Industrial Standards for Battery Acid Performance Metrics

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Evolution and Performance Goals

Battery acid, primarily composed of sulfuric acid and water, has been a crucial component in lead-acid batteries since their invention in the mid-19th century. The evolution of battery acid performance has been closely tied to the development of lead-acid batteries, which have seen significant improvements in efficiency, longevity, and safety over the years.

Initially, battery acid was used in flooded lead-acid batteries, where the liquid electrolyte was freely suspended within the battery casing. As technology progressed, valve-regulated lead-acid (VRLA) batteries were introduced, utilizing absorbed glass mat (AGM) or gel technologies to immobilize the electrolyte. This advancement reduced the risk of acid spills and improved battery performance in various applications.

The primary goals for battery acid performance have evolved to meet the increasing demands of modern energy storage systems. These goals include enhancing energy density, improving charge acceptance rates, extending cycle life, and reducing maintenance requirements. Additionally, there has been a focus on developing environmentally friendly formulations and improving safety aspects of battery acid handling and disposal.

One of the key performance metrics for battery acid is its specific gravity, which indicates the concentration of sulfuric acid in the electrolyte. Optimizing this parameter is crucial for achieving the right balance between battery capacity and longevity. Another important metric is the acid's purity, as contaminants can significantly impact battery performance and lifespan.

In recent years, there has been a growing emphasis on developing advanced electrolyte additives to enhance battery acid performance. These additives aim to reduce sulfation, minimize grid corrosion, and improve charge acceptance. Research is also being conducted on novel electrolyte compositions that could potentially replace traditional sulfuric acid-based solutions, offering improved performance characteristics and environmental benefits.

The automotive industry has been a major driver in setting performance goals for battery acid, particularly in the context of start-stop systems and hybrid electric vehicles. These applications require batteries capable of withstanding frequent charge-discharge cycles and delivering high power output, placing increased demands on the electrolyte's performance.

As the world moves towards more sustainable energy solutions, the focus on battery acid performance goals has expanded to include environmental considerations. This includes developing recyclable electrolytes, reducing the environmental impact of battery production and disposal, and improving the overall sustainability of lead-acid battery technology.

Initially, battery acid was used in flooded lead-acid batteries, where the liquid electrolyte was freely suspended within the battery casing. As technology progressed, valve-regulated lead-acid (VRLA) batteries were introduced, utilizing absorbed glass mat (AGM) or gel technologies to immobilize the electrolyte. This advancement reduced the risk of acid spills and improved battery performance in various applications.

The primary goals for battery acid performance have evolved to meet the increasing demands of modern energy storage systems. These goals include enhancing energy density, improving charge acceptance rates, extending cycle life, and reducing maintenance requirements. Additionally, there has been a focus on developing environmentally friendly formulations and improving safety aspects of battery acid handling and disposal.

One of the key performance metrics for battery acid is its specific gravity, which indicates the concentration of sulfuric acid in the electrolyte. Optimizing this parameter is crucial for achieving the right balance between battery capacity and longevity. Another important metric is the acid's purity, as contaminants can significantly impact battery performance and lifespan.

In recent years, there has been a growing emphasis on developing advanced electrolyte additives to enhance battery acid performance. These additives aim to reduce sulfation, minimize grid corrosion, and improve charge acceptance. Research is also being conducted on novel electrolyte compositions that could potentially replace traditional sulfuric acid-based solutions, offering improved performance characteristics and environmental benefits.

The automotive industry has been a major driver in setting performance goals for battery acid, particularly in the context of start-stop systems and hybrid electric vehicles. These applications require batteries capable of withstanding frequent charge-discharge cycles and delivering high power output, placing increased demands on the electrolyte's performance.

As the world moves towards more sustainable energy solutions, the focus on battery acid performance goals has expanded to include environmental considerations. This includes developing recyclable electrolytes, reducing the environmental impact of battery production and disposal, and improving the overall sustainability of lead-acid battery technology.

Market Demand Analysis for High-Performance Battery Acids

The market demand for high-performance battery acids has been steadily increasing in recent years, driven by the rapid growth of electric vehicles, renewable energy storage systems, and portable electronic devices. This surge in demand is primarily attributed to the critical role that battery acids play in enhancing the overall performance, efficiency, and lifespan of batteries.

In the automotive sector, the shift towards electric vehicles has created a significant market for advanced battery technologies. High-performance battery acids are essential for improving the power density, charging speed, and cycle life of electric vehicle batteries. As governments worldwide implement stricter emissions regulations and offer incentives for electric vehicle adoption, the demand for these specialized battery acids is expected to grow exponentially.

The renewable energy sector is another key driver of market demand for high-performance battery acids. As solar and wind power installations continue to expand globally, the need for efficient energy storage solutions has become paramount. Advanced battery acids are crucial for developing large-scale energy storage systems that can effectively store and distribute renewable energy, addressing the intermittency issues associated with these power sources.

In the consumer electronics market, the constant push for longer-lasting and faster-charging devices has led to increased demand for high-performance battery acids. Smartphones, laptops, and wearable devices require batteries that can deliver high energy density and rapid charging capabilities while maintaining safety and longevity. This has created a substantial market opportunity for innovative battery acid formulations.

The industrial sector also contributes significantly to the market demand for high-performance battery acids. Uninterruptible power supply (UPS) systems, telecommunications infrastructure, and data centers rely heavily on advanced battery technologies to ensure continuous operation and minimize downtime. The growing importance of these critical systems in the digital economy has further fueled the demand for high-quality battery acids.

Geographically, the Asia-Pacific region, particularly China, Japan, and South Korea, leads the market demand for high-performance battery acids. This is largely due to the concentration of battery manufacturing facilities and the rapid adoption of electric vehicles in these countries. North America and Europe are also experiencing substantial growth in demand, driven by increasing investments in renewable energy and electric vehicle infrastructure.

As the market for high-performance battery acids continues to expand, manufacturers are focusing on developing innovative formulations that can meet the evolving requirements of various industries. This includes improving the stability, conductivity, and environmental sustainability of battery acids while reducing costs and enhancing safety features. The ongoing research and development efforts in this field are expected to further stimulate market growth and create new opportunities for technological advancements in battery performance metrics.

In the automotive sector, the shift towards electric vehicles has created a significant market for advanced battery technologies. High-performance battery acids are essential for improving the power density, charging speed, and cycle life of electric vehicle batteries. As governments worldwide implement stricter emissions regulations and offer incentives for electric vehicle adoption, the demand for these specialized battery acids is expected to grow exponentially.

The renewable energy sector is another key driver of market demand for high-performance battery acids. As solar and wind power installations continue to expand globally, the need for efficient energy storage solutions has become paramount. Advanced battery acids are crucial for developing large-scale energy storage systems that can effectively store and distribute renewable energy, addressing the intermittency issues associated with these power sources.

In the consumer electronics market, the constant push for longer-lasting and faster-charging devices has led to increased demand for high-performance battery acids. Smartphones, laptops, and wearable devices require batteries that can deliver high energy density and rapid charging capabilities while maintaining safety and longevity. This has created a substantial market opportunity for innovative battery acid formulations.

The industrial sector also contributes significantly to the market demand for high-performance battery acids. Uninterruptible power supply (UPS) systems, telecommunications infrastructure, and data centers rely heavily on advanced battery technologies to ensure continuous operation and minimize downtime. The growing importance of these critical systems in the digital economy has further fueled the demand for high-quality battery acids.

Geographically, the Asia-Pacific region, particularly China, Japan, and South Korea, leads the market demand for high-performance battery acids. This is largely due to the concentration of battery manufacturing facilities and the rapid adoption of electric vehicles in these countries. North America and Europe are also experiencing substantial growth in demand, driven by increasing investments in renewable energy and electric vehicle infrastructure.

As the market for high-performance battery acids continues to expand, manufacturers are focusing on developing innovative formulations that can meet the evolving requirements of various industries. This includes improving the stability, conductivity, and environmental sustainability of battery acids while reducing costs and enhancing safety features. The ongoing research and development efforts in this field are expected to further stimulate market growth and create new opportunities for technological advancements in battery performance metrics.

Current Challenges in Battery Acid Technology

The battery acid technology sector faces several significant challenges that impede progress and innovation. One of the primary issues is the lack of standardization in performance metrics across the industry. This absence of unified standards makes it difficult to compare different battery acid formulations accurately, hindering effective research and development efforts.

Another critical challenge is the environmental impact of traditional battery acid compositions. As global environmental regulations become more stringent, manufacturers are under increasing pressure to develop eco-friendly alternatives that maintain or improve upon current performance levels. This necessitates a delicate balance between performance optimization and environmental sustainability.

The stability and longevity of battery acid formulations present another hurdle. Current technologies often struggle to maintain consistent performance over extended periods, especially under varying temperature and usage conditions. This instability can lead to reduced battery life and potentially hazardous situations, particularly in high-demand applications such as electric vehicles and renewable energy storage systems.

Safety concerns continue to be a significant challenge in battery acid technology. The corrosive nature of many acid formulations poses risks to both users and the environment. Developing safer alternatives that retain the necessary electrochemical properties is a complex task that requires innovative approaches and extensive testing.

The scalability of production processes for advanced battery acid formulations is another obstacle. As demand for high-performance batteries grows, particularly in emerging markets like electric vehicles and grid-scale energy storage, manufacturers must find ways to scale up production while maintaining quality and cost-effectiveness.

Recycling and disposal of spent battery acid also present ongoing challenges. Current recycling processes are often inefficient and environmentally problematic. Developing more effective, sustainable recycling methods is crucial for reducing the environmental footprint of battery technology and conserving valuable resources.

Lastly, the industry faces challenges in adapting battery acid technology to new and emerging battery chemistries. As researchers explore alternatives to traditional lead-acid batteries, such as lithium-ion and solid-state batteries, the role and composition of electrolytes must evolve. This requires significant research and development efforts to create compatible, high-performance acid formulations for these new battery types.

Another critical challenge is the environmental impact of traditional battery acid compositions. As global environmental regulations become more stringent, manufacturers are under increasing pressure to develop eco-friendly alternatives that maintain or improve upon current performance levels. This necessitates a delicate balance between performance optimization and environmental sustainability.

The stability and longevity of battery acid formulations present another hurdle. Current technologies often struggle to maintain consistent performance over extended periods, especially under varying temperature and usage conditions. This instability can lead to reduced battery life and potentially hazardous situations, particularly in high-demand applications such as electric vehicles and renewable energy storage systems.

Safety concerns continue to be a significant challenge in battery acid technology. The corrosive nature of many acid formulations poses risks to both users and the environment. Developing safer alternatives that retain the necessary electrochemical properties is a complex task that requires innovative approaches and extensive testing.

The scalability of production processes for advanced battery acid formulations is another obstacle. As demand for high-performance batteries grows, particularly in emerging markets like electric vehicles and grid-scale energy storage, manufacturers must find ways to scale up production while maintaining quality and cost-effectiveness.

Recycling and disposal of spent battery acid also present ongoing challenges. Current recycling processes are often inefficient and environmentally problematic. Developing more effective, sustainable recycling methods is crucial for reducing the environmental footprint of battery technology and conserving valuable resources.

Lastly, the industry faces challenges in adapting battery acid technology to new and emerging battery chemistries. As researchers explore alternatives to traditional lead-acid batteries, such as lithium-ion and solid-state batteries, the role and composition of electrolytes must evolve. This requires significant research and development efforts to create compatible, high-performance acid formulations for these new battery types.

Existing Battery Acid Performance Metrics

01 Battery performance monitoring and analysis

Systems and methods for monitoring and analyzing battery performance metrics, including acid levels, voltage, and capacity. These solutions involve data collection, real-time monitoring, and advanced analytics to assess battery health and predict potential issues.- Battery performance monitoring and analysis: Systems and methods for monitoring and analyzing battery performance metrics, including acid levels, voltage, and capacity. These solutions involve real-time data collection, advanced analytics, and predictive modeling to assess battery health and optimize performance.

- Battery acid quality assessment: Techniques for evaluating the quality and composition of battery acid, including density measurements, pH levels, and impurity detection. These methods help in maintaining optimal acid conditions for improved battery life and performance.

- Battery performance prediction and optimization: Advanced algorithms and machine learning techniques for predicting battery performance based on historical data and current metrics. These systems can recommend optimization strategies to enhance battery efficiency and lifespan.

- Battery acid maintenance and replenishment: Innovative approaches for maintaining proper battery acid levels and composition, including automated replenishment systems and smart sensors that detect when acid needs to be added or replaced to maintain optimal performance.

- Battery performance benchmarking and reporting: Tools and methodologies for benchmarking battery performance against industry standards and generating comprehensive reports. These solutions help in identifying areas for improvement and tracking progress over time.

02 Battery acid quality assessment

Techniques for evaluating the quality of battery acid, including density measurements, chemical composition analysis, and impurity detection. These methods help in maintaining optimal battery performance and extending battery life.Expand Specific Solutions03 Battery performance prediction and optimization

Algorithms and models for predicting battery performance based on historical data and current conditions. These tools enable proactive maintenance and optimization of battery systems, improving overall efficiency and reliability.Expand Specific Solutions04 Battery acid management systems

Integrated systems for managing battery acid levels, including automated monitoring, replenishment, and maintenance processes. These systems help maintain optimal acid concentrations and reduce the risk of battery failure.Expand Specific Solutions05 Battery performance testing and diagnostics

Advanced testing and diagnostic tools for assessing battery performance, including load testing, impedance measurements, and thermal analysis. These methods provide comprehensive insights into battery health and help identify potential issues before they lead to failure.Expand Specific Solutions

Key Players in Battery Acid Industry

The industrial standards for battery acid performance metrics are in a mature stage of development, with a well-established market and significant competition among key players. The global battery market size is substantial, driven by increasing demand in automotive, industrial, and consumer electronics sectors. Technologically, the field is advanced, with companies like Furukawa Battery, GS Yuasa, and Exide Technologies leading innovation. These firms, along with others such as Cabot Corp. and Energizer Brands, are continuously improving battery acid formulations and performance metrics. The involvement of research institutions like CSIRO and ETRI, alongside major corporations like Samsung Electronics, indicates ongoing efforts to push the boundaries of battery technology and standardization.

GS Yuasa International Ltd.

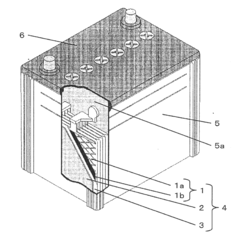

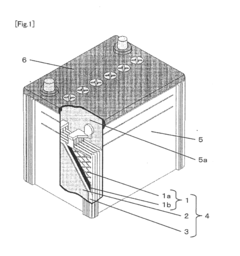

Technical Solution: GS Yuasa has developed advanced lead-acid battery technologies that comply with industrial standards for battery acid performance metrics. Their approach includes the use of advanced grid alloys and active material formulations to enhance corrosion resistance and cycle life. They have implemented precision electrolyte density control systems to maintain optimal acid concentration levels, which is crucial for battery performance and longevity[1]. GS Yuasa also employs advanced formation techniques that ensure uniform acid distribution and plate activation, resulting in batteries that meet or exceed industry standards for capacity, cold-cranking amps, and charge acceptance[3].

Strengths: Extensive experience in lead-acid battery manufacturing, strong R&D capabilities, and global presence. Weaknesses: Potential higher production costs due to advanced materials and processes, which may impact pricing competitiveness.

Exide Technologies, LLC

Technical Solution: Exide Technologies has developed proprietary acid circulation systems that ensure uniform acid density throughout the battery, meeting industrial standards for acid performance metrics. Their approach includes the use of advanced separators with optimized porosity to facilitate acid flow and prevent stratification[2]. Exide has also implemented precise electrolyte filling techniques and formation processes that contribute to consistent acid specific gravity across cells, enhancing overall battery performance and lifespan. Additionally, they have developed innovative acid additives that improve charge acceptance and reduce water loss, aligning with industry standards for maintenance-free batteries[4].

Strengths: Wide range of battery products for various applications, strong distribution network. Weaknesses: Past financial challenges may have impacted R&D investments, potentially affecting cutting-edge innovations.

Core Innovations in Battery Acid Formulations

Lead acid battery

PatentActiveUS20180026310A1

Innovation

- A lead acid battery design with a positive to negative electrode active material mass ratio of 1.25 to 1.65, incorporating bismuth in the negative electrode grid and carbon in the negative electrode active material to prevent stratification and enhance charging efficiency, ensuring homogeneous charge/discharge reactions.

Lead-acid battery

PatentActiveJP2020167079A

Innovation

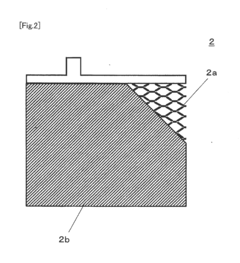

- Optimizing the average pore diameter, density, thickness, and aspect ratio of the negative electrode active material, along with the concentration of aluminum ions in the electrolyte, to enhance the penetration and utilization of the electrolyte, thereby improving charge acceptance and life performance.

Environmental Impact and Regulations

The environmental impact of battery acid and related regulations are critical considerations in the development and implementation of industrial standards for battery acid performance metrics. The production, use, and disposal of battery acid can have significant environmental consequences, necessitating stringent regulations and guidelines to mitigate potential harm.

Battery acid, primarily composed of sulfuric acid, poses substantial risks to ecosystems and human health if not properly managed. Accidental spills or improper disposal can lead to soil and water contamination, affecting plant and animal life. The acidic nature of these substances can alter soil pH, disrupt aquatic ecosystems, and potentially enter the food chain. Furthermore, the production of battery acid involves energy-intensive processes and the use of raw materials, contributing to carbon emissions and resource depletion.

Recognizing these environmental concerns, regulatory bodies worldwide have established comprehensive frameworks to govern the handling, transportation, and disposal of battery acid. In the United States, the Environmental Protection Agency (EPA) enforces strict guidelines under the Resource Conservation and Recovery Act (RCRA) and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA). These regulations classify spent battery acid as hazardous waste, mandating specific handling and disposal procedures.

The European Union has implemented the Battery Directive (2006/66/EC), which sets standards for battery collection, recycling, and disposal. This directive aims to minimize the negative impact of batteries and accumulators on the environment, promoting the recovery of valuable materials and reducing the volume of hazardous waste in landfills. Similar regulations exist in other regions, such as China's Measures for the Administration of the Prevention and Control of Environmental Pollution by Waste Batteries.

To address these environmental and regulatory challenges, the battery industry has been developing more sustainable practices. Closed-loop recycling systems for lead-acid batteries have become increasingly efficient, with recycling rates exceeding 99% in some countries. Additionally, research into alternative electrolytes and battery chemistries aims to reduce the reliance on sulfuric acid, potentially mitigating environmental risks associated with traditional battery acid.

The development of industrial standards for battery acid performance metrics must, therefore, incorporate environmental considerations and regulatory compliance. These standards should not only focus on performance and efficiency but also on minimizing environmental impact throughout the battery lifecycle. This includes optimizing acid composition for easier recycling, improving containment systems to prevent leaks, and developing metrics for assessing the overall environmental footprint of battery production and use.

Battery acid, primarily composed of sulfuric acid, poses substantial risks to ecosystems and human health if not properly managed. Accidental spills or improper disposal can lead to soil and water contamination, affecting plant and animal life. The acidic nature of these substances can alter soil pH, disrupt aquatic ecosystems, and potentially enter the food chain. Furthermore, the production of battery acid involves energy-intensive processes and the use of raw materials, contributing to carbon emissions and resource depletion.

Recognizing these environmental concerns, regulatory bodies worldwide have established comprehensive frameworks to govern the handling, transportation, and disposal of battery acid. In the United States, the Environmental Protection Agency (EPA) enforces strict guidelines under the Resource Conservation and Recovery Act (RCRA) and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA). These regulations classify spent battery acid as hazardous waste, mandating specific handling and disposal procedures.

The European Union has implemented the Battery Directive (2006/66/EC), which sets standards for battery collection, recycling, and disposal. This directive aims to minimize the negative impact of batteries and accumulators on the environment, promoting the recovery of valuable materials and reducing the volume of hazardous waste in landfills. Similar regulations exist in other regions, such as China's Measures for the Administration of the Prevention and Control of Environmental Pollution by Waste Batteries.

To address these environmental and regulatory challenges, the battery industry has been developing more sustainable practices. Closed-loop recycling systems for lead-acid batteries have become increasingly efficient, with recycling rates exceeding 99% in some countries. Additionally, research into alternative electrolytes and battery chemistries aims to reduce the reliance on sulfuric acid, potentially mitigating environmental risks associated with traditional battery acid.

The development of industrial standards for battery acid performance metrics must, therefore, incorporate environmental considerations and regulatory compliance. These standards should not only focus on performance and efficiency but also on minimizing environmental impact throughout the battery lifecycle. This includes optimizing acid composition for easier recycling, improving containment systems to prevent leaks, and developing metrics for assessing the overall environmental footprint of battery production and use.

Safety Standards and Protocols

Safety standards and protocols play a crucial role in ensuring the safe handling, storage, and use of battery acid in industrial settings. These standards are designed to protect workers, equipment, and the environment from potential hazards associated with battery acid exposure and accidents.

The Occupational Safety and Health Administration (OSHA) has established comprehensive guidelines for the handling of battery acid in the workplace. These guidelines include requirements for personal protective equipment (PPE), such as chemical-resistant gloves, face shields, and aprons. OSHA also mandates proper labeling of battery acid containers and storage areas, as well as the provision of eyewash stations and safety showers in areas where battery acid is handled.

The International Electrotechnical Commission (IEC) has developed specific standards for battery safety, including IEC 62485-3, which covers safety requirements for secondary batteries and battery installations. This standard addresses various aspects of battery acid safety, including ventilation requirements, electrolyte handling procedures, and emergency response protocols.

The United Nations (UN) has established regulations for the transportation of dangerous goods, including battery acid. These regulations, known as the UN Recommendations on the Transport of Dangerous Goods, provide guidelines for packaging, labeling, and documentation requirements for shipping battery acid internationally.

Many countries have adopted their own national standards for battery acid safety. For example, in the United States, the National Fire Protection Association (NFPA) has developed NFPA 70E, which addresses electrical safety in the workplace and includes provisions for battery acid handling. Similarly, the European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which imposes strict requirements on the manufacture, import, and use of chemical substances, including battery acid.

Industry-specific standards also exist for battery acid safety. The Battery Council International (BCI) has developed a comprehensive set of safety guidelines for lead-acid battery manufacturing and recycling facilities. These guidelines cover topics such as spill prevention, containment, and cleanup procedures, as well as proper disposal methods for spent battery acid.

To ensure compliance with these safety standards and protocols, many organizations implement regular training programs for employees who work with battery acid. These programs typically cover topics such as proper handling techniques, emergency response procedures, and the use of personal protective equipment. Additionally, regular safety audits and inspections are conducted to identify potential hazards and ensure that all safety measures are being properly implemented and maintained.

The Occupational Safety and Health Administration (OSHA) has established comprehensive guidelines for the handling of battery acid in the workplace. These guidelines include requirements for personal protective equipment (PPE), such as chemical-resistant gloves, face shields, and aprons. OSHA also mandates proper labeling of battery acid containers and storage areas, as well as the provision of eyewash stations and safety showers in areas where battery acid is handled.

The International Electrotechnical Commission (IEC) has developed specific standards for battery safety, including IEC 62485-3, which covers safety requirements for secondary batteries and battery installations. This standard addresses various aspects of battery acid safety, including ventilation requirements, electrolyte handling procedures, and emergency response protocols.

The United Nations (UN) has established regulations for the transportation of dangerous goods, including battery acid. These regulations, known as the UN Recommendations on the Transport of Dangerous Goods, provide guidelines for packaging, labeling, and documentation requirements for shipping battery acid internationally.

Many countries have adopted their own national standards for battery acid safety. For example, in the United States, the National Fire Protection Association (NFPA) has developed NFPA 70E, which addresses electrical safety in the workplace and includes provisions for battery acid handling. Similarly, the European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which imposes strict requirements on the manufacture, import, and use of chemical substances, including battery acid.

Industry-specific standards also exist for battery acid safety. The Battery Council International (BCI) has developed a comprehensive set of safety guidelines for lead-acid battery manufacturing and recycling facilities. These guidelines cover topics such as spill prevention, containment, and cleanup procedures, as well as proper disposal methods for spent battery acid.

To ensure compliance with these safety standards and protocols, many organizations implement regular training programs for employees who work with battery acid. These programs typically cover topics such as proper handling techniques, emergency response procedures, and the use of personal protective equipment. Additionally, regular safety audits and inspections are conducted to identify potential hazards and ensure that all safety measures are being properly implemented and maintained.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!