Design Of Hydrogel Grippers For Delicate Biological Sample Handling

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Grippers Background and Objectives

Hydrogel grippers represent a revolutionary approach to handling delicate biological samples, emerging from the convergence of materials science, robotics, and bioengineering. These soft robotic devices utilize stimuli-responsive hydrogel materials that can undergo reversible volume changes in response to environmental triggers such as temperature, pH, or light. The development of hydrogel grippers can be traced back to early soft robotics research in the 1990s, but significant advancements have occurred within the past decade as demand for gentle manipulation techniques in biological research has increased.

The evolution of hydrogel technology has progressed from simple swelling materials to sophisticated architectures with programmable mechanical properties. Early hydrogel systems lacked the precision and control necessary for delicate sample handling, while contemporary designs incorporate multi-responsive materials and complex geometrical configurations that enable selective gripping and release mechanisms. This technological progression has been driven by the growing need for non-destructive manipulation methods in fields such as tissue engineering, cell biology, and microsurgery.

Current research trends in hydrogel grippers focus on enhancing responsiveness, improving mechanical strength without sacrificing compliance, and developing biocompatible formulations suitable for direct contact with living tissues. The integration of sensing capabilities within hydrogel structures represents another significant trend, allowing for feedback-controlled operation and adaptive gripping forces based on sample characteristics.

The primary objective of hydrogel gripper development is to create handling systems that can safely manipulate fragile biological entities without causing mechanical damage or physiological disruption. This includes the ability to maintain sample viability during transfer operations, preserve structural integrity of delicate tissues, and minimize contamination risks associated with traditional handling methods. Additionally, these systems aim to provide precise spatial control at microscale dimensions, enabling manipulation of individual cells or small tissue constructs.

Secondary objectives include developing hydrogel formulations with rapid response times to facilitate efficient sample processing, creating systems compatible with existing laboratory automation platforms, and ensuring reproducibility of gripping performance across diverse biological sample types. Long-term goals encompass the development of fully autonomous hydrogel-based manipulation systems capable of adapting to heterogeneous sample populations without human intervention.

The successful realization of these objectives would address critical challenges in biological research and clinical applications, potentially revolutionizing procedures ranging from in vitro fertilization to regenerative medicine therapies. By providing gentle yet secure handling capabilities, hydrogel grippers promise to expand the range of manipulable biological entities and enhance preservation of native biological properties during experimental procedures.

The evolution of hydrogel technology has progressed from simple swelling materials to sophisticated architectures with programmable mechanical properties. Early hydrogel systems lacked the precision and control necessary for delicate sample handling, while contemporary designs incorporate multi-responsive materials and complex geometrical configurations that enable selective gripping and release mechanisms. This technological progression has been driven by the growing need for non-destructive manipulation methods in fields such as tissue engineering, cell biology, and microsurgery.

Current research trends in hydrogel grippers focus on enhancing responsiveness, improving mechanical strength without sacrificing compliance, and developing biocompatible formulations suitable for direct contact with living tissues. The integration of sensing capabilities within hydrogel structures represents another significant trend, allowing for feedback-controlled operation and adaptive gripping forces based on sample characteristics.

The primary objective of hydrogel gripper development is to create handling systems that can safely manipulate fragile biological entities without causing mechanical damage or physiological disruption. This includes the ability to maintain sample viability during transfer operations, preserve structural integrity of delicate tissues, and minimize contamination risks associated with traditional handling methods. Additionally, these systems aim to provide precise spatial control at microscale dimensions, enabling manipulation of individual cells or small tissue constructs.

Secondary objectives include developing hydrogel formulations with rapid response times to facilitate efficient sample processing, creating systems compatible with existing laboratory automation platforms, and ensuring reproducibility of gripping performance across diverse biological sample types. Long-term goals encompass the development of fully autonomous hydrogel-based manipulation systems capable of adapting to heterogeneous sample populations without human intervention.

The successful realization of these objectives would address critical challenges in biological research and clinical applications, potentially revolutionizing procedures ranging from in vitro fertilization to regenerative medicine therapies. By providing gentle yet secure handling capabilities, hydrogel grippers promise to expand the range of manipulable biological entities and enhance preservation of native biological properties during experimental procedures.

Market Analysis for Soft Robotic Handling Solutions

The global market for soft robotic handling solutions is experiencing significant growth, driven by increasing demand across multiple sectors including healthcare, biotechnology, and research laboratories. The market size for precision handling technologies was valued at approximately $3.2 billion in 2022 and is projected to reach $7.5 billion by 2028, representing a compound annual growth rate of 15.3%. Within this broader market, hydrogel-based gripping technologies are emerging as a rapidly expanding segment due to their unique capabilities in handling delicate biological samples.

Healthcare and life sciences sectors represent the largest market segments, accounting for nearly 45% of the total market share. This dominance is attributed to the growing need for precise manipulation of tissues, cells, and other biological materials in surgical procedures, laboratory testing, and pharmaceutical research. The increasing focus on personalized medicine and regenerative therapies has further accelerated demand for advanced handling solutions that can interact with biological samples without causing damage.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 18.7% during the forecast period, primarily due to expanding healthcare infrastructure, increasing research activities, and rising investments in biotechnology across countries like China, Japan, and South Korea.

Key market drivers include technological advancements in materials science, particularly in the development of biocompatible hydrogels with tunable mechanical properties. The growing emphasis on minimally invasive procedures in healthcare settings has also created substantial demand for soft gripping technologies that can navigate complex biological environments with minimal tissue disruption.

Customer requirements in this market emphasize several critical factors: biocompatibility, precision control, adaptability to different sample types, sterilization capability, and integration with existing workflows. End-users are increasingly seeking solutions that offer both gentleness and reliability when handling fragile biological specimens.

Market challenges include high development costs, regulatory hurdles for medical applications, and technical limitations in scaling production while maintaining consistent performance. Additionally, there is significant competition from alternative technologies such as vacuum-based handling systems and traditional mechanical grippers, which currently hold established positions in certain application niches.

The competitive landscape features a mix of established medical device manufacturers, specialized robotics companies, and innovative startups. Recent market trends indicate increasing strategic partnerships between material science companies and robotics firms to accelerate product development and commercialization of hydrogel-based handling solutions.

Healthcare and life sciences sectors represent the largest market segments, accounting for nearly 45% of the total market share. This dominance is attributed to the growing need for precise manipulation of tissues, cells, and other biological materials in surgical procedures, laboratory testing, and pharmaceutical research. The increasing focus on personalized medicine and regenerative therapies has further accelerated demand for advanced handling solutions that can interact with biological samples without causing damage.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 18.7% during the forecast period, primarily due to expanding healthcare infrastructure, increasing research activities, and rising investments in biotechnology across countries like China, Japan, and South Korea.

Key market drivers include technological advancements in materials science, particularly in the development of biocompatible hydrogels with tunable mechanical properties. The growing emphasis on minimally invasive procedures in healthcare settings has also created substantial demand for soft gripping technologies that can navigate complex biological environments with minimal tissue disruption.

Customer requirements in this market emphasize several critical factors: biocompatibility, precision control, adaptability to different sample types, sterilization capability, and integration with existing workflows. End-users are increasingly seeking solutions that offer both gentleness and reliability when handling fragile biological specimens.

Market challenges include high development costs, regulatory hurdles for medical applications, and technical limitations in scaling production while maintaining consistent performance. Additionally, there is significant competition from alternative technologies such as vacuum-based handling systems and traditional mechanical grippers, which currently hold established positions in certain application niches.

The competitive landscape features a mix of established medical device manufacturers, specialized robotics companies, and innovative startups. Recent market trends indicate increasing strategic partnerships between material science companies and robotics firms to accelerate product development and commercialization of hydrogel-based handling solutions.

Current Challenges in Hydrogel Gripper Technology

Despite significant advancements in hydrogel gripper technology for biological sample handling, several critical challenges persist that impede widespread adoption and optimal performance. The primary challenge lies in achieving the delicate balance between gripping strength and sample protection. Current hydrogel grippers often struggle to maintain sufficient adhesion to securely hold samples while simultaneously avoiding damage to fragile biological structures.

Material stability presents another significant hurdle, as many hydrogels exhibit performance degradation during extended operation. Environmental sensitivity causes swelling or contraction in response to pH changes, temperature fluctuations, or ionic strength variations in the surrounding medium, resulting in unpredictable gripping behavior. This instability is particularly problematic when handling samples across different buffer solutions or temperature conditions.

Response time limitations further constrain practical applications, with many current hydrogel systems demonstrating slow actuation speeds. The delay between stimulus application and mechanical response can be problematic in time-sensitive biological procedures, where rapid and precise manipulation is essential. This sluggish behavior stems from the diffusion-limited nature of many stimuli-responsive hydrogel systems.

Biocompatibility concerns persist despite hydrogels' generally favorable biological profiles. Some formulations incorporate potentially cytotoxic components or leach chemicals during operation that may compromise sample integrity. Additionally, sterilization procedures often degrade hydrogel performance characteristics, creating a challenging trade-off between maintaining sterility and preserving functional properties.

Manufacturing reproducibility represents a substantial technical barrier, with batch-to-batch variations affecting performance consistency. The complex chemistry involved in hydrogel synthesis makes standardization difficult, resulting in grippers with inconsistent mechanical properties and response characteristics. This variability is particularly problematic for applications requiring precise and repeatable sample manipulation.

Integration challenges with existing laboratory automation systems further limit adoption. Most current hydrogel grippers lack standardized interfaces for robotic systems, requiring custom adaptations that increase implementation complexity and cost. The absence of plug-and-play solutions restricts their incorporation into established workflows.

Sensing and feedback mechanisms remain underdeveloped in current hydrogel gripper designs. Unlike traditional rigid grippers equipped with force sensors, hydrogel systems typically lack integrated sensing capabilities to monitor gripping forces or detect potential sample damage in real-time. This absence of feedback mechanisms increases the risk of sample damage during manipulation procedures.

Durability concerns also plague existing designs, with many hydrogel grippers exhibiting limited operational lifespans before performance degradation necessitates replacement. Repeated actuation cycles often lead to mechanical fatigue and diminished responsiveness, increasing operational costs and reducing reliability in high-throughput applications.

Material stability presents another significant hurdle, as many hydrogels exhibit performance degradation during extended operation. Environmental sensitivity causes swelling or contraction in response to pH changes, temperature fluctuations, or ionic strength variations in the surrounding medium, resulting in unpredictable gripping behavior. This instability is particularly problematic when handling samples across different buffer solutions or temperature conditions.

Response time limitations further constrain practical applications, with many current hydrogel systems demonstrating slow actuation speeds. The delay between stimulus application and mechanical response can be problematic in time-sensitive biological procedures, where rapid and precise manipulation is essential. This sluggish behavior stems from the diffusion-limited nature of many stimuli-responsive hydrogel systems.

Biocompatibility concerns persist despite hydrogels' generally favorable biological profiles. Some formulations incorporate potentially cytotoxic components or leach chemicals during operation that may compromise sample integrity. Additionally, sterilization procedures often degrade hydrogel performance characteristics, creating a challenging trade-off between maintaining sterility and preserving functional properties.

Manufacturing reproducibility represents a substantial technical barrier, with batch-to-batch variations affecting performance consistency. The complex chemistry involved in hydrogel synthesis makes standardization difficult, resulting in grippers with inconsistent mechanical properties and response characteristics. This variability is particularly problematic for applications requiring precise and repeatable sample manipulation.

Integration challenges with existing laboratory automation systems further limit adoption. Most current hydrogel grippers lack standardized interfaces for robotic systems, requiring custom adaptations that increase implementation complexity and cost. The absence of plug-and-play solutions restricts their incorporation into established workflows.

Sensing and feedback mechanisms remain underdeveloped in current hydrogel gripper designs. Unlike traditional rigid grippers equipped with force sensors, hydrogel systems typically lack integrated sensing capabilities to monitor gripping forces or detect potential sample damage in real-time. This absence of feedback mechanisms increases the risk of sample damage during manipulation procedures.

Durability concerns also plague existing designs, with many hydrogel grippers exhibiting limited operational lifespans before performance degradation necessitates replacement. Repeated actuation cycles often lead to mechanical fatigue and diminished responsiveness, increasing operational costs and reducing reliability in high-throughput applications.

Current Hydrogel Gripper Design Approaches

01 Hydrogel-based soft grippers for delicate object handling

Hydrogel-based soft grippers provide gentle handling capabilities for delicate objects due to their compliant nature and high water content. These grippers can conform to irregular shapes while maintaining low contact forces, making them ideal for handling fragile items. The responsive nature of hydrogels to various stimuli (temperature, pH, electric field) allows for controlled gripping and releasing actions without damaging sensitive surfaces.- Hydrogel-based soft grippers for delicate object handling: Hydrogel-based soft grippers provide gentle handling capabilities for delicate objects due to their compliant nature and high water content. These grippers can conform to irregular shapes while maintaining low contact forces, making them ideal for handling fragile items. The responsive nature of hydrogels to various stimuli (temperature, pH, electric fields) allows for controlled gripping and releasing actions without damaging sensitive surfaces.

- Biomimetic gripper designs for enhanced delicate handling: Biomimetic grippers inspired by natural mechanisms like octopus tentacles or gecko feet offer superior delicate handling capabilities. These designs incorporate microstructures and specialized surface patterns that enable adhesion through van der Waals forces or capillary action rather than mechanical pressure. The resulting grippers can pick up delicate objects with minimal force and conform to various surface geometries while preventing damage.

- Adaptive control systems for precision gripping: Advanced control systems enable hydrogel grippers to adapt to different object properties in real-time. These systems incorporate sensors that provide feedback on grip force, object position, and material properties, allowing for precise adjustment of gripping parameters. Machine learning algorithms can optimize handling strategies for different types of delicate objects, ensuring consistent performance across varying conditions and minimizing the risk of damage.

- Multi-fingered hydrogel gripper configurations: Multi-fingered hydrogel gripper designs offer enhanced dexterity and stability for handling delicate objects. These configurations typically feature three or more finger-like projections that can independently actuate to accommodate objects of various shapes and sizes. The distributed contact points reduce pressure at any single location, making these grippers particularly suitable for handling fragile or easily deformable items while maintaining secure grasping.

- Stimuli-responsive release mechanisms: Specialized release mechanisms in hydrogel grippers enable controlled detachment from delicate objects. These mechanisms respond to specific stimuli such as temperature changes, electric fields, or chemical triggers, causing the hydrogel to change its properties and gently release the held object. This controlled release prevents damage that might occur with conventional mechanical grippers, making them ideal for applications involving fragile biological samples, electronics, or other sensitive materials.

02 Biomimetic gripper designs for enhanced delicate handling

Biomimetic grippers inspired by natural mechanisms such as octopus tentacles or gecko feet offer superior delicate handling capabilities. These designs incorporate microstructures and specialized surface patterns that enable adhesion through van der Waals forces or capillary action rather than mechanical pressure. This approach allows for secure gripping of delicate objects without applying damaging forces, particularly useful for handling biological samples or electronic components.Expand Specific Solutions03 Adaptive control systems for hydrogel grippers

Advanced control systems enable hydrogel grippers to automatically adjust gripping forces based on object fragility. These systems incorporate sensors that provide real-time feedback on contact pressure and object characteristics, allowing the gripper to modulate its stiffness and conformability. Machine learning algorithms can be employed to optimize handling parameters for different object types, ensuring consistent delicate handling across various applications.Expand Specific Solutions04 Multi-material composite hydrogel grippers

Composite hydrogel grippers combine different materials to achieve optimal performance for delicate handling. These designs typically feature a soft hydrogel contact layer bonded to stiffer supporting structures, creating a gradient of mechanical properties. The composite approach allows for precise control of deformation characteristics while maintaining gentle contact with delicate objects. Additional functional materials can be incorporated to provide sensing capabilities or stimuli-responsive behavior.Expand Specific Solutions05 Specialized end-effector designs for industry-specific delicate handling

Specialized end-effector designs address industry-specific challenges in delicate handling applications. These include customized gripper geometries for handling fragile electronics, food products, or medical devices. The designs incorporate features such as variable compliance zones, controlled suction capabilities, or electrostatic adhesion mechanisms. Some implementations include interchangeable gripper modules that can be rapidly swapped to accommodate different delicate handling requirements within the same production environment.Expand Specific Solutions

Leading Research Groups and Companies in Hydrogel Technology

The hydrogel grippers market for delicate biological sample handling is in an early growth phase, characterized by significant research activity but limited commercial deployment. The market size remains modest but is expanding rapidly due to increasing applications in medical diagnostics, tissue engineering, and laboratory automation. From a technological maturity perspective, academic institutions like Northwestern University, Johns Hopkins University, and Hokkaido University are leading fundamental research, while companies such as Bio-Rad Laboratories, Abbott Laboratories, and BASF are beginning to commercialize applications. The technology demonstrates promising capabilities for non-destructive manipulation of fragile biological specimens, with recent innovations focusing on stimuli-responsive materials and precision control mechanisms. Integration with existing laboratory automation systems from companies like Tecan Trading AG and Inpeco SpA represents a key development pathway.

Northwestern University

Technical Solution: Northwestern University has pioneered innovative hydrogel grippers based on their proprietary "4D printing" technology that combines stimuli-responsive materials with precise fabrication methods. Their approach utilizes photocrosslinkable hydrogels with embedded magnetic nanoparticles to create grippers that respond to both magnetic fields and environmental stimuli such as pH, temperature, and ionic strength[2]. The university's research team has developed a composite hydrogel system combining poly(ethylene glycol) diacrylate (PEGDA) with alginate and gelatin methacryloyl (GelMA) to mimic the mechanical properties of biological tissues while maintaining excellent biocompatibility. These grippers feature microscale surface patterning that enhances contact with biological samples without adhesion, allowing for secure holding during manipulation and clean release afterward[4]. A distinctive aspect of Northwestern's technology is the incorporation of real-time feedback mechanisms through embedded fluorescent sensors that can detect applied forces, ensuring minimal damage to delicate samples during handling operations.

Strengths: Dual-responsive system (magnetic and environmental stimuli) offers precise control over gripper movement and gripping force. Biomimetic surface patterning provides secure sample holding without adhesion issues. Integrated sensing capabilities allow for real-time force feedback. Weaknesses: Magnetic nanoparticle incorporation may introduce additional regulatory hurdles for clinical applications. The complex fabrication process could present scaling challenges for mass production.

Dalian University of Technology

Technical Solution: Dalian University of Technology has developed an innovative hydrogel gripper system specifically engineered for handling fragile biological specimens. Their approach centers on a double-network hydrogel composition that combines a rigid polyacrylamide network with a softer, more elastic alginate-calcium network[1]. This dual-network structure provides both mechanical strength and gentle contact surfaces. The university's research team has implemented a gradient crosslinking technique that creates differential swelling properties across the gripper structure, enabling directional bending responses to environmental stimuli such as pH changes or specific ion concentrations[3]. A notable feature of their technology is the incorporation of surface micropatterning inspired by gecko foot structures, which enhances contact area with biological samples while minimizing adhesion forces that could damage delicate tissues. The grippers are fabricated using a specialized microfluidic system that allows precise control over size and shape, with capabilities for producing grippers ranging from millimeter to micrometer scales suitable for different biological applications[5].

Strengths: The double-network structure provides excellent mechanical stability while maintaining gentle sample contact. Gradient crosslinking enables complex motion patterns without external power sources. The biomimetic surface patterning enhances gripping without damaging samples. Weaknesses: The complex fabrication process may present challenges for mass production and standardization. The ionic crosslinking mechanism may be sensitive to environmental conditions, potentially affecting reliability in varied biological media.

Key Innovations in Biocompatible Hydrogel Materials

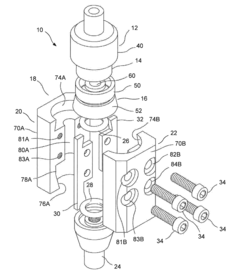

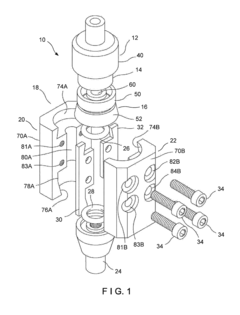

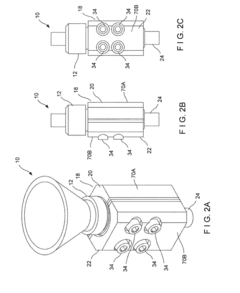

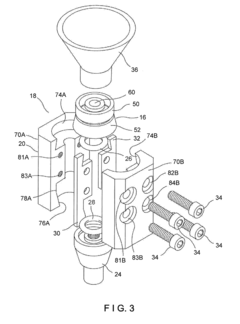

Molding grip fixture

PatentActiveUS20160069783A1

Innovation

- A two-piece clamp with undercut apertures and internal threading to securely engage sample materials, allowing for precise gripping and molding within a mold, enabling the testing of very soft materials without crushing, and facilitating tensile tests with improved load detection.

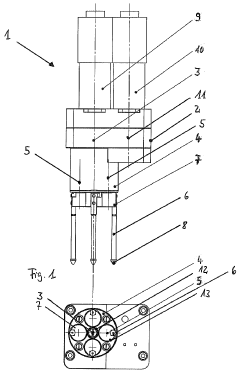

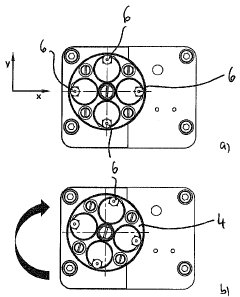

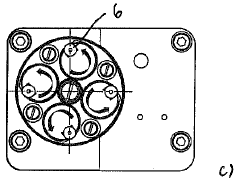

Gripper

PatentWO2013164160A1

Innovation

- A gripper with eccentrically arranged gripper fingers that utilize a combination of rotational movements of the fingers and the gripper base to achieve a linear feed movement, eliminating the need for complex linear drives and preventing shearing forces by applying a radially aligned clamping force.

Biocompatibility and Safety Considerations

Biocompatibility is a critical consideration in the design of hydrogel grippers for biological sample handling. These devices must not trigger adverse immune responses or cause toxicity when in contact with living tissues or cells. The materials selected for hydrogel grippers, primarily polymers such as polyethylene glycol (PEG), alginate, and polyacrylamide, must undergo rigorous biocompatibility testing according to ISO 10993 standards to ensure they do not release harmful leachables or cause cellular damage.

Surface chemistry plays a vital role in determining how biological samples interact with the gripper. Modifications such as anti-fouling coatings can prevent protein adsorption and cell adhesion, reducing contamination risks and preserving sample integrity. Additionally, hydrogel composition can be tailored to match the mechanical properties of target tissues, minimizing physical stress during manipulation.

Sterilization compatibility represents another crucial safety aspect, as hydrogel grippers must withstand common sterilization methods without degradation or toxic byproduct formation. Researchers have developed hydrogels capable of withstanding ethylene oxide treatment, gamma irradiation, or autoclave processes while maintaining their functional properties. However, each sterilization method presents unique challenges for different hydrogel formulations.

The potential for microbial contamination must be addressed through both material selection and design features. Incorporating antimicrobial agents such as silver nanoparticles or quaternary ammonium compounds can provide inherent resistance to bacterial colonization, though these additives must themselves be evaluated for biocompatibility. Some advanced hydrogel formulations include stimuli-responsive elements that can trigger the release of antimicrobial compounds only when needed.

Degradation behavior of hydrogel grippers requires careful engineering, especially for applications involving long-term sample storage or transport. Controlled biodegradation pathways ensure that any breakdown products are non-toxic and readily metabolized or cleared from biological systems. Recent advances in this area include hydrogels with programmable degradation timelines that align with specific experimental protocols.

Regulatory compliance frameworks vary globally but generally require comprehensive documentation of material safety, manufacturing consistency, and performance reliability. The FDA's guidance on biocompatibility testing for medical devices provides a valuable reference point, even for research-grade tools. Emerging international standards specifically addressing soft robotics in biological applications are currently under development, which will further formalize safety requirements for hydrogel grippers.

Surface chemistry plays a vital role in determining how biological samples interact with the gripper. Modifications such as anti-fouling coatings can prevent protein adsorption and cell adhesion, reducing contamination risks and preserving sample integrity. Additionally, hydrogel composition can be tailored to match the mechanical properties of target tissues, minimizing physical stress during manipulation.

Sterilization compatibility represents another crucial safety aspect, as hydrogel grippers must withstand common sterilization methods without degradation or toxic byproduct formation. Researchers have developed hydrogels capable of withstanding ethylene oxide treatment, gamma irradiation, or autoclave processes while maintaining their functional properties. However, each sterilization method presents unique challenges for different hydrogel formulations.

The potential for microbial contamination must be addressed through both material selection and design features. Incorporating antimicrobial agents such as silver nanoparticles or quaternary ammonium compounds can provide inherent resistance to bacterial colonization, though these additives must themselves be evaluated for biocompatibility. Some advanced hydrogel formulations include stimuli-responsive elements that can trigger the release of antimicrobial compounds only when needed.

Degradation behavior of hydrogel grippers requires careful engineering, especially for applications involving long-term sample storage or transport. Controlled biodegradation pathways ensure that any breakdown products are non-toxic and readily metabolized or cleared from biological systems. Recent advances in this area include hydrogels with programmable degradation timelines that align with specific experimental protocols.

Regulatory compliance frameworks vary globally but generally require comprehensive documentation of material safety, manufacturing consistency, and performance reliability. The FDA's guidance on biocompatibility testing for medical devices provides a valuable reference point, even for research-grade tools. Emerging international standards specifically addressing soft robotics in biological applications are currently under development, which will further formalize safety requirements for hydrogel grippers.

Scalability and Manufacturing Challenges

The scalability and manufacturing of hydrogel grippers for biological sample handling presents significant challenges that must be addressed for widespread adoption. Current laboratory-scale production methods typically involve photolithography, soft lithography, or 3D printing techniques that work well for research purposes but face limitations when considering industrial-scale production. The transition from lab to commercial manufacturing requires overcoming several key hurdles related to consistency, throughput, and cost-effectiveness.

Material consistency represents a primary challenge, as hydrogels are inherently sensitive to environmental conditions during synthesis. Small variations in temperature, humidity, or reagent concentrations can lead to significant batch-to-batch variability in mechanical properties, swelling behavior, and responsiveness. This inconsistency becomes particularly problematic when handling delicate biological samples where precise control over gripper behavior is essential for preventing damage to tissues or cells.

Production speed presents another significant barrier to scalability. Current fabrication methods for high-precision hydrogel grippers are relatively slow, with typical throughput rates insufficient for commercial applications. For example, photolithography-based approaches require multiple processing steps including mask alignment, UV exposure, and development, each adding time and complexity to the manufacturing workflow. While 3D printing offers design flexibility, the layer-by-layer deposition process remains time-intensive for complex gripper geometries.

The integration of sensing and actuation components further complicates manufacturing scalability. Advanced hydrogel grippers often incorporate embedded sensors, conductive elements, or stimuli-responsive components that require precise positioning during fabrication. Current manufacturing techniques struggle to reliably integrate these elements at high throughput while maintaining the delicate balance of mechanical properties required for biological sample handling.

Cost considerations also impact scalability significantly. The specialized materials used in biocompatible hydrogels, including high-purity polymers and bioactive components, carry premium prices that scale linearly with production volume. Additionally, the complex equipment required for precision manufacturing, such as high-resolution photolithography systems or specialized bioprinters, represents substantial capital investment that affects the economic viability of large-scale production.

Quality control presents perhaps the most critical challenge for manufacturing scalable hydrogel grippers. Unlike conventional rigid grippers, hydrogel-based systems exhibit complex mechanical behaviors that are difficult to characterize using standard industrial quality metrics. Developing reliable, high-throughput testing protocols to verify gripper performance, particularly for biological sample handling applications where safety is paramount, remains an ongoing challenge that directly impacts manufacturing scalability.

Material consistency represents a primary challenge, as hydrogels are inherently sensitive to environmental conditions during synthesis. Small variations in temperature, humidity, or reagent concentrations can lead to significant batch-to-batch variability in mechanical properties, swelling behavior, and responsiveness. This inconsistency becomes particularly problematic when handling delicate biological samples where precise control over gripper behavior is essential for preventing damage to tissues or cells.

Production speed presents another significant barrier to scalability. Current fabrication methods for high-precision hydrogel grippers are relatively slow, with typical throughput rates insufficient for commercial applications. For example, photolithography-based approaches require multiple processing steps including mask alignment, UV exposure, and development, each adding time and complexity to the manufacturing workflow. While 3D printing offers design flexibility, the layer-by-layer deposition process remains time-intensive for complex gripper geometries.

The integration of sensing and actuation components further complicates manufacturing scalability. Advanced hydrogel grippers often incorporate embedded sensors, conductive elements, or stimuli-responsive components that require precise positioning during fabrication. Current manufacturing techniques struggle to reliably integrate these elements at high throughput while maintaining the delicate balance of mechanical properties required for biological sample handling.

Cost considerations also impact scalability significantly. The specialized materials used in biocompatible hydrogels, including high-purity polymers and bioactive components, carry premium prices that scale linearly with production volume. Additionally, the complex equipment required for precision manufacturing, such as high-resolution photolithography systems or specialized bioprinters, represents substantial capital investment that affects the economic viability of large-scale production.

Quality control presents perhaps the most critical challenge for manufacturing scalable hydrogel grippers. Unlike conventional rigid grippers, hydrogel-based systems exhibit complex mechanical behaviors that are difficult to characterize using standard industrial quality metrics. Developing reliable, high-throughput testing protocols to verify gripper performance, particularly for biological sample handling applications where safety is paramount, remains an ongoing challenge that directly impacts manufacturing scalability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!