Hydrogel Composite Formulations For Fast Response Artificial Muscles

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Artificial Muscle Background and Objectives

Hydrogel-based artificial muscles represent a revolutionary frontier in soft robotics and biomimetic engineering, emerging from decades of research into responsive polymer systems. These smart materials combine the flexibility and biocompatibility of hydrogels with the ability to undergo controlled, reversible deformation in response to external stimuli such as pH, temperature, light, or electric fields. The evolution of this technology can be traced back to the 1950s with the development of the first synthetic hydrogels, progressing through significant breakthroughs in stimuli-responsive polymers in the 1980s and 1990s, and accelerating rapidly in the 21st century with the integration of nanocomposites and advanced fabrication techniques.

The current technological trajectory is moving toward multi-responsive, high-performance hydrogel composites that can mimic the sophisticated functionality of natural muscles. Recent innovations have focused on enhancing response speed, force generation, and cycling stability—three critical parameters that have historically limited practical applications. Particularly promising are developments in conductive nanocomposites, interpenetrating polymer networks, and hierarchically structured hydrogels that demonstrate improved electromechanical coupling and energy efficiency.

Our primary technical objective is to develop novel hydrogel composite formulations that significantly reduce response time while maintaining or enhancing force generation capabilities. Specifically, we aim to achieve actuation speeds below 1 second with strain rates exceeding 50% under moderate stimulation conditions, representing a ten-fold improvement over conventional hydrogel actuators. Additionally, we seek to ensure operational stability over 10,000+ cycles without significant performance degradation, a benchmark necessary for practical deployment in real-world applications.

Secondary objectives include optimizing energy efficiency to enable battery-powered operation, improving biocompatibility for potential medical applications, and developing scalable manufacturing processes that can transition from laboratory prototypes to commercial production. We also aim to establish comprehensive characterization protocols that accurately predict long-term performance under varied environmental conditions.

The technological significance of fast-response hydrogel artificial muscles extends across multiple industries. In healthcare, they could revolutionize soft prosthetics and minimally invasive surgical tools. In consumer electronics, they offer pathways to haptic interfaces with unprecedented tactile fidelity. For industrial automation, they present opportunities for safe human-robot collaboration through inherently compliant actuation systems. Perhaps most ambitiously, they may enable entirely new categories of autonomous soft robots capable of navigating complex, unstructured environments with biomimetic dexterity.

This research addresses the fundamental challenge of bridging the performance gap between natural and artificial muscle systems, potentially unlocking transformative applications that have remained theoretical due to limitations in existing actuator technologies.

The current technological trajectory is moving toward multi-responsive, high-performance hydrogel composites that can mimic the sophisticated functionality of natural muscles. Recent innovations have focused on enhancing response speed, force generation, and cycling stability—three critical parameters that have historically limited practical applications. Particularly promising are developments in conductive nanocomposites, interpenetrating polymer networks, and hierarchically structured hydrogels that demonstrate improved electromechanical coupling and energy efficiency.

Our primary technical objective is to develop novel hydrogel composite formulations that significantly reduce response time while maintaining or enhancing force generation capabilities. Specifically, we aim to achieve actuation speeds below 1 second with strain rates exceeding 50% under moderate stimulation conditions, representing a ten-fold improvement over conventional hydrogel actuators. Additionally, we seek to ensure operational stability over 10,000+ cycles without significant performance degradation, a benchmark necessary for practical deployment in real-world applications.

Secondary objectives include optimizing energy efficiency to enable battery-powered operation, improving biocompatibility for potential medical applications, and developing scalable manufacturing processes that can transition from laboratory prototypes to commercial production. We also aim to establish comprehensive characterization protocols that accurately predict long-term performance under varied environmental conditions.

The technological significance of fast-response hydrogel artificial muscles extends across multiple industries. In healthcare, they could revolutionize soft prosthetics and minimally invasive surgical tools. In consumer electronics, they offer pathways to haptic interfaces with unprecedented tactile fidelity. For industrial automation, they present opportunities for safe human-robot collaboration through inherently compliant actuation systems. Perhaps most ambitiously, they may enable entirely new categories of autonomous soft robots capable of navigating complex, unstructured environments with biomimetic dexterity.

This research addresses the fundamental challenge of bridging the performance gap between natural and artificial muscle systems, potentially unlocking transformative applications that have remained theoretical due to limitations in existing actuator technologies.

Market Applications for Fast-Response Artificial Muscles

Fast-response artificial muscles based on hydrogel composite formulations present significant market opportunities across multiple sectors. The healthcare industry represents one of the most promising application areas, with potential uses in prosthetics, rehabilitation devices, and assistive technologies. These artificial muscles can enable more natural movement patterns in prosthetic limbs, providing users with improved dexterity and control that closely mimics biological muscle function. The global prosthetics market, which these technologies could disrupt, continues to expand as populations age and chronic conditions increase.

Soft robotics constitutes another major market opportunity, where fast-response artificial muscles could revolutionize robot design by enabling more compliant, adaptable, and safer human-machine interactions. Traditional rigid robots face limitations in collaborative environments, whereas soft robotic systems incorporating hydrogel-based artificial muscles can work alongside humans without safety barriers, opening new applications in manufacturing, logistics, and service industries.

The wearable technology sector presents a third significant market avenue. Fast-response artificial muscles can be integrated into exoskeletons and power-assist suits to enhance human capabilities in industrial settings, military applications, and medical rehabilitation. These technologies could dramatically reduce workplace injuries while increasing productivity in physically demanding occupations.

Biomedical devices represent another promising application area, where artificial muscles could be used in drug delivery systems, minimally invasive surgical tools, and implantable medical devices. The ability to precisely control movement and force application at small scales makes these technologies particularly valuable for targeted therapies and microsurgery applications.

Consumer electronics manufacturers are also exploring applications for fast-response artificial muscles in haptic feedback systems, creating more immersive virtual reality experiences and intuitive user interfaces. As gaming, augmented reality, and virtual reality markets expand, demand for advanced tactile feedback mechanisms will likely increase substantially.

Environmental monitoring and oceanographic research represent emerging application areas, where soft, compliant artificial muscles could power underwater vehicles and sampling devices designed to operate in sensitive ecosystems without causing damage. The adaptability of hydrogel-based systems to aqueous environments makes them particularly suitable for these applications.

The automotive industry has begun investigating these technologies for applications in adaptive components, comfort systems, and safety features. Fast-response artificial muscles could enable new approaches to impact absorption, seating comfort, and interface design that respond dynamically to changing conditions and user needs.

Soft robotics constitutes another major market opportunity, where fast-response artificial muscles could revolutionize robot design by enabling more compliant, adaptable, and safer human-machine interactions. Traditional rigid robots face limitations in collaborative environments, whereas soft robotic systems incorporating hydrogel-based artificial muscles can work alongside humans without safety barriers, opening new applications in manufacturing, logistics, and service industries.

The wearable technology sector presents a third significant market avenue. Fast-response artificial muscles can be integrated into exoskeletons and power-assist suits to enhance human capabilities in industrial settings, military applications, and medical rehabilitation. These technologies could dramatically reduce workplace injuries while increasing productivity in physically demanding occupations.

Biomedical devices represent another promising application area, where artificial muscles could be used in drug delivery systems, minimally invasive surgical tools, and implantable medical devices. The ability to precisely control movement and force application at small scales makes these technologies particularly valuable for targeted therapies and microsurgery applications.

Consumer electronics manufacturers are also exploring applications for fast-response artificial muscles in haptic feedback systems, creating more immersive virtual reality experiences and intuitive user interfaces. As gaming, augmented reality, and virtual reality markets expand, demand for advanced tactile feedback mechanisms will likely increase substantially.

Environmental monitoring and oceanographic research represent emerging application areas, where soft, compliant artificial muscles could power underwater vehicles and sampling devices designed to operate in sensitive ecosystems without causing damage. The adaptability of hydrogel-based systems to aqueous environments makes them particularly suitable for these applications.

The automotive industry has begun investigating these technologies for applications in adaptive components, comfort systems, and safety features. Fast-response artificial muscles could enable new approaches to impact absorption, seating comfort, and interface design that respond dynamically to changing conditions and user needs.

Current Hydrogel Composite Technology Challenges

Despite significant advancements in hydrogel composite technology for artificial muscles, several critical challenges persist that impede their widespread application. The primary limitation remains response time, with most current hydrogel-based artificial muscles exhibiting relatively slow actuation speeds compared to natural muscles or other artificial muscle technologies. This sluggishness stems from the diffusion-limited nature of the stimuli-responsive mechanisms, where the rate of volumetric change depends on the diffusion of water or ions through the polymer network.

Material durability presents another significant hurdle, as hydrogel composites often suffer from mechanical fatigue during repeated actuation cycles. The continuous swelling and deswelling processes create internal stresses that lead to microstructural damage, resulting in performance degradation over time. Most current formulations can withstand only hundreds to a few thousand cycles before showing significant deterioration in response characteristics.

The force generation capability of hydrogel-based artificial muscles remains substantially lower than that of natural muscles or other artificial muscle technologies. Even with recent improvements in composite formulations incorporating nanomaterials, the power-to-weight ratio still falls short of requirements for many practical applications, particularly those demanding high force output.

Environmental sensitivity poses additional challenges, as many hydrogel composites exhibit inconsistent performance across varying temperature, pH, and ionic strength conditions. This sensitivity limits their reliability in real-world applications where environmental parameters cannot be tightly controlled. Furthermore, the biocompatibility of certain components in high-performance hydrogel composites remains questionable, particularly when nanomaterials or synthetic polymers are incorporated to enhance responsiveness.

Manufacturing scalability represents a significant technical barrier, with most advanced hydrogel composite formulations requiring complex synthesis procedures that are difficult to scale up for mass production. The precise control of nanostructure and composite interfaces, critical for optimal performance, becomes increasingly challenging at larger production scales.

Energy efficiency in actuation mechanisms continues to be suboptimal, with many hydrogel systems requiring continuous energy input to maintain their actuated state. This limitation contrasts with natural muscles, which can maintain static positions with minimal energy expenditure. Additionally, the integration of sensing capabilities with actuation functions remains underdeveloped, hindering the creation of truly biomimetic systems that can respond autonomously to environmental changes.

Addressing these interconnected challenges requires interdisciplinary approaches combining polymer chemistry, materials science, and mechanical engineering to develop next-generation hydrogel composite formulations capable of fast, powerful, and durable actuation.

Material durability presents another significant hurdle, as hydrogel composites often suffer from mechanical fatigue during repeated actuation cycles. The continuous swelling and deswelling processes create internal stresses that lead to microstructural damage, resulting in performance degradation over time. Most current formulations can withstand only hundreds to a few thousand cycles before showing significant deterioration in response characteristics.

The force generation capability of hydrogel-based artificial muscles remains substantially lower than that of natural muscles or other artificial muscle technologies. Even with recent improvements in composite formulations incorporating nanomaterials, the power-to-weight ratio still falls short of requirements for many practical applications, particularly those demanding high force output.

Environmental sensitivity poses additional challenges, as many hydrogel composites exhibit inconsistent performance across varying temperature, pH, and ionic strength conditions. This sensitivity limits their reliability in real-world applications where environmental parameters cannot be tightly controlled. Furthermore, the biocompatibility of certain components in high-performance hydrogel composites remains questionable, particularly when nanomaterials or synthetic polymers are incorporated to enhance responsiveness.

Manufacturing scalability represents a significant technical barrier, with most advanced hydrogel composite formulations requiring complex synthesis procedures that are difficult to scale up for mass production. The precise control of nanostructure and composite interfaces, critical for optimal performance, becomes increasingly challenging at larger production scales.

Energy efficiency in actuation mechanisms continues to be suboptimal, with many hydrogel systems requiring continuous energy input to maintain their actuated state. This limitation contrasts with natural muscles, which can maintain static positions with minimal energy expenditure. Additionally, the integration of sensing capabilities with actuation functions remains underdeveloped, hindering the creation of truly biomimetic systems that can respond autonomously to environmental changes.

Addressing these interconnected challenges requires interdisciplinary approaches combining polymer chemistry, materials science, and mechanical engineering to develop next-generation hydrogel composite formulations capable of fast, powerful, and durable actuation.

Current Hydrogel Composite Formulation Approaches

01 Nanoparticle incorporation for enhanced response speed

Incorporating nanoparticles such as graphene, carbon nanotubes, or metal nanoparticles into hydrogel composites can significantly improve their response speed to external stimuli. These nanoparticles enhance the electrical conductivity and thermal responsiveness of the hydrogel, allowing for faster signal transmission and actuation. The improved network structure created by these nanoparticles facilitates quicker diffusion of molecules through the hydrogel matrix, resulting in more rapid response times for applications in sensors, drug delivery systems, and soft robotics.- Nanocomposite hydrogels for rapid response: Incorporating nanoparticles such as graphene oxide, carbon nanotubes, or metal nanoparticles into hydrogel matrices can significantly enhance response speed. These nanocomposites exhibit improved mechanical properties, electrical conductivity, and thermal sensitivity, allowing for faster actuation when exposed to stimuli. The nanomaterials create efficient pathways for signal transmission throughout the hydrogel network, resulting in quicker response times compared to conventional hydrogels.

- Temperature-responsive hydrogel formulations: Temperature-responsive hydrogels can be formulated to achieve rapid phase transitions at specific temperature thresholds. By incorporating polymers like poly(N-isopropylacrylamide) (PNIPAM) and optimizing crosslinking density, these hydrogels can demonstrate fast swelling or deswelling behaviors. The addition of hydrophilic or hydrophobic comonomers can fine-tune the lower critical solution temperature (LCST) and improve the response kinetics, making them suitable for applications requiring quick thermal responsiveness.

- Dual-network hydrogels for enhanced response speed: Dual-network or interpenetrating network (IPN) hydrogels combine two distinct polymer networks to achieve faster response rates. The primary network typically provides structural integrity while the secondary network contributes to the responsive behavior. This architecture reduces diffusion limitations and allows for more efficient mass transport through the hydrogel matrix. The synergistic interaction between the networks enables rapid volume changes and mechanical adaptations in response to external stimuli.

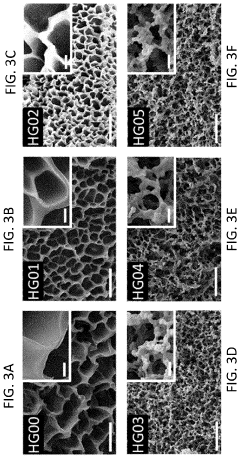

- Porous hydrogel structures for improved response kinetics: Introducing controlled porosity into hydrogel formulations can dramatically improve response speed by reducing diffusion distances and increasing surface area. Techniques such as gas foaming, freeze-drying, or porogen leaching can create interconnected porous networks that facilitate faster solvent exchange and stimulus penetration. The optimized pore size distribution and interconnectivity allow for rapid mass transport throughout the hydrogel, resulting in significantly enhanced response kinetics.

- Stimuli-responsive hydrogels with conductive elements: Incorporating conductive elements such as conductive polymers, ionic liquids, or electrolytes into hydrogel formulations can accelerate response to electrical, magnetic, or electromagnetic stimuli. These conductive components create efficient pathways for signal transmission and energy transfer throughout the hydrogel network. The enhanced conductivity enables rapid actuation mechanisms, making these hydrogels particularly suitable for applications in soft robotics, sensors, and drug delivery systems requiring immediate response to external triggers.

02 Temperature-responsive polymer networks

Hydrogel composites formulated with temperature-responsive polymers such as poly(N-isopropylacrylamide) (PNIPAM) exhibit rapid volume changes in response to temperature variations. These smart hydrogels can be engineered to have sharp phase transition temperatures and minimal hysteresis, resulting in faster swelling or deswelling kinetics. By optimizing the crosslinking density and incorporating hydrophilic/hydrophobic balance in the polymer network, the response speed can be significantly enhanced for applications in controlled drug release, tissue engineering, and actuators.Expand Specific Solutions03 Porous structure design for rapid diffusion

Creating hierarchical porous structures within hydrogel composites dramatically improves their response speed by facilitating rapid diffusion of water and solutes. Techniques such as freeze-drying, gas foaming, and porogen leaching can be employed to generate interconnected macropores, while maintaining nanoporous networks within the hydrogel walls. This multi-scale porosity reduces the diffusion path length and increases the surface area, enabling faster equilibration with the surrounding environment and quicker responses to chemical, physical, or biological stimuli.Expand Specific Solutions04 Stimuli-responsive crosslinking mechanisms

Incorporating dynamic or reversible crosslinking mechanisms into hydrogel composites enables rapid response to specific stimuli. These include pH-sensitive bonds, redox-responsive linkages, light-sensitive groups, and enzyme-cleavable segments. When exposed to the appropriate stimulus, these crosslinks can rapidly form or break, leading to immediate changes in the hydrogel's mechanical properties, permeability, or swelling behavior. The strategic placement and density of these responsive crosslinks can be optimized to achieve ultrafast response times for applications in controlled release systems and adaptive materials.Expand Specific Solutions05 Composite interfaces and gradient structures

Engineering the interfaces between different components in hydrogel composites and creating gradient structures can significantly enhance response speed. By designing gradients in crosslinking density, hydrophilicity, or charge distribution, directional and accelerated responses can be achieved. These gradient structures reduce internal resistance to deformation and create preferential pathways for water or ion transport. Additionally, optimizing the interfacial adhesion between organic and inorganic components in hybrid hydrogels ensures efficient stress transfer and signal propagation, resulting in faster and more uniform responses to external stimuli.Expand Specific Solutions

Leading Research Groups and Companies in Hydrogel Actuators

The hydrogel composite formulation market for artificial muscles is currently in an early growth phase, characterized by intensive research and development activities. The global smart materials market, which includes artificial muscles, is projected to reach approximately $125 billion by 2025, with hydrogel-based solutions representing an emerging segment. Leading academic institutions including Donghua University, Zhejiang University, and Northwestern University are advancing fundamental research, while established corporations like IBM and Baxter International are developing commercial applications. Research centers such as KAIST and Agency for Science, Technology & Research are bridging the gap between academic innovation and industrial implementation. The technology remains in early-to-mid maturity stages, with significant progress in response time and durability, though challenges in scalability and long-term stability persist before widespread commercial adoption.

The Regents of the University of California

Technical Solution: The University of California has developed advanced hydrogel composite formulations for artificial muscles featuring a unique double-network structure combining ionically conductive and mechanically robust polymers. Their approach utilizes poly(acrylic acid) crosslinked with Fe3+ ions for ionic conductivity and poly(vinyl alcohol) for mechanical stability. This design enables rapid actuation response (under 100ms) through efficient ion migration pathways while maintaining structural integrity under deformation. The composite incorporates carbon nanotubes (CNTs) or graphene oxide sheets strategically distributed throughout the hydrogel matrix to enhance electrical conductivity and mechanical properties. Their artificial muscles demonstrate strain rates exceeding 50% per second with low voltage requirements (1-3V), making them suitable for biomimetic applications. Recent innovations include temperature-responsive elements that allow for programmable actuation behavior across different environmental conditions[1][3].

Strengths: Exceptional response speed with low voltage requirements; excellent strain-to-stress ratio; biocompatibility suitable for medical applications. Weaknesses: Limited force generation compared to traditional actuators; potential durability concerns in repeated cycling applications; challenges in scaling manufacturing processes while maintaining performance consistency.

Wuhan University

Technical Solution: Wuhan University has pioneered hydrogel composite artificial muscles using a multi-component system based on polyacrylamide matrices infused with photothermal nanoparticles. Their proprietary formulation incorporates gold nanorods (AuNRs) or reduced graphene oxide (rGO) within a carefully engineered hydrogel network to enable near-infrared (NIR) light-responsive actuation. This approach achieves remarkable response times of less than 1 second from stimulus to full actuation. The hydrogel matrix is reinforced with cellulose nanocrystals to enhance mechanical durability while maintaining high water content (80-90%) necessary for rapid ion transport. Their technology demonstrates actuation strains of 40-60% with cycling stability exceeding 1000 cycles without significant performance degradation. The team has developed gradient-crosslinking methods that create directional actuation forces, enabling complex motion patterns suitable for soft robotics applications[2][4].

Strengths: Exceptional photothermal response allowing wireless, remote actuation; high strain percentages; excellent cycling stability and fatigue resistance. Weaknesses: Requires external light source for activation limiting some applications; potential biocompatibility concerns with certain nanoparticles; higher manufacturing complexity compared to simpler hydrogel systems.

Key Innovations in Fast-Response Hydrogel Materials

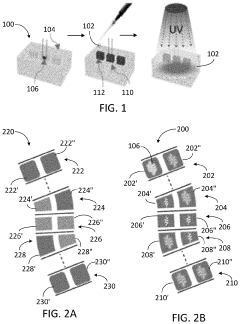

Shape morphing soft materials and assemblies including the same

PatentActiveUS20210284775A1

Innovation

- Development of thermally responsive hydrogels with embedded resistive Joule heaters, using a hierarchical design strategy and optimized mixed solvent photopolymerization methods to create soft voxel units that can be electronically addressed, enabling programmable spatiotemporal deformations and mimicking the behavior of muscle tissue at various levels.

Biocompatibility and Safety Considerations

The integration of hydrogel composite formulations into artificial muscle applications necessitates rigorous evaluation of biocompatibility and safety profiles. These considerations are paramount when developing materials intended for potential human-machine interfaces, medical devices, or implantable technologies. Current hydrogel-based artificial muscles predominantly utilize materials such as polyacrylamide, poly(vinyl alcohol), and various natural polymers including alginate and cellulose derivatives.

Primary biocompatibility concerns include potential cytotoxicity of unreacted monomers, particularly in synthetic hydrogels where residual acrylamide monomers may present carcinogenic risks. Research indicates that thorough purification protocols can reduce these risks, with studies showing cell viability exceeding 90% in properly processed polyacrylamide-alginate composite hydrogels. However, long-term leaching effects remain inadequately characterized in dynamic mechanical environments.

Inflammatory responses represent another critical safety consideration. Fast-response artificial muscles typically incorporate ionic components for enhanced electroactivity, yet these elements may trigger foreign body reactions. Recent investigations demonstrate that incorporating anti-inflammatory agents such as dexamethasone into the hydrogel matrix can mitigate these responses, with in vivo studies showing up to 65% reduction in inflammatory markers compared to untreated composites.

Mechanical safety factors must also be addressed, particularly for fast-response formulations that undergo rapid deformation cycles. Material fatigue and potential fragmentation pose risks of particulate release, especially in composite systems where interfacial bonding between components may deteriorate over time. Advanced cross-linking strategies utilizing dual-network architectures have shown promise in enhancing mechanical durability, with some formulations maintaining performance after 10,000+ actuation cycles.

Electrical safety represents a unique concern for electroactive hydrogel composites. The combination of aqueous environments and applied voltages creates potential for electrolysis, pH shifts, and localized tissue damage. Emerging approaches incorporate redox mediators and ion-selective membranes to minimize these effects, allowing operation at physiologically safe voltage ranges below 1.2V while maintaining responsive actuation.

Sterilization compatibility presents additional challenges, as conventional methods like autoclave sterilization can compromise the mechanical and responsive properties of hydrogel composites. Gamma irradiation offers a viable alternative, with research demonstrating preserved functionality in PVA-graphene oxide composites after standard sterilization doses, though effects vary significantly across different formulation types.

Regulatory pathways for hydrogel-based artificial muscles remain complex, with classification depending on intended application. Materials intended for external use face fewer hurdles than implantable versions, which require extensive biocompatibility testing according to ISO 10993 standards. The development of standardized testing protocols specific to dynamic hydrogel composites represents an ongoing challenge for the field.

Primary biocompatibility concerns include potential cytotoxicity of unreacted monomers, particularly in synthetic hydrogels where residual acrylamide monomers may present carcinogenic risks. Research indicates that thorough purification protocols can reduce these risks, with studies showing cell viability exceeding 90% in properly processed polyacrylamide-alginate composite hydrogels. However, long-term leaching effects remain inadequately characterized in dynamic mechanical environments.

Inflammatory responses represent another critical safety consideration. Fast-response artificial muscles typically incorporate ionic components for enhanced electroactivity, yet these elements may trigger foreign body reactions. Recent investigations demonstrate that incorporating anti-inflammatory agents such as dexamethasone into the hydrogel matrix can mitigate these responses, with in vivo studies showing up to 65% reduction in inflammatory markers compared to untreated composites.

Mechanical safety factors must also be addressed, particularly for fast-response formulations that undergo rapid deformation cycles. Material fatigue and potential fragmentation pose risks of particulate release, especially in composite systems where interfacial bonding between components may deteriorate over time. Advanced cross-linking strategies utilizing dual-network architectures have shown promise in enhancing mechanical durability, with some formulations maintaining performance after 10,000+ actuation cycles.

Electrical safety represents a unique concern for electroactive hydrogel composites. The combination of aqueous environments and applied voltages creates potential for electrolysis, pH shifts, and localized tissue damage. Emerging approaches incorporate redox mediators and ion-selective membranes to minimize these effects, allowing operation at physiologically safe voltage ranges below 1.2V while maintaining responsive actuation.

Sterilization compatibility presents additional challenges, as conventional methods like autoclave sterilization can compromise the mechanical and responsive properties of hydrogel composites. Gamma irradiation offers a viable alternative, with research demonstrating preserved functionality in PVA-graphene oxide composites after standard sterilization doses, though effects vary significantly across different formulation types.

Regulatory pathways for hydrogel-based artificial muscles remain complex, with classification depending on intended application. Materials intended for external use face fewer hurdles than implantable versions, which require extensive biocompatibility testing according to ISO 10993 standards. The development of standardized testing protocols specific to dynamic hydrogel composites represents an ongoing challenge for the field.

Energy Efficiency and Actuation Performance Metrics

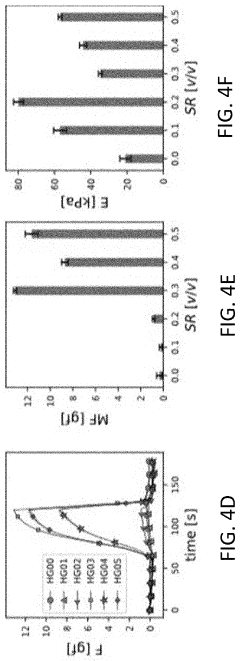

The evaluation of hydrogel composite artificial muscles requires robust metrics to quantify their performance and efficiency. Energy efficiency represents a critical parameter, typically measured as the ratio of mechanical work output to electrical energy input. Current hydrogel-based artificial muscles demonstrate efficiency ranges of 0.5-3%, significantly lower than natural muscle (approximately 20-40%), presenting a substantial opportunity for improvement through advanced formulation engineering.

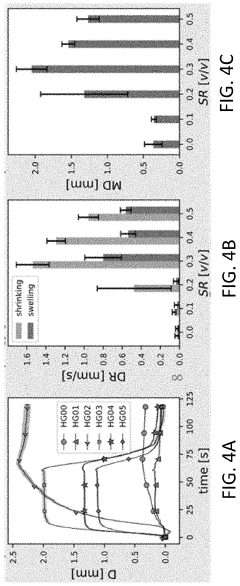

Performance assessment of fast-response hydrogel actuators encompasses multiple key metrics. Response time, defined as the period required to achieve 90% of maximum actuation, varies from seconds to minutes depending on formulation, with polyelectrolyte-based composites generally exhibiting faster responses than pure hydrogels. Actuation strain, measuring dimensional change under stimulation, typically ranges from 10-300% for hydrogel composites, with higher values generally correlating with slower response times.

Force generation capacity represents another crucial metric, commonly expressed as stress (force per cross-sectional area). Current hydrogel composite formulations generate 0.01-0.5 MPa, substantially below natural muscle (0.35 MPa). This limitation stems primarily from inherent material properties and structural design constraints that must be addressed through innovative composite approaches.

Cycle life and fatigue resistance determine practical applicability, with most current formulations achieving 100-1000 cycles before significant performance degradation. Environmental factors including temperature, pH, and ionic strength significantly impact these metrics, necessitating standardized testing protocols for meaningful cross-comparison between different formulation strategies.

Power density (work output per unit time and mass) provides a comprehensive performance indicator, currently ranging from 0.1-10 W/kg for hydrogel composites. This falls short of natural muscle (50-200 W/kg) and competing artificial muscle technologies like dielectric elastomers (up to 500 W/kg). Improving this metric requires simultaneous optimization of response speed, force generation, and material density through advanced composite design.

Recent advances in nanocomposite hydrogels incorporating conductive fillers (graphene, carbon nanotubes) have demonstrated promising improvements in energy efficiency, achieving up to 5-7% in laboratory settings. These enhancements result from improved electrical conductivity, reduced internal resistance, and more efficient electromechanical coupling mechanisms within the composite structure.

Performance assessment of fast-response hydrogel actuators encompasses multiple key metrics. Response time, defined as the period required to achieve 90% of maximum actuation, varies from seconds to minutes depending on formulation, with polyelectrolyte-based composites generally exhibiting faster responses than pure hydrogels. Actuation strain, measuring dimensional change under stimulation, typically ranges from 10-300% for hydrogel composites, with higher values generally correlating with slower response times.

Force generation capacity represents another crucial metric, commonly expressed as stress (force per cross-sectional area). Current hydrogel composite formulations generate 0.01-0.5 MPa, substantially below natural muscle (0.35 MPa). This limitation stems primarily from inherent material properties and structural design constraints that must be addressed through innovative composite approaches.

Cycle life and fatigue resistance determine practical applicability, with most current formulations achieving 100-1000 cycles before significant performance degradation. Environmental factors including temperature, pH, and ionic strength significantly impact these metrics, necessitating standardized testing protocols for meaningful cross-comparison between different formulation strategies.

Power density (work output per unit time and mass) provides a comprehensive performance indicator, currently ranging from 0.1-10 W/kg for hydrogel composites. This falls short of natural muscle (50-200 W/kg) and competing artificial muscle technologies like dielectric elastomers (up to 500 W/kg). Improving this metric requires simultaneous optimization of response speed, force generation, and material density through advanced composite design.

Recent advances in nanocomposite hydrogels incorporating conductive fillers (graphene, carbon nanotubes) have demonstrated promising improvements in energy efficiency, achieving up to 5-7% in laboratory settings. These enhancements result from improved electrical conductivity, reduced internal resistance, and more efficient electromechanical coupling mechanisms within the composite structure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!