Innovations in integrating AMOLED with holographic display systems.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED-Holographic Integration Background

The integration of AMOLED (Active-Matrix Organic Light-Emitting Diode) technology with holographic display systems represents a significant advancement in display technology. This convergence aims to combine the high-quality image production of AMOLED screens with the immersive, three-dimensional visual experience offered by holographic displays.

AMOLED technology, first introduced in the early 2000s, has revolutionized display quality in various electronic devices. It offers superior color reproduction, high contrast ratios, and energy efficiency compared to traditional LCD screens. The self-emitting nature of OLED pixels eliminates the need for backlighting, resulting in thinner and more flexible displays.

Holographic display systems, on the other hand, have been a subject of research and development for several decades. These systems create three-dimensional images that appear to float in space, providing a more immersive and interactive visual experience. However, traditional holographic displays often suffer from limitations in brightness, color reproduction, and viewing angles.

The integration of AMOLED and holographic technologies seeks to address these limitations by leveraging the strengths of both systems. AMOLED's ability to produce vibrant colors and deep blacks can significantly enhance the visual quality of holographic images. Additionally, the thin and flexible nature of AMOLED panels opens up new possibilities for designing compact and versatile holographic display devices.

Recent advancements in materials science and optics have paved the way for this integration. Researchers have been exploring novel organic materials that can simultaneously function as light-emitting elements and holographic recording media. This approach could potentially lead to the development of AMOLED panels capable of generating holographic images directly, without the need for additional optical components.

The potential applications of integrated AMOLED-holographic displays are vast and diverse. In the consumer electronics sector, this technology could revolutionize smartphones, tablets, and televisions by offering glasses-free 3D experiences. In professional fields such as medicine, engineering, and architecture, these displays could provide more accurate and intuitive ways to visualize complex data and structures.

As research in this area progresses, we can expect to see continued innovations in areas such as pixel density, refresh rates, and energy efficiency. The ultimate goal is to create seamless, high-resolution holographic displays that can be integrated into everyday devices, bringing us closer to the futuristic vision of ubiquitous 3D interfaces depicted in science fiction.

AMOLED technology, first introduced in the early 2000s, has revolutionized display quality in various electronic devices. It offers superior color reproduction, high contrast ratios, and energy efficiency compared to traditional LCD screens. The self-emitting nature of OLED pixels eliminates the need for backlighting, resulting in thinner and more flexible displays.

Holographic display systems, on the other hand, have been a subject of research and development for several decades. These systems create three-dimensional images that appear to float in space, providing a more immersive and interactive visual experience. However, traditional holographic displays often suffer from limitations in brightness, color reproduction, and viewing angles.

The integration of AMOLED and holographic technologies seeks to address these limitations by leveraging the strengths of both systems. AMOLED's ability to produce vibrant colors and deep blacks can significantly enhance the visual quality of holographic images. Additionally, the thin and flexible nature of AMOLED panels opens up new possibilities for designing compact and versatile holographic display devices.

Recent advancements in materials science and optics have paved the way for this integration. Researchers have been exploring novel organic materials that can simultaneously function as light-emitting elements and holographic recording media. This approach could potentially lead to the development of AMOLED panels capable of generating holographic images directly, without the need for additional optical components.

The potential applications of integrated AMOLED-holographic displays are vast and diverse. In the consumer electronics sector, this technology could revolutionize smartphones, tablets, and televisions by offering glasses-free 3D experiences. In professional fields such as medicine, engineering, and architecture, these displays could provide more accurate and intuitive ways to visualize complex data and structures.

As research in this area progresses, we can expect to see continued innovations in areas such as pixel density, refresh rates, and energy efficiency. The ultimate goal is to create seamless, high-resolution holographic displays that can be integrated into everyday devices, bringing us closer to the futuristic vision of ubiquitous 3D interfaces depicted in science fiction.

Market Demand Analysis

The integration of AMOLED with holographic display systems represents a significant advancement in display technology, addressing the growing market demand for immersive and high-quality visual experiences. This innovative combination has sparked interest across various sectors, particularly in consumer electronics, automotive, healthcare, and entertainment industries.

In the consumer electronics market, there is a strong demand for smartphones, tablets, and wearable devices with enhanced display capabilities. The integration of AMOLED and holographic technologies offers the potential for more vibrant, three-dimensional visuals while maintaining energy efficiency. Market research indicates that consumers are increasingly willing to pay a premium for devices with advanced display features, driving manufacturers to invest in these cutting-edge technologies.

The automotive industry is another key market for this integrated technology. As vehicles become more autonomous and connected, there is a growing need for advanced in-car display systems. Holographic AMOLED displays could revolutionize dashboard interfaces, heads-up displays, and entertainment systems, providing drivers and passengers with more intuitive and immersive information presentation.

In healthcare, the demand for high-resolution, three-dimensional imaging is driving the adoption of advanced display technologies. Holographic AMOLED systems could significantly improve medical imaging, surgical planning, and telemedicine applications. The ability to visualize complex anatomical structures in 3D with high color accuracy and contrast could enhance diagnostic accuracy and surgical outcomes.

The entertainment and gaming industries are also showing strong interest in this technology. Theme parks, museums, and interactive exhibitions are exploring holographic AMOLED displays to create more engaging and immersive experiences for visitors. In the gaming sector, there is a growing demand for displays that can render highly detailed, three-dimensional environments without the need for special glasses or headsets.

Market analysts project substantial growth in the holographic display market, with AMOLED integration expected to play a crucial role. The global holographic display market is anticipated to expand significantly over the next five years, driven by technological advancements and increasing applications across various industries.

However, challenges such as high production costs and technical complexities in integrating these technologies currently limit widespread adoption. As research and development efforts continue to address these issues, the market is expected to see more affordable and commercially viable solutions, further driving demand and market growth.

In the consumer electronics market, there is a strong demand for smartphones, tablets, and wearable devices with enhanced display capabilities. The integration of AMOLED and holographic technologies offers the potential for more vibrant, three-dimensional visuals while maintaining energy efficiency. Market research indicates that consumers are increasingly willing to pay a premium for devices with advanced display features, driving manufacturers to invest in these cutting-edge technologies.

The automotive industry is another key market for this integrated technology. As vehicles become more autonomous and connected, there is a growing need for advanced in-car display systems. Holographic AMOLED displays could revolutionize dashboard interfaces, heads-up displays, and entertainment systems, providing drivers and passengers with more intuitive and immersive information presentation.

In healthcare, the demand for high-resolution, three-dimensional imaging is driving the adoption of advanced display technologies. Holographic AMOLED systems could significantly improve medical imaging, surgical planning, and telemedicine applications. The ability to visualize complex anatomical structures in 3D with high color accuracy and contrast could enhance diagnostic accuracy and surgical outcomes.

The entertainment and gaming industries are also showing strong interest in this technology. Theme parks, museums, and interactive exhibitions are exploring holographic AMOLED displays to create more engaging and immersive experiences for visitors. In the gaming sector, there is a growing demand for displays that can render highly detailed, three-dimensional environments without the need for special glasses or headsets.

Market analysts project substantial growth in the holographic display market, with AMOLED integration expected to play a crucial role. The global holographic display market is anticipated to expand significantly over the next five years, driven by technological advancements and increasing applications across various industries.

However, challenges such as high production costs and technical complexities in integrating these technologies currently limit widespread adoption. As research and development efforts continue to address these issues, the market is expected to see more affordable and commercially viable solutions, further driving demand and market growth.

Technical Challenges

The integration of AMOLED (Active-Matrix Organic Light-Emitting Diode) technology with holographic display systems presents several significant technical challenges that researchers and engineers must overcome to achieve seamless and effective implementation.

One of the primary obstacles is the alignment and synchronization between the AMOLED panel and the holographic optical elements. Precise spatial and temporal coordination is crucial to ensure that the light emitted by the AMOLED pixels accurately interacts with the holographic diffraction patterns. Any misalignment or timing discrepancies can result in distorted or blurred holographic images, compromising the overall visual quality and user experience.

Another major challenge lies in the resolution limitations of current AMOLED displays when applied to holographic systems. Holographic displays typically require extremely high pixel densities to reproduce detailed and realistic 3D images. While AMOLED technology has made significant strides in resolution, achieving the ultra-high pixel densities necessary for convincing holographic reproduction remains a formidable task.

Power consumption and heat management pose additional hurdles in the integration process. Holographic displays often demand high brightness levels to create visible and vibrant 3D images, which can lead to increased power draw and heat generation in AMOLED panels. Developing efficient power management systems and effective heat dissipation mechanisms is crucial to ensure the longevity and reliability of integrated AMOLED-holographic devices.

The color reproduction and gamut of AMOLED displays present another technical challenge when combined with holographic systems. Holographic images require precise color control to maintain accuracy and depth perception. Achieving a wide color gamut while ensuring color consistency across different viewing angles is essential for creating immersive holographic experiences.

Furthermore, the integration of touch functionality with AMOLED-holographic displays introduces additional complexities. Traditional touch sensors may interfere with the holographic diffraction patterns or compromise the display's optical properties. Developing transparent and responsive touch interfaces that seamlessly coexist with both AMOLED and holographic elements is a significant engineering challenge.

Lastly, the manufacturing processes for integrating AMOLED and holographic technologies present their own set of difficulties. Ensuring consistent quality, yield rates, and cost-effectiveness in mass production requires innovative fabrication techniques and stringent quality control measures. The development of scalable manufacturing processes that can reliably produce integrated AMOLED-holographic displays remains a key challenge for widespread adoption of this technology.

One of the primary obstacles is the alignment and synchronization between the AMOLED panel and the holographic optical elements. Precise spatial and temporal coordination is crucial to ensure that the light emitted by the AMOLED pixels accurately interacts with the holographic diffraction patterns. Any misalignment or timing discrepancies can result in distorted or blurred holographic images, compromising the overall visual quality and user experience.

Another major challenge lies in the resolution limitations of current AMOLED displays when applied to holographic systems. Holographic displays typically require extremely high pixel densities to reproduce detailed and realistic 3D images. While AMOLED technology has made significant strides in resolution, achieving the ultra-high pixel densities necessary for convincing holographic reproduction remains a formidable task.

Power consumption and heat management pose additional hurdles in the integration process. Holographic displays often demand high brightness levels to create visible and vibrant 3D images, which can lead to increased power draw and heat generation in AMOLED panels. Developing efficient power management systems and effective heat dissipation mechanisms is crucial to ensure the longevity and reliability of integrated AMOLED-holographic devices.

The color reproduction and gamut of AMOLED displays present another technical challenge when combined with holographic systems. Holographic images require precise color control to maintain accuracy and depth perception. Achieving a wide color gamut while ensuring color consistency across different viewing angles is essential for creating immersive holographic experiences.

Furthermore, the integration of touch functionality with AMOLED-holographic displays introduces additional complexities. Traditional touch sensors may interfere with the holographic diffraction patterns or compromise the display's optical properties. Developing transparent and responsive touch interfaces that seamlessly coexist with both AMOLED and holographic elements is a significant engineering challenge.

Lastly, the manufacturing processes for integrating AMOLED and holographic technologies present their own set of difficulties. Ensuring consistent quality, yield rates, and cost-effectiveness in mass production requires innovative fabrication techniques and stringent quality control measures. The development of scalable manufacturing processes that can reliably produce integrated AMOLED-holographic displays remains a key challenge for widespread adoption of this technology.

Current Integration Solutions

01 AMOLED integration with holographic display systems

Integration of AMOLED technology with holographic display systems to create advanced visual experiences. This combination leverages the high contrast and color accuracy of AMOLED screens with the depth and dimensionality of holographic displays, resulting in more immersive and realistic 3D imagery.- Integration of AMOLED and holographic display technologies: This approach combines AMOLED (Active Matrix Organic Light Emitting Diode) technology with holographic display systems to create advanced visual experiences. The integration allows for high-resolution, vibrant displays with the added depth and dimensionality of holographic imagery, potentially revolutionizing fields such as augmented reality and immersive entertainment.

- Holographic optical elements for AMOLED displays: Holographic optical elements are incorporated into AMOLED display systems to enhance image quality, viewing angles, and overall performance. These elements can manipulate light paths, reduce glare, and improve color reproduction, resulting in more efficient and visually appealing displays for various applications.

- Waveguide-based holographic AMOLED systems: This technology utilizes waveguide structures in combination with AMOLED and holographic technologies to create compact, high-performance display systems. The waveguide approach allows for efficient light transmission and manipulation, enabling thinner device profiles and improved energy efficiency in applications such as head-mounted displays and smart glasses.

- Color management in holographic AMOLED displays: Advanced color management techniques are developed for integrated holographic AMOLED displays to ensure accurate and vibrant color reproduction. These methods address challenges such as color shift, gamut mapping, and consistency across viewing angles, resulting in more realistic and immersive visual experiences.

- Eye-tracking and foveated rendering for holographic AMOLED displays: This approach incorporates eye-tracking technology and foveated rendering techniques into holographic AMOLED display systems. By focusing rendering resources on the area of the display where the user is looking, these systems can optimize performance, reduce power consumption, and enhance the overall visual experience in applications such as virtual reality and augmented reality headsets.

02 Holographic optical elements for AMOLED displays

Incorporation of holographic optical elements into AMOLED display systems to enhance image quality and viewing angles. These elements can manipulate light paths, reduce glare, and improve overall display performance, making the integration of holographic technology with AMOLED more effective.Expand Specific Solutions03 Light field technology in AMOLED-holographic hybrid displays

Utilization of light field technology in combination with AMOLED and holographic displays to create more realistic 3D images. This approach allows for multiple viewing angles and depth perception without the need for special glasses, enhancing the user experience in various applications such as gaming and virtual reality.Expand Specific Solutions04 Waveguide-based holographic AMOLED displays

Development of waveguide-based systems that integrate holographic elements with AMOLED displays. This technology allows for thinner and more compact display designs while maintaining high-quality holographic images, making it suitable for wearable devices and augmented reality applications.Expand Specific Solutions05 Color management in holographic AMOLED systems

Implementation of advanced color management techniques for holographic AMOLED displays. This includes color calibration, gamut mapping, and dynamic range optimization to ensure accurate and vivid color reproduction in holographic images displayed on AMOLED screens.Expand Specific Solutions

Key Industry Players

The integration of AMOLED with holographic display systems is an emerging technology at the intersection of advanced display and holographic imaging. This field is in its early development stage, with significant potential for growth as demand for immersive and high-resolution displays increases. The market size is expanding, driven by applications in consumer electronics, automotive, and augmented reality. Technologically, it's still evolving, with companies like BOE Technology, Samsung Electronics, and TCL China Star Optoelectronics leading research efforts. Academic institutions such as MIT and industry players like Intel are also contributing to advancements. The competitive landscape is characterized by a mix of established display manufacturers and innovative startups, each striving to overcome technical challenges and commercialize this cutting-edge technology.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an innovative approach to integrating AMOLED with holographic display systems. Their technology utilizes a high-resolution AMOLED panel as the light source for holographic projection. The company has implemented advanced pixel-level light field control, allowing for precise manipulation of light waves to create realistic 3D holographic images. BOE's system incorporates a proprietary optical waveguide design that enhances the viewing angle and depth of the holographic display[1]. They have also developed specialized thin-film transistors (TFTs) optimized for holographic applications, which enable faster response times and improved color accuracy in the holographic output[2].

Strengths: High-resolution display capabilities, advanced light field control, and improved viewing angles. Weaknesses: Potential high production costs and complexity in mass manufacturing.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has made significant strides in integrating AMOLED with holographic display systems. Their approach focuses on leveraging their expertise in AMOLED technology to create high-fidelity holographic displays. Samsung's system uses a specially designed AMOLED panel with micro-lens array overlays to generate light field projections[3]. They have developed proprietary algorithms for real-time hologram generation and rendering, which work in tandem with their advanced AMOLED hardware. Samsung's solution also incorporates eye-tracking technology to optimize the holographic viewing experience for individual users[4]. Additionally, they have made breakthroughs in reducing the power consumption of their holographic AMOLED displays, making them more suitable for mobile applications[5].

Strengths: Established AMOLED manufacturing capabilities, advanced hologram rendering algorithms, and energy-efficient designs. Weaknesses: Potential limitations in scaling to larger display sizes.

Core Patents and Innovations

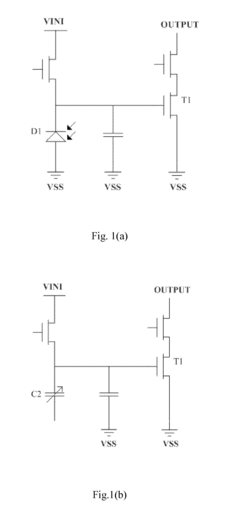

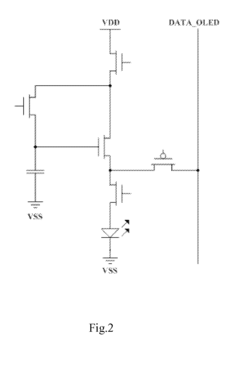

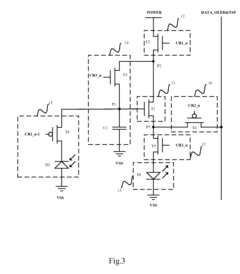

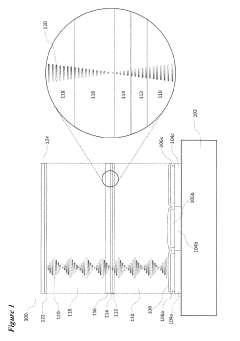

Active matrix organic light emitting diode pixel unit circuit, display panel and electronic product

PatentActiveUS9459721B2

Innovation

- The AMOLED pixel unit circuit is redesigned to include a light emitting module, a driving module, a threshold compensating module, a light emission controlling module, a touch sensing module, and an induction signal outputting module, which utilize existing data lines and control signals to integrate the TSP in Cell circuit, sharing circuit elements and control signals to minimize additional components.

Active Matrix Enhanced Organic Light Emitting Diode Displays for Large Screen Graphic Display Applications

PatentActiveUS20190207126A1

Innovation

- Replacing vacuum-deposited layered structures with a chiral liquid crystalline structure built by solvent casting and photopolymerization, using chiral liquid crystalline band edge emission enhanced OLEDs (C-OLEDs) that form a helical photonic crystal, reducing the number of layers and manufacturing complexity.

Manufacturing Processes

The integration of AMOLED technology with holographic display systems presents unique manufacturing challenges that require innovative approaches. The production process begins with the fabrication of the AMOLED panel, which involves depositing multiple layers of organic materials on a substrate using techniques such as vacuum thermal evaporation or inkjet printing. These layers must be precisely controlled to ensure uniform light emission and color accuracy.

Simultaneously, the holographic display components are manufactured separately. This typically involves creating a holographic optical element (HOE) using photopolymer materials and laser interference patterns. The HOE is crucial for manipulating light to create the three-dimensional holographic image.

The critical innovation in manufacturing lies in the seamless integration of these two distinct technologies. One approach involves developing a hybrid substrate that can accommodate both the AMOLED layers and the holographic elements. This requires careful material selection to ensure compatibility and maintain the performance of both systems.

Another innovative manufacturing process involves the use of advanced lithography techniques to create nanoscale structures that serve both as light-emitting elements for the AMOLED and as diffractive elements for the holographic display. This approach reduces the overall thickness of the device and improves optical efficiency.

Quality control is paramount in the manufacturing process. Advanced inspection systems, such as automated optical inspection (AOI) and atomic force microscopy (AFM), are employed to detect defects at the nanoscale level. These systems ensure the integrity of both the AMOLED pixels and the holographic elements.

The final assembly stage requires precise alignment of the AMOLED panel with the holographic components. Innovative bonding techniques, such as optically clear adhesives or direct bonding methods, are used to minimize light loss and maintain image quality. The entire assembly process often takes place in cleanroom environments to prevent contamination that could affect the delicate organic materials or optical surfaces.

Scalability remains a significant challenge in manufacturing these integrated systems. Current production methods are often limited to small-scale or prototype devices. Innovations in roll-to-roll processing and large-area deposition techniques are being explored to enable mass production of AMOLED-holographic hybrid displays, potentially revolutionizing the consumer electronics and augmented reality markets.

Simultaneously, the holographic display components are manufactured separately. This typically involves creating a holographic optical element (HOE) using photopolymer materials and laser interference patterns. The HOE is crucial for manipulating light to create the three-dimensional holographic image.

The critical innovation in manufacturing lies in the seamless integration of these two distinct technologies. One approach involves developing a hybrid substrate that can accommodate both the AMOLED layers and the holographic elements. This requires careful material selection to ensure compatibility and maintain the performance of both systems.

Another innovative manufacturing process involves the use of advanced lithography techniques to create nanoscale structures that serve both as light-emitting elements for the AMOLED and as diffractive elements for the holographic display. This approach reduces the overall thickness of the device and improves optical efficiency.

Quality control is paramount in the manufacturing process. Advanced inspection systems, such as automated optical inspection (AOI) and atomic force microscopy (AFM), are employed to detect defects at the nanoscale level. These systems ensure the integrity of both the AMOLED pixels and the holographic elements.

The final assembly stage requires precise alignment of the AMOLED panel with the holographic components. Innovative bonding techniques, such as optically clear adhesives or direct bonding methods, are used to minimize light loss and maintain image quality. The entire assembly process often takes place in cleanroom environments to prevent contamination that could affect the delicate organic materials or optical surfaces.

Scalability remains a significant challenge in manufacturing these integrated systems. Current production methods are often limited to small-scale or prototype devices. Innovations in roll-to-roll processing and large-area deposition techniques are being explored to enable mass production of AMOLED-holographic hybrid displays, potentially revolutionizing the consumer electronics and augmented reality markets.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the integration of AMOLED with holographic display systems. The combination of these two technologies presents unique challenges and opportunities for optimizing power consumption. AMOLED displays are known for their energy efficiency, particularly when displaying dark content, as individual pixels can be turned off completely. However, holographic systems typically require significant computational power and light output, which can be energy-intensive.

One of the primary focuses in this integration is the development of low-power holographic projection techniques that can work in tandem with AMOLED's energy-saving characteristics. Researchers are exploring the use of advanced light-field manipulation algorithms that can reduce the overall energy required to generate holographic images. These algorithms aim to minimize the number of light sources needed and optimize the distribution of light across the display surface.

Another area of innovation is the implementation of adaptive brightness control systems that dynamically adjust the power consumption based on the content being displayed and ambient lighting conditions. This approach leverages the inherent capabilities of AMOLED technology to vary pixel brightness independently, allowing for precise control over energy usage in different parts of the holographic image.

The development of more efficient optical components is also crucial in reducing overall system power consumption. Advanced micro-lens arrays and diffractive optical elements are being designed to improve light utilization, reducing the amount of energy wasted through light scattering and absorption. These components work in conjunction with AMOLED's emissive properties to create holographic images with less power input.

Thermal management is another key aspect of energy efficiency in these integrated systems. As both AMOLED and holographic technologies can generate significant heat, innovative cooling solutions are being developed. These include the use of advanced heat-dissipating materials and the integration of micro-fluidic cooling channels within the display structure. Effective thermal management not only improves energy efficiency but also extends the lifespan of the display components.

Lastly, the integration of smart power management systems is being explored to optimize energy usage across different operational modes. These systems can intelligently switch between 2D AMOLED display mode and 3D holographic mode, depending on the content and user interaction, thereby conserving energy when full holographic capabilities are not required. This adaptive approach ensures that the system only consumes the energy necessary for the current display requirements, maximizing overall efficiency.

One of the primary focuses in this integration is the development of low-power holographic projection techniques that can work in tandem with AMOLED's energy-saving characteristics. Researchers are exploring the use of advanced light-field manipulation algorithms that can reduce the overall energy required to generate holographic images. These algorithms aim to minimize the number of light sources needed and optimize the distribution of light across the display surface.

Another area of innovation is the implementation of adaptive brightness control systems that dynamically adjust the power consumption based on the content being displayed and ambient lighting conditions. This approach leverages the inherent capabilities of AMOLED technology to vary pixel brightness independently, allowing for precise control over energy usage in different parts of the holographic image.

The development of more efficient optical components is also crucial in reducing overall system power consumption. Advanced micro-lens arrays and diffractive optical elements are being designed to improve light utilization, reducing the amount of energy wasted through light scattering and absorption. These components work in conjunction with AMOLED's emissive properties to create holographic images with less power input.

Thermal management is another key aspect of energy efficiency in these integrated systems. As both AMOLED and holographic technologies can generate significant heat, innovative cooling solutions are being developed. These include the use of advanced heat-dissipating materials and the integration of micro-fluidic cooling channels within the display structure. Effective thermal management not only improves energy efficiency but also extends the lifespan of the display components.

Lastly, the integration of smart power management systems is being explored to optimize energy usage across different operational modes. These systems can intelligently switch between 2D AMOLED display mode and 3D holographic mode, depending on the content and user interaction, thereby conserving energy when full holographic capabilities are not required. This adaptive approach ensures that the system only consumes the energy necessary for the current display requirements, maximizing overall efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!