Investigating Polysilane's Role in Radio Frequency Devices

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane RF Tech Evolution

The evolution of polysilane technology in radio frequency (RF) devices has been marked by significant advancements and breakthroughs over the past few decades. Initially, polysilanes were primarily studied for their unique electronic properties, with researchers focusing on their potential applications in optoelectronics and photoresistors. However, as the demand for high-performance RF devices grew, scientists began to explore the possibilities of utilizing polysilanes in this field.

In the early stages of development, polysilanes were investigated for their potential to enhance the performance of traditional silicon-based RF devices. Researchers discovered that the incorporation of polysilane layers could improve the electron mobility and reduce signal loss in certain RF components. This led to a surge in interest and research efforts aimed at optimizing polysilane structures for RF applications.

The mid-2000s saw a significant breakthrough when scientists successfully demonstrated the use of polysilanes in high-frequency transistors. These transistors exhibited improved switching speeds and lower power consumption compared to their conventional counterparts. This milestone paved the way for the integration of polysilanes into various RF devices, including amplifiers, filters, and antennas.

As the technology progressed, researchers began to focus on developing novel polysilane-based materials with tailored properties for specific RF applications. This involved experimenting with different side-chain structures and molecular weights to achieve desired electrical and thermal characteristics. The advent of advanced synthesis techniques and characterization methods played a crucial role in accelerating this process.

In recent years, the integration of polysilanes with other emerging materials, such as graphene and carbon nanotubes, has opened up new possibilities for RF device design. These hybrid structures have shown promise in achieving unprecedented levels of performance in terms of frequency response, power handling, and miniaturization.

The latest developments in polysilane RF technology have focused on addressing the challenges posed by 5G and beyond 5G communications. Researchers are exploring the potential of polysilanes in millimeter-wave and terahertz applications, where their unique properties could offer advantages in terms of signal propagation and device efficiency.

Looking ahead, the evolution of polysilane technology in RF devices is expected to continue at a rapid pace. Ongoing research efforts are aimed at further improving the stability and reliability of polysilane-based RF components, as well as developing scalable manufacturing processes for commercial applications. As the demand for high-performance RF devices continues to grow across various industries, polysilanes are poised to play an increasingly important role in shaping the future of wireless communication technologies.

In the early stages of development, polysilanes were investigated for their potential to enhance the performance of traditional silicon-based RF devices. Researchers discovered that the incorporation of polysilane layers could improve the electron mobility and reduce signal loss in certain RF components. This led to a surge in interest and research efforts aimed at optimizing polysilane structures for RF applications.

The mid-2000s saw a significant breakthrough when scientists successfully demonstrated the use of polysilanes in high-frequency transistors. These transistors exhibited improved switching speeds and lower power consumption compared to their conventional counterparts. This milestone paved the way for the integration of polysilanes into various RF devices, including amplifiers, filters, and antennas.

As the technology progressed, researchers began to focus on developing novel polysilane-based materials with tailored properties for specific RF applications. This involved experimenting with different side-chain structures and molecular weights to achieve desired electrical and thermal characteristics. The advent of advanced synthesis techniques and characterization methods played a crucial role in accelerating this process.

In recent years, the integration of polysilanes with other emerging materials, such as graphene and carbon nanotubes, has opened up new possibilities for RF device design. These hybrid structures have shown promise in achieving unprecedented levels of performance in terms of frequency response, power handling, and miniaturization.

The latest developments in polysilane RF technology have focused on addressing the challenges posed by 5G and beyond 5G communications. Researchers are exploring the potential of polysilanes in millimeter-wave and terahertz applications, where their unique properties could offer advantages in terms of signal propagation and device efficiency.

Looking ahead, the evolution of polysilane technology in RF devices is expected to continue at a rapid pace. Ongoing research efforts are aimed at further improving the stability and reliability of polysilane-based RF components, as well as developing scalable manufacturing processes for commercial applications. As the demand for high-performance RF devices continues to grow across various industries, polysilanes are poised to play an increasingly important role in shaping the future of wireless communication technologies.

RF Device Market Demand

The radio frequency (RF) device market has been experiencing significant growth and transformation, driven by the increasing demand for wireless communication technologies and the rapid advancement of 5G networks. This market encompasses a wide range of devices, including smartphones, tablets, IoT devices, and infrastructure equipment for wireless networks. The global RF device market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong in the coming years.

One of the primary drivers of market demand is the ongoing rollout of 5G networks worldwide. As telecommunications companies invest heavily in 5G infrastructure, there is a growing need for advanced RF devices capable of supporting higher frequencies and wider bandwidths. This shift towards 5G has created opportunities for innovative materials and technologies, including potential applications for polysilane in RF devices.

The consumer electronics sector, particularly smartphones and wearable devices, remains a significant contributor to RF device market demand. With the increasing integration of multiple wireless technologies (e.g., 5G, Wi-Fi 6, Bluetooth) into a single device, there is a growing need for compact, efficient, and high-performance RF components. This trend aligns well with the potential benefits of polysilane-based RF devices, which could offer improved performance characteristics in smaller form factors.

In the automotive industry, the rise of connected and autonomous vehicles is driving demand for sophisticated RF devices. These vehicles require robust communication systems for vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) connectivity, creating new opportunities for advanced RF technologies. The potential of polysilane in this sector could be significant, particularly if it can offer advantages in terms of reliability and performance under challenging automotive conditions.

The Internet of Things (IoT) ecosystem is another major factor influencing RF device market demand. As the number of connected devices continues to grow exponentially, there is an increasing need for RF components that can operate efficiently across a wide range of frequencies and power levels. This diverse and expanding market presents opportunities for novel materials like polysilane to address specific challenges in IoT applications, such as low-power operation and miniaturization.

Industrial and military applications also contribute to the overall demand for RF devices. These sectors often require specialized RF components capable of operating in harsh environments or meeting stringent performance criteria. The potential of polysilane to enhance the capabilities of RF devices in these demanding applications could open up new market segments and drive further innovation in the field.

As the RF device market continues to evolve, there is a growing emphasis on energy efficiency and sustainability. This trend aligns with the potential benefits of polysilane-based RF devices, which may offer improved power efficiency compared to traditional materials. Market demand is increasingly favoring technologies that can deliver high performance while minimizing energy consumption, a factor that could influence the adoption of novel materials and designs in RF devices.

One of the primary drivers of market demand is the ongoing rollout of 5G networks worldwide. As telecommunications companies invest heavily in 5G infrastructure, there is a growing need for advanced RF devices capable of supporting higher frequencies and wider bandwidths. This shift towards 5G has created opportunities for innovative materials and technologies, including potential applications for polysilane in RF devices.

The consumer electronics sector, particularly smartphones and wearable devices, remains a significant contributor to RF device market demand. With the increasing integration of multiple wireless technologies (e.g., 5G, Wi-Fi 6, Bluetooth) into a single device, there is a growing need for compact, efficient, and high-performance RF components. This trend aligns well with the potential benefits of polysilane-based RF devices, which could offer improved performance characteristics in smaller form factors.

In the automotive industry, the rise of connected and autonomous vehicles is driving demand for sophisticated RF devices. These vehicles require robust communication systems for vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) connectivity, creating new opportunities for advanced RF technologies. The potential of polysilane in this sector could be significant, particularly if it can offer advantages in terms of reliability and performance under challenging automotive conditions.

The Internet of Things (IoT) ecosystem is another major factor influencing RF device market demand. As the number of connected devices continues to grow exponentially, there is an increasing need for RF components that can operate efficiently across a wide range of frequencies and power levels. This diverse and expanding market presents opportunities for novel materials like polysilane to address specific challenges in IoT applications, such as low-power operation and miniaturization.

Industrial and military applications also contribute to the overall demand for RF devices. These sectors often require specialized RF components capable of operating in harsh environments or meeting stringent performance criteria. The potential of polysilane to enhance the capabilities of RF devices in these demanding applications could open up new market segments and drive further innovation in the field.

As the RF device market continues to evolve, there is a growing emphasis on energy efficiency and sustainability. This trend aligns with the potential benefits of polysilane-based RF devices, which may offer improved power efficiency compared to traditional materials. Market demand is increasingly favoring technologies that can deliver high performance while minimizing energy consumption, a factor that could influence the adoption of novel materials and designs in RF devices.

Polysilane Challenges in RF

Polysilane, a class of silicon-based polymers, has garnered significant attention in the field of radio frequency (RF) devices due to its unique properties and potential applications. However, the integration of polysilane into RF devices presents several challenges that researchers and engineers must overcome to fully harness its capabilities.

One of the primary challenges in utilizing polysilane for RF applications is its inherent instability under certain environmental conditions. Polysilane tends to degrade when exposed to ultraviolet (UV) light, which can lead to changes in its electrical and mechanical properties over time. This photosensitivity poses a significant hurdle for outdoor RF applications or devices that may be exposed to sunlight during operation or storage.

Another critical challenge is the optimization of polysilane's electrical properties for RF performance. While polysilane exhibits promising characteristics, such as low dielectric loss and high thermal stability, fine-tuning these properties to meet the specific requirements of different RF devices and frequency ranges remains a complex task. Researchers must develop precise control over the molecular structure and composition of polysilane to achieve the desired electrical behavior consistently.

The processing and fabrication of polysilane-based RF components also present significant challenges. Traditional semiconductor manufacturing techniques may not be directly applicable to polysilane, necessitating the development of new fabrication methods. Issues such as achieving uniform film thickness, controlling surface roughness, and ensuring proper adhesion to substrates must be addressed to create reliable and high-performance RF devices.

Compatibility with existing RF materials and components is another hurdle that needs to be overcome. Integrating polysilane into established RF device architectures requires careful consideration of material interfaces, thermal management, and potential electromagnetic interactions. Ensuring seamless integration without compromising the performance of other device components is crucial for the successful adoption of polysilane in RF applications.

The long-term reliability and stability of polysilane-based RF devices remain areas of concern. RF components are often subjected to harsh operating conditions, including high temperatures, mechanical stress, and electromagnetic interference. Developing polysilane formulations and device structures that can maintain consistent performance over extended periods and under various environmental conditions is essential for commercial viability.

Lastly, the scalability of polysilane production and device fabrication processes poses a significant challenge for widespread adoption in the RF industry. Developing cost-effective and efficient manufacturing techniques that can produce high-quality polysilane materials and devices at scale is crucial for commercial success. This includes addressing issues related to material purity, process repeatability, and yield optimization.

One of the primary challenges in utilizing polysilane for RF applications is its inherent instability under certain environmental conditions. Polysilane tends to degrade when exposed to ultraviolet (UV) light, which can lead to changes in its electrical and mechanical properties over time. This photosensitivity poses a significant hurdle for outdoor RF applications or devices that may be exposed to sunlight during operation or storage.

Another critical challenge is the optimization of polysilane's electrical properties for RF performance. While polysilane exhibits promising characteristics, such as low dielectric loss and high thermal stability, fine-tuning these properties to meet the specific requirements of different RF devices and frequency ranges remains a complex task. Researchers must develop precise control over the molecular structure and composition of polysilane to achieve the desired electrical behavior consistently.

The processing and fabrication of polysilane-based RF components also present significant challenges. Traditional semiconductor manufacturing techniques may not be directly applicable to polysilane, necessitating the development of new fabrication methods. Issues such as achieving uniform film thickness, controlling surface roughness, and ensuring proper adhesion to substrates must be addressed to create reliable and high-performance RF devices.

Compatibility with existing RF materials and components is another hurdle that needs to be overcome. Integrating polysilane into established RF device architectures requires careful consideration of material interfaces, thermal management, and potential electromagnetic interactions. Ensuring seamless integration without compromising the performance of other device components is crucial for the successful adoption of polysilane in RF applications.

The long-term reliability and stability of polysilane-based RF devices remain areas of concern. RF components are often subjected to harsh operating conditions, including high temperatures, mechanical stress, and electromagnetic interference. Developing polysilane formulations and device structures that can maintain consistent performance over extended periods and under various environmental conditions is essential for commercial viability.

Lastly, the scalability of polysilane production and device fabrication processes poses a significant challenge for widespread adoption in the RF industry. Developing cost-effective and efficient manufacturing techniques that can produce high-quality polysilane materials and devices at scale is crucial for commercial success. This includes addressing issues related to material purity, process repeatability, and yield optimization.

Current Polysilane RF Solutions

01 Synthesis and properties of polysilanes

Polysilanes are synthesized through various methods and exhibit unique properties. These silicon-based polymers have a backbone consisting of silicon atoms and can be modified with different substituents. They possess interesting optical and electronic properties, making them suitable for various applications in materials science and electronics.- Synthesis and properties of polysilanes: Polysilanes are synthesized through various methods and exhibit unique properties. These silicon-based polymers have applications in electronics, optics, and materials science due to their electronic and optical characteristics. The synthesis methods and resulting properties can be tailored for specific applications.

- Polysilane-based coatings and films: Polysilanes are used to create coatings and films with specific properties. These coatings can be applied to various substrates and may offer benefits such as improved durability, optical properties, or electronic characteristics. The formulation and application methods of polysilane-based coatings are crucial for their performance.

- Polysilanes in photoresist applications: Polysilanes are utilized in photoresist formulations for semiconductor manufacturing. Their unique properties make them suitable for lithography processes, allowing for the creation of fine patterns on substrates. The development of polysilane-based photoresists involves optimizing their photosensitivity and resolution capabilities.

- Functionalization and modification of polysilanes: Polysilanes can be functionalized or modified to enhance their properties or introduce new functionalities. This may involve adding specific side groups, creating copolymers, or incorporating other elements into the polymer backbone. These modifications allow for the tailoring of polysilanes for specific applications or to improve their performance characteristics.

- Polysilanes in electronic and optical devices: Polysilanes are employed in the fabrication of electronic and optical devices due to their unique electronic structure and optical properties. They can be used as active materials in organic electronics, photovoltaics, and light-emitting devices. The development of polysilane-based devices involves optimizing the polymer structure and device architecture for improved performance.

02 Applications in photoresists and lithography

Polysilanes are utilized in photoresist formulations and lithographic processes. Their photosensitivity and ability to undergo photochemical reactions make them valuable in the fabrication of microelectronic devices and semiconductor manufacturing. They can be used as positive or negative photoresists, offering high resolution and good etching resistance.Expand Specific Solutions03 Polysilane-based coatings and films

Polysilanes are employed in the development of coatings and thin films with specific properties. These materials can be used to create protective layers, optical coatings, or functional surfaces with tailored characteristics. The silicon-based structure of polysilanes contributes to their thermal stability and resistance to various environmental factors.Expand Specific Solutions04 Modification and functionalization of polysilanes

Polysilanes can be modified and functionalized to enhance their properties or introduce new functionalities. This includes the incorporation of various organic groups, metal atoms, or other elements into the polymer structure. Such modifications allow for the fine-tuning of optical, electronic, or mechanical properties, expanding the range of potential applications.Expand Specific Solutions05 Polysilanes in electronic and optoelectronic devices

Polysilanes find applications in electronic and optoelectronic devices due to their unique electronic structure and charge transport properties. They can be used as semiconducting materials, light-emitting components, or charge transport layers in various devices such as organic light-emitting diodes (OLEDs), solar cells, and field-effect transistors.Expand Specific Solutions

Key RF Polysilane Players

The investigation into polysilane's role in radio frequency devices is in its early stages, with the market still emerging and relatively small. The technology's maturity is low, but growing interest from key players indicates potential for rapid development. Companies like JSR Corp., Shin-Etsu Chemical, and Wacker Chemie are leading research efforts, leveraging their expertise in silicon-based materials. Academic institutions such as Shanghai University and Technische Universität Wien are also contributing to fundamental research. While commercial applications are limited, the involvement of major chemical and electronics firms suggests recognition of polysilane's promise in next-generation RF devices.

JSR Corp.

Technical Solution: JSR Corp. has made significant strides in developing polysilane-based materials for RF applications. Their research focuses on creating high-performance polysilane resins that offer excellent dielectric properties and processability. JSR has successfully engineered polysilane copolymers that demonstrate low dielectric constants and loss tangents across a wide frequency range, making them suitable for 5G and beyond applications[2]. The company has also developed a novel surface modification technique for polysilane films, enhancing their adhesion to various substrates commonly used in RF devices[4]. Additionally, JSR has explored the use of polysilanes as precursors for silicon carbide coatings, which provide enhanced thermal management in high-power RF components[6].

Strengths: Advanced polysilane copolymer technology, expertise in surface modification techniques, and diverse application range. Weaknesses: Limited long-term stability data for some formulations and potential regulatory challenges for new materials.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has been actively investigating the role of polysilanes in RF devices, leveraging its extensive experience in silicon-based chemistry. The company has developed a range of polysilane formulations tailored for specific RF applications, including low-loss substrates for high-frequency circuit boards and dielectric resonators[7]. Wacker's research has led to the creation of polysilane-based composite materials that combine the benefits of organic polymers with the thermal and electrical properties of silicon[9]. They have also pioneered a solvent-free processing method for polysilane coatings, which has shown promise in reducing manufacturing costs and environmental impact for RF device production[11].

Strengths: Strong background in silicon chemistry, diverse polysilane product portfolio, and eco-friendly processing techniques. Weaknesses: Relatively new entrant in the RF-specific polysilane market and potential challenges in competing with established RF material suppliers.

Polysilane RF Innovations

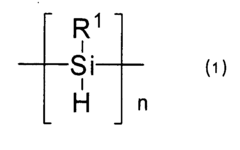

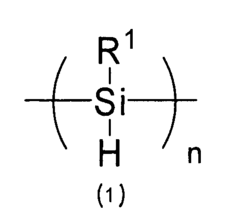

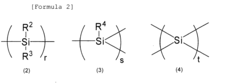

Polysilane and polysilane-containing resin composition

PatentInactiveUS8163863B2

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups like hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Polysilane and resin composition containing polysilane

PatentInactiveEP1958979A1

Innovation

- Introducing a Si-H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups such as hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Polysilane RF Manufacturing

Polysilane manufacturing for radio frequency (RF) devices involves a complex process that requires precision and advanced techniques. The production of polysilane materials suitable for RF applications begins with the synthesis of high-purity silane monomers. These monomers are typically produced through the reduction of silicon tetrachloride or the direct reaction of silicon with hydrogen chloride.

Once the silane monomers are obtained, they undergo polymerization to form polysilane chains. This step is critical in determining the final properties of the material. Various polymerization methods can be employed, including thermal polymerization, catalytic polymerization, and plasma-enhanced chemical vapor deposition (PECVD). Each method offers different advantages in terms of molecular weight control, chain length distribution, and structural uniformity.

The polymerization process is followed by a series of purification steps to remove any residual monomers, catalysts, or impurities that could affect the RF performance of the final product. These purification techniques may include recrystallization, solvent extraction, and chromatography. The purity of the polysilane is crucial for its application in RF devices, as even trace amounts of contaminants can significantly impact the material's dielectric properties and overall performance.

After purification, the polysilane undergoes further processing to achieve the desired form for RF device integration. This may involve solution processing, where the polysilane is dissolved in an appropriate solvent and then deposited onto substrates using techniques such as spin-coating or dip-coating. Alternatively, vapor deposition methods can be used to create thin films of polysilane with precise thickness control.

The manufacturing process also includes the incorporation of additives or dopants to enhance specific properties of the polysilane for RF applications. These additives can modify the material's conductivity, dielectric constant, or thermal stability. The precise formulation and mixing of these components are critical to achieving the desired RF characteristics.

Quality control measures are implemented throughout the manufacturing process to ensure consistency and reliability of the polysilane materials. This includes in-line monitoring of molecular weight, chemical composition, and structural properties using techniques such as gel permeation chromatography (GPC), nuclear magnetic resonance (NMR) spectroscopy, and X-ray diffraction (XRD).

The final stages of polysilane RF manufacturing involve the integration of the material into device structures. This may include patterning techniques such as photolithography or direct writing to create specific geometries required for RF components. The polysilane may also be combined with other materials to form composite structures that leverage the unique properties of each component.

Once the silane monomers are obtained, they undergo polymerization to form polysilane chains. This step is critical in determining the final properties of the material. Various polymerization methods can be employed, including thermal polymerization, catalytic polymerization, and plasma-enhanced chemical vapor deposition (PECVD). Each method offers different advantages in terms of molecular weight control, chain length distribution, and structural uniformity.

The polymerization process is followed by a series of purification steps to remove any residual monomers, catalysts, or impurities that could affect the RF performance of the final product. These purification techniques may include recrystallization, solvent extraction, and chromatography. The purity of the polysilane is crucial for its application in RF devices, as even trace amounts of contaminants can significantly impact the material's dielectric properties and overall performance.

After purification, the polysilane undergoes further processing to achieve the desired form for RF device integration. This may involve solution processing, where the polysilane is dissolved in an appropriate solvent and then deposited onto substrates using techniques such as spin-coating or dip-coating. Alternatively, vapor deposition methods can be used to create thin films of polysilane with precise thickness control.

The manufacturing process also includes the incorporation of additives or dopants to enhance specific properties of the polysilane for RF applications. These additives can modify the material's conductivity, dielectric constant, or thermal stability. The precise formulation and mixing of these components are critical to achieving the desired RF characteristics.

Quality control measures are implemented throughout the manufacturing process to ensure consistency and reliability of the polysilane materials. This includes in-line monitoring of molecular weight, chemical composition, and structural properties using techniques such as gel permeation chromatography (GPC), nuclear magnetic resonance (NMR) spectroscopy, and X-ray diffraction (XRD).

The final stages of polysilane RF manufacturing involve the integration of the material into device structures. This may include patterning techniques such as photolithography or direct writing to create specific geometries required for RF components. The polysilane may also be combined with other materials to form composite structures that leverage the unique properties of each component.

Environmental Impact of Polysilane

The environmental impact of polysilane in radio frequency devices is a crucial aspect to consider as the technology advances. Polysilanes, being silicon-based polymers, have unique properties that make them attractive for use in electronic and optical applications. However, their production, use, and disposal can have significant environmental implications.

The manufacturing process of polysilanes often involves the use of chlorosilanes as precursors, which can be harmful to the environment if not properly handled. These chemicals can contribute to air and water pollution if released during production. Additionally, the synthesis of polysilanes may require energy-intensive processes, potentially increasing the carbon footprint associated with their manufacture.

In terms of device operation, polysilanes used in radio frequency applications generally have a low environmental impact during use. They do not emit harmful radiation or substances under normal operating conditions. However, the long-term stability of polysilanes in various environmental conditions needs further investigation to ensure they do not degrade and release potentially harmful compounds over time.

End-of-life considerations for polysilane-based radio frequency devices are an important environmental concern. As electronic waste continues to be a global issue, the recyclability and biodegradability of polysilanes must be addressed. Currently, there is limited research on the decomposition of polysilanes in natural environments, and their potential to persist as microplastics or release silicon-based compounds into ecosystems remains a topic of study.

The potential for bioaccumulation of polysilane derivatives in the food chain is another area requiring attention. While silicon is generally considered non-toxic, the long-term effects of exposure to polysilane breakdown products on various organisms are not fully understood. This gap in knowledge necessitates further ecotoxicological studies to assess the potential risks to wildlife and human health.

On a positive note, the use of polysilanes in radio frequency devices may contribute to improved energy efficiency in telecommunications infrastructure. This could lead to reduced power consumption and, consequently, lower greenhouse gas emissions associated with the operation of these systems. Furthermore, if polysilanes enable the development of more compact and lightweight devices, this could result in material savings and reduced transportation-related emissions.

As the demand for radio frequency devices continues to grow, particularly with the expansion of 5G networks and IoT applications, the cumulative environmental impact of polysilane use may become more significant. It is essential for researchers and manufacturers to prioritize the development of environmentally friendly synthesis methods, explore bio-based alternatives, and design products with end-of-life recyclability in mind to mitigate potential negative impacts on the environment.

The manufacturing process of polysilanes often involves the use of chlorosilanes as precursors, which can be harmful to the environment if not properly handled. These chemicals can contribute to air and water pollution if released during production. Additionally, the synthesis of polysilanes may require energy-intensive processes, potentially increasing the carbon footprint associated with their manufacture.

In terms of device operation, polysilanes used in radio frequency applications generally have a low environmental impact during use. They do not emit harmful radiation or substances under normal operating conditions. However, the long-term stability of polysilanes in various environmental conditions needs further investigation to ensure they do not degrade and release potentially harmful compounds over time.

End-of-life considerations for polysilane-based radio frequency devices are an important environmental concern. As electronic waste continues to be a global issue, the recyclability and biodegradability of polysilanes must be addressed. Currently, there is limited research on the decomposition of polysilanes in natural environments, and their potential to persist as microplastics or release silicon-based compounds into ecosystems remains a topic of study.

The potential for bioaccumulation of polysilane derivatives in the food chain is another area requiring attention. While silicon is generally considered non-toxic, the long-term effects of exposure to polysilane breakdown products on various organisms are not fully understood. This gap in knowledge necessitates further ecotoxicological studies to assess the potential risks to wildlife and human health.

On a positive note, the use of polysilanes in radio frequency devices may contribute to improved energy efficiency in telecommunications infrastructure. This could lead to reduced power consumption and, consequently, lower greenhouse gas emissions associated with the operation of these systems. Furthermore, if polysilanes enable the development of more compact and lightweight devices, this could result in material savings and reduced transportation-related emissions.

As the demand for radio frequency devices continues to grow, particularly with the expansion of 5G networks and IoT applications, the cumulative environmental impact of polysilane use may become more significant. It is essential for researchers and manufacturers to prioritize the development of environmentally friendly synthesis methods, explore bio-based alternatives, and design products with end-of-life recyclability in mind to mitigate potential negative impacts on the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!