Investigating Polysilane's UV Stability for Outdoor Applications

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane UV Stability Background and Objectives

Polysilanes, a class of silicon-based polymers, have garnered significant attention in recent years due to their unique electronic and optical properties. These materials, characterized by a backbone of silicon atoms, exhibit remarkable potential for various applications, particularly in the realm of outdoor technologies. The investigation into polysilane's UV stability for outdoor applications stems from the growing demand for durable and efficient materials in sectors such as solar energy, outdoor displays, and protective coatings.

The development of polysilanes can be traced back to the 1920s, with significant advancements occurring in the 1980s and 1990s. Initially, these materials were primarily studied for their semiconducting properties. However, as research progressed, their photosensitive nature and potential for UV-related applications became increasingly apparent. The evolution of polysilane technology has been driven by the need for materials that can withstand prolonged exposure to sunlight while maintaining their functional properties.

In the context of outdoor applications, UV stability is a critical factor. Ultraviolet radiation, a component of sunlight, can cause significant degradation in many materials, leading to reduced performance and shortened lifespans. The investigation into polysilane's UV stability aims to address this challenge by exploring the material's ability to resist UV-induced degradation while retaining its desirable properties.

The primary objective of this research is to comprehensively evaluate the UV stability of polysilanes in outdoor environments. This involves assessing their resistance to photo-oxidation, structural changes under UV exposure, and the retention of optical and electronic properties over extended periods. Additionally, the study aims to identify potential modifications or additives that could enhance the UV stability of polysilanes, thereby expanding their applicability in outdoor settings.

Another crucial aspect of this investigation is to compare the UV stability of polysilanes with that of conventional materials used in similar applications. This comparative analysis will help determine the competitive advantage of polysilanes and identify specific outdoor applications where they could offer superior performance.

Furthermore, the research seeks to understand the underlying mechanisms of UV-induced changes in polysilanes. This fundamental knowledge is essential for developing strategies to mitigate degradation and design more robust polysilane-based materials for outdoor use. By elucidating these mechanisms, researchers can pave the way for tailored polysilane structures with enhanced UV stability.

Ultimately, this investigation into polysilane's UV stability for outdoor applications aims to bridge the gap between laboratory research and practical implementation. The findings from this study will not only contribute to the scientific understanding of polysilanes but also inform the development of new materials and technologies for various outdoor applications, potentially revolutionizing fields such as renewable energy, outdoor electronics, and protective coatings.

The development of polysilanes can be traced back to the 1920s, with significant advancements occurring in the 1980s and 1990s. Initially, these materials were primarily studied for their semiconducting properties. However, as research progressed, their photosensitive nature and potential for UV-related applications became increasingly apparent. The evolution of polysilane technology has been driven by the need for materials that can withstand prolonged exposure to sunlight while maintaining their functional properties.

In the context of outdoor applications, UV stability is a critical factor. Ultraviolet radiation, a component of sunlight, can cause significant degradation in many materials, leading to reduced performance and shortened lifespans. The investigation into polysilane's UV stability aims to address this challenge by exploring the material's ability to resist UV-induced degradation while retaining its desirable properties.

The primary objective of this research is to comprehensively evaluate the UV stability of polysilanes in outdoor environments. This involves assessing their resistance to photo-oxidation, structural changes under UV exposure, and the retention of optical and electronic properties over extended periods. Additionally, the study aims to identify potential modifications or additives that could enhance the UV stability of polysilanes, thereby expanding their applicability in outdoor settings.

Another crucial aspect of this investigation is to compare the UV stability of polysilanes with that of conventional materials used in similar applications. This comparative analysis will help determine the competitive advantage of polysilanes and identify specific outdoor applications where they could offer superior performance.

Furthermore, the research seeks to understand the underlying mechanisms of UV-induced changes in polysilanes. This fundamental knowledge is essential for developing strategies to mitigate degradation and design more robust polysilane-based materials for outdoor use. By elucidating these mechanisms, researchers can pave the way for tailored polysilane structures with enhanced UV stability.

Ultimately, this investigation into polysilane's UV stability for outdoor applications aims to bridge the gap between laboratory research and practical implementation. The findings from this study will not only contribute to the scientific understanding of polysilanes but also inform the development of new materials and technologies for various outdoor applications, potentially revolutionizing fields such as renewable energy, outdoor electronics, and protective coatings.

Market Analysis for UV-Stable Outdoor Materials

The market for UV-stable outdoor materials has been experiencing significant growth in recent years, driven by increasing demand across various industries such as construction, automotive, and agriculture. This trend is expected to continue as the need for durable, long-lasting materials in outdoor applications grows.

The global market for UV-stable materials is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other segments in the materials industry. This growth is primarily attributed to the rising awareness of the damaging effects of UV radiation on conventional materials and the subsequent need for more resilient alternatives.

In the construction sector, UV-stable materials are gaining traction for use in roofing, siding, and outdoor furniture. The automotive industry is another key driver, with a growing demand for UV-resistant coatings and components to enhance vehicle longevity and aesthetics. Additionally, the agricultural sector is increasingly adopting UV-stable materials for greenhouse coverings and crop protection.

Polysilane, as a potential UV-stable material for outdoor applications, enters a competitive market dominated by established solutions such as UV-stabilized polymers, coatings, and additives. However, the unique properties of polysilane, including its potential for enhanced UV stability, could position it as a disruptive technology in this space.

The market for UV-stable outdoor materials is characterized by a strong focus on innovation and product development. Companies are investing heavily in research and development to create more efficient and cost-effective solutions. This trend aligns well with the investigation into polysilane's UV stability, as there is a clear market appetite for novel materials that can offer superior performance in outdoor environments.

Geographically, North America and Europe currently lead the market for UV-stable materials, owing to stringent regulations regarding material durability and environmental protection. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and increasing awareness of UV protection in countries like China and India.

Consumer preferences are shifting towards more sustainable and environmentally friendly materials, which could potentially benefit polysilane if it can demonstrate eco-friendly characteristics alongside its UV stability. This shift is influencing product development strategies across the industry, with a growing emphasis on materials that offer both performance and sustainability.

In conclusion, the market analysis for UV-stable outdoor materials reveals a robust and growing sector with significant opportunities for innovative solutions. The investigation into polysilane's UV stability for outdoor applications aligns well with current market trends and demands, potentially offering a new avenue for addressing the persistent challenges in this field.

The global market for UV-stable materials is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other segments in the materials industry. This growth is primarily attributed to the rising awareness of the damaging effects of UV radiation on conventional materials and the subsequent need for more resilient alternatives.

In the construction sector, UV-stable materials are gaining traction for use in roofing, siding, and outdoor furniture. The automotive industry is another key driver, with a growing demand for UV-resistant coatings and components to enhance vehicle longevity and aesthetics. Additionally, the agricultural sector is increasingly adopting UV-stable materials for greenhouse coverings and crop protection.

Polysilane, as a potential UV-stable material for outdoor applications, enters a competitive market dominated by established solutions such as UV-stabilized polymers, coatings, and additives. However, the unique properties of polysilane, including its potential for enhanced UV stability, could position it as a disruptive technology in this space.

The market for UV-stable outdoor materials is characterized by a strong focus on innovation and product development. Companies are investing heavily in research and development to create more efficient and cost-effective solutions. This trend aligns well with the investigation into polysilane's UV stability, as there is a clear market appetite for novel materials that can offer superior performance in outdoor environments.

Geographically, North America and Europe currently lead the market for UV-stable materials, owing to stringent regulations regarding material durability and environmental protection. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and increasing awareness of UV protection in countries like China and India.

Consumer preferences are shifting towards more sustainable and environmentally friendly materials, which could potentially benefit polysilane if it can demonstrate eco-friendly characteristics alongside its UV stability. This shift is influencing product development strategies across the industry, with a growing emphasis on materials that offer both performance and sustainability.

In conclusion, the market analysis for UV-stable outdoor materials reveals a robust and growing sector with significant opportunities for innovative solutions. The investigation into polysilane's UV stability for outdoor applications aligns well with current market trends and demands, potentially offering a new avenue for addressing the persistent challenges in this field.

Current Challenges in Polysilane UV Stability

Despite the promising properties of polysilanes for outdoor applications, their UV stability remains a significant challenge. The primary issue lies in the susceptibility of the Si-Si backbone to photodegradation when exposed to UV radiation. This degradation process leads to chain scission, resulting in a loss of molecular weight and deterioration of the material's mechanical and optical properties.

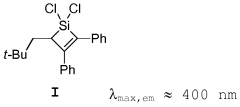

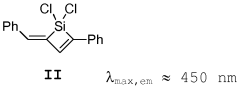

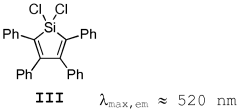

One of the key challenges is maintaining the balance between UV absorption and stability. While polysilanes exhibit excellent UV absorption properties, making them suitable for UV-blocking applications, this same characteristic also contributes to their instability. The absorbed UV energy can cause homolytic cleavage of the Si-Si bonds, initiating a cascade of degradation reactions.

The rate of photodegradation in polysilanes is influenced by various factors, including the molecular structure, substituents on the silicon atoms, and the presence of impurities or additives. Controlling these factors to enhance UV stability without compromising the desired properties of polysilanes is a complex task that requires careful molecular design and synthesis strategies.

Another significant challenge is the development of effective stabilization methods. Traditional UV stabilizers used for organic polymers often prove ineffective for polysilanes due to the unique nature of their inorganic backbone. Finding compatible and efficient stabilizers that can protect the Si-Si bonds without interfering with the material's functionality is an ongoing area of research.

The environmental factors in outdoor applications pose additional challenges to polysilane stability. Variations in temperature, humidity, and the presence of atmospheric pollutants can accelerate the degradation process, making it difficult to predict and control the long-term performance of polysilane-based materials in real-world conditions.

Furthermore, the mechanism of UV-induced degradation in polysilanes is not fully understood, particularly in complex outdoor environments. This knowledge gap hinders the development of targeted stabilization strategies and makes it challenging to model and predict the material's behavior under different exposure conditions.

Lastly, the scalability of UV-stable polysilane production remains a significant hurdle. While laboratory-scale synthesis of more stable polysilane derivatives has shown promise, translating these improvements to large-scale, cost-effective manufacturing processes is essential for widespread adoption in outdoor applications. Overcoming these challenges requires a multidisciplinary approach, combining advances in polymer chemistry, materials science, and process engineering.

One of the key challenges is maintaining the balance between UV absorption and stability. While polysilanes exhibit excellent UV absorption properties, making them suitable for UV-blocking applications, this same characteristic also contributes to their instability. The absorbed UV energy can cause homolytic cleavage of the Si-Si bonds, initiating a cascade of degradation reactions.

The rate of photodegradation in polysilanes is influenced by various factors, including the molecular structure, substituents on the silicon atoms, and the presence of impurities or additives. Controlling these factors to enhance UV stability without compromising the desired properties of polysilanes is a complex task that requires careful molecular design and synthesis strategies.

Another significant challenge is the development of effective stabilization methods. Traditional UV stabilizers used for organic polymers often prove ineffective for polysilanes due to the unique nature of their inorganic backbone. Finding compatible and efficient stabilizers that can protect the Si-Si bonds without interfering with the material's functionality is an ongoing area of research.

The environmental factors in outdoor applications pose additional challenges to polysilane stability. Variations in temperature, humidity, and the presence of atmospheric pollutants can accelerate the degradation process, making it difficult to predict and control the long-term performance of polysilane-based materials in real-world conditions.

Furthermore, the mechanism of UV-induced degradation in polysilanes is not fully understood, particularly in complex outdoor environments. This knowledge gap hinders the development of targeted stabilization strategies and makes it challenging to model and predict the material's behavior under different exposure conditions.

Lastly, the scalability of UV-stable polysilane production remains a significant hurdle. While laboratory-scale synthesis of more stable polysilane derivatives has shown promise, translating these improvements to large-scale, cost-effective manufacturing processes is essential for widespread adoption in outdoor applications. Overcoming these challenges requires a multidisciplinary approach, combining advances in polymer chemistry, materials science, and process engineering.

Existing UV Stabilization Techniques for Polysilanes

01 UV stabilization of polysilanes

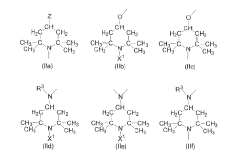

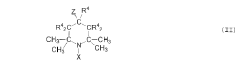

Various methods are employed to enhance the UV stability of polysilanes. These include the incorporation of UV stabilizers, modification of the polysilane structure, and the use of protective coatings. These techniques aim to prevent or reduce the degradation of polysilanes when exposed to ultraviolet radiation, thereby extending their lifespan and maintaining their properties in various applications.- UV-stable polysilane compositions: Polysilane compositions can be modified to enhance their UV stability. This can be achieved through the incorporation of specific additives or by altering the molecular structure of the polysilane. These modifications help to prevent degradation of the polysilane when exposed to UV radiation, making them suitable for various applications where UV resistance is crucial.

- Polysilane coatings with improved UV resistance: UV-stable polysilane coatings can be developed by incorporating UV absorbers or stabilizers into the formulation. These coatings provide protection to underlying substrates while maintaining their own integrity under UV exposure. The improved UV resistance makes them suitable for outdoor applications and protective coatings in various industries.

- Synthesis methods for UV-stable polysilanes: Novel synthesis methods can be employed to produce polysilanes with enhanced UV stability. These methods may involve the use of specific catalysts, reaction conditions, or precursor materials that result in polysilanes with improved resistance to UV-induced degradation. The synthesized polysilanes exhibit better performance in applications where UV exposure is a concern.

- Polysilane-based UV-resistant materials: Polysilanes can be incorporated into various materials to impart UV resistance. This includes the development of UV-resistant polymers, composites, and hybrid materials that utilize polysilanes as a key component. These materials find applications in areas such as electronics, optics, and protective coatings where UV stability is essential.

- Characterization and testing of UV-stable polysilanes: Methods for characterizing and testing the UV stability of polysilanes are crucial for assessing their performance. This includes techniques for measuring UV absorption, monitoring degradation rates, and evaluating long-term stability under various conditions. These characterization methods help in the development and optimization of UV-stable polysilane formulations for specific applications.

02 Polysilane composition for improved UV resistance

Specific polysilane compositions are developed to enhance UV resistance. These compositions may include additives, co-polymers, or modified side chains that contribute to improved stability under UV exposure. The careful selection and combination of components in the polysilane formulation can significantly impact its ability to withstand UV radiation.Expand Specific Solutions03 UV-curable polysilane formulations

UV-curable polysilane formulations are designed to utilize UV radiation for curing or crosslinking, rather than degradation. These formulations often contain photoinitiators and other reactive components that enable rapid curing upon exposure to UV light, resulting in a stable, crosslinked structure with enhanced UV resistance.Expand Specific Solutions04 Surface treatment and coating for UV protection

Surface treatments and protective coatings are applied to polysilane-based materials to enhance their UV stability. These treatments may include the application of UV-absorbing layers, reflective coatings, or surface modifications that reduce the penetration of UV radiation into the polysilane structure.Expand Specific Solutions05 Nanocomposite polysilane materials for UV stability

Nanocomposite materials incorporating polysilanes are developed to enhance UV stability. These materials often combine polysilanes with nanoparticles or other nanoscale structures that can absorb or scatter UV radiation, providing improved protection to the polysilane matrix. The synergistic effects of the nanocomposite structure contribute to enhanced overall UV stability.Expand Specific Solutions

Key Players in Polysilane Research and Production

The investigation of polysilane's UV stability for outdoor applications is currently in an emerging stage, with the market showing significant growth potential. The global market for UV-stable materials is expanding, driven by increasing demand in sectors such as construction, automotive, and electronics. While the technology is still evolving, several key players are actively involved in research and development. Companies like BASF, Wacker Chemie, and Shin-Etsu Chemical are at the forefront, leveraging their expertise in polymer science and materials engineering. Other notable contributors include Covestro, Sika Technology, and 3M Innovative Properties, each bringing unique capabilities to advance the field. As the technology matures, we can expect to see more innovative solutions and applications emerging from these industry leaders.

BASF Corp.

Technical Solution: BASF has developed a novel approach to enhance polysilane's UV stability for outdoor applications. Their research focuses on incorporating specialized UV absorbers and hindered amine light stabilizers (HALS) into polysilane formulations. This combination effectively reduces UV-induced degradation by absorbing harmful radiation and scavenging free radicals[1]. BASF's proprietary nanoparticle technology further enhances UV protection by creating a physical barrier against UV rays[3]. The company has also explored the use of surface modification techniques to improve the compatibility between polysilane and stabilizing additives, resulting in more uniform distribution and enhanced long-term stability[5].

Strengths: Comprehensive approach combining chemical and physical UV protection methods. Weaknesses: Potential increase in production costs due to specialized additives and nanoparticle technology.

Shin-Etsu Chemical Co., Ltd.

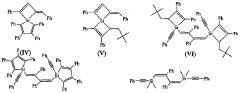

Technical Solution: Shin-Etsu Chemical has made significant strides in improving polysilane's UV stability through molecular design modifications. Their approach involves the synthesis of copolymers with UV-resistant side groups, such as phenyl or naphthyl moieties, which act as internal UV stabilizers[2]. The company has also developed a proprietary crosslinking technology that enhances the overall structural integrity of polysilane films when exposed to UV radiation[4]. Additionally, Shin-Etsu has explored the incorporation of silicon-based nanocomposites into polysilane matrices, which have shown promising results in reducing UV-induced degradation while maintaining optical transparency[6].

Strengths: Innovative molecular-level approach to UV stability. Weaknesses: Potential alterations to polysilane's inherent properties due to molecular modifications.

Innovative Approaches to Enhance Polysilane UV Resistance

Photoluminescent and/or electroluminescent material, method for production and use thereof and component comprising such a material

PatentWO2013068490A1

Innovation

- Development of polysilanes with stilbene and styrene units that are crosslinked to form stable, moisture-resistant materials with enhanced luminescence efficiency, suitable for use in optoelectronic components.

Coating composition for sealing surfaces

PatentWO2019114990A1

Innovation

- A moisture-curing coating composition incorporating silane-terminated polymers combined with specific HALS stabilizers having multiple functional groups, which are regenerated through the Denisov cycle, offering enhanced and long-lasting UV protection.

Environmental Impact of UV-Stable Polysilanes

The environmental impact of UV-stable polysilanes is a critical consideration in their outdoor applications. These materials, while offering enhanced durability and performance under ultraviolet exposure, may have both positive and negative effects on the environment throughout their lifecycle.

One of the primary environmental benefits of UV-stable polysilanes is their potential to extend the lifespan of outdoor products and structures. By improving resistance to degradation caused by sunlight, these materials can significantly reduce the frequency of replacement and maintenance. This longevity translates to decreased resource consumption and waste generation over time, aligning with sustainability goals and circular economy principles.

However, the production of UV-stable polysilanes may involve energy-intensive processes and the use of potentially harmful chemicals. The synthesis of these materials often requires specialized catalysts and precursors, which could have their own environmental footprints. It is crucial to assess the overall lifecycle impact, including raw material extraction, manufacturing, and end-of-life disposal, to fully understand the environmental implications.

The disposal and degradation of UV-stable polysilanes in the environment is another area of concern. While their resistance to UV degradation is beneficial for product longevity, it may also lead to persistence in the environment if not properly managed at the end of their useful life. Research into biodegradable or easily recyclable UV-stable polysilanes is ongoing to address this challenge.

In outdoor applications, UV-stable polysilanes may interact with other environmental factors such as moisture, temperature fluctuations, and atmospheric pollutants. These interactions could potentially lead to the release of micro-particles or chemical byproducts into the surrounding ecosystem. Long-term studies are needed to fully understand the ecological impact of these materials in various environmental conditions.

The use of UV-stable polysilanes in solar energy applications presents an interesting environmental trade-off. While these materials can enhance the efficiency and lifespan of solar panels, contributing to renewable energy production, the environmental cost of their manufacture and disposal must be weighed against these benefits. Lifecycle assessments are essential to determine the net environmental impact in such applications.

As research in this field progresses, there is a growing focus on developing more environmentally friendly UV-stable polysilanes. This includes exploring bio-based precursors, optimizing synthesis processes for reduced energy consumption, and designing materials with improved end-of-life recyclability or biodegradability. These advancements aim to mitigate potential negative environmental impacts while maintaining the beneficial properties of UV stability.

One of the primary environmental benefits of UV-stable polysilanes is their potential to extend the lifespan of outdoor products and structures. By improving resistance to degradation caused by sunlight, these materials can significantly reduce the frequency of replacement and maintenance. This longevity translates to decreased resource consumption and waste generation over time, aligning with sustainability goals and circular economy principles.

However, the production of UV-stable polysilanes may involve energy-intensive processes and the use of potentially harmful chemicals. The synthesis of these materials often requires specialized catalysts and precursors, which could have their own environmental footprints. It is crucial to assess the overall lifecycle impact, including raw material extraction, manufacturing, and end-of-life disposal, to fully understand the environmental implications.

The disposal and degradation of UV-stable polysilanes in the environment is another area of concern. While their resistance to UV degradation is beneficial for product longevity, it may also lead to persistence in the environment if not properly managed at the end of their useful life. Research into biodegradable or easily recyclable UV-stable polysilanes is ongoing to address this challenge.

In outdoor applications, UV-stable polysilanes may interact with other environmental factors such as moisture, temperature fluctuations, and atmospheric pollutants. These interactions could potentially lead to the release of micro-particles or chemical byproducts into the surrounding ecosystem. Long-term studies are needed to fully understand the ecological impact of these materials in various environmental conditions.

The use of UV-stable polysilanes in solar energy applications presents an interesting environmental trade-off. While these materials can enhance the efficiency and lifespan of solar panels, contributing to renewable energy production, the environmental cost of their manufacture and disposal must be weighed against these benefits. Lifecycle assessments are essential to determine the net environmental impact in such applications.

As research in this field progresses, there is a growing focus on developing more environmentally friendly UV-stable polysilanes. This includes exploring bio-based precursors, optimizing synthesis processes for reduced energy consumption, and designing materials with improved end-of-life recyclability or biodegradability. These advancements aim to mitigate potential negative environmental impacts while maintaining the beneficial properties of UV stability.

Regulatory Framework for Outdoor Polymer Applications

The regulatory framework for outdoor polymer applications, particularly concerning polysilane's UV stability, is a critical aspect of product development and market entry. In the United States, the Environmental Protection Agency (EPA) plays a pivotal role in regulating the use of polymers in outdoor settings. The EPA's Toxic Substances Control Act (TSCA) requires manufacturers to submit premanufacture notices for new chemical substances, including novel polymers, ensuring their safety for environmental exposure.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant framework that impacts the use of polysilanes in outdoor applications. Under REACH, manufacturers must register substances produced or imported in quantities over one tonne per year, providing detailed information on their properties, uses, and potential risks.

In addition to these overarching regulations, specific standards apply to UV-stable polymers in outdoor use. The International Organization for Standardization (ISO) has developed several relevant standards, such as ISO 4892 for methods of exposure to laboratory light sources, which is crucial for testing polysilane's UV stability. ASTM International also provides standards like ASTM G154 for operating fluorescent ultraviolet lamps for exposure of nonmetallic materials.

For construction applications, building codes often incorporate requirements for UV resistance in outdoor materials. The International Building Code (IBC) and local adaptations may specify minimum performance criteria for polymers used in exterior applications, including resistance to weathering and UV degradation.

In the automotive industry, regulations such as FMVSS 108 in the United States and ECE regulations in Europe govern the use of polymers in exterior vehicle components, with specific requirements for UV stability and durability. These regulations ensure that materials used in headlamps, taillights, and other exterior parts maintain their integrity and performance over time.

The food packaging industry also has stringent regulations for polymers that may be exposed to sunlight. The U.S. Food and Drug Administration (FDA) regulates food contact substances, including those used in outdoor packaging, under the Federal Food, Drug, and Cosmetic Act. Similarly, the European Food Safety Authority (EFSA) provides guidelines for materials intended to come into contact with food, which may include considerations for UV stability in outdoor storage scenarios.

As environmental concerns grow, regulations are evolving to address the entire lifecycle of polymers. The EU's Circular Economy Action Plan, for instance, aims to ensure that all plastic packaging is reusable or recyclable by 2030, which may influence the development and use of UV-stable polymers like polysilanes in outdoor applications.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant framework that impacts the use of polysilanes in outdoor applications. Under REACH, manufacturers must register substances produced or imported in quantities over one tonne per year, providing detailed information on their properties, uses, and potential risks.

In addition to these overarching regulations, specific standards apply to UV-stable polymers in outdoor use. The International Organization for Standardization (ISO) has developed several relevant standards, such as ISO 4892 for methods of exposure to laboratory light sources, which is crucial for testing polysilane's UV stability. ASTM International also provides standards like ASTM G154 for operating fluorescent ultraviolet lamps for exposure of nonmetallic materials.

For construction applications, building codes often incorporate requirements for UV resistance in outdoor materials. The International Building Code (IBC) and local adaptations may specify minimum performance criteria for polymers used in exterior applications, including resistance to weathering and UV degradation.

In the automotive industry, regulations such as FMVSS 108 in the United States and ECE regulations in Europe govern the use of polymers in exterior vehicle components, with specific requirements for UV stability and durability. These regulations ensure that materials used in headlamps, taillights, and other exterior parts maintain their integrity and performance over time.

The food packaging industry also has stringent regulations for polymers that may be exposed to sunlight. The U.S. Food and Drug Administration (FDA) regulates food contact substances, including those used in outdoor packaging, under the Federal Food, Drug, and Cosmetic Act. Similarly, the European Food Safety Authority (EFSA) provides guidelines for materials intended to come into contact with food, which may include considerations for UV stability in outdoor storage scenarios.

As environmental concerns grow, regulations are evolving to address the entire lifecycle of polymers. The EU's Circular Economy Action Plan, for instance, aims to ensure that all plastic packaging is reusable or recyclable by 2030, which may influence the development and use of UV-stable polymers like polysilanes in outdoor applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!