Isocyanate Expertise: Addressing Environmental Concerns

JUL 10, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Development and Environmental Goals

Isocyanates have been a cornerstone in various industries for decades, particularly in the production of polyurethanes. However, their development has been accompanied by growing environmental concerns. The evolution of isocyanate technology has been driven by the dual goals of enhancing performance and addressing ecological issues.

Initially, isocyanates were primarily valued for their versatility and reactivity in polymer chemistry. The early focus was on improving their synthesis methods and expanding their applications. As environmental awareness increased, the industry began to shift its attention towards developing more sustainable isocyanate products and processes.

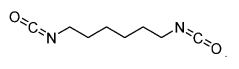

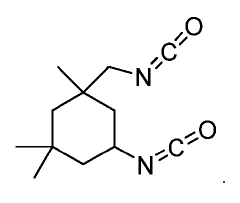

One of the key environmental goals in isocyanate development has been the reduction of volatile organic compound (VOC) emissions. This has led to the creation of low-VOC and zero-VOC isocyanate formulations, which significantly decrease the environmental impact during application and curing processes. Additionally, efforts have been made to develop water-based systems, further reducing the reliance on organic solvents.

Another critical objective has been the minimization of hazardous waste generation during isocyanate production. This has prompted research into more efficient synthesis routes and the exploration of bio-based raw materials as alternatives to petroleum-derived precursors. The use of renewable resources not only addresses sustainability concerns but also contributes to reducing the carbon footprint of isocyanate manufacturing.

The industry has also focused on improving the safety profile of isocyanates, both for workers and end-users. This has led to the development of blocked isocyanates and encapsulation technologies, which reduce exposure risks during handling and application. Furthermore, research into non-isocyanate polyurethanes (NIPUs) has gained momentum as a potential long-term solution to completely eliminate isocyanate-related health and environmental concerns.

Energy efficiency in isocyanate production has become another key environmental goal. Manufacturers have invested in process optimizations and the integration of renewable energy sources to reduce the overall energy consumption and associated greenhouse gas emissions. This aligns with broader industry efforts to achieve carbon neutrality and comply with increasingly stringent environmental regulations.

As the industry continues to evolve, the focus on sustainable isocyanate development remains paramount. Future goals include further advancements in green chemistry principles, such as atom economy and the use of catalysts to enhance reaction efficiency while minimizing waste. Additionally, the development of closed-loop recycling systems for isocyanate-based products is being explored to address end-of-life environmental concerns and promote a circular economy approach.

Initially, isocyanates were primarily valued for their versatility and reactivity in polymer chemistry. The early focus was on improving their synthesis methods and expanding their applications. As environmental awareness increased, the industry began to shift its attention towards developing more sustainable isocyanate products and processes.

One of the key environmental goals in isocyanate development has been the reduction of volatile organic compound (VOC) emissions. This has led to the creation of low-VOC and zero-VOC isocyanate formulations, which significantly decrease the environmental impact during application and curing processes. Additionally, efforts have been made to develop water-based systems, further reducing the reliance on organic solvents.

Another critical objective has been the minimization of hazardous waste generation during isocyanate production. This has prompted research into more efficient synthesis routes and the exploration of bio-based raw materials as alternatives to petroleum-derived precursors. The use of renewable resources not only addresses sustainability concerns but also contributes to reducing the carbon footprint of isocyanate manufacturing.

The industry has also focused on improving the safety profile of isocyanates, both for workers and end-users. This has led to the development of blocked isocyanates and encapsulation technologies, which reduce exposure risks during handling and application. Furthermore, research into non-isocyanate polyurethanes (NIPUs) has gained momentum as a potential long-term solution to completely eliminate isocyanate-related health and environmental concerns.

Energy efficiency in isocyanate production has become another key environmental goal. Manufacturers have invested in process optimizations and the integration of renewable energy sources to reduce the overall energy consumption and associated greenhouse gas emissions. This aligns with broader industry efforts to achieve carbon neutrality and comply with increasingly stringent environmental regulations.

As the industry continues to evolve, the focus on sustainable isocyanate development remains paramount. Future goals include further advancements in green chemistry principles, such as atom economy and the use of catalysts to enhance reaction efficiency while minimizing waste. Additionally, the development of closed-loop recycling systems for isocyanate-based products is being explored to address end-of-life environmental concerns and promote a circular economy approach.

Market Demand for Eco-Friendly Isocyanates

The market demand for eco-friendly isocyanates has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations. This trend is particularly evident in industries such as automotive, construction, and furniture manufacturing, where isocyanates are widely used in the production of polyurethanes.

Environmental awareness among consumers has led to a shift in preferences towards more sustainable products. This has created a significant opportunity for eco-friendly isocyanates, as manufacturers seek to meet consumer demands while complying with increasingly stringent environmental regulations. The automotive industry, for instance, has been actively exploring bio-based and low-emission isocyanates to reduce the carbon footprint of vehicle interiors and improve air quality.

In the construction sector, there is a rising demand for green building materials, including eco-friendly insulation foams and coatings. This has spurred research and development efforts to create isocyanates with reduced environmental impact, such as those derived from renewable resources or formulated to minimize volatile organic compound (VOC) emissions.

The furniture industry has also shown a growing interest in sustainable isocyanates, particularly for use in adhesives and coatings. Manufacturers are responding to consumer preferences for environmentally responsible products by incorporating eco-friendly materials into their production processes.

The global market for eco-friendly isocyanates is expected to experience substantial growth in the coming years. Factors contributing to this growth include increasing awareness of health and environmental issues associated with traditional isocyanates, government initiatives promoting sustainable chemistry, and the potential for cost savings through improved efficiency and reduced waste.

However, challenges remain in the widespread adoption of eco-friendly isocyanates. These include higher production costs compared to conventional alternatives, technical limitations in performance for certain applications, and the need for further research to develop more sustainable production methods. Despite these challenges, the market potential for eco-friendly isocyanates remains strong, with ongoing innovations and collaborations between industry players and research institutions driving progress in this field.

As the demand for sustainable materials continues to grow across various sectors, the market for eco-friendly isocyanates is poised for significant expansion. This presents opportunities for companies to differentiate themselves through innovative product offerings and sustainable practices, potentially gaining a competitive edge in an increasingly environmentally conscious marketplace.

Environmental awareness among consumers has led to a shift in preferences towards more sustainable products. This has created a significant opportunity for eco-friendly isocyanates, as manufacturers seek to meet consumer demands while complying with increasingly stringent environmental regulations. The automotive industry, for instance, has been actively exploring bio-based and low-emission isocyanates to reduce the carbon footprint of vehicle interiors and improve air quality.

In the construction sector, there is a rising demand for green building materials, including eco-friendly insulation foams and coatings. This has spurred research and development efforts to create isocyanates with reduced environmental impact, such as those derived from renewable resources or formulated to minimize volatile organic compound (VOC) emissions.

The furniture industry has also shown a growing interest in sustainable isocyanates, particularly for use in adhesives and coatings. Manufacturers are responding to consumer preferences for environmentally responsible products by incorporating eco-friendly materials into their production processes.

The global market for eco-friendly isocyanates is expected to experience substantial growth in the coming years. Factors contributing to this growth include increasing awareness of health and environmental issues associated with traditional isocyanates, government initiatives promoting sustainable chemistry, and the potential for cost savings through improved efficiency and reduced waste.

However, challenges remain in the widespread adoption of eco-friendly isocyanates. These include higher production costs compared to conventional alternatives, technical limitations in performance for certain applications, and the need for further research to develop more sustainable production methods. Despite these challenges, the market potential for eco-friendly isocyanates remains strong, with ongoing innovations and collaborations between industry players and research institutions driving progress in this field.

As the demand for sustainable materials continues to grow across various sectors, the market for eco-friendly isocyanates is poised for significant expansion. This presents opportunities for companies to differentiate themselves through innovative product offerings and sustainable practices, potentially gaining a competitive edge in an increasingly environmentally conscious marketplace.

Current Challenges in Isocyanate Production

The production of isocyanates faces several significant challenges in the current environmental landscape. One of the primary concerns is the use of phosgene as a key raw material in traditional manufacturing processes. Phosgene is highly toxic and poses severe health and safety risks, necessitating stringent handling protocols and safety measures. This not only increases production costs but also raises environmental and worker safety concerns.

Another major challenge is the emission of volatile organic compounds (VOCs) during isocyanate production. These emissions contribute to air pollution and can have detrimental effects on both human health and the environment. Regulatory bodies worldwide are imposing increasingly stringent limits on VOC emissions, forcing manufacturers to invest in costly abatement technologies and process modifications.

The energy-intensive nature of isocyanate production presents a significant environmental challenge. The high temperatures and pressures required in the manufacturing process result in substantial energy consumption and associated greenhouse gas emissions. This aspect of production is coming under increasing scrutiny as industries worldwide strive to reduce their carbon footprint and meet sustainability targets.

Water consumption and wastewater management also pose significant challenges in isocyanate production. The process requires large volumes of water for cooling and cleaning, and the resulting wastewater often contains hazardous substances that require specialized treatment before disposal. This not only increases production costs but also raises concerns about water resource management and potential environmental contamination.

The use of non-renewable fossil fuel-based raw materials in isocyanate production is another pressing issue. As global efforts to transition towards more sustainable and renewable resources intensify, the industry faces pressure to find alternative feedstocks that can reduce its dependence on petrochemicals.

Lastly, the management of by-products and waste streams from isocyanate production presents ongoing challenges. Some of these by-products can be hazardous and require specialized handling and disposal methods, adding complexity and cost to the production process. The industry is under increasing pressure to develop more efficient processes that minimize waste generation and maximize resource utilization.

Another major challenge is the emission of volatile organic compounds (VOCs) during isocyanate production. These emissions contribute to air pollution and can have detrimental effects on both human health and the environment. Regulatory bodies worldwide are imposing increasingly stringent limits on VOC emissions, forcing manufacturers to invest in costly abatement technologies and process modifications.

The energy-intensive nature of isocyanate production presents a significant environmental challenge. The high temperatures and pressures required in the manufacturing process result in substantial energy consumption and associated greenhouse gas emissions. This aspect of production is coming under increasing scrutiny as industries worldwide strive to reduce their carbon footprint and meet sustainability targets.

Water consumption and wastewater management also pose significant challenges in isocyanate production. The process requires large volumes of water for cooling and cleaning, and the resulting wastewater often contains hazardous substances that require specialized treatment before disposal. This not only increases production costs but also raises concerns about water resource management and potential environmental contamination.

The use of non-renewable fossil fuel-based raw materials in isocyanate production is another pressing issue. As global efforts to transition towards more sustainable and renewable resources intensify, the industry faces pressure to find alternative feedstocks that can reduce its dependence on petrochemicals.

Lastly, the management of by-products and waste streams from isocyanate production presents ongoing challenges. Some of these by-products can be hazardous and require specialized handling and disposal methods, adding complexity and cost to the production process. The industry is under increasing pressure to develop more efficient processes that minimize waste generation and maximize resource utilization.

Existing Green Isocyanate Solutions

01 Environmental impact assessment of isocyanates

Isocyanates are known to have potential environmental impacts. Assessment methods are developed to evaluate their effects on air, water, and soil quality. These assessments consider factors such as toxicity, persistence, and bioaccumulation potential of isocyanates in the environment.- Environmental impact assessment of isocyanates: Isocyanates are known to have potential environmental impacts. Environmental impact assessments are conducted to evaluate the effects of isocyanates on air, water, and soil quality. These assessments help in developing strategies to mitigate the negative impacts and ensure compliance with environmental regulations.

- Reduction of isocyanate emissions: Efforts are being made to reduce isocyanate emissions in industrial processes. This includes developing new technologies and methods for capturing and treating isocyanate vapors, improving production processes to minimize releases, and implementing better handling and storage practices to prevent accidental spills or leaks.

- Biodegradable alternatives to isocyanates: Research is ongoing to develop biodegradable alternatives to traditional isocyanates. These alternatives aim to provide similar functional properties while reducing environmental persistence and toxicity. Bio-based materials and green chemistry approaches are being explored to create more environmentally friendly substitutes.

- Monitoring and detection of isocyanates in the environment: Advanced monitoring and detection methods are being developed to track isocyanate levels in various environmental matrices. These techniques help in early detection of contamination, assessment of environmental fate, and evaluation of the effectiveness of control measures. Improved analytical methods contribute to better environmental management of isocyanates.

- Regulatory compliance and environmental management systems: Industries using isocyanates are implementing comprehensive environmental management systems to ensure regulatory compliance and minimize environmental impacts. This includes developing protocols for safe handling, storage, and disposal of isocyanates, as well as implementing training programs for workers to reduce the risk of environmental contamination.

02 Reduction of isocyanate emissions in manufacturing processes

Techniques are developed to minimize isocyanate emissions during production and application processes. These include improved ventilation systems, closed-loop manufacturing, and the use of alternative raw materials or processes that reduce the release of isocyanates into the environment.Expand Specific Solutions03 Biodegradable alternatives to traditional isocyanates

Research is conducted on developing biodegradable alternatives to conventional isocyanates. These eco-friendly substitutes aim to maintain similar performance characteristics while reducing environmental persistence and potential ecological harm.Expand Specific Solutions04 Monitoring and control systems for isocyanate exposure

Advanced monitoring and control systems are implemented to detect and manage isocyanate exposure in industrial settings and the environment. These systems help in early detection of leaks or spills, ensuring prompt response to minimize environmental impact.Expand Specific Solutions05 Waste management and disposal of isocyanate-containing materials

Proper waste management and disposal techniques are developed for materials containing isocyanates. These methods focus on safe handling, treatment, and disposal to prevent environmental contamination and reduce the overall ecological footprint of isocyanate-based products.Expand Specific Solutions

Key Players in Isocyanate Industry

The isocyanate industry is in a mature growth phase, with a global market size expected to reach $38 billion by 2025. Technological advancements are primarily focused on addressing environmental concerns and improving sustainability. Key players like Wanhua Chemical, BASF, Covestro, and DuPont are investing heavily in R&D to develop eco-friendly alternatives and production processes. The market is characterized by intense competition and consolidation, with established companies leveraging their expertise to maintain market share. Emerging trends include bio-based isocyanates and low-VOC formulations, reflecting the industry's shift towards greener solutions in response to stringent environmental regulations and growing consumer awareness.

Wanhua Chemical Group Co., Ltd.

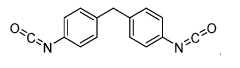

Technical Solution: Wanhua Chemical has developed innovative isocyanate technologies to address environmental concerns. Their approach includes the use of water-based polyurethane dispersions (PUDs) that significantly reduce volatile organic compound (VOC) emissions[1]. They have also implemented a closed-loop production system that minimizes waste and recycles by-products[2]. Wanhua's MDI (methylene diphenyl diisocyanate) production process incorporates advanced catalysts and reactor designs, improving energy efficiency by up to 30% compared to conventional methods[3]. Additionally, they have invested in bio-based isocyanates derived from renewable resources, reducing reliance on fossil fuels[4].

Strengths: Advanced eco-friendly technologies, reduced emissions, improved energy efficiency. Weaknesses: Higher production costs for bio-based alternatives, potential limitations in certain high-performance applications.

BASF SE

Technical Solution: BASF has developed a comprehensive approach to address environmental concerns in isocyanate production and use. Their EcoEfficiency Analysis tool evaluates the entire life cycle of isocyanate-based products, optimizing both environmental impact and cost-effectiveness[1]. BASF's Elastollan® TPU (thermoplastic polyurethane) range includes grades made with bio-based raw materials, reducing carbon footprint by up to 50%[2]. They have also introduced a novel aliphatic isocyanate, Basonat®, which offers low VOC emissions and improved durability for coatings[3]. BASF's commitment to sustainability extends to their production processes, implementing energy-efficient technologies that have reduced CO2 emissions in isocyanate manufacturing by approximately 35% since 2000[4].

Strengths: Comprehensive life cycle approach, bio-based alternatives, reduced emissions in production. Weaknesses: Higher costs associated with bio-based materials, potential performance trade-offs in some applications.

Innovations in Eco-Friendly Isocyanates

Flow chemistry synthesis of isocyanates

PatentWO2021119606A1

Innovation

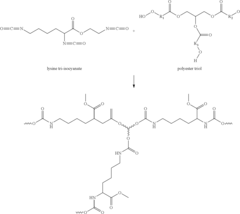

- A continuous flow process involving the mixing of acyl hydrazides with nitrous acid to form acyl azides, followed by heating in the presence of an organic solvent to produce isocyanates through Curtius rearrangement, offering a safer and more scalable method for isocyanate synthesis.

Isocyanate manufacture

PatentActiveUS20120202961A1

Innovation

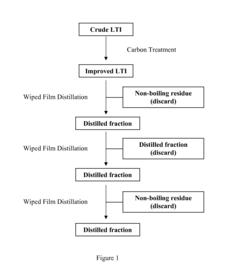

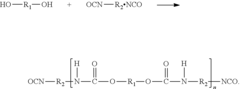

- The use of diphosgene (ClCO2CCl3) as a substitute for phosgene, allowing for the production of isocyanates at elevated temperatures, either through a two-reactor system or directly in a one-reactor system with a catalyst, to generate isocyanates like lysine ester triisocyanate (LTI) with high purity by reacting an amine with disphosgene.

Environmental Regulations on Isocyanates

Environmental regulations on isocyanates have become increasingly stringent in recent years due to growing concerns about their potential health and environmental impacts. These regulations aim to protect workers, consumers, and the environment from exposure to these potentially hazardous chemicals.

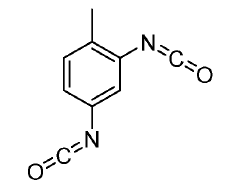

In the United States, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for various isocyanates in the workplace. For instance, the PEL for toluene diisocyanate (TDI) is set at 0.02 parts per million (ppm) for an 8-hour time-weighted average. The National Institute for Occupational Safety and Health (NIOSH) has recommended even lower exposure limits for some isocyanates.

The Environmental Protection Agency (EPA) regulates isocyanates under the Toxic Substances Control Act (TSCA). In 2011, the EPA added diisocyanates and related compounds to the TSCA Work Plan, indicating increased scrutiny and potential for further regulation. The agency has also implemented significant new use rules (SNURs) for certain isocyanates, requiring manufacturers to notify the EPA before using these substances in new ways.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register chemicals and provide safety data. Some isocyanates, such as methylene diphenyl diisocyanate (MDI), are subject to specific restrictions under REACH, including requirements for worker training and the use of personal protective equipment.

Japan has implemented the Chemical Substances Control Law, which regulates the manufacture, import, and use of chemical substances, including isocyanates. The law requires manufacturers and importers to conduct safety assessments and report production volumes for certain isocyanates.

Many countries have also established regulations on volatile organic compound (VOC) emissions, which can affect the use of isocyanates in various products, particularly in the coatings and adhesives industries. These regulations often set limits on the VOC content of products or require the use of low-VOC alternatives.

As environmental concerns continue to grow, it is likely that regulations on isocyanates will become even more stringent in the future. This may include lower exposure limits, increased reporting requirements, and potentially the phasing out of certain isocyanates in favor of safer alternatives. Companies working with isocyanates must stay informed about these evolving regulations and adapt their practices accordingly to ensure compliance and minimize environmental impact.

In the United States, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for various isocyanates in the workplace. For instance, the PEL for toluene diisocyanate (TDI) is set at 0.02 parts per million (ppm) for an 8-hour time-weighted average. The National Institute for Occupational Safety and Health (NIOSH) has recommended even lower exposure limits for some isocyanates.

The Environmental Protection Agency (EPA) regulates isocyanates under the Toxic Substances Control Act (TSCA). In 2011, the EPA added diisocyanates and related compounds to the TSCA Work Plan, indicating increased scrutiny and potential for further regulation. The agency has also implemented significant new use rules (SNURs) for certain isocyanates, requiring manufacturers to notify the EPA before using these substances in new ways.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register chemicals and provide safety data. Some isocyanates, such as methylene diphenyl diisocyanate (MDI), are subject to specific restrictions under REACH, including requirements for worker training and the use of personal protective equipment.

Japan has implemented the Chemical Substances Control Law, which regulates the manufacture, import, and use of chemical substances, including isocyanates. The law requires manufacturers and importers to conduct safety assessments and report production volumes for certain isocyanates.

Many countries have also established regulations on volatile organic compound (VOC) emissions, which can affect the use of isocyanates in various products, particularly in the coatings and adhesives industries. These regulations often set limits on the VOC content of products or require the use of low-VOC alternatives.

As environmental concerns continue to grow, it is likely that regulations on isocyanates will become even more stringent in the future. This may include lower exposure limits, increased reporting requirements, and potentially the phasing out of certain isocyanates in favor of safer alternatives. Companies working with isocyanates must stay informed about these evolving regulations and adapt their practices accordingly to ensure compliance and minimize environmental impact.

Life Cycle Assessment of Isocyanates

Life Cycle Assessment (LCA) of isocyanates is a crucial tool for evaluating the environmental impact of these widely used chemical compounds throughout their entire lifecycle. This comprehensive analysis encompasses raw material extraction, production processes, transportation, use phase, and end-of-life disposal or recycling.

The production of isocyanates, primarily derived from fossil fuels, involves energy-intensive processes that contribute significantly to their environmental footprint. The synthesis of key precursors, such as toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI), requires substantial energy inputs and generates various emissions. These emissions include greenhouse gases, volatile organic compounds (VOCs), and potentially hazardous byproducts.

During the use phase, isocyanates exhibit both positive and negative environmental impacts. On the positive side, their application in insulation materials contributes to energy efficiency in buildings, potentially offsetting initial production-related emissions over time. However, concerns arise regarding the release of unreacted isocyanates and their potential health effects on workers and end-users.

End-of-life considerations for isocyanate-containing products present significant challenges. Many polyurethane products, which are based on isocyanates, are difficult to recycle due to their thermoset nature. Incineration is often employed as a disposal method, but this process can release toxic substances if not properly controlled.

Recent LCA studies have focused on comparing traditional isocyanate-based products with bio-based alternatives. These assessments typically consider factors such as global warming potential, ozone depletion, acidification, and resource depletion. Results often show trade-offs between different environmental impact categories, highlighting the complexity of sustainable material selection.

Efforts to improve the environmental profile of isocyanates include the development of more efficient production processes, the use of renewable feedstocks, and the implementation of better emission control technologies. Additionally, research into novel recycling methods for polyurethane products aims to address end-of-life issues and promote a more circular economy approach.

The LCA of isocyanates also extends to their role in enabling lightweight materials for automotive and aerospace applications. While the production of these materials may have higher initial environmental costs, their use can lead to significant fuel savings and reduced emissions over the lifetime of vehicles, presenting a complex balance in environmental impact assessment.

The production of isocyanates, primarily derived from fossil fuels, involves energy-intensive processes that contribute significantly to their environmental footprint. The synthesis of key precursors, such as toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI), requires substantial energy inputs and generates various emissions. These emissions include greenhouse gases, volatile organic compounds (VOCs), and potentially hazardous byproducts.

During the use phase, isocyanates exhibit both positive and negative environmental impacts. On the positive side, their application in insulation materials contributes to energy efficiency in buildings, potentially offsetting initial production-related emissions over time. However, concerns arise regarding the release of unreacted isocyanates and their potential health effects on workers and end-users.

End-of-life considerations for isocyanate-containing products present significant challenges. Many polyurethane products, which are based on isocyanates, are difficult to recycle due to their thermoset nature. Incineration is often employed as a disposal method, but this process can release toxic substances if not properly controlled.

Recent LCA studies have focused on comparing traditional isocyanate-based products with bio-based alternatives. These assessments typically consider factors such as global warming potential, ozone depletion, acidification, and resource depletion. Results often show trade-offs between different environmental impact categories, highlighting the complexity of sustainable material selection.

Efforts to improve the environmental profile of isocyanates include the development of more efficient production processes, the use of renewable feedstocks, and the implementation of better emission control technologies. Additionally, research into novel recycling methods for polyurethane products aims to address end-of-life issues and promote a more circular economy approach.

The LCA of isocyanates also extends to their role in enabling lightweight materials for automotive and aerospace applications. While the production of these materials may have higher initial environmental costs, their use can lead to significant fuel savings and reduced emissions over the lifetime of vehicles, presenting a complex balance in environmental impact assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!