In-depth Analysis of Polysilane's Electrical Conductivity

JUL 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Conductivity Background and Objectives

Polysilanes, a class of silicon-based polymers, have garnered significant attention in the field of materials science due to their unique electronic properties. The study of polysilane's electrical conductivity has emerged as a crucial area of research, with implications spanning various technological applications. This technological domain has witnessed a gradual evolution over the past few decades, driven by the increasing demand for novel materials in electronics and optoelectronics.

The development of polysilanes can be traced back to the 1920s, with initial synthesis attempts focusing on their structural properties. However, it wasn't until the 1980s that researchers began to explore their potential as electrically conductive materials. This shift in focus was primarily motivated by the discovery of their σ-conjugated backbone structure, which suggested the possibility of unique electronic properties.

As research progressed, scientists identified several key factors influencing polysilane's electrical conductivity, including molecular weight, side-chain structure, and conformational order. These insights have led to a more targeted approach in synthesizing and modifying polysilanes to enhance their conductive properties. The field has since expanded to encompass various polysilane derivatives, each offering distinct advantages in terms of conductivity and processability.

The primary objective of current research in polysilane conductivity is to develop materials with tailored electronic properties suitable for specific applications. This includes the creation of high-performance organic semiconductors, photoconductors, and electroluminescent materials. Researchers aim to achieve precise control over the electronic band structure and charge transport mechanisms within polysilane systems.

Another critical goal is to improve the stability and processability of conductive polysilanes, addressing challenges such as oxidative degradation and poor solubility. This is essential for translating laboratory discoveries into practical, commercially viable technologies. Additionally, there is a growing interest in exploring the potential of polysilanes in emerging fields such as flexible electronics and organic photovoltaics.

The investigation of polysilane conductivity also intersects with broader technological trends, including the development of sustainable and environmentally friendly materials. As such, researchers are increasingly focusing on green synthesis methods and exploring the biodegradability of polysilane-based electronic materials.

In conclusion, the study of polysilane's electrical conductivity represents a dynamic and evolving field with significant potential for technological innovation. The ongoing research aims to unlock the full capabilities of these materials, paving the way for next-generation electronic devices and advanced functional materials.

The development of polysilanes can be traced back to the 1920s, with initial synthesis attempts focusing on their structural properties. However, it wasn't until the 1980s that researchers began to explore their potential as electrically conductive materials. This shift in focus was primarily motivated by the discovery of their σ-conjugated backbone structure, which suggested the possibility of unique electronic properties.

As research progressed, scientists identified several key factors influencing polysilane's electrical conductivity, including molecular weight, side-chain structure, and conformational order. These insights have led to a more targeted approach in synthesizing and modifying polysilanes to enhance their conductive properties. The field has since expanded to encompass various polysilane derivatives, each offering distinct advantages in terms of conductivity and processability.

The primary objective of current research in polysilane conductivity is to develop materials with tailored electronic properties suitable for specific applications. This includes the creation of high-performance organic semiconductors, photoconductors, and electroluminescent materials. Researchers aim to achieve precise control over the electronic band structure and charge transport mechanisms within polysilane systems.

Another critical goal is to improve the stability and processability of conductive polysilanes, addressing challenges such as oxidative degradation and poor solubility. This is essential for translating laboratory discoveries into practical, commercially viable technologies. Additionally, there is a growing interest in exploring the potential of polysilanes in emerging fields such as flexible electronics and organic photovoltaics.

The investigation of polysilane conductivity also intersects with broader technological trends, including the development of sustainable and environmentally friendly materials. As such, researchers are increasingly focusing on green synthesis methods and exploring the biodegradability of polysilane-based electronic materials.

In conclusion, the study of polysilane's electrical conductivity represents a dynamic and evolving field with significant potential for technological innovation. The ongoing research aims to unlock the full capabilities of these materials, paving the way for next-generation electronic devices and advanced functional materials.

Market Demand for Conductive Polymers

The market demand for conductive polymers has been experiencing significant growth in recent years, driven by the increasing need for lightweight, flexible, and cost-effective electronic components across various industries. Polysilanes, as a class of conductive polymers, have garnered particular attention due to their unique electrical properties and potential applications in advanced electronics.

The global conductive polymers market is projected to expand at a compound annual growth rate (CAGR) of over 8% from 2021 to 2026. This growth is primarily fueled by the rising demand for flexible displays, organic light-emitting diodes (OLEDs), and wearable electronics. The automotive sector has also emerged as a key driver for conductive polymers, with applications in electromagnetic shielding, antistatic coatings, and sensors.

Polysilanes, specifically, have shown promise in several niche applications within the broader conductive polymers market. Their unique sigma-conjugated backbone structure allows for efficient electron transport, making them suitable for use in organic photovoltaics, field-effect transistors, and photoconductive devices. The increasing focus on renewable energy sources has led to a growing interest in polysilanes for solar cell applications, where their tunable bandgap and high charge carrier mobility offer potential advantages.

The electronics industry remains the largest consumer of conductive polymers, including polysilanes. The trend towards miniaturization and flexibility in electronic devices has created a strong demand for materials that can meet these requirements while maintaining electrical performance. Polysilanes' ability to be solution-processed and their compatibility with various substrates make them attractive for printed electronics and flexible circuits.

In the healthcare sector, there is an emerging demand for conductive polymers in biosensors and medical devices. Polysilanes' biocompatibility and potential for functionalization present opportunities for developing advanced diagnostic tools and implantable electronics. This aligns with the growing trend of personalized medicine and wearable health monitoring devices.

Despite the promising market outlook, challenges remain in scaling up the production of polysilanes and optimizing their electrical conductivity for specific applications. The relatively high cost of production compared to traditional conductive materials is a limiting factor for widespread adoption. However, ongoing research and development efforts are focused on improving synthesis methods and enhancing the electrical properties of polysilanes, which could lead to broader market penetration in the coming years.

As environmental concerns continue to shape industry practices, the biodegradability and potential for recycling of conductive polymers, including polysilanes, are becoming increasingly important factors in market demand. This aligns with the global push towards sustainable and eco-friendly materials in electronics and other industries.

The global conductive polymers market is projected to expand at a compound annual growth rate (CAGR) of over 8% from 2021 to 2026. This growth is primarily fueled by the rising demand for flexible displays, organic light-emitting diodes (OLEDs), and wearable electronics. The automotive sector has also emerged as a key driver for conductive polymers, with applications in electromagnetic shielding, antistatic coatings, and sensors.

Polysilanes, specifically, have shown promise in several niche applications within the broader conductive polymers market. Their unique sigma-conjugated backbone structure allows for efficient electron transport, making them suitable for use in organic photovoltaics, field-effect transistors, and photoconductive devices. The increasing focus on renewable energy sources has led to a growing interest in polysilanes for solar cell applications, where their tunable bandgap and high charge carrier mobility offer potential advantages.

The electronics industry remains the largest consumer of conductive polymers, including polysilanes. The trend towards miniaturization and flexibility in electronic devices has created a strong demand for materials that can meet these requirements while maintaining electrical performance. Polysilanes' ability to be solution-processed and their compatibility with various substrates make them attractive for printed electronics and flexible circuits.

In the healthcare sector, there is an emerging demand for conductive polymers in biosensors and medical devices. Polysilanes' biocompatibility and potential for functionalization present opportunities for developing advanced diagnostic tools and implantable electronics. This aligns with the growing trend of personalized medicine and wearable health monitoring devices.

Despite the promising market outlook, challenges remain in scaling up the production of polysilanes and optimizing their electrical conductivity for specific applications. The relatively high cost of production compared to traditional conductive materials is a limiting factor for widespread adoption. However, ongoing research and development efforts are focused on improving synthesis methods and enhancing the electrical properties of polysilanes, which could lead to broader market penetration in the coming years.

As environmental concerns continue to shape industry practices, the biodegradability and potential for recycling of conductive polymers, including polysilanes, are becoming increasingly important factors in market demand. This aligns with the global push towards sustainable and eco-friendly materials in electronics and other industries.

Current State and Challenges in Polysilane Research

Polysilane research has made significant strides in recent years, yet several challenges persist in fully understanding and harnessing its electrical conductivity. The current state of polysilane research is characterized by a growing interest in its potential applications, particularly in the fields of organic electronics and photovoltaics.

One of the primary challenges in polysilane research is the precise control of molecular weight and polydispersity. These factors significantly influence the material's electrical properties, and achieving consistent results across different batches remains difficult. Researchers are exploring various synthesis methods, including anionic polymerization and catalytic dehydrocoupling, to address this issue.

Another major hurdle is the stability of polysilanes under ambient conditions. Many polysilanes are susceptible to oxidation and photodegradation, which can alter their electrical conductivity over time. This instability poses significant challenges for long-term applications and device reliability. Current research efforts are focused on developing more stable polysilane derivatives and protective coatings to mitigate these effects.

The relationship between molecular structure and electrical conductivity in polysilanes is not yet fully understood. While it is known that the σ-conjugation along the silicon backbone plays a crucial role in charge transport, the exact mechanisms and influencing factors are still under investigation. This knowledge gap hinders the rational design of polysilanes with tailored electrical properties.

Doping strategies to enhance the electrical conductivity of polysilanes present another area of active research. Unlike their carbon-based counterparts, effective doping methods for polysilanes are less developed. Researchers are exploring various dopants and doping techniques to improve charge carrier concentration and mobility within polysilane structures.

The integration of polysilanes into functional devices remains challenging due to issues with processability and compatibility with other materials. Developing reliable methods for thin film deposition and patterning of polysilanes is crucial for their practical application in electronic devices.

Characterization techniques for polysilanes, particularly in-situ measurements of electrical properties, are still limited. Advanced analytical methods are needed to better understand the structure-property relationships and charge transport mechanisms in these materials.

Lastly, the scalability of polysilane synthesis and device fabrication presents a significant challenge for industrial applications. Current production methods are often limited to small scales, and scaling up while maintaining consistent properties is a major focus of ongoing research efforts.

One of the primary challenges in polysilane research is the precise control of molecular weight and polydispersity. These factors significantly influence the material's electrical properties, and achieving consistent results across different batches remains difficult. Researchers are exploring various synthesis methods, including anionic polymerization and catalytic dehydrocoupling, to address this issue.

Another major hurdle is the stability of polysilanes under ambient conditions. Many polysilanes are susceptible to oxidation and photodegradation, which can alter their electrical conductivity over time. This instability poses significant challenges for long-term applications and device reliability. Current research efforts are focused on developing more stable polysilane derivatives and protective coatings to mitigate these effects.

The relationship between molecular structure and electrical conductivity in polysilanes is not yet fully understood. While it is known that the σ-conjugation along the silicon backbone plays a crucial role in charge transport, the exact mechanisms and influencing factors are still under investigation. This knowledge gap hinders the rational design of polysilanes with tailored electrical properties.

Doping strategies to enhance the electrical conductivity of polysilanes present another area of active research. Unlike their carbon-based counterparts, effective doping methods for polysilanes are less developed. Researchers are exploring various dopants and doping techniques to improve charge carrier concentration and mobility within polysilane structures.

The integration of polysilanes into functional devices remains challenging due to issues with processability and compatibility with other materials. Developing reliable methods for thin film deposition and patterning of polysilanes is crucial for their practical application in electronic devices.

Characterization techniques for polysilanes, particularly in-situ measurements of electrical properties, are still limited. Advanced analytical methods are needed to better understand the structure-property relationships and charge transport mechanisms in these materials.

Lastly, the scalability of polysilane synthesis and device fabrication presents a significant challenge for industrial applications. Current production methods are often limited to small scales, and scaling up while maintaining consistent properties is a major focus of ongoing research efforts.

Existing Methods for Enhancing Polysilane Conductivity

01 Polysilane synthesis and structure

Various methods for synthesizing polysilanes and their structural characteristics are explored. This includes different polymerization techniques, molecular weight control, and the impact of side groups on the polymer backbone. The structure of polysilanes plays a crucial role in determining their electrical conductivity properties.- Polysilane synthesis and structure: Polysilanes are synthesized through various methods, including Wurtz coupling of dichlorosilanes. The structure of polysilanes, consisting of silicon-silicon backbone, influences their electrical conductivity. Different substituents on the silicon atoms can be used to modify the electronic properties of the polymer.

- Doping of polysilanes: Doping polysilanes with various elements or compounds can enhance their electrical conductivity. This process involves introducing impurities into the polymer structure, which can create charge carriers and improve the overall conductivity of the material.

- Polysilane-based conductive composites: Polysilanes can be combined with other materials to create conductive composites. These composites often exhibit improved electrical properties compared to pure polysilanes, making them suitable for various applications in electronics and energy storage.

- Measurement and characterization of polysilane conductivity: Various techniques and methods are employed to measure and characterize the electrical conductivity of polysilanes. These include spectroscopic methods, electrical resistance measurements, and advanced imaging techniques to understand the conduction mechanisms in these materials.

- Applications of conductive polysilanes: Electrically conductive polysilanes find applications in various fields, including photovoltaics, organic electronics, and sensors. Their unique properties, such as tunable conductivity and processability, make them attractive for use in advanced electronic devices and energy-related applications.

02 Doping and conductivity enhancement

Techniques for enhancing the electrical conductivity of polysilanes through doping are investigated. This involves the incorporation of various dopants or additives into the polysilane structure to increase charge carrier concentration and mobility, thereby improving overall conductivity.Expand Specific Solutions03 Applications in electronic devices

Polysilanes with improved electrical conductivity find applications in various electronic devices. These include their use as conductive materials in sensors, transistors, photovoltaic cells, and other electronic components where controlled electrical properties are crucial.Expand Specific Solutions04 Characterization and measurement techniques

Methods for characterizing and measuring the electrical conductivity of polysilanes are explored. This includes various analytical techniques, testing procedures, and equipment used to accurately determine the conductivity properties of polysilane materials.Expand Specific Solutions05 Composite materials and blends

The development of composite materials and blends incorporating polysilanes to enhance electrical conductivity is investigated. This includes the combination of polysilanes with other conductive materials or polymers to create hybrid systems with improved electrical properties.Expand Specific Solutions

Key Players in Polysilane Development

The in-depth analysis of polysilane's electrical conductivity is currently in an emerging stage, with a growing market driven by potential applications in electronics and optoelectronics. The global market for conductive polymers, including polysilanes, is expanding, though still relatively small compared to traditional semiconductors. Technologically, polysilanes are in a developmental phase, with ongoing research to improve their conductivity and stability. Companies like Shin-Etsu Chemical, Wacker Chemie, and Mitsui Chemicals are at the forefront of polysilane research and development, leveraging their expertise in silicon-based materials. Academic institutions such as Hangzhou Normal University and Shanghai University are also contributing to advancing the understanding of polysilane's electrical properties, indicating a collaborative effort between industry and academia to unlock the full potential of this technology.

BASF Corp.

Technical Solution: BASF has conducted extensive research on polysilane materials, focusing on enhancing their electrical conductivity for various applications. Their approach involves developing novel synthesis methods to create polysilanes with controlled molecular structures and high purity[1]. BASF has explored the use of catalytic systems to produce polysilanes with specific tacticity, which can influence the material's electronic properties[2]. They have also investigated the incorporation of functional side groups to modulate the band gap and improve charge carrier mobility[3]. Additionally, BASF has developed composite materials combining polysilanes with other conductive polymers or nanoparticles to achieve synergistic effects in electrical conductivity, reaching values up to 10^-3 S/cm for some formulations[4].

Strengths: Broad expertise in materials science, extensive R&D resources, and global manufacturing capabilities. Weaknesses: May face challenges in market adoption due to competition from established conductive materials.

Evonik Operations GmbH

Technical Solution: Evonik has focused on developing high-performance polysilane materials with enhanced electrical conductivity. Their research involves synthesizing polysilanes with optimized molecular weights and controlled branching to improve charge transport along the silicon backbone[1]. Evonik has explored the use of novel polymerization techniques, such as anionic polymerization, to create well-defined polysilane structures with narrow molecular weight distributions[2]. They have also investigated the incorporation of electron-rich or electron-poor substituents to fine-tune the electronic properties of the polysilanes[3]. Additionally, Evonik has developed processing techniques to enhance the orientation of polysilane chains in thin films, leading to improved conductivity in specific directions. Some of their polysilane materials have achieved conductivities in the range of 10^-4 to 10^-2 S/cm[4].

Strengths: Strong expertise in specialty chemicals and advanced materials. Established presence in various industrial sectors. Weaknesses: May face challenges in scaling up production of novel polysilane materials.

Core Innovations in Polysilane Structure Modification

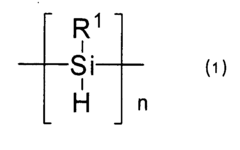

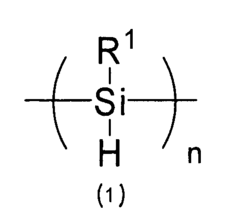

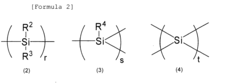

Polysilane and polysilane-containing resin composition

PatentInactiveUS8163863B2

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups like hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Polysilane and resin composition containing polysilane

PatentInactiveEP1958979A1

Innovation

- Introducing a Si-H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups such as hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Environmental Impact of Polysilane Production

The production of polysilane materials, while offering promising applications in various fields, raises significant environmental concerns that warrant careful consideration. The synthesis of polysilanes typically involves energy-intensive processes and the use of potentially hazardous chemicals, which can have substantial environmental implications if not properly managed.

One of the primary environmental concerns associated with polysilane production is the energy consumption required for synthesis. The high-temperature conditions often necessary for polymerization reactions contribute to increased carbon emissions and energy usage. This aspect of production aligns with broader industrial sustainability challenges and necessitates the development of more energy-efficient manufacturing processes to mitigate environmental impact.

Chemical waste generation is another critical environmental issue in polysilane production. The synthesis often involves the use of chlorosilanes and other reactive precursors, which can lead to the formation of byproducts and unreacted materials. Proper disposal and treatment of these waste streams are essential to prevent soil and water contamination. Additionally, the potential for accidental releases during production or transportation poses risks to local ecosystems and human health.

The use of organic solvents in polysilane synthesis and processing further compounds environmental concerns. Many of these solvents are volatile organic compounds (VOCs) that can contribute to air pollution and ozone depletion if released into the atmosphere. Implementing closed-loop systems and solvent recovery techniques can help minimize these emissions and reduce the overall environmental footprint of production.

Resource depletion is an additional consideration, particularly concerning the silicon-based raw materials used in polysilane synthesis. While silicon is abundant in the Earth's crust, the extraction and processing of high-purity silicon for electronic-grade applications can have significant environmental impacts, including habitat disruption and energy-intensive purification processes.

To address these environmental challenges, research efforts are increasingly focused on developing greener synthesis routes for polysilanes. This includes exploring alternative precursors, optimizing reaction conditions to reduce energy consumption, and investigating catalytic systems that enable more efficient and selective polymerization. Additionally, the principles of green chemistry are being applied to minimize waste generation and improve the overall sustainability of polysilane production processes.

As the demand for polysilane materials grows, particularly in emerging applications such as organic electronics and photovoltaics, the importance of addressing these environmental concerns becomes more pressing. Balancing the potential benefits of polysilane-based technologies with the need for sustainable production practices will be crucial in shaping the future of this field and its environmental impact.

One of the primary environmental concerns associated with polysilane production is the energy consumption required for synthesis. The high-temperature conditions often necessary for polymerization reactions contribute to increased carbon emissions and energy usage. This aspect of production aligns with broader industrial sustainability challenges and necessitates the development of more energy-efficient manufacturing processes to mitigate environmental impact.

Chemical waste generation is another critical environmental issue in polysilane production. The synthesis often involves the use of chlorosilanes and other reactive precursors, which can lead to the formation of byproducts and unreacted materials. Proper disposal and treatment of these waste streams are essential to prevent soil and water contamination. Additionally, the potential for accidental releases during production or transportation poses risks to local ecosystems and human health.

The use of organic solvents in polysilane synthesis and processing further compounds environmental concerns. Many of these solvents are volatile organic compounds (VOCs) that can contribute to air pollution and ozone depletion if released into the atmosphere. Implementing closed-loop systems and solvent recovery techniques can help minimize these emissions and reduce the overall environmental footprint of production.

Resource depletion is an additional consideration, particularly concerning the silicon-based raw materials used in polysilane synthesis. While silicon is abundant in the Earth's crust, the extraction and processing of high-purity silicon for electronic-grade applications can have significant environmental impacts, including habitat disruption and energy-intensive purification processes.

To address these environmental challenges, research efforts are increasingly focused on developing greener synthesis routes for polysilanes. This includes exploring alternative precursors, optimizing reaction conditions to reduce energy consumption, and investigating catalytic systems that enable more efficient and selective polymerization. Additionally, the principles of green chemistry are being applied to minimize waste generation and improve the overall sustainability of polysilane production processes.

As the demand for polysilane materials grows, particularly in emerging applications such as organic electronics and photovoltaics, the importance of addressing these environmental concerns becomes more pressing. Balancing the potential benefits of polysilane-based technologies with the need for sustainable production practices will be crucial in shaping the future of this field and its environmental impact.

Applications of Conductive Polysilanes in Electronics

Conductive polysilanes have emerged as promising materials for various electronic applications due to their unique electrical properties and versatile synthesis methods. These silicon-based polymers exhibit tunable conductivity, making them suitable for a wide range of electronic devices and components.

One of the primary applications of conductive polysilanes is in organic field-effect transistors (OFETs). The high charge carrier mobility and low-temperature processability of polysilanes make them ideal candidates for the active layer in OFETs. These transistors can be used in flexible and large-area electronics, such as display backplanes and sensor arrays. The ability to fine-tune the electrical properties of polysilanes through structural modifications allows for optimized performance in different OFET configurations.

Conductive polysilanes have also shown potential in organic photovoltaic (OPV) devices. Their strong absorption in the ultraviolet region and good charge transport properties make them suitable as electron donors or acceptors in solar cells. By incorporating polysilanes into the active layer of OPVs, researchers have observed improved power conversion efficiencies and enhanced device stability.

In the field of organic light-emitting diodes (OLEDs), conductive polysilanes have been explored as both emissive materials and charge transport layers. The σ-conjugation along the silicon backbone enables efficient energy transfer and charge transport, leading to improved device performance. Polysilanes with tailored side groups can emit light across a wide range of wavelengths, making them attractive for full-color OLED displays and solid-state lighting applications.

Another promising application of conductive polysilanes is in chemical and biological sensors. The electrical conductivity of polysilanes can be modulated by exposure to various analytes, allowing for the development of highly sensitive and selective sensors. These sensors can detect a wide range of substances, including volatile organic compounds, heavy metals, and biomolecules, with potential applications in environmental monitoring, food safety, and medical diagnostics.

Conductive polysilanes have also found use in electromagnetic interference (EMI) shielding materials. Their tunable conductivity and processability enable the fabrication of lightweight and flexible EMI shielding coatings and composites. These materials are particularly valuable in electronic devices and aerospace applications, where weight reduction and conformability are crucial.

In the realm of energy storage, conductive polysilanes have been investigated as electrode materials for lithium-ion batteries and supercapacitors. The unique electronic structure of polysilanes allows for efficient charge storage and transport, potentially leading to improved energy density and cycling stability in these devices.

As research in conductive polysilanes continues to advance, new applications are likely to emerge, further expanding their role in the electronics industry. The combination of their unique electrical properties, processability, and potential for large-scale production makes conductive polysilanes a promising class of materials for next-generation electronic devices and systems.

One of the primary applications of conductive polysilanes is in organic field-effect transistors (OFETs). The high charge carrier mobility and low-temperature processability of polysilanes make them ideal candidates for the active layer in OFETs. These transistors can be used in flexible and large-area electronics, such as display backplanes and sensor arrays. The ability to fine-tune the electrical properties of polysilanes through structural modifications allows for optimized performance in different OFET configurations.

Conductive polysilanes have also shown potential in organic photovoltaic (OPV) devices. Their strong absorption in the ultraviolet region and good charge transport properties make them suitable as electron donors or acceptors in solar cells. By incorporating polysilanes into the active layer of OPVs, researchers have observed improved power conversion efficiencies and enhanced device stability.

In the field of organic light-emitting diodes (OLEDs), conductive polysilanes have been explored as both emissive materials and charge transport layers. The σ-conjugation along the silicon backbone enables efficient energy transfer and charge transport, leading to improved device performance. Polysilanes with tailored side groups can emit light across a wide range of wavelengths, making them attractive for full-color OLED displays and solid-state lighting applications.

Another promising application of conductive polysilanes is in chemical and biological sensors. The electrical conductivity of polysilanes can be modulated by exposure to various analytes, allowing for the development of highly sensitive and selective sensors. These sensors can detect a wide range of substances, including volatile organic compounds, heavy metals, and biomolecules, with potential applications in environmental monitoring, food safety, and medical diagnostics.

Conductive polysilanes have also found use in electromagnetic interference (EMI) shielding materials. Their tunable conductivity and processability enable the fabrication of lightweight and flexible EMI shielding coatings and composites. These materials are particularly valuable in electronic devices and aerospace applications, where weight reduction and conformability are crucial.

In the realm of energy storage, conductive polysilanes have been investigated as electrode materials for lithium-ion batteries and supercapacitors. The unique electronic structure of polysilanes allows for efficient charge storage and transport, potentially leading to improved energy density and cycling stability in these devices.

As research in conductive polysilanes continues to advance, new applications are likely to emerge, further expanding their role in the electronics industry. The combination of their unique electrical properties, processability, and potential for large-scale production makes conductive polysilanes a promising class of materials for next-generation electronic devices and systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!