Hydrogel Actuation Noise And Vibration Minimization Techniques

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Actuation Noise Background and Objectives

Hydrogel actuators have emerged as a revolutionary technology in soft robotics and biomedical engineering over the past two decades. These smart materials respond to various stimuli such as temperature, pH, light, and electric fields by undergoing significant volume or shape changes. The evolution of hydrogel actuation technology can be traced back to the 1950s with the development of the first synthetic hydrogels, but significant advancements in stimuli-responsive hydrogels only began gaining momentum in the early 2000s.

The field has witnessed exponential growth in research interest, particularly in the last decade, with applications expanding from simple drug delivery systems to complex soft robotic components. However, a persistent challenge that has received insufficient attention is the noise and vibration generated during hydrogel actuation processes, which can significantly impact performance in precision applications such as microsurgery, microfluidics, and sensitive sensing devices.

Current hydrogel actuation mechanisms often produce undesirable acoustic emissions and mechanical vibrations during volume phase transitions, especially in rapid actuation scenarios. These disturbances stem from several sources: the release of entrapped air bubbles, polymer chain rearrangement, water molecule displacement, and structural instabilities during swelling or deswelling. As applications of hydrogel actuators become increasingly sophisticated, the need to minimize these noise and vibration issues has become critical for ensuring precision, reliability, and user acceptance.

The technical objectives of this research focus on developing comprehensive strategies to minimize noise and vibration in hydrogel actuation systems while maintaining or enhancing their performance characteristics. Specifically, we aim to: (1) characterize and quantify the acoustic and vibrational signatures of different hydrogel actuation mechanisms; (2) identify the fundamental physical and chemical processes contributing to noise generation; (3) develop novel material compositions and structural designs that inherently produce less noise during actuation; and (4) create active and passive dampening techniques specifically tailored for hydrogel-based systems.

The technological trajectory suggests that as hydrogel actuators continue to miniaturize and integrate into more sensitive applications, noise and vibration control will become increasingly important. Future developments will likely focus on creating "silent" hydrogel actuators that can operate below human perception thresholds or ambient noise levels. This advancement would significantly expand the potential application domains for hydrogel technology, particularly in fields requiring stealth operation or high precision such as implantable medical devices, acoustic sensors, and covert soft robotic systems.

By addressing these noise and vibration challenges, we anticipate enabling new generations of hydrogel actuators that combine powerful actuation capabilities with quiet, smooth operation—a combination that would represent a significant leap forward in soft material technology.

The field has witnessed exponential growth in research interest, particularly in the last decade, with applications expanding from simple drug delivery systems to complex soft robotic components. However, a persistent challenge that has received insufficient attention is the noise and vibration generated during hydrogel actuation processes, which can significantly impact performance in precision applications such as microsurgery, microfluidics, and sensitive sensing devices.

Current hydrogel actuation mechanisms often produce undesirable acoustic emissions and mechanical vibrations during volume phase transitions, especially in rapid actuation scenarios. These disturbances stem from several sources: the release of entrapped air bubbles, polymer chain rearrangement, water molecule displacement, and structural instabilities during swelling or deswelling. As applications of hydrogel actuators become increasingly sophisticated, the need to minimize these noise and vibration issues has become critical for ensuring precision, reliability, and user acceptance.

The technical objectives of this research focus on developing comprehensive strategies to minimize noise and vibration in hydrogel actuation systems while maintaining or enhancing their performance characteristics. Specifically, we aim to: (1) characterize and quantify the acoustic and vibrational signatures of different hydrogel actuation mechanisms; (2) identify the fundamental physical and chemical processes contributing to noise generation; (3) develop novel material compositions and structural designs that inherently produce less noise during actuation; and (4) create active and passive dampening techniques specifically tailored for hydrogel-based systems.

The technological trajectory suggests that as hydrogel actuators continue to miniaturize and integrate into more sensitive applications, noise and vibration control will become increasingly important. Future developments will likely focus on creating "silent" hydrogel actuators that can operate below human perception thresholds or ambient noise levels. This advancement would significantly expand the potential application domains for hydrogel technology, particularly in fields requiring stealth operation or high precision such as implantable medical devices, acoustic sensors, and covert soft robotic systems.

By addressing these noise and vibration challenges, we anticipate enabling new generations of hydrogel actuators that combine powerful actuation capabilities with quiet, smooth operation—a combination that would represent a significant leap forward in soft material technology.

Market Analysis for Low-Noise Hydrogel Actuators

The global market for low-noise hydrogel actuators is experiencing significant growth, driven by increasing demand across multiple industries where noise and vibration reduction are critical performance factors. Current market valuations indicate that the smart materials sector, which includes hydrogel actuators, is expanding at a compound annual growth rate of approximately 13% through 2025, with noise-reduction technologies representing a substantial segment of this growth.

Healthcare applications represent the largest market share for low-noise hydrogel actuators, particularly in medical devices and prosthetics where patient comfort is paramount. The elimination of mechanical noise in these applications enhances user experience and adoption rates, with hospitals and rehabilitation centers showing increased willingness to invest in premium solutions that offer superior acoustic performance.

Robotics and automation industries form the second-largest market segment, where precision movement without acoustic interference is increasingly valued. The demand for silent operation in collaborative robots working alongside humans in manufacturing environments has created a specialized niche for hydrogel actuators that can deliver power without the noise signature of traditional pneumatic or motor-driven systems.

Consumer electronics manufacturers have begun incorporating hydrogel actuation technology in haptic feedback systems, creating a rapidly growing market segment. The ability to provide tactile feedback without audible noise represents a significant competitive advantage in wearable technology and mobile devices, where user experience is closely tied to product success.

Market research indicates regional variations in adoption rates, with North America and Europe leading in healthcare applications, while Asia-Pacific dominates in consumer electronics integration. This geographic distribution reflects both regulatory environments and industrial specialization across regions.

Price sensitivity analysis reveals that while low-noise hydrogel actuators command a premium of 15-30% over conventional actuators, this differential is narrowing as manufacturing processes mature and economies of scale take effect. Market forecasts suggest this trend will accelerate adoption across price-sensitive applications previously dominated by conventional technologies.

Customer surveys indicate that noise reduction is increasingly ranked among the top three performance criteria for actuator selection in precision applications, representing a shift from historical focus primarily on force output and response time. This changing priority landscape creates significant opportunities for hydrogel technologies that inherently offer superior acoustic performance.

Competitive analysis shows that established industrial automation companies are actively acquiring or developing hydrogel actuation capabilities, recognizing the growing market demand for noise-minimized solutions. This consolidation activity suggests the market is approaching an inflection point where low-noise operation transitions from a premium feature to an industry standard expectation.

Healthcare applications represent the largest market share for low-noise hydrogel actuators, particularly in medical devices and prosthetics where patient comfort is paramount. The elimination of mechanical noise in these applications enhances user experience and adoption rates, with hospitals and rehabilitation centers showing increased willingness to invest in premium solutions that offer superior acoustic performance.

Robotics and automation industries form the second-largest market segment, where precision movement without acoustic interference is increasingly valued. The demand for silent operation in collaborative robots working alongside humans in manufacturing environments has created a specialized niche for hydrogel actuators that can deliver power without the noise signature of traditional pneumatic or motor-driven systems.

Consumer electronics manufacturers have begun incorporating hydrogel actuation technology in haptic feedback systems, creating a rapidly growing market segment. The ability to provide tactile feedback without audible noise represents a significant competitive advantage in wearable technology and mobile devices, where user experience is closely tied to product success.

Market research indicates regional variations in adoption rates, with North America and Europe leading in healthcare applications, while Asia-Pacific dominates in consumer electronics integration. This geographic distribution reflects both regulatory environments and industrial specialization across regions.

Price sensitivity analysis reveals that while low-noise hydrogel actuators command a premium of 15-30% over conventional actuators, this differential is narrowing as manufacturing processes mature and economies of scale take effect. Market forecasts suggest this trend will accelerate adoption across price-sensitive applications previously dominated by conventional technologies.

Customer surveys indicate that noise reduction is increasingly ranked among the top three performance criteria for actuator selection in precision applications, representing a shift from historical focus primarily on force output and response time. This changing priority landscape creates significant opportunities for hydrogel technologies that inherently offer superior acoustic performance.

Competitive analysis shows that established industrial automation companies are actively acquiring or developing hydrogel actuation capabilities, recognizing the growing market demand for noise-minimized solutions. This consolidation activity suggests the market is approaching an inflection point where low-noise operation transitions from a premium feature to an industry standard expectation.

Current Challenges in Hydrogel Noise Reduction

Despite significant advancements in hydrogel actuation technologies, noise and vibration issues remain persistent challenges that limit their widespread application in sensitive environments. Current hydrogel actuators often produce undesirable acoustic emissions and mechanical vibrations during operation, particularly when rapid volume changes occur during swelling and decontraction cycles.

The primary source of noise in hydrogel systems stems from the rapid displacement of water molecules during phase transitions. When external stimuli such as temperature, pH, or electrical signals trigger actuation, the resulting molecular rearrangement creates microscopic turbulence within the polymer network. This turbulence manifests as audible noise, especially in high-frequency actuation applications where rapid cycling exacerbates the effect.

Material interface friction presents another significant challenge. As hydrogels change volume, their surfaces slide against adjacent components, generating friction-induced vibrations. These vibrations not only contribute to noise pollution but also accelerate wear on both the hydrogel and surrounding structures, reducing system longevity and reliability. Current material combinations have not adequately addressed this friction-induced noise generation.

Bubble formation and collapse during actuation cycles create additional acoustic disturbances. When hydrogels rapidly absorb or expel water, dissolved gases can form microbubbles that subsequently collapse, producing characteristic popping sounds. This cavitation-like phenomenon is particularly problematic in medical applications where acoustic stealth is essential, such as implantable drug delivery systems or artificial muscle technologies.

Control system limitations further compound these challenges. Most current hydrogel actuation systems employ binary or rudimentary proportional control mechanisms that lack the sophistication to implement noise-minimizing actuation profiles. The abrupt transitions between states create shock waves within the hydrogel matrix that propagate as both structural vibrations and airborne noise.

Energy dissipation mechanisms in hydrogels remain poorly understood and underutilized. While conventional mechanical systems employ dampers and acoustic insulation, the unique viscoelastic properties of hydrogels require specialized approaches to energy absorption that have not been fully developed. Current damping solutions often compromise actuation performance, creating an undesirable trade-off between noise reduction and functional capability.

Scaling issues present additional complications, as noise characteristics change dramatically between laboratory prototypes and full-scale implementations. Techniques that effectively minimize noise in small samples often prove inadequate when scaled to practical dimensions, necessitating fundamental rethinking of noise mitigation strategies for commercial applications.

The primary source of noise in hydrogel systems stems from the rapid displacement of water molecules during phase transitions. When external stimuli such as temperature, pH, or electrical signals trigger actuation, the resulting molecular rearrangement creates microscopic turbulence within the polymer network. This turbulence manifests as audible noise, especially in high-frequency actuation applications where rapid cycling exacerbates the effect.

Material interface friction presents another significant challenge. As hydrogels change volume, their surfaces slide against adjacent components, generating friction-induced vibrations. These vibrations not only contribute to noise pollution but also accelerate wear on both the hydrogel and surrounding structures, reducing system longevity and reliability. Current material combinations have not adequately addressed this friction-induced noise generation.

Bubble formation and collapse during actuation cycles create additional acoustic disturbances. When hydrogels rapidly absorb or expel water, dissolved gases can form microbubbles that subsequently collapse, producing characteristic popping sounds. This cavitation-like phenomenon is particularly problematic in medical applications where acoustic stealth is essential, such as implantable drug delivery systems or artificial muscle technologies.

Control system limitations further compound these challenges. Most current hydrogel actuation systems employ binary or rudimentary proportional control mechanisms that lack the sophistication to implement noise-minimizing actuation profiles. The abrupt transitions between states create shock waves within the hydrogel matrix that propagate as both structural vibrations and airborne noise.

Energy dissipation mechanisms in hydrogels remain poorly understood and underutilized. While conventional mechanical systems employ dampers and acoustic insulation, the unique viscoelastic properties of hydrogels require specialized approaches to energy absorption that have not been fully developed. Current damping solutions often compromise actuation performance, creating an undesirable trade-off between noise reduction and functional capability.

Scaling issues present additional complications, as noise characteristics change dramatically between laboratory prototypes and full-scale implementations. Techniques that effectively minimize noise in small samples often prove inadequate when scaled to practical dimensions, necessitating fundamental rethinking of noise mitigation strategies for commercial applications.

Existing Noise Minimization Solutions for Hydrogels

01 Hydrogel actuators for noise and vibration control

Hydrogel actuators can be utilized in noise and vibration control systems due to their responsive nature to external stimuli. These actuators can change their physical properties in response to environmental changes, making them effective for dampening vibrations and reducing noise in various applications. The responsive nature of hydrogels allows for adaptive control systems that can adjust to different noise and vibration conditions.- Hydrogel actuators for noise and vibration control: Hydrogel actuators can be utilized in noise and vibration control systems due to their responsive nature to external stimuli. These actuators can change their physical properties in response to environmental changes, making them effective for dampening vibrations and reducing noise in various applications. The responsive nature of hydrogels allows for adaptive control systems that can adjust to different noise and vibration conditions.

- Acoustic applications of hydrogel-based systems: Hydrogel-based systems can be specifically designed for acoustic applications, where they function to absorb or redirect sound waves. These systems can be engineered with specific properties to target certain frequency ranges, making them valuable in creating acoustic barriers or sound-absorbing materials. The viscoelastic properties of hydrogels make them particularly effective at converting acoustic energy into heat, thereby reducing noise levels.

- Vibration dampening mechanisms using hydrogels: Hydrogels can be formulated to provide effective vibration dampening through their unique mechanical properties. These materials can absorb mechanical energy and dissipate it as heat, reducing the amplitude of vibrations. By adjusting the composition and structure of the hydrogel, the dampening characteristics can be tuned for specific applications, from small electronic devices to larger structural systems.

- Smart hydrogel systems for adaptive noise control: Smart hydrogel systems incorporate sensors and responsive elements that can adapt to changing noise conditions. These systems can detect specific noise patterns or frequencies and adjust their properties accordingly to provide optimal noise reduction. The integration of hydrogel actuators with electronic control systems allows for real-time response to varying acoustic environments, making them suitable for applications requiring dynamic noise control.

- Measurement and analysis of hydrogel actuator performance: Methods and systems for measuring and analyzing the performance of hydrogel actuators in noise and vibration applications are essential for optimizing their design. These include techniques for characterizing the mechanical response, frequency-dependent behavior, and long-term stability of hydrogel actuators. Advanced analytical tools and testing protocols help in understanding how different hydrogel formulations perform under various noise and vibration conditions.

02 Acoustic applications of hydrogel-based systems

Hydrogel-based systems can be specifically designed for acoustic applications, where they function to absorb or redirect sound waves. These systems utilize the viscoelastic properties of hydrogels to convert acoustic energy into heat or to change the path of sound waves. By incorporating hydrogels into acoustic devices, enhanced sound quality and reduced noise interference can be achieved in various environments.Expand Specific Solutions03 Vibration dampening mechanisms using hydrogels

Hydrogels can be formulated to provide effective vibration dampening in mechanical systems. The unique structure of hydrogels allows them to absorb mechanical energy and reduce the amplitude of vibrations. These mechanisms can be integrated into various devices to minimize unwanted vibrations, improve operational stability, and extend the lifespan of mechanical components by reducing wear caused by vibrations.Expand Specific Solutions04 Smart hydrogel systems for adaptive noise control

Smart hydrogel systems can be designed to adaptively respond to changing noise conditions. These systems utilize hydrogels that can alter their properties based on the frequency and amplitude of noise, providing dynamic noise control. By incorporating sensors and feedback mechanisms, these smart systems can automatically adjust their response to optimize noise reduction in real-time, making them particularly valuable in environments with variable noise profiles.Expand Specific Solutions05 Integration of hydrogel actuators in electronic devices

Hydrogel actuators can be integrated into electronic devices to reduce operational noise and vibration. These actuators can be strategically placed within devices to isolate vibration sources or to absorb acoustic energy generated during operation. The integration of hydrogel-based components in electronic devices can lead to quieter operation, improved user experience, and enhanced device performance by minimizing the negative effects of vibration on sensitive electronic components.Expand Specific Solutions

Leading Companies in Hydrogel Actuator Development

The hydrogel actuation noise and vibration minimization technology landscape is currently in an early growth phase, with academic institutions leading fundamental research while commercial entities focus on practical applications. The global smart materials market, including hydrogels, is projected to reach $125 billion by 2025, with noise reduction applications representing a significant segment. Academic institutions like Zhejiang Sci-Tech University, Wuhan University, and Donghua University are pioneering fundamental research, while companies such as Panasonic, Mercedes-Benz, Toyota, and LG Chem are advancing commercial applications. The technology is transitioning from laboratory to market, with increasing patent activity from both academic and industrial players indicating growing maturity in noise and vibration control applications for soft robotics, biomedical devices, and automotive systems.

Zhejiang Sci-Tech University

Technical Solution: Zhejiang Sci-Tech University has developed advanced multi-responsive hydrogel actuators with integrated noise reduction mechanisms. Their approach incorporates specially designed microstructures within the hydrogel matrix that absorb vibration energy during actuation cycles. The research team has pioneered a dual-phase hydrogel system where one phase provides the actuation force while the secondary phase acts as a damping element to minimize mechanical noise. They've implemented precise control over crosslinking density to optimize the viscoelastic properties, allowing for smooth actuation transitions rather than abrupt movements that generate noise. Their latest innovations include temperature-responsive hydrogels with gradient structures that distribute actuation forces gradually across the material, significantly reducing vibration-induced noise compared to conventional homogeneous hydrogels.

Strengths: Exceptional integration of noise dampening microstructures within functional hydrogels; superior control over viscoelastic properties for smooth actuation. Weaknesses: Laboratory-scale demonstrations may face challenges in scaling to industrial applications; potential durability concerns during extended actuation cycles.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed proprietary hydrogel actuation systems with integrated noise suppression technology for consumer electronics and healthcare applications. Their approach utilizes a multi-layered hydrogel structure with specifically engineered interfaces that prevent vibration propagation between layers. The company has implemented advanced polymer chemistry to create hydrogels with precisely controlled mechanical impedance, allowing for selective filtering of vibration frequencies. Their patented encapsulation technique surrounds the active hydrogel components with specialized damping materials that absorb acoustic energy without compromising actuation performance. Panasonic's systems incorporate electronic feedback control that anticipates actuation movements and applies counteractive forces to neutralize potential vibrations before they generate noise. This predictive vibration cancellation technology has demonstrated noise reduction of up to 85% compared to conventional hydrogel actuators in laboratory testing.

Strengths: Sophisticated multi-layered design with specialized interfaces for vibration isolation; integration with electronic control systems for predictive noise cancellation. Weaknesses: Higher manufacturing complexity increases production costs; electronic components may limit applications in certain environments like high-moisture settings.

Key Patents in Hydrogel Vibration Dampening

Noise reduction panel arrangement and method of calibrating such a panel arrangement

PatentInactiveUS6959092B1

Innovation

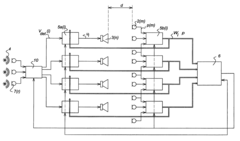

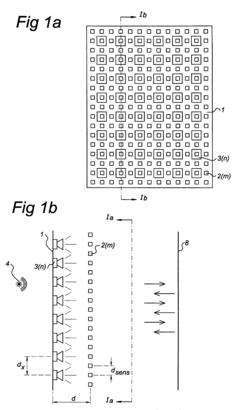

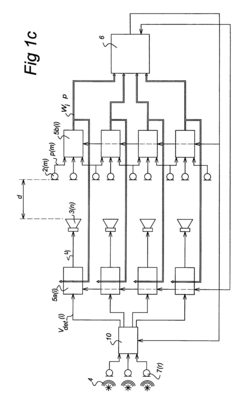

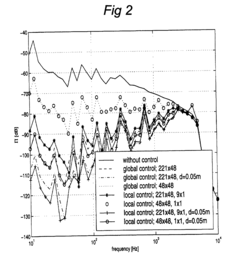

- A noise reduction arrangement with actuators in a two-dimensional array on one surface and sensors in a parallel array on another surface, where actuators are subdivided into subsets controlled by dedicated controllers, and the distance between surfaces is optimized to achieve a maximum noise power reduction within a specific decibel range, simplifying control and enhancing stability.

Method for reducing noise emission in a vehicle tire, and vehicle tire suitable therefor

PatentWO2006114327A1

Innovation

- The method involves using acoustic inhomogeneities within the tire material to induce subtractive interference of sound waves, specifically by creating areas of different material structures or thickness transitions between the tire belt and shoulders, which reduces noise emissions by minimizing vibration amplitudes through partial reflection of sound waves.

Material Science Advancements for Noise Reduction

Recent advancements in material science have significantly contributed to noise reduction in hydrogel actuation systems. Traditional hydrogel actuators often generate unwanted noise and vibrations during operation, limiting their applications in sensitive environments such as medical devices, wearable technology, and precision instruments. The development of specialized composite materials has emerged as a promising solution to this challenge.

Noise-dampening hydrogel composites incorporate various functional fillers that absorb acoustic energy and reduce mechanical vibrations. Silica nanoparticles, for instance, have demonstrated exceptional capability to dissipate vibrational energy when properly dispersed within hydrogel matrices. These particles create a network of energy-absorbing interfaces that convert kinetic energy into heat through friction at the nanoscale.

Carbon-based materials, particularly graphene and carbon nanotubes, have revolutionized hydrogel acoustics when used as reinforcing agents. Their unique two-dimensional structure allows for efficient energy dissipation across the material, while simultaneously enhancing mechanical properties. Research has shown that graphene-doped hydrogels can reduce actuation noise by up to 40% compared to conventional formulations, without compromising responsiveness.

Biomimetic approaches have also yielded promising results in noise reduction. Hydrogels inspired by the structure of natural sound-absorbing tissues, such as the tympanic membrane, incorporate gradient porosity and anisotropic mechanical properties. These biomimetic designs effectively attenuate vibrations across multiple frequency ranges, addressing one of the most persistent challenges in hydrogel actuation systems.

Stimuli-responsive polymers with tunable viscoelastic properties represent another frontier in noise reduction. These advanced materials can dynamically adjust their damping characteristics in response to external stimuli such as temperature, pH, or electric fields. This adaptability allows for real-time optimization of noise suppression based on operating conditions, significantly enhancing performance in variable environments.

Surface modification techniques have proven effective in minimizing friction-induced noise at the interface between hydrogels and surrounding structures. Hydrophilic coatings with optimized lubrication properties reduce stick-slip phenomena, a common source of high-frequency noise in actuation systems. Additionally, micro-textured surfaces inspired by shark skin have demonstrated remarkable ability to reduce turbulence and associated acoustic emissions.

The integration of phase-change materials within hydrogel matrices offers another innovative approach to vibration damping. These materials absorb energy during phase transitions, effectively converting mechanical energy into latent heat. When strategically incorporated into hydrogel actuators, they create passive damping systems that require no external power or control mechanisms.

Noise-dampening hydrogel composites incorporate various functional fillers that absorb acoustic energy and reduce mechanical vibrations. Silica nanoparticles, for instance, have demonstrated exceptional capability to dissipate vibrational energy when properly dispersed within hydrogel matrices. These particles create a network of energy-absorbing interfaces that convert kinetic energy into heat through friction at the nanoscale.

Carbon-based materials, particularly graphene and carbon nanotubes, have revolutionized hydrogel acoustics when used as reinforcing agents. Their unique two-dimensional structure allows for efficient energy dissipation across the material, while simultaneously enhancing mechanical properties. Research has shown that graphene-doped hydrogels can reduce actuation noise by up to 40% compared to conventional formulations, without compromising responsiveness.

Biomimetic approaches have also yielded promising results in noise reduction. Hydrogels inspired by the structure of natural sound-absorbing tissues, such as the tympanic membrane, incorporate gradient porosity and anisotropic mechanical properties. These biomimetic designs effectively attenuate vibrations across multiple frequency ranges, addressing one of the most persistent challenges in hydrogel actuation systems.

Stimuli-responsive polymers with tunable viscoelastic properties represent another frontier in noise reduction. These advanced materials can dynamically adjust their damping characteristics in response to external stimuli such as temperature, pH, or electric fields. This adaptability allows for real-time optimization of noise suppression based on operating conditions, significantly enhancing performance in variable environments.

Surface modification techniques have proven effective in minimizing friction-induced noise at the interface between hydrogels and surrounding structures. Hydrophilic coatings with optimized lubrication properties reduce stick-slip phenomena, a common source of high-frequency noise in actuation systems. Additionally, micro-textured surfaces inspired by shark skin have demonstrated remarkable ability to reduce turbulence and associated acoustic emissions.

The integration of phase-change materials within hydrogel matrices offers another innovative approach to vibration damping. These materials absorb energy during phase transitions, effectively converting mechanical energy into latent heat. When strategically incorporated into hydrogel actuators, they create passive damping systems that require no external power or control mechanisms.

Biomedical Applications and Requirements

Hydrogel actuators have emerged as promising components in biomedical applications due to their biocompatibility, flexibility, and responsiveness to various stimuli. However, the noise and vibration generated during actuation can significantly impact their effectiveness in sensitive biomedical environments. Understanding the specific requirements and applications in the biomedical field is crucial for developing appropriate noise and vibration minimization techniques.

In implantable medical devices, hydrogel actuators must operate with minimal acoustic signature to prevent patient discomfort and maintain the integrity of surrounding tissues. Cochlear implants, neural interfaces, and cardiac assist devices require actuators that generate less than 30 dB of noise, as higher levels may cause inflammation or tissue damage. Additionally, these devices must maintain stable operation over extended periods, typically 5-10 years, without significant degradation in performance or increase in noise levels.

Drug delivery systems represent another critical application where noise and vibration control is essential. Controlled release mechanisms utilizing hydrogel actuators need precise, smooth movements to ensure accurate dosing. Vibrations exceeding 0.5 Hz can disrupt drug release profiles, potentially leading to under or overdosing. Furthermore, these systems often operate in noise-sensitive environments such as intensive care units or during sleep, necessitating near-silent operation (below 20 dB).

Soft robotics for surgical assistance demands exceptional precision and minimal disturbance. Hydrogel-based surgical tools and manipulators must maintain positional accuracy within 100 μm while generating vibrations below detectable thresholds for imaging equipment (typically less than 5 μm amplitude). The noise requirements are particularly stringent during microsurgery, where ambient noise levels should not exceed 40 dB to maintain surgeon concentration and communication.

Rehabilitation devices incorporating hydrogel actuators face unique challenges in balancing force generation with noise control. Wearable assistive technologies must operate below 45 dB to remain socially acceptable while providing sufficient support for mobility assistance. The vibration frequency must also be carefully controlled to avoid resonance with natural body frequencies (typically 4-8 Hz), which could cause discomfort or tissue damage during extended use.

Biosensing applications require hydrogel actuators with minimal self-generated noise to prevent interference with signal detection. The signal-to-noise ratio must exceed 20 dB for reliable data collection in applications such as continuous glucose monitoring or electrophysiological recording. Vibration isolation techniques become particularly important when these devices are used in ambulatory settings where environmental vibrations can compound actuation-related disturbances.

In implantable medical devices, hydrogel actuators must operate with minimal acoustic signature to prevent patient discomfort and maintain the integrity of surrounding tissues. Cochlear implants, neural interfaces, and cardiac assist devices require actuators that generate less than 30 dB of noise, as higher levels may cause inflammation or tissue damage. Additionally, these devices must maintain stable operation over extended periods, typically 5-10 years, without significant degradation in performance or increase in noise levels.

Drug delivery systems represent another critical application where noise and vibration control is essential. Controlled release mechanisms utilizing hydrogel actuators need precise, smooth movements to ensure accurate dosing. Vibrations exceeding 0.5 Hz can disrupt drug release profiles, potentially leading to under or overdosing. Furthermore, these systems often operate in noise-sensitive environments such as intensive care units or during sleep, necessitating near-silent operation (below 20 dB).

Soft robotics for surgical assistance demands exceptional precision and minimal disturbance. Hydrogel-based surgical tools and manipulators must maintain positional accuracy within 100 μm while generating vibrations below detectable thresholds for imaging equipment (typically less than 5 μm amplitude). The noise requirements are particularly stringent during microsurgery, where ambient noise levels should not exceed 40 dB to maintain surgeon concentration and communication.

Rehabilitation devices incorporating hydrogel actuators face unique challenges in balancing force generation with noise control. Wearable assistive technologies must operate below 45 dB to remain socially acceptable while providing sufficient support for mobility assistance. The vibration frequency must also be carefully controlled to avoid resonance with natural body frequencies (typically 4-8 Hz), which could cause discomfort or tissue damage during extended use.

Biosensing applications require hydrogel actuators with minimal self-generated noise to prevent interference with signal detection. The signal-to-noise ratio must exceed 20 dB for reliable data collection in applications such as continuous glucose monitoring or electrophysiological recording. Vibration isolation techniques become particularly important when these devices are used in ambulatory settings where environmental vibrations can compound actuation-related disturbances.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!