Integration Of Hydrogel Actuators With Soft Sensors For Tactile Feedback

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Actuator Technology Background and Objectives

Hydrogel actuators represent a revolutionary class of soft robotic components that have gained significant attention over the past decade. These materials combine the mechanical flexibility of hydrogels with responsive properties that enable controlled deformation under various stimuli such as temperature, pH, light, or electrical signals. The evolution of hydrogel actuator technology can be traced back to the early 2000s when researchers began exploring stimuli-responsive polymers for biomimetic applications. Since then, the field has witnessed exponential growth, particularly in the last five years, with breakthroughs in material composition, actuation mechanisms, and fabrication techniques.

The integration of hydrogel actuators with soft sensors for tactile feedback represents a convergence of two complementary technologies aimed at creating more sophisticated soft robotic systems. This integration addresses the critical need for closed-loop control systems in soft robotics, where actuators can respond to environmental feedback collected through embedded sensing elements. The technological trajectory shows a clear shift from discrete components toward fully integrated systems that mimic the sensorimotor capabilities found in biological organisms.

Current research objectives in this field focus on several key areas. First, enhancing the response time of hydrogel actuators, which traditionally suffer from slow actuation speeds due to diffusion-limited processes. Second, improving the mechanical durability and cycle life of these materials, which often degrade after repeated actuation cycles. Third, developing seamless integration methods that preserve both the actuation and sensing capabilities without compromising either functionality.

The ultimate technical goal is to create fully autonomous soft robotic systems with integrated sensing and actuation capabilities that can operate in complex, unstructured environments. This includes applications in wearable technology, healthcare devices, and human-machine interfaces where natural tactile feedback is essential. Researchers aim to achieve response times under one second, force generation comparable to human muscle tissue (approximately 0.3 MPa), and sensing resolution capable of detecting pressure variations as small as 1 kPa.

Looking forward, the field is trending toward multi-material fabrication approaches that enable the creation of monolithic structures with spatially varying properties. This includes gradient materials that transition smoothly between sensing and actuation regions, as well as 3D printing techniques that allow for complex geometries with embedded functionality. The convergence with other emerging technologies, such as stretchable electronics and biodegradable polymers, further expands the potential applications and capabilities of integrated hydrogel-based systems.

The integration of hydrogel actuators with soft sensors for tactile feedback represents a convergence of two complementary technologies aimed at creating more sophisticated soft robotic systems. This integration addresses the critical need for closed-loop control systems in soft robotics, where actuators can respond to environmental feedback collected through embedded sensing elements. The technological trajectory shows a clear shift from discrete components toward fully integrated systems that mimic the sensorimotor capabilities found in biological organisms.

Current research objectives in this field focus on several key areas. First, enhancing the response time of hydrogel actuators, which traditionally suffer from slow actuation speeds due to diffusion-limited processes. Second, improving the mechanical durability and cycle life of these materials, which often degrade after repeated actuation cycles. Third, developing seamless integration methods that preserve both the actuation and sensing capabilities without compromising either functionality.

The ultimate technical goal is to create fully autonomous soft robotic systems with integrated sensing and actuation capabilities that can operate in complex, unstructured environments. This includes applications in wearable technology, healthcare devices, and human-machine interfaces where natural tactile feedback is essential. Researchers aim to achieve response times under one second, force generation comparable to human muscle tissue (approximately 0.3 MPa), and sensing resolution capable of detecting pressure variations as small as 1 kPa.

Looking forward, the field is trending toward multi-material fabrication approaches that enable the creation of monolithic structures with spatially varying properties. This includes gradient materials that transition smoothly between sensing and actuation regions, as well as 3D printing techniques that allow for complex geometries with embedded functionality. The convergence with other emerging technologies, such as stretchable electronics and biodegradable polymers, further expands the potential applications and capabilities of integrated hydrogel-based systems.

Market Analysis for Tactile Feedback Systems

The global market for tactile feedback systems is experiencing significant growth, driven by advancements in robotics, virtual reality, medical devices, and consumer electronics. The integration of hydrogel actuators with soft sensors represents a particularly promising segment within this broader market, addressing the critical need for more natural and responsive haptic interfaces.

Current market valuations indicate that the global haptic technology market is projected to reach approximately $4.6 billion by 2026, with a compound annual growth rate exceeding 12%. Within this market, soft tactile feedback systems are emerging as a high-growth subsector, particularly as traditional rigid systems face limitations in applications requiring biomimetic properties.

Healthcare applications represent the largest market opportunity, with surgical robotics and prosthetics driving demand for advanced tactile feedback solutions. The medical tactile sensors market alone is growing at nearly 15% annually, with particular emphasis on solutions that can accurately mimic human touch sensitivity and provide real-time feedback.

Consumer electronics constitutes the second-largest market segment, with gaming, smartphones, and wearable devices incorporating increasingly sophisticated haptic feedback systems. The integration of hydrogel-based solutions offers significant advantages in this space due to their conformability, biocompatibility, and potential for miniaturization.

Industrial robotics presents another substantial growth area, with collaborative robots (cobots) requiring advanced tactile sensing capabilities to ensure safe human-robot interaction. This segment is expected to grow at over 20% annually as manufacturing increasingly adopts automation solutions that can work alongside human operators.

Market analysis reveals several key customer requirements driving adoption: durability under repeated deformation cycles, response time under 10 milliseconds, power efficiency for portable applications, and manufacturing scalability. Hydrogel actuator and sensor integration addresses many of these requirements, particularly in applications where traditional rigid systems are unsuitable.

Regional analysis shows North America leading market share at approximately 35%, followed by Asia-Pacific at 30% with the fastest growth rate. Europe accounts for 25% of the market, with particular strength in medical applications. The remaining 10% is distributed across other regions, with emerging economies showing increasing adoption rates.

Price sensitivity varies significantly by application, with medical devices commanding premium pricing while consumer electronics require more cost-effective solutions. Current hydrogel-based systems face cost challenges in mass-market applications, though economies of scale and manufacturing innovations are gradually improving their commercial viability.

Current market valuations indicate that the global haptic technology market is projected to reach approximately $4.6 billion by 2026, with a compound annual growth rate exceeding 12%. Within this market, soft tactile feedback systems are emerging as a high-growth subsector, particularly as traditional rigid systems face limitations in applications requiring biomimetic properties.

Healthcare applications represent the largest market opportunity, with surgical robotics and prosthetics driving demand for advanced tactile feedback solutions. The medical tactile sensors market alone is growing at nearly 15% annually, with particular emphasis on solutions that can accurately mimic human touch sensitivity and provide real-time feedback.

Consumer electronics constitutes the second-largest market segment, with gaming, smartphones, and wearable devices incorporating increasingly sophisticated haptic feedback systems. The integration of hydrogel-based solutions offers significant advantages in this space due to their conformability, biocompatibility, and potential for miniaturization.

Industrial robotics presents another substantial growth area, with collaborative robots (cobots) requiring advanced tactile sensing capabilities to ensure safe human-robot interaction. This segment is expected to grow at over 20% annually as manufacturing increasingly adopts automation solutions that can work alongside human operators.

Market analysis reveals several key customer requirements driving adoption: durability under repeated deformation cycles, response time under 10 milliseconds, power efficiency for portable applications, and manufacturing scalability. Hydrogel actuator and sensor integration addresses many of these requirements, particularly in applications where traditional rigid systems are unsuitable.

Regional analysis shows North America leading market share at approximately 35%, followed by Asia-Pacific at 30% with the fastest growth rate. Europe accounts for 25% of the market, with particular strength in medical applications. The remaining 10% is distributed across other regions, with emerging economies showing increasing adoption rates.

Price sensitivity varies significantly by application, with medical devices commanding premium pricing while consumer electronics require more cost-effective solutions. Current hydrogel-based systems face cost challenges in mass-market applications, though economies of scale and manufacturing innovations are gradually improving their commercial viability.

Current Challenges in Soft Sensor-Actuator Integration

The integration of hydrogel actuators with soft sensors for tactile feedback represents a significant frontier in soft robotics, yet numerous challenges impede seamless implementation. Material compatibility remains a primary obstacle, as hydrogels and sensing materials often require different chemical environments to function optimally. Hydrogels typically demand hydration to maintain their mechanical properties, while many electronic sensing components require dry conditions to prevent short circuits or degradation. This fundamental incompatibility necessitates complex interfacing solutions that can preserve the functionality of both components.

Fabrication challenges further complicate integration efforts. Current manufacturing techniques struggle to precisely position sensing elements within or alongside hydrogel actuators without compromising either component's performance. Traditional microfabrication methods developed for rigid electronics prove inadequate for these highly deformable materials, while 3D printing approaches face resolution limitations and material constraints when attempting to co-print sensing and actuation elements.

Signal interference presents another significant hurdle. The electrical signals used to activate hydrogel actuators can create noise that disrupts the sensitive measurements from tactile sensors. Conversely, the sensing mechanisms themselves may inadvertently affect actuator performance through mechanical constraints or electrical interactions. This bidirectional interference necessitates sophisticated signal processing and isolation strategies that add complexity to system design.

Durability and reliability concerns persist throughout integrated systems. Hydrogels are susceptible to dehydration, mechanical fatigue, and environmental degradation, while soft sensors often suffer from hysteresis, drift, and limited lifespan under repeated deformation. These reliability issues become magnified when the components are integrated, as failure modes can compound and accelerate degradation across the system.

Power management represents a critical challenge, particularly for untethered applications. Hydrogel actuators typically require substantial energy input for activation, while maintaining low-power sensing capabilities demands efficient energy distribution systems. The development of energy-efficient actuation mechanisms and self-powered sensing solutions remains an active research area with significant technical barriers.

Scalability limitations restrict widespread adoption of these integrated systems. Current laboratory prototypes often demonstrate impressive capabilities but face significant hurdles in scaling to commercial production. Manufacturing processes that work for small-scale demonstrations frequently prove impractical or prohibitively expensive at larger scales, limiting potential applications.

Standardization gaps further hinder progress, as the field lacks established testing protocols and performance metrics for integrated sensor-actuator systems. This absence of standardization complicates comparative analysis between different approaches and slows the identification of optimal integration strategies.

Fabrication challenges further complicate integration efforts. Current manufacturing techniques struggle to precisely position sensing elements within or alongside hydrogel actuators without compromising either component's performance. Traditional microfabrication methods developed for rigid electronics prove inadequate for these highly deformable materials, while 3D printing approaches face resolution limitations and material constraints when attempting to co-print sensing and actuation elements.

Signal interference presents another significant hurdle. The electrical signals used to activate hydrogel actuators can create noise that disrupts the sensitive measurements from tactile sensors. Conversely, the sensing mechanisms themselves may inadvertently affect actuator performance through mechanical constraints or electrical interactions. This bidirectional interference necessitates sophisticated signal processing and isolation strategies that add complexity to system design.

Durability and reliability concerns persist throughout integrated systems. Hydrogels are susceptible to dehydration, mechanical fatigue, and environmental degradation, while soft sensors often suffer from hysteresis, drift, and limited lifespan under repeated deformation. These reliability issues become magnified when the components are integrated, as failure modes can compound and accelerate degradation across the system.

Power management represents a critical challenge, particularly for untethered applications. Hydrogel actuators typically require substantial energy input for activation, while maintaining low-power sensing capabilities demands efficient energy distribution systems. The development of energy-efficient actuation mechanisms and self-powered sensing solutions remains an active research area with significant technical barriers.

Scalability limitations restrict widespread adoption of these integrated systems. Current laboratory prototypes often demonstrate impressive capabilities but face significant hurdles in scaling to commercial production. Manufacturing processes that work for small-scale demonstrations frequently prove impractical or prohibitively expensive at larger scales, limiting potential applications.

Standardization gaps further hinder progress, as the field lacks established testing protocols and performance metrics for integrated sensor-actuator systems. This absence of standardization complicates comparative analysis between different approaches and slows the identification of optimal integration strategies.

Current Integration Methods for Hydrogel-Sensor Systems

01 Hydrogel-based tactile feedback systems

Hydrogel actuators can be integrated with soft sensors to create tactile feedback systems that mimic the sensation of touch. These systems utilize the responsive nature of hydrogels to environmental stimuli to generate mechanical movements that can be detected by users. The combination of hydrogel actuators with soft sensing elements enables the development of more natural and intuitive tactile interfaces for various applications including virtual reality and human-computer interaction.- Hydrogel-based tactile feedback systems: Hydrogel actuators can be integrated with soft sensors to create responsive tactile feedback systems. These systems utilize the unique properties of hydrogels, which can change shape or stiffness in response to various stimuli. When combined with soft sensors, these actuators can provide realistic tactile sensations that mimic natural touch experiences. The integration allows for dynamic feedback that can adjust based on user interaction or programmed responses.

- Soft sensors for haptic interfaces: Soft sensors can be incorporated into haptic interfaces to detect user interactions and trigger appropriate tactile feedback. These sensors are typically made from flexible materials that can conform to various surfaces and detect pressure, stretch, or other physical inputs. The data from these sensors is processed to control hydrogel actuators, creating a closed-loop system that provides realistic tactile feedback. This technology is particularly valuable in virtual reality, gaming, and medical simulation applications.

- Materials and fabrication methods for integrated systems: Advanced materials and fabrication techniques are essential for creating effective hydrogel actuators integrated with soft sensors. These methods include 3D printing, microfabrication, and novel composite material development. Conductive hydrogels can serve dual purposes as both sensing elements and actuators. Multi-material printing allows for seamless integration of different functional components within a single device, enabling more compact and efficient tactile feedback systems.

- Applications in wearable technology: Hydrogel actuators with integrated soft sensors are increasingly being applied in wearable technology to provide tactile feedback. These systems can be incorporated into gloves, armbands, or other wearable devices to enhance user experience in virtual reality, augmented reality, or remote operation scenarios. The flexibility and conformability of these integrated systems make them comfortable for extended wear while still providing precise and localized tactile sensations to the user.

- Control systems for tactile feedback coordination: Sophisticated control systems are required to coordinate the operation of hydrogel actuators and soft sensors for effective tactile feedback. These systems process sensor inputs, determine appropriate responses, and control the actuation parameters of the hydrogels. Machine learning algorithms can be employed to improve the naturalistic feel of the tactile feedback by adapting to user preferences and environmental conditions. Real-time processing capabilities ensure minimal latency between sensor detection and actuator response, which is crucial for creating convincing tactile experiences.

02 Soft sensors for haptic feedback in wearable devices

Soft sensors integrated with hydrogel actuators can be incorporated into wearable devices to provide haptic feedback. These sensors detect user movements or environmental changes and trigger the hydrogel actuators to provide tactile responses. The flexibility and conformability of both the sensors and actuators make them ideal for wearable applications, allowing for comfortable and responsive tactile feedback systems that can be worn for extended periods without causing discomfort.Expand Specific Solutions03 Electroactive hydrogel actuators for tactile interfaces

Electroactive hydrogels can be used as actuators in tactile feedback systems, responding to electrical stimuli by changing shape or volume. When integrated with soft sensors, these electroactive hydrogel actuators can create dynamic tactile interfaces that provide real-time feedback based on user interactions. The electrical responsiveness of these hydrogels allows for precise control over the tactile sensations generated, enabling more sophisticated and nuanced feedback mechanisms.Expand Specific Solutions04 Biomimetic tactile sensing with hydrogel structures

Hydrogel actuators can be designed to mimic biological tactile sensing mechanisms, creating biomimetic systems that replicate the sensitivity and responsiveness of human touch. These systems integrate soft sensors with hydrogel structures that deform in ways similar to human skin and tissue. The biomimetic approach allows for more intuitive and natural tactile feedback, making these systems particularly valuable for applications in prosthetics, robotics, and medical devices where human-like touch sensing is beneficial.Expand Specific Solutions05 Multi-modal feedback systems combining hydrogel actuators with other sensory outputs

Advanced tactile feedback systems can integrate hydrogel actuators with soft sensors and additional sensory output modalities such as visual or auditory feedback. These multi-modal systems provide enhanced user experiences by engaging multiple senses simultaneously. The hydrogel components provide the tactile dimension while being coordinated with other feedback mechanisms to create more immersive and informative interactions, particularly valuable in gaming, virtual reality, and assistive technology applications.Expand Specific Solutions

Leading Research Groups and Companies in Soft Robotics

The integration of hydrogel actuators with soft sensors for tactile feedback is currently in an early growth phase, with market size expanding as applications in wearable technology, robotics, and medical devices gain traction. The technology is approaching maturity but still faces challenges in durability and scalability. Academic institutions like MIT, Northwestern University, and University of California are leading fundamental research, while companies such as Apple, HaptX, and Immersion Corporation are developing commercial applications. Artimus Robotics and Titan Haptics represent specialized startups focusing on innovative actuator technologies. Asian players including Toyoda Gosei and AAC Acoustic Technologies are advancing manufacturing capabilities. The competitive landscape shows a balance between academic innovation and industrial implementation, with increasing cross-sector collaborations accelerating development toward more sophisticated tactile feedback systems.

City University of Hong Kong

Technical Solution: City University of Hong Kong has developed an innovative hydrogel-based tactile sensing and actuation system that leverages ionic conductivity for both functions. Their approach utilizes a multi-layered composite structure where highly conductive hydrogels are strategically patterned to form sensing elements that simultaneously function as electroactive actuators. The university's research team has created a proprietary formulation incorporating metal nanoparticles within the hydrogel matrix to enhance electrical conductivity while maintaining mechanical compliance. Their system employs a unique electrode configuration that enables localized deformation control while simultaneously monitoring pressure distribution through impedance measurements. The technology features self-contained sensing and feedback mechanisms where detected stimuli automatically trigger corresponding actuator responses, creating a biomimetic touch experience. Recent advancements include the development of anisotropic hydrogel structures that provide directional sensing capabilities and the integration of wireless power transfer systems for untethered operation in wearable applications.

Strengths: Exceptional conformability to complex surfaces; high spatial resolution for both sensing and actuation; excellent biocompatibility suitable for skin-interfacing applications. Weaknesses: Sensitivity to environmental humidity affecting performance consistency; relatively complex manufacturing process limiting mass production; potential for dehydration in extended use scenarios.

Northwestern University

Technical Solution: Northwestern University has pioneered a comprehensive approach to hydrogel actuator-sensor integration focusing on biomimetic applications. Their technology utilizes temperature-responsive hydrogels combined with embedded ionic liquid networks to create multifunctional systems capable of both sensing and actuation. The university's research team has developed a proprietary "sandwich" structure where highly conductive hydrogel layers are separated by a dielectric elastomer, forming a capacitive sensor that simultaneously functions as an actuator. Their innovation includes incorporating carbon nanomaterials within the hydrogel matrix to enhance conductivity and mechanical properties. Northwestern's system demonstrates remarkable sensitivity to mechanical deformation while providing programmable actuation patterns through localized electrical stimulation. The technology employs a closed-loop control system where sensor feedback directly modulates actuator behavior, enabling adaptive responses to environmental changes. Recent developments include self-healing capabilities and 3D printable formulations for complex geometries.

Strengths: Exceptional sensitivity to both pressure and shear forces; seamless integration of sensing and actuation functions; biocompatible materials suitable for wearable and implantable applications. Weaknesses: Temperature sensitivity affecting performance consistency; relatively slow response time compared to conventional electronic systems; limited long-term stability in varying environmental conditions.

Key Patents and Research in Hydrogel-Based Tactile Feedback

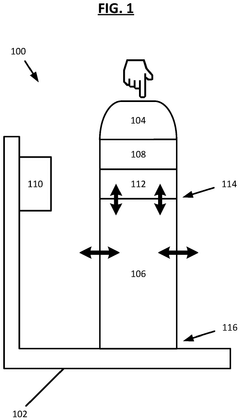

Interface for delivering tactile stimulation

PatentWO2022269186A1

Innovation

- A tactile stimulation interface utilizing acoustic metamaterials with confinement zones and piezoelectric or electromagnetic actuators to generate and transmit acoustic waves, creating localized vibration zones by reflecting specific frequency ranges, thereby enhancing spatial resolution and haptic fidelity.

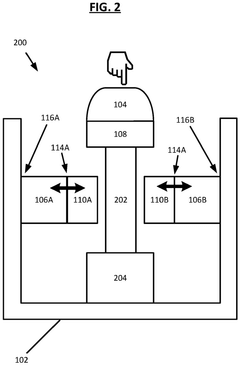

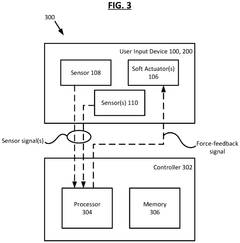

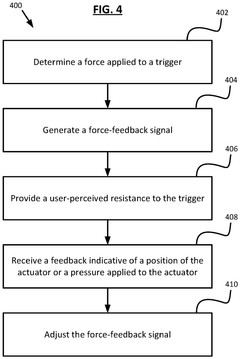

Adaptive triggers implementing soft actuators

PatentPendingEP4488805A1

Innovation

- The use of soft actuators in user input devices, combined with sensors and a controller, to provide adjustable and real-time haptic feedback by controlling the position and resistance of a trigger, allowing for more immersive and realistic simulations.

Biocompatibility and Safety Considerations

The integration of hydrogel actuators with soft sensors for tactile feedback applications necessitates rigorous assessment of biocompatibility and safety considerations, particularly when these systems interface with human tissue. Hydrogels, while generally considered biocompatible, exhibit varying degrees of tissue compatibility depending on their chemical composition, crosslinking mechanisms, and degradation products.

Primary biocompatibility concerns include potential inflammatory responses, cytotoxicity, and immunogenicity. Hydrogels based on natural polymers such as alginate, collagen, and hyaluronic acid typically demonstrate superior biocompatibility compared to synthetic alternatives. However, synthetic hydrogels offer greater tunability of mechanical properties and degradation rates, creating an important design trade-off. Recent advances in hybrid hydrogels combine the advantages of both natural and synthetic materials to optimize biocompatibility while maintaining desired mechanical characteristics.

The electrical components integrated within these systems present additional safety challenges. Conductive materials used in soft sensors, including carbon nanotubes, silver nanowires, and ionic liquids, must be thoroughly evaluated for potential leaching and long-term tissue effects. Encapsulation strategies using biocompatible elastomers have shown promise in mitigating these risks while maintaining sensor functionality.

For applications involving direct skin contact, dermatological compatibility testing is essential. ISO 10993 standards provide a framework for biological evaluation, including cytotoxicity, sensitization, and irritation assessments. More invasive applications require additional testing for systemic toxicity, genotoxicity, and carcinogenicity potential.

Long-term stability represents another critical safety consideration. Hydrogel degradation may release potentially harmful byproducts or alter the mechanical properties of the system over time. Accelerated aging studies can help predict long-term performance and identify potential failure modes before clinical implementation.

Sterilization compatibility must also be addressed, as common sterilization methods like ethylene oxide, gamma irradiation, and autoclave processing can significantly alter hydrogel properties. Recent research has focused on developing hydrogel formulations that maintain structural integrity and functionality after sterilization.

Regulatory pathways for these integrated systems vary by application and jurisdiction. In the United States, the FDA classification depends on the intended use, with most tactile feedback systems falling under Class II medical devices requiring 510(k) clearance. The European Union's Medical Device Regulation (MDR) imposes similar requirements with emphasis on clinical evaluation and post-market surveillance.

As this technology advances toward clinical applications, standardized testing protocols specific to hydrogel-based actuator-sensor systems will be essential to ensure consistent safety evaluation across the industry.

Primary biocompatibility concerns include potential inflammatory responses, cytotoxicity, and immunogenicity. Hydrogels based on natural polymers such as alginate, collagen, and hyaluronic acid typically demonstrate superior biocompatibility compared to synthetic alternatives. However, synthetic hydrogels offer greater tunability of mechanical properties and degradation rates, creating an important design trade-off. Recent advances in hybrid hydrogels combine the advantages of both natural and synthetic materials to optimize biocompatibility while maintaining desired mechanical characteristics.

The electrical components integrated within these systems present additional safety challenges. Conductive materials used in soft sensors, including carbon nanotubes, silver nanowires, and ionic liquids, must be thoroughly evaluated for potential leaching and long-term tissue effects. Encapsulation strategies using biocompatible elastomers have shown promise in mitigating these risks while maintaining sensor functionality.

For applications involving direct skin contact, dermatological compatibility testing is essential. ISO 10993 standards provide a framework for biological evaluation, including cytotoxicity, sensitization, and irritation assessments. More invasive applications require additional testing for systemic toxicity, genotoxicity, and carcinogenicity potential.

Long-term stability represents another critical safety consideration. Hydrogel degradation may release potentially harmful byproducts or alter the mechanical properties of the system over time. Accelerated aging studies can help predict long-term performance and identify potential failure modes before clinical implementation.

Sterilization compatibility must also be addressed, as common sterilization methods like ethylene oxide, gamma irradiation, and autoclave processing can significantly alter hydrogel properties. Recent research has focused on developing hydrogel formulations that maintain structural integrity and functionality after sterilization.

Regulatory pathways for these integrated systems vary by application and jurisdiction. In the United States, the FDA classification depends on the intended use, with most tactile feedback systems falling under Class II medical devices requiring 510(k) clearance. The European Union's Medical Device Regulation (MDR) imposes similar requirements with emphasis on clinical evaluation and post-market surveillance.

As this technology advances toward clinical applications, standardized testing protocols specific to hydrogel-based actuator-sensor systems will be essential to ensure consistent safety evaluation across the industry.

Energy Efficiency and Power Requirements

The energy efficiency of integrated hydrogel actuator-sensor systems represents a critical challenge in developing practical tactile feedback solutions. Current hydrogel actuators typically require significant electrical input for activation, with power consumption ranging from 0.5-2W depending on actuation frequency and amplitude. This relatively high power requirement stems from the inherent electrical resistance of ionic hydrogels and energy losses during the electrochemical processes that drive actuation. When combined with soft sensors, the overall system efficiency decreases further due to additional power needed for continuous sensing operations and signal processing.

Recent advancements have focused on improving energy efficiency through material optimization and circuit design. Researchers have developed hydrogels with enhanced ionic conductivity by incorporating metallic nanoparticles and conductive polymers, reducing internal resistance by up to 40%. Additionally, novel circuit designs utilizing capacitive energy storage have demonstrated the ability to recapture and reuse up to 30% of the energy during actuation cycles, significantly extending operational time for battery-powered applications.

Power management strategies have emerged as another crucial aspect of these integrated systems. Adaptive duty cycling, where the system alternates between active and low-power states based on interaction needs, has shown promise in reducing average power consumption by 50-70%. Furthermore, energy harvesting technologies such as piezoelectric elements and triboelectric generators are being integrated to supplement battery power, potentially enabling self-sustaining operation in specific use scenarios.

Miniaturization of power delivery components presents another significant challenge. Traditional rigid batteries and power management circuits limit the flexibility and conformability of the overall system. Research into flexible thin-film batteries and stretchable power delivery networks has shown promising results, with prototypes maintaining functionality under deformations of up to 30% strain while powering hydrogel actuator-sensor systems.

The thermal management of these systems also impacts energy efficiency. Joule heating during actuation can lead to water evaporation from hydrogels, changing their mechanical properties and increasing power requirements over time. Encapsulation techniques using breathable yet waterproof membranes have demonstrated the ability to maintain hydrogel hydration levels while allowing heat dissipation, extending operational lifetime by up to 300% in laboratory conditions.

For practical applications in wearable haptic feedback devices, the current energy requirements limit continuous operation to approximately 2-4 hours before recharging is necessary. This constraint represents a significant barrier to widespread adoption, highlighting the need for further research into ultra-low-power actuation mechanisms and more efficient energy storage solutions specifically designed for soft, flexible systems.

Recent advancements have focused on improving energy efficiency through material optimization and circuit design. Researchers have developed hydrogels with enhanced ionic conductivity by incorporating metallic nanoparticles and conductive polymers, reducing internal resistance by up to 40%. Additionally, novel circuit designs utilizing capacitive energy storage have demonstrated the ability to recapture and reuse up to 30% of the energy during actuation cycles, significantly extending operational time for battery-powered applications.

Power management strategies have emerged as another crucial aspect of these integrated systems. Adaptive duty cycling, where the system alternates between active and low-power states based on interaction needs, has shown promise in reducing average power consumption by 50-70%. Furthermore, energy harvesting technologies such as piezoelectric elements and triboelectric generators are being integrated to supplement battery power, potentially enabling self-sustaining operation in specific use scenarios.

Miniaturization of power delivery components presents another significant challenge. Traditional rigid batteries and power management circuits limit the flexibility and conformability of the overall system. Research into flexible thin-film batteries and stretchable power delivery networks has shown promising results, with prototypes maintaining functionality under deformations of up to 30% strain while powering hydrogel actuator-sensor systems.

The thermal management of these systems also impacts energy efficiency. Joule heating during actuation can lead to water evaporation from hydrogels, changing their mechanical properties and increasing power requirements over time. Encapsulation techniques using breathable yet waterproof membranes have demonstrated the ability to maintain hydrogel hydration levels while allowing heat dissipation, extending operational lifetime by up to 300% in laboratory conditions.

For practical applications in wearable haptic feedback devices, the current energy requirements limit continuous operation to approximately 2-4 hours before recharging is necessary. This constraint represents a significant barrier to widespread adoption, highlighting the need for further research into ultra-low-power actuation mechanisms and more efficient energy storage solutions specifically designed for soft, flexible systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!