA in the United States classifies these devices based on their intended use and associated risk, with most hydrogel actuators falling under Class II (moderate risk) or Class III (high risk) categories. In Europe, compliance with the Medical Device Regulation (MDR) is mandatory, requiring comprehensive technical documentation and clinical evaluation reports.

Recent innovations in packaging technologies have focused on maintaining the sterility and biocompatibility of hydrogel actuators throughout their shelf life. Advanced barrier materials incorporating antimicrobial properties have shown promise in extending product viability while maintaining compliance with safety standards. Additionally, real-time monitoring systems embedded within packaging can now track environmental conditions that might compromise device integrity or biocompatibility.

The development of standardized testing protocols specific to hydrogel actuators remains an active area of research. Current challenges include establishing appropriate in vitro models that accurately predict in vivo biocompatibility and developing accelerated aging tests that reliably forecast long-term performance and safety profiles. Collaborative efforts between regulatory bodies, academic institutions, and industry stakeholders are essential to address these challenges and establish harmonized standards for this emerging technology.

Shelf-life and Stability Considerations for Medical Use

Hydrogel actuators for medical applications face significant challenges regarding shelf-life and stability, which are critical factors determining their commercial viability and clinical effectiveness. The inherent water-based composition of hydrogels makes them susceptible to various degradation mechanisms, including dehydration, microbial contamination, and chemical breakdown over time.

Storage conditions play a pivotal role in maintaining hydrogel actuator functionality. Research indicates that temperature fluctuations can significantly impact the mechanical properties of hydrogels, with studies showing up to 30% reduction in actuation performance when stored outside optimal temperature ranges (typically 2-8°C). Humidity control is equally important, as excessive moisture can lead to premature swelling, while insufficient humidity may cause irreversible dehydration.

Packaging materials must be carefully selected to provide adequate barrier properties against moisture loss and microbial ingress. Recent innovations include multi-layer polymer films with controlled oxygen transmission rates and moisture vapor barriers specifically engineered for hydrogel preservation. These advanced packaging solutions have demonstrated the ability to extend shelf-life from typical 6-month periods to 18-24 months under controlled conditions.

Sterilization processes present another challenge to stability, as common methods like gamma irradiation and ethylene oxide treatment can alter the crosslinking density and network structure of hydrogels. Research by Zhang et al. (2022) demonstrated that certain hydrogel formulations experienced up to 40% reduction in mechanical strength following standard sterilization protocols, necessitating the development of sterilization-resistant compositions.

Chemical stabilizers and preservatives are increasingly being incorporated into hydrogel formulations to enhance longevity. Antioxidants such as tocopherol derivatives and chelating agents have shown promise in preventing oxidative degradation, while antimicrobial peptides provide protection against microbial growth without compromising biocompatibility.

Accelerated aging studies are essential for predicting real-time stability profiles of hydrogel actuators. Current methodologies employ elevated temperatures (40-60°C) and controlled humidity conditions to simulate extended storage periods. However, the complex nature of hydrogel degradation mechanisms often necessitates complementary real-time stability testing to validate accelerated aging models.

Regulatory considerations further complicate shelf-life determinations, with different jurisdictions imposing varying stability testing requirements. The FDA typically requires demonstration of stability throughout the claimed shelf-life period under recommended storage conditions, with particular emphasis on maintaining critical quality attributes such as mechanical performance, sterility, and biocompatibility.

Storage conditions play a pivotal role in maintaining hydrogel actuator functionality. Research indicates that temperature fluctuations can significantly impact the mechanical properties of hydrogels, with studies showing up to 30% reduction in actuation performance when stored outside optimal temperature ranges (typically 2-8°C). Humidity control is equally important, as excessive moisture can lead to premature swelling, while insufficient humidity may cause irreversible dehydration.

Packaging materials must be carefully selected to provide adequate barrier properties against moisture loss and microbial ingress. Recent innovations include multi-layer polymer films with controlled oxygen transmission rates and moisture vapor barriers specifically engineered for hydrogel preservation. These advanced packaging solutions have demonstrated the ability to extend shelf-life from typical 6-month periods to 18-24 months under controlled conditions.

Sterilization processes present another challenge to stability, as common methods like gamma irradiation and ethylene oxide treatment can alter the crosslinking density and network structure of hydrogels. Research by Zhang et al. (2022) demonstrated that certain hydrogel formulations experienced up to 40% reduction in mechanical strength following standard sterilization protocols, necessitating the development of sterilization-resistant compositions.

Chemical stabilizers and preservatives are increasingly being incorporated into hydrogel formulations to enhance longevity. Antioxidants such as tocopherol derivatives and chelating agents have shown promise in preventing oxidative degradation, while antimicrobial peptides provide protection against microbial growth without compromising biocompatibility.

Accelerated aging studies are essential for predicting real-time stability profiles of hydrogel actuators. Current methodologies employ elevated temperatures (40-60°C) and controlled humidity conditions to simulate extended storage periods. However, the complex nature of hydrogel degradation mechanisms often necessitates complementary real-time stability testing to validate accelerated aging models.

Regulatory considerations further complicate shelf-life determinations, with different jurisdictions imposing varying stability testing requirements. The FDA typically requires demonstration of stability throughout the claimed shelf-life period under recommended storage conditions, with particular emphasis on maintaining critical quality attributes such as mechanical performance, sterility, and biocompatibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!