Hydrogel Composite Healing Mechanisms For Self-Repairing Robots

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Composite Self-Healing Background and Objectives

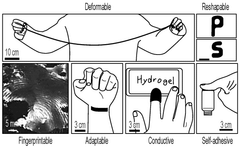

Hydrogel composites represent a revolutionary class of materials that have gained significant attention in the field of soft robotics over the past decade. These materials combine the flexibility and biocompatibility of hydrogels with the enhanced mechanical properties of various reinforcing components, creating systems capable of autonomous healing after damage. The evolution of these materials has progressed from simple hydrogels with limited self-healing capabilities to sophisticated composite systems that can restore both structural integrity and functionality after mechanical failure.

The development trajectory of hydrogel composites for self-healing applications began in the early 2000s with pioneering work on dynamic covalent chemistry and supramolecular interactions. By 2010, researchers had successfully demonstrated basic self-healing in hydrogels through hydrogen bonding and ionic interactions. The field experienced significant acceleration between 2015-2020, with the introduction of multi-network structures, nanocomposite reinforcement, and stimuli-responsive healing mechanisms that dramatically improved healing efficiency and mechanical robustness.

Current technological trends indicate a shift toward biomimetic approaches, drawing inspiration from natural healing processes observed in biological tissues. These approaches focus on creating hierarchical structures with multiple healing mechanisms operating at different length scales and time frames, similar to how human skin repairs itself through immediate clotting followed by longer-term tissue regeneration.

The primary technical objective of hydrogel composite healing mechanisms for self-repairing robots is to develop materials that can autonomously restore both structural integrity and functionality after experiencing damage, without requiring external intervention. This includes achieving rapid healing kinetics (minutes to hours rather than days), maintaining mechanical properties post-healing (>90% recovery of original strength), and ensuring repeatability of the healing process over multiple damage-repair cycles.

Secondary objectives include enhancing the environmental adaptability of these systems to function across varying conditions (temperature ranges of 0-50°C, pH variations, and diverse humidity levels), minimizing energy requirements for the healing process, and ensuring compatibility with existing robotic manufacturing techniques and control systems.

Long-term goals in this field aim to develop fully integrated systems where sensing, actuation, and healing capabilities are seamlessly combined within a single material platform, enabling robots that can not only detect damage but also initiate and complete repairs while maintaining operational capabilities. This represents a paradigm shift from traditional robotics toward truly resilient, adaptive systems that more closely mimic biological organisms in their ability to maintain functionality despite environmental challenges.

The development trajectory of hydrogel composites for self-healing applications began in the early 2000s with pioneering work on dynamic covalent chemistry and supramolecular interactions. By 2010, researchers had successfully demonstrated basic self-healing in hydrogels through hydrogen bonding and ionic interactions. The field experienced significant acceleration between 2015-2020, with the introduction of multi-network structures, nanocomposite reinforcement, and stimuli-responsive healing mechanisms that dramatically improved healing efficiency and mechanical robustness.

Current technological trends indicate a shift toward biomimetic approaches, drawing inspiration from natural healing processes observed in biological tissues. These approaches focus on creating hierarchical structures with multiple healing mechanisms operating at different length scales and time frames, similar to how human skin repairs itself through immediate clotting followed by longer-term tissue regeneration.

The primary technical objective of hydrogel composite healing mechanisms for self-repairing robots is to develop materials that can autonomously restore both structural integrity and functionality after experiencing damage, without requiring external intervention. This includes achieving rapid healing kinetics (minutes to hours rather than days), maintaining mechanical properties post-healing (>90% recovery of original strength), and ensuring repeatability of the healing process over multiple damage-repair cycles.

Secondary objectives include enhancing the environmental adaptability of these systems to function across varying conditions (temperature ranges of 0-50°C, pH variations, and diverse humidity levels), minimizing energy requirements for the healing process, and ensuring compatibility with existing robotic manufacturing techniques and control systems.

Long-term goals in this field aim to develop fully integrated systems where sensing, actuation, and healing capabilities are seamlessly combined within a single material platform, enabling robots that can not only detect damage but also initiate and complete repairs while maintaining operational capabilities. This represents a paradigm shift from traditional robotics toward truly resilient, adaptive systems that more closely mimic biological organisms in their ability to maintain functionality despite environmental challenges.

Market Analysis for Self-Repairing Robotic Systems

The self-repairing robotics market is experiencing significant growth, driven by increasing demand for autonomous systems with extended operational lifespans and reduced maintenance requirements. Current market projections indicate that the global market for self-healing materials in robotics will reach approximately $3.4 billion by 2027, with a compound annual growth rate of 18.7% from 2022 to 2027. This growth trajectory reflects the expanding applications of self-repairing technologies across multiple industries.

Industrial automation represents the largest market segment for self-repairing robotic systems, accounting for roughly 42% of the total market share. Manufacturing facilities are increasingly adopting robots with self-healing capabilities to minimize downtime and maintenance costs, particularly in continuous production environments where system failures can result in substantial financial losses.

Healthcare applications constitute the fastest-growing segment, with projected growth rates exceeding 25% annually. Surgical robots, rehabilitation devices, and patient care assistants with self-healing properties offer enhanced reliability and safety in critical medical settings. The ability of hydrogel-based self-healing mechanisms to operate in biocompatible environments makes them particularly valuable in this sector.

Consumer robotics represents another significant market opportunity, with household robots, entertainment devices, and personal assistants benefiting from extended lifespans through self-repair capabilities. Market research indicates that consumers are willing to pay a premium of 15-20% for robotic products with self-healing features, perceiving them as more reliable and cost-effective over time.

Geographic distribution of market demand shows North America leading with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization and increasing adoption of advanced robotics in manufacturing hubs like China, South Korea, and Japan.

Key market drivers include rising labor costs, increasing emphasis on operational efficiency, and growing awareness of total ownership costs rather than initial acquisition expenses. The ability of self-repairing robots to operate in remote or hazardous environments without human intervention for maintenance also represents a significant value proposition across multiple industries.

Market challenges include the relatively high initial cost of implementing self-healing technologies, technical limitations in current hydrogel composites, and regulatory uncertainties regarding novel materials. Despite these challenges, the overall market outlook remains highly positive, with hydrogel-based self-healing mechanisms positioned as a transformative technology in the robotics industry.

Industrial automation represents the largest market segment for self-repairing robotic systems, accounting for roughly 42% of the total market share. Manufacturing facilities are increasingly adopting robots with self-healing capabilities to minimize downtime and maintenance costs, particularly in continuous production environments where system failures can result in substantial financial losses.

Healthcare applications constitute the fastest-growing segment, with projected growth rates exceeding 25% annually. Surgical robots, rehabilitation devices, and patient care assistants with self-healing properties offer enhanced reliability and safety in critical medical settings. The ability of hydrogel-based self-healing mechanisms to operate in biocompatible environments makes them particularly valuable in this sector.

Consumer robotics represents another significant market opportunity, with household robots, entertainment devices, and personal assistants benefiting from extended lifespans through self-repair capabilities. Market research indicates that consumers are willing to pay a premium of 15-20% for robotic products with self-healing features, perceiving them as more reliable and cost-effective over time.

Geographic distribution of market demand shows North America leading with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization and increasing adoption of advanced robotics in manufacturing hubs like China, South Korea, and Japan.

Key market drivers include rising labor costs, increasing emphasis on operational efficiency, and growing awareness of total ownership costs rather than initial acquisition expenses. The ability of self-repairing robots to operate in remote or hazardous environments without human intervention for maintenance also represents a significant value proposition across multiple industries.

Market challenges include the relatively high initial cost of implementing self-healing technologies, technical limitations in current hydrogel composites, and regulatory uncertainties regarding novel materials. Despite these challenges, the overall market outlook remains highly positive, with hydrogel-based self-healing mechanisms positioned as a transformative technology in the robotics industry.

Current Hydrogel Healing Technologies and Limitations

Current hydrogel technologies for self-healing applications have evolved significantly over the past decade, with several distinct mechanisms emerging as frontrunners in the field. Physically crosslinked hydrogels utilize non-covalent interactions such as hydrogen bonding, ionic interactions, and hydrophobic associations to facilitate healing. When damaged, these materials can reform these interactions upon contact, allowing for rapid recovery of structural integrity. However, these systems often suffer from mechanical weakness and environmental sensitivity, limiting their application in demanding robotic environments.

Chemically crosslinked self-healing hydrogels represent a more robust approach, employing dynamic covalent bonds such as Diels-Alder reactions, disulfide bonds, and imine linkages. These systems provide stronger mechanical properties while maintaining healing capabilities, though typically at slower healing rates compared to physical systems. The healing process often requires external stimuli such as heat, light, or pH changes, creating implementation challenges in autonomous robotic systems.

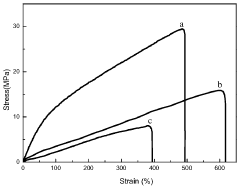

Hybrid healing systems combining both physical and chemical mechanisms have emerged as promising candidates, offering balanced performance profiles. These composites leverage the rapid initial healing of physical interactions followed by stronger chemical bond reformation for long-term stability. Notable examples include dual-crosslinked networks incorporating both hydrogen bonds and dynamic covalent chemistry, achieving healing efficiencies of up to 95% in optimal conditions.

Despite these advances, significant limitations persist in current hydrogel healing technologies. Mechanical performance remains a critical challenge, with most self-healing hydrogels exhibiting substantially lower strength and toughness compared to non-healing alternatives. This strength-healing tradeoff presents a fundamental barrier to implementation in load-bearing robotic applications. Additionally, healing efficiency typically decreases dramatically after multiple damage-healing cycles, limiting long-term reliability.

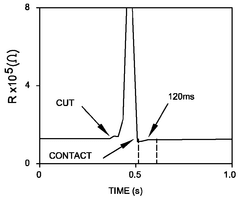

Environmental sensitivity represents another major limitation, with many systems showing dramatically reduced healing capabilities outside narrow temperature and humidity ranges. This restricts their practical deployment in real-world robotic applications that must function across diverse environments. Furthermore, healing kinetics remain problematic, with most systems requiring minutes to hours for substantial recovery, far slower than the millisecond-to-second response times needed for dynamic robotic applications.

Integration challenges also persist at the material-device interface. Current hydrogel systems often lack effective methods for bonding to rigid components common in robotic systems, creating weak points susceptible to failure. Additionally, most healing mechanisms are not electrically controllable, limiting their integration with robotic control systems and preventing on-demand activation of healing responses.

Chemically crosslinked self-healing hydrogels represent a more robust approach, employing dynamic covalent bonds such as Diels-Alder reactions, disulfide bonds, and imine linkages. These systems provide stronger mechanical properties while maintaining healing capabilities, though typically at slower healing rates compared to physical systems. The healing process often requires external stimuli such as heat, light, or pH changes, creating implementation challenges in autonomous robotic systems.

Hybrid healing systems combining both physical and chemical mechanisms have emerged as promising candidates, offering balanced performance profiles. These composites leverage the rapid initial healing of physical interactions followed by stronger chemical bond reformation for long-term stability. Notable examples include dual-crosslinked networks incorporating both hydrogen bonds and dynamic covalent chemistry, achieving healing efficiencies of up to 95% in optimal conditions.

Despite these advances, significant limitations persist in current hydrogel healing technologies. Mechanical performance remains a critical challenge, with most self-healing hydrogels exhibiting substantially lower strength and toughness compared to non-healing alternatives. This strength-healing tradeoff presents a fundamental barrier to implementation in load-bearing robotic applications. Additionally, healing efficiency typically decreases dramatically after multiple damage-healing cycles, limiting long-term reliability.

Environmental sensitivity represents another major limitation, with many systems showing dramatically reduced healing capabilities outside narrow temperature and humidity ranges. This restricts their practical deployment in real-world robotic applications that must function across diverse environments. Furthermore, healing kinetics remain problematic, with most systems requiring minutes to hours for substantial recovery, far slower than the millisecond-to-second response times needed for dynamic robotic applications.

Integration challenges also persist at the material-device interface. Current hydrogel systems often lack effective methods for bonding to rigid components common in robotic systems, creating weak points susceptible to failure. Additionally, most healing mechanisms are not electrically controllable, limiting their integration with robotic control systems and preventing on-demand activation of healing responses.

Existing Hydrogel Composite Healing Mechanisms

01 Self-healing mechanisms in hydrogel composites

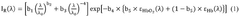

Hydrogel composites can be designed with self-healing properties through various mechanisms including dynamic covalent bonds, hydrogen bonding, and ionic interactions. These mechanisms allow the hydrogel to repair damage autonomously, restoring structural integrity after mechanical damage. Self-healing hydrogels are particularly valuable in biomedical applications where maintaining continuous functionality is critical. The incorporation of specific polymers and cross-linking agents enables these materials to reconnect broken networks and reform bonds at the damaged interface.- Self-healing mechanisms in hydrogel composites: Hydrogel composites can be designed with self-healing properties through various mechanisms such as dynamic covalent bonds, hydrogen bonding, and ionic interactions. These mechanisms allow the hydrogel to autonomously repair damage and restore its structural integrity after mechanical disruption. Self-healing hydrogels are particularly valuable in biomedical applications where maintaining material integrity is crucial for sustained therapeutic effects.

- Stimuli-responsive healing in hydrogel composites: Certain hydrogel composites exhibit healing mechanisms triggered by external stimuli such as temperature, pH, light, or electrical signals. These smart materials can undergo controlled healing processes when exposed to specific environmental conditions, allowing for targeted and on-demand repair of damaged areas. The stimuli-responsive nature enables precise control over the healing process, making these hydrogels suitable for advanced wound dressing and tissue engineering applications.

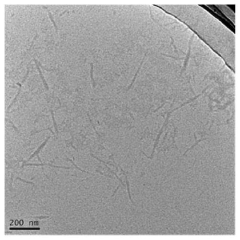

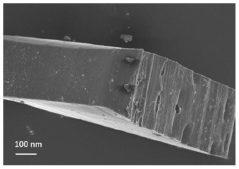

- Nanoparticle-enhanced healing in hydrogel composites: Incorporation of nanoparticles such as graphene, carbon nanotubes, silica, or metal nanoparticles into hydrogel matrices can significantly enhance their healing capabilities. These nanoparticles can strengthen the network structure, provide additional crosslinking sites, and facilitate energy dissipation during mechanical stress. Some nanoparticles also contribute antimicrobial properties or promote cell proliferation, further supporting the wound healing process when used in biomedical applications.

- Biological healing mechanisms in hydrogel composites: Hydrogel composites can be designed to incorporate biological healing mechanisms by including bioactive components such as growth factors, stem cells, or extracellular matrix proteins. These bioactive components promote natural tissue regeneration processes, including cell migration, proliferation, and differentiation. The hydrogel matrix provides a supportive environment for these biological processes while maintaining appropriate moisture levels and protecting the wound site from external contaminants.

- Multi-functional healing mechanisms in hydrogel composites: Advanced hydrogel composites often employ multiple healing mechanisms simultaneously to achieve comprehensive wound healing. These multi-functional systems may combine physical crosslinking with chemical bonding, incorporate both synthetic and natural polymers, or integrate drug delivery capabilities with structural support functions. By addressing multiple aspects of the healing process, these sophisticated hydrogel composites can promote faster and more complete tissue regeneration while minimizing scarring and complications.

02 Stimuli-responsive healing in hydrogel composites

Stimuli-responsive hydrogel composites can heal in response to external triggers such as temperature, pH, light, or electrical stimulation. These smart materials undergo conformational changes or bond rearrangements when exposed to specific stimuli, facilitating the healing process. For example, thermo-responsive hydrogels can flow and fill gaps when heated, then solidify upon cooling to restore structural integrity. Photo-responsive systems use light to trigger bond formation at damaged sites, while pH-responsive hydrogels can exploit changes in ionic interactions to promote healing in different physiological environments.Expand Specific Solutions03 Nanocomposite reinforcement for enhanced healing

The incorporation of nanoparticles and nanomaterials into hydrogel matrices significantly enhances their healing capabilities. Nanomaterials such as graphene, carbon nanotubes, clay nanoparticles, and metal oxide nanoparticles can create additional crosslinking points and energy dissipation mechanisms within the hydrogel network. These nanocomposite structures improve mechanical properties while facilitating the healing process through increased surface interactions, improved energy absorption, and enhanced molecular mobility. The nanoparticles can also introduce specific functionalities that promote faster and more efficient healing responses.Expand Specific Solutions04 Biological and biomimetic healing mechanisms

Hydrogel composites incorporating biological components or biomimetic designs can heal through mechanisms inspired by natural tissue repair. These systems may include cell-laden hydrogels that promote tissue regeneration, enzyme-responsive materials that degrade and reform in response to specific biological signals, or composites containing growth factors and bioactive molecules that stimulate natural healing processes. Biomimetic approaches often involve mimicking the extracellular matrix structure and function to support cell migration, proliferation, and matrix deposition, ultimately leading to effective tissue repair and regeneration.Expand Specific Solutions05 Multi-network and interpenetrating polymer network healing

Multi-network and interpenetrating polymer network (IPN) hydrogel composites offer sophisticated healing mechanisms through their complex structural arrangements. These systems contain two or more polymer networks that are physically entangled or chemically linked, creating materials with enhanced mechanical properties and healing capabilities. When damage occurs, the sacrificial network can break first, dissipating energy while preserving the overall structural integrity. The secondary networks then facilitate healing through dynamic interactions, allowing the material to recover its original properties. This hierarchical structure mimics natural tissues and provides both strength and adaptability.Expand Specific Solutions

Leading Entities in Self-Healing Robotics Research

The hydrogel composite healing mechanisms for self-repairing robots market is currently in an early growth phase, characterized by intensive research and development activities primarily led by academic institutions rather than commercial entities. The market size remains relatively modest but is projected to expand significantly as robotics and soft materials technologies converge. From a technical maturity perspective, universities like MIT, Northwestern University, and Xiamen University are pioneering fundamental research, while specialized companies such as denovoMATRIX GmbH and 3-D Matrix, Inc. are beginning to commercialize applications. Research institutions in Asia, particularly in China (Southeast University, Beijing University of Chemical Technology) and South Korea (GIST, Korea Institute of Materials Science), are making substantial contributions to advancing self-healing hydrogel technologies for robotic applications, suggesting a globally distributed innovation landscape.

Vrije Universiteit Brussel

Technical Solution: Vrije Universiteit Brussel has developed an innovative hydrogel composite system specifically designed for soft robotic applications requiring self-healing capabilities. Their approach centers on a unique double-network hydrogel structure incorporating both permanent and sacrificial bonds that work in tandem to provide mechanical robustness and healing functionality. The system features dynamic Diels-Alder chemistry that enables thermally activated healing, allowing damaged robots to recover functionality through a controlled heating process. VUB researchers have pioneered the integration of this self-healing hydrogel with pneumatic actuators, creating soft robots that can recover from punctures and tears that would otherwise be catastrophic failures. Their technology incorporates specially designed microchannels within the hydrogel matrix that facilitate rapid healing agent delivery to damaged areas, significantly accelerating the repair process. Recent advancements include the development of a hybrid hydrogel-elastomer composite that combines the self-healing properties of hydrogels with the mechanical durability of elastomers, addressing one of the key limitations in hydrogel-based soft robotics.

Strengths: Excellent integration with pneumatic soft robotic systems; controlled healing activation through temperature; hybrid material approach overcomes traditional hydrogel limitations. Weaknesses: Requires external thermal activation for optimal healing; more complex fabrication process than single-network systems; potential challenges in scaling to larger robotic systems.

The Regents of the University of California

Technical Solution: The University of California has developed a groundbreaking hydrogel composite system for self-healing robots based on biomimetic principles derived from marine organisms. Their technology features a multi-phase hydrogel network incorporating both covalent and non-covalent crosslinking mechanisms that work synergistically to achieve rapid and efficient healing. The system utilizes specially engineered mussel-inspired catechol chemistry that enables strong adhesion even in wet environments, addressing a critical challenge in hydrogel-based self-healing materials. UC researchers have incorporated microcapsules containing reactive healing agents that are released upon mechanical damage, initiating an autonomous repair process without external intervention. Their latest innovation includes a gradient-structured hydrogel composite that provides varying mechanical properties throughout the material, allowing for customized stiffness and flexibility in different robot components while maintaining uniform healing capabilities. The system has demonstrated remarkable healing efficiency with recovery of over 85% mechanical strength within 2 hours at room temperature and nearly complete restoration after 24 hours.

Strengths: Excellent healing performance in wet environments; biomimetic approach enhances biocompatibility; customizable mechanical properties for different robot components. Weaknesses: Complex manufacturing process increases production costs; healing agents in microcapsules can be depleted after multiple damage events; potential long-term stability issues in extreme environments.

Key Patents and Research in Self-Healing Robotics

Self-healing hydrogel

PatentWO2025064595A2

Innovation

- A self-healing hydrogel comprising a network of poly(3,4-ethylenedioxythiophene):polystyrene sulfonate (PEDOT:PSS), polyvinyl alcohol (PVA), sodium tetraborate, glycerol, and water, bonded together by intermolecular interactions, which reduces electrical hysteresis and enhances healing efficiency.

Synthetic method of cellulose-based ionic liquid self-repairing gel

PatentActiveCN109942755A

Innovation

- Cellulose is used as raw material, and ionic liquid is used as the reaction medium to synthesize cellulose-based ionic liquid self-healing gel through the assistance of hydrogen bonds and ionic bonds. The material can achieve self-healing without high-temperature calcination and complex environmental conditions.

Material Sustainability and Environmental Impact

The sustainability profile of hydrogel composites used in self-repairing robots represents a critical dimension of their overall viability. Current hydrogel materials predominantly utilize synthetic polymers derived from petroleum resources, raising significant environmental concerns regarding their production, use, and end-of-life management. The carbon footprint associated with manufacturing these materials often exceeds that of conventional rigid components, primarily due to energy-intensive polymerization processes and chemical treatments required to achieve desired mechanical properties.

Biodegradability characteristics vary substantially across different hydrogel formulations. While naturally derived hydrogels (alginate, chitosan, cellulose-based) demonstrate promising degradation profiles in environmental conditions, synthetic variants containing polyacrylamide or polyvinyl alcohol exhibit persistence that may span decades. This persistence creates potential ecological hazards when these materials eventually enter waste streams or natural environments through disposal or wear.

Water consumption presents another sustainability challenge, as hydrogel production and maintenance typically require substantial water resources. Self-healing mechanisms often depend on hydration levels, creating an ongoing resource demand throughout the operational lifecycle of the robot. Recent innovations have begun addressing this concern through the development of hydrogels capable of extracting moisture from ambient air, potentially reducing direct water inputs.

Toxicity profiles of hydrogel components warrant careful consideration, particularly regarding monomers, crosslinking agents, and additives that enhance healing capabilities. Several common crosslinkers (glutaraldehyde, formaldehyde-based compounds) present documented ecotoxicological risks if released into aquatic environments. Progressive research has identified alternative, bio-based crosslinking mechanisms that significantly reduce these hazards while maintaining functional performance.

Recyclability represents perhaps the most challenging aspect of hydrogel sustainability. The intimate integration of multiple polymers, nanoparticles, and functional additives creates complex material systems that resist conventional recycling approaches. Emerging technologies exploring selective dissolution methods show promise for component recovery, though commercial viability remains distant. The most promising near-term strategy involves designing hydrogel composites with controlled degradation triggers, enabling programmed breakdown at end-of-life.

Life cycle assessment studies indicate that despite these challenges, self-healing hydrogels may offer net environmental benefits through extended product lifespans and reduced replacement frequency. The ability to autonomously repair rather than replace components could potentially offset initial sustainability deficits, particularly in applications where maintenance access is limited or hazardous.

Biodegradability characteristics vary substantially across different hydrogel formulations. While naturally derived hydrogels (alginate, chitosan, cellulose-based) demonstrate promising degradation profiles in environmental conditions, synthetic variants containing polyacrylamide or polyvinyl alcohol exhibit persistence that may span decades. This persistence creates potential ecological hazards when these materials eventually enter waste streams or natural environments through disposal or wear.

Water consumption presents another sustainability challenge, as hydrogel production and maintenance typically require substantial water resources. Self-healing mechanisms often depend on hydration levels, creating an ongoing resource demand throughout the operational lifecycle of the robot. Recent innovations have begun addressing this concern through the development of hydrogels capable of extracting moisture from ambient air, potentially reducing direct water inputs.

Toxicity profiles of hydrogel components warrant careful consideration, particularly regarding monomers, crosslinking agents, and additives that enhance healing capabilities. Several common crosslinkers (glutaraldehyde, formaldehyde-based compounds) present documented ecotoxicological risks if released into aquatic environments. Progressive research has identified alternative, bio-based crosslinking mechanisms that significantly reduce these hazards while maintaining functional performance.

Recyclability represents perhaps the most challenging aspect of hydrogel sustainability. The intimate integration of multiple polymers, nanoparticles, and functional additives creates complex material systems that resist conventional recycling approaches. Emerging technologies exploring selective dissolution methods show promise for component recovery, though commercial viability remains distant. The most promising near-term strategy involves designing hydrogel composites with controlled degradation triggers, enabling programmed breakdown at end-of-life.

Life cycle assessment studies indicate that despite these challenges, self-healing hydrogels may offer net environmental benefits through extended product lifespans and reduced replacement frequency. The ability to autonomously repair rather than replace components could potentially offset initial sustainability deficits, particularly in applications where maintenance access is limited or hazardous.

Biomimetic Design Principles for Self-Healing Systems

Nature has perfected self-healing mechanisms through millions of years of evolution, providing invaluable inspiration for developing autonomous repair systems in robotics. Biomimetic design principles for self-healing hydrogel composites in robots draw heavily from biological healing processes observed in organisms ranging from simple invertebrates to complex mammals.

The fundamental principle of biological self-healing involves damage detection followed by material mobilization to the injured site. In human skin, for instance, platelets aggregate at wounds, forming clots that initiate the healing cascade. Similarly, hydrogel composites can be engineered with embedded microcapsules containing healing agents that rupture upon mechanical damage, releasing materials that polymerize and restore structural integrity.

Vascular networks represent another critical biomimetic principle. Just as blood vessels deliver healing components throughout living organisms, synthetic vascular systems can be incorporated into hydrogel matrices to supply healing agents to damaged areas. These networks can be designed with hierarchical structures mimicking natural circulatory systems, enabling efficient material transport across different scales within the robotic structure.

Gradient interfaces found in natural tissues like cartilage-bone junctions provide inspiration for designing robust connections between hydrogels and other robotic components. These biomimetic interfaces distribute stress more evenly, reducing failure points and enhancing overall durability while maintaining flexibility where needed.

Stimulus-responsive healing mechanisms observed in plants and marine organisms offer templates for environmentally triggered repair systems. Hydrogels can be engineered to respond to specific stimuli such as temperature, pH, or light, initiating healing processes only when necessary, thus conserving resources and extending operational lifespans of robotic systems.

Multi-phase healing, as seen in bone regeneration, suggests sequential healing approaches for complex robotic systems. Initial rapid stabilization followed by slower, more comprehensive restoration can be implemented through hydrogels with varying crosslinking densities and degradation rates, ensuring both immediate functionality and long-term durability.

Cellular communication principles provide models for implementing feedback mechanisms in self-healing robots. By incorporating sensors analogous to cellular mechanoreceptors, robots can continuously monitor structural integrity and trigger appropriate healing responses before catastrophic failure occurs, mimicking the preemptive maintenance observed in biological systems.

The fundamental principle of biological self-healing involves damage detection followed by material mobilization to the injured site. In human skin, for instance, platelets aggregate at wounds, forming clots that initiate the healing cascade. Similarly, hydrogel composites can be engineered with embedded microcapsules containing healing agents that rupture upon mechanical damage, releasing materials that polymerize and restore structural integrity.

Vascular networks represent another critical biomimetic principle. Just as blood vessels deliver healing components throughout living organisms, synthetic vascular systems can be incorporated into hydrogel matrices to supply healing agents to damaged areas. These networks can be designed with hierarchical structures mimicking natural circulatory systems, enabling efficient material transport across different scales within the robotic structure.

Gradient interfaces found in natural tissues like cartilage-bone junctions provide inspiration for designing robust connections between hydrogels and other robotic components. These biomimetic interfaces distribute stress more evenly, reducing failure points and enhancing overall durability while maintaining flexibility where needed.

Stimulus-responsive healing mechanisms observed in plants and marine organisms offer templates for environmentally triggered repair systems. Hydrogels can be engineered to respond to specific stimuli such as temperature, pH, or light, initiating healing processes only when necessary, thus conserving resources and extending operational lifespans of robotic systems.

Multi-phase healing, as seen in bone regeneration, suggests sequential healing approaches for complex robotic systems. Initial rapid stabilization followed by slower, more comprehensive restoration can be implemented through hydrogels with varying crosslinking densities and degradation rates, ensuring both immediate functionality and long-term durability.

Cellular communication principles provide models for implementing feedback mechanisms in self-healing robots. By incorporating sensors analogous to cellular mechanoreceptors, robots can continuously monitor structural integrity and trigger appropriate healing responses before catastrophic failure occurs, mimicking the preemptive maintenance observed in biological systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!