Isocyanate Industry Response to Green Chemistry Movements

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Tech Evolution

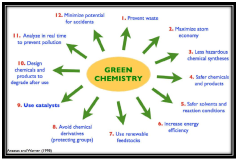

The isocyanate industry has undergone significant technological evolution in response to green chemistry movements. This progression can be traced through several key stages, each marked by advancements aimed at improving sustainability and reducing environmental impact.

In the early stages, the focus was primarily on optimizing existing production processes to minimize waste and energy consumption. Manufacturers implemented more efficient catalysts and improved reactor designs to increase yield and reduce byproducts. This period also saw the introduction of better purification techniques to enhance product quality while reducing the use of harmful solvents.

As environmental concerns gained prominence, the industry shifted towards developing alternative raw materials. Researchers explored bio-based feedstocks as potential replacements for petroleum-derived precursors. This led to the emergence of partially bio-based isocyanates, which offered a more sustainable option without compromising performance characteristics.

The next phase of evolution centered on reducing the toxicity of isocyanates themselves. Scientists developed blocked isocyanates and isocyanate-free systems that could provide similar functionality with improved safety profiles. These innovations were particularly important in applications where exposure risks were high, such as in consumer products and construction materials.

Recent years have witnessed a surge in research focused on circular economy principles. The industry has made strides in developing recyclable and biodegradable isocyanate-based products, particularly in the polyurethane sector. This includes advancements in chemical recycling technologies that can break down polyurethane foams and coatings into their constituent monomers for reuse.

Concurrently, there has been a push towards more energy-efficient and environmentally friendly production methods. The adoption of microreactor technology and continuous flow processes has allowed for better control over reaction conditions, resulting in higher yields and reduced waste. Additionally, the integration of renewable energy sources in manufacturing facilities has further reduced the carbon footprint of isocyanate production.

The latest frontier in isocyanate technology evolution involves the application of green chemistry principles at the molecular level. Researchers are exploring novel molecular designs that incorporate easily degradable linkages or reactive groups that facilitate recycling. This approach aims to create "smart" isocyanates that maintain their performance during use but can be readily broken down at the end of their lifecycle.

Throughout this evolutionary journey, the isocyanate industry has demonstrated a commitment to addressing environmental concerns while maintaining the unique properties that make isocyanates invaluable in numerous applications. The ongoing research and development efforts continue to push the boundaries of green chemistry in this field, promising even more sustainable solutions in the future.

In the early stages, the focus was primarily on optimizing existing production processes to minimize waste and energy consumption. Manufacturers implemented more efficient catalysts and improved reactor designs to increase yield and reduce byproducts. This period also saw the introduction of better purification techniques to enhance product quality while reducing the use of harmful solvents.

As environmental concerns gained prominence, the industry shifted towards developing alternative raw materials. Researchers explored bio-based feedstocks as potential replacements for petroleum-derived precursors. This led to the emergence of partially bio-based isocyanates, which offered a more sustainable option without compromising performance characteristics.

The next phase of evolution centered on reducing the toxicity of isocyanates themselves. Scientists developed blocked isocyanates and isocyanate-free systems that could provide similar functionality with improved safety profiles. These innovations were particularly important in applications where exposure risks were high, such as in consumer products and construction materials.

Recent years have witnessed a surge in research focused on circular economy principles. The industry has made strides in developing recyclable and biodegradable isocyanate-based products, particularly in the polyurethane sector. This includes advancements in chemical recycling technologies that can break down polyurethane foams and coatings into their constituent monomers for reuse.

Concurrently, there has been a push towards more energy-efficient and environmentally friendly production methods. The adoption of microreactor technology and continuous flow processes has allowed for better control over reaction conditions, resulting in higher yields and reduced waste. Additionally, the integration of renewable energy sources in manufacturing facilities has further reduced the carbon footprint of isocyanate production.

The latest frontier in isocyanate technology evolution involves the application of green chemistry principles at the molecular level. Researchers are exploring novel molecular designs that incorporate easily degradable linkages or reactive groups that facilitate recycling. This approach aims to create "smart" isocyanates that maintain their performance during use but can be readily broken down at the end of their lifecycle.

Throughout this evolutionary journey, the isocyanate industry has demonstrated a commitment to addressing environmental concerns while maintaining the unique properties that make isocyanates invaluable in numerous applications. The ongoing research and development efforts continue to push the boundaries of green chemistry in this field, promising even more sustainable solutions in the future.

Green Chemistry Market Trends

The green chemistry movement has significantly impacted the global chemical industry, driving a shift towards more sustainable practices and environmentally friendly products. This trend has particularly affected the isocyanate industry, which has been under scrutiny due to the environmental and health concerns associated with traditional isocyanate production and use.

Market analysis indicates a growing demand for green chemistry solutions in the isocyanate sector. Consumers and regulatory bodies are increasingly prioritizing eco-friendly alternatives, leading to a surge in research and development efforts focused on sustainable isocyanate production methods and bio-based alternatives. This shift is reflected in the increasing market share of green isocyanate products, which are projected to experience substantial growth in the coming years.

The adoption of green chemistry principles in the isocyanate industry is driven by several factors. Stringent environmental regulations, particularly in developed economies, have pushed manufacturers to invest in cleaner production processes and safer end products. Additionally, corporate sustainability initiatives and consumer preferences for environmentally responsible products have created a strong market pull for green isocyanate solutions.

Key market trends in the green chemistry movement within the isocyanate industry include the development of bio-based isocyanates, water-based polyurethane systems, and isocyanate-free alternatives. These innovations aim to reduce the environmental footprint of isocyanate production and address health concerns associated with traditional isocyanates.

The market for green isocyanate products is experiencing rapid growth across various end-use industries, including automotive, construction, and furniture manufacturing. This growth is supported by advancements in technology that have improved the performance and cost-effectiveness of sustainable alternatives, making them increasingly competitive with conventional isocyanates.

Geographically, Europe and North America lead in the adoption of green chemistry practices in the isocyanate industry, driven by strict regulatory frameworks and high consumer awareness. However, emerging economies in Asia-Pacific are showing increasing interest in green isocyanate solutions, presenting significant growth opportunities for market players.

Despite the positive market trends, challenges remain in the widespread adoption of green chemistry in the isocyanate industry. These include higher production costs, technical limitations in certain applications, and the need for extensive research and development to match the performance of traditional isocyanates. However, ongoing innovations and increasing scale of production are expected to address these challenges over time, further driving the market growth for green isocyanate solutions.

Market analysis indicates a growing demand for green chemistry solutions in the isocyanate sector. Consumers and regulatory bodies are increasingly prioritizing eco-friendly alternatives, leading to a surge in research and development efforts focused on sustainable isocyanate production methods and bio-based alternatives. This shift is reflected in the increasing market share of green isocyanate products, which are projected to experience substantial growth in the coming years.

The adoption of green chemistry principles in the isocyanate industry is driven by several factors. Stringent environmental regulations, particularly in developed economies, have pushed manufacturers to invest in cleaner production processes and safer end products. Additionally, corporate sustainability initiatives and consumer preferences for environmentally responsible products have created a strong market pull for green isocyanate solutions.

Key market trends in the green chemistry movement within the isocyanate industry include the development of bio-based isocyanates, water-based polyurethane systems, and isocyanate-free alternatives. These innovations aim to reduce the environmental footprint of isocyanate production and address health concerns associated with traditional isocyanates.

The market for green isocyanate products is experiencing rapid growth across various end-use industries, including automotive, construction, and furniture manufacturing. This growth is supported by advancements in technology that have improved the performance and cost-effectiveness of sustainable alternatives, making them increasingly competitive with conventional isocyanates.

Geographically, Europe and North America lead in the adoption of green chemistry practices in the isocyanate industry, driven by strict regulatory frameworks and high consumer awareness. However, emerging economies in Asia-Pacific are showing increasing interest in green isocyanate solutions, presenting significant growth opportunities for market players.

Despite the positive market trends, challenges remain in the widespread adoption of green chemistry in the isocyanate industry. These include higher production costs, technical limitations in certain applications, and the need for extensive research and development to match the performance of traditional isocyanates. However, ongoing innovations and increasing scale of production are expected to address these challenges over time, further driving the market growth for green isocyanate solutions.

Eco-Friendly Isocyanate Challenges

The isocyanate industry faces significant challenges in adapting to the growing demand for eco-friendly alternatives driven by green chemistry movements. One of the primary obstacles is the inherent toxicity of isocyanates, particularly methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI), which are widely used in polyurethane production. These compounds pose health risks to workers and consumers, necessitating stringent safety measures during manufacturing and application processes.

Environmental concerns also present a major challenge, as traditional isocyanate production relies heavily on fossil fuel-derived raw materials and energy-intensive processes. The industry must find ways to reduce its carbon footprint and minimize waste generation to align with sustainability goals. Additionally, the end-of-life disposal of isocyanate-based products, such as polyurethane foams, remains problematic due to their non-biodegradable nature and potential for releasing harmful substances during incineration or landfilling.

Another significant hurdle is the development of bio-based alternatives that can match the performance characteristics of conventional isocyanates. While progress has been made in creating bio-based polyols, finding suitable replacements for the isocyanate component that offer comparable reactivity, durability, and cost-effectiveness has proven challenging. This is particularly true for applications requiring high-performance materials, such as automotive parts or construction insulation.

Regulatory pressures also pose a considerable challenge to the isocyanate industry. Increasingly stringent environmental regulations and chemical safety standards are forcing manufacturers to invest in costly emission control technologies and explore alternative production methods. The potential for future bans or restrictions on certain isocyanates further complicates long-term planning and investment decisions within the industry.

The transition to eco-friendly isocyanates also faces economic barriers. Developing and scaling up new, greener technologies often requires substantial capital investment, which can be a deterrent for companies, especially in a competitive market environment. Moreover, the higher costs associated with bio-based raw materials and novel production processes can make eco-friendly isocyanates less economically viable compared to their conventional counterparts, at least in the short term.

Lastly, the industry must overcome technical challenges in formulation and processing when incorporating eco-friendly alternatives. Existing manufacturing equipment and processes may require significant modifications to accommodate new materials, potentially disrupting established production lines and supply chains. Ensuring consistent quality and performance across a wide range of applications while using more environmentally benign components remains an ongoing challenge for researchers and product developers in the isocyanate industry.

Environmental concerns also present a major challenge, as traditional isocyanate production relies heavily on fossil fuel-derived raw materials and energy-intensive processes. The industry must find ways to reduce its carbon footprint and minimize waste generation to align with sustainability goals. Additionally, the end-of-life disposal of isocyanate-based products, such as polyurethane foams, remains problematic due to their non-biodegradable nature and potential for releasing harmful substances during incineration or landfilling.

Another significant hurdle is the development of bio-based alternatives that can match the performance characteristics of conventional isocyanates. While progress has been made in creating bio-based polyols, finding suitable replacements for the isocyanate component that offer comparable reactivity, durability, and cost-effectiveness has proven challenging. This is particularly true for applications requiring high-performance materials, such as automotive parts or construction insulation.

Regulatory pressures also pose a considerable challenge to the isocyanate industry. Increasingly stringent environmental regulations and chemical safety standards are forcing manufacturers to invest in costly emission control technologies and explore alternative production methods. The potential for future bans or restrictions on certain isocyanates further complicates long-term planning and investment decisions within the industry.

The transition to eco-friendly isocyanates also faces economic barriers. Developing and scaling up new, greener technologies often requires substantial capital investment, which can be a deterrent for companies, especially in a competitive market environment. Moreover, the higher costs associated with bio-based raw materials and novel production processes can make eco-friendly isocyanates less economically viable compared to their conventional counterparts, at least in the short term.

Lastly, the industry must overcome technical challenges in formulation and processing when incorporating eco-friendly alternatives. Existing manufacturing equipment and processes may require significant modifications to accommodate new materials, potentially disrupting established production lines and supply chains. Ensuring consistent quality and performance across a wide range of applications while using more environmentally benign components remains an ongoing challenge for researchers and product developers in the isocyanate industry.

Current Green Isocyanate Solutions

01 Isocyanate production processes

Various methods and processes for producing isocyanates are employed in the industry. These may include reactions involving phosgene, thermal decomposition of carbamates, or novel catalytic processes. Improvements in production efficiency, yield, and environmental impact are key focus areas.- Isocyanate production processes: Various methods and processes for producing isocyanates are employed in the industry. These may include reactions involving amines and phosgene, as well as alternative routes using carbamates or ureas. Continuous improvement in production techniques aims to enhance efficiency and reduce environmental impact.

- Applications in polyurethane manufacturing: Isocyanates are crucial components in the production of polyurethanes, which find widespread use in industries such as construction, automotive, and furniture. The industry focuses on developing specialized isocyanate formulations to meet specific performance requirements for different polyurethane applications.

- Environmental and safety considerations: The isocyanate industry places significant emphasis on addressing environmental concerns and safety issues associated with the production and handling of these chemicals. This includes developing safer production methods, improving containment systems, and implementing stringent safety protocols to protect workers and the environment.

- Innovations in isocyanate-based materials: Ongoing research and development in the isocyanate industry focus on creating novel materials with enhanced properties. This includes the development of bio-based isocyanates, low-VOC formulations, and isocyanate-modified polymers for advanced applications in sectors such as electronics and aerospace.

- Market trends and industry dynamics: The isocyanate industry is influenced by various market trends, including shifts in demand from key end-use sectors, regulatory changes, and technological advancements. Industry players are adapting to these dynamics through strategic investments, mergers and acquisitions, and diversification of product portfolios to maintain competitiveness.

02 Applications in polyurethane manufacturing

Isocyanates are crucial components in the production of polyurethanes, which find applications in various industries such as automotive, construction, and furniture. The industry focuses on developing specialized isocyanate formulations for specific polyurethane properties and applications.Expand Specific Solutions03 Environmental and safety considerations

The isocyanate industry places significant emphasis on addressing environmental concerns and safety issues. This includes developing less toxic alternatives, improving handling and storage methods, and implementing stricter safety protocols in production and usage.Expand Specific Solutions04 Innovations in isocyanate-based materials

Ongoing research in the isocyanate industry focuses on developing new materials with enhanced properties. This includes creating novel isocyanate-based polymers, composites, and hybrid materials for advanced applications in sectors like aerospace, electronics, and medical devices.Expand Specific Solutions05 Market trends and industry dynamics

The isocyanate industry is influenced by global market trends, regulatory changes, and technological advancements. Key aspects include supply chain management, raw material availability, pricing fluctuations, and the shift towards more sustainable and bio-based isocyanates.Expand Specific Solutions

Key Green Isocyanate Players

The isocyanate industry's response to green chemistry movements is evolving within a mature market characterized by significant scale and established players. The sector is transitioning from growth to consolidation, with a global market size estimated in the billions. Technologically, companies are at varying stages of adopting greener practices. Industry leaders like Wanhua Chemical, Covestro, and BASF are investing in bio-based alternatives and more sustainable production processes. Mitsui Chemicals and Repsol are also making strides in eco-friendly innovations. However, the pace of change varies, with some firms more proactive than others in embracing green chemistry principles.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed a range of bio-based polyols and isocyanates as part of their green chemistry initiative. Their WANNATE® PM series of modified MDI products utilize renewable raw materials and offer reduced carbon footprint[1]. The company has also invested in water-based polyurethane dispersions (PUDs) that eliminate the need for organic solvents, significantly reducing VOC emissions[2]. Additionally, Wanhua has made strides in developing non-isocyanate polyurethanes (NIPUs) using cyclic carbonates and amines, which offer a more environmentally friendly alternative to traditional isocyanate-based systems[3].

Strengths: Strong R&D capabilities in bio-based and low-VOC products. Weaknesses: Transitioning large-scale production to green alternatives may be challenging and costly.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has responded to green chemistry movements in the isocyanate industry through various initiatives. They have developed bio-based polyols derived from castor oil and other plant-based materials, which can be used in conjunction with isocyanates to produce more sustainable polyurethanes[11]. The company has also focused on improving the energy efficiency of their isocyanate production processes, implementing advanced catalysts and process optimizations to reduce carbon emissions[12]. Mitsui Chemicals is exploring the use of CO2 as a raw material for polycarbonate production, which could potentially be extended to isocyanate-related chemistries in the future[13]. Additionally, they are investing in recycling technologies for polyurethane materials to create a more circular economy for isocyanate-based products.

Strengths: Strong focus on bio-based materials and process efficiency improvements. Weaknesses: May face challenges in scaling up new technologies to meet market demands.

Innovative Eco-Isocyanate Patents

Green manufacturing concept for the pharmaceutical industry

PatentPendingIN202311004692A

Innovation

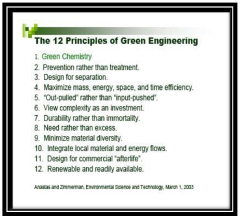

- Adoption of Green Chemistry and Green Engineering principles, including the use of biocatalysis, reduced solvent usage, and innovative synthetic routes, to enhance efficiency, reduce waste, and promote sustainability, with metrics like the E-factor measuring progress and encouraging industry-wide adoption.

Sustainable preparation of organic amino compounds for the production of organic isocyanates

PatentWO2024017890A2

Innovation

- A process using green hydrogen and green ammonia to produce organic amino compounds, which are then used to synthesize isocyanates, incorporating renewable energy sources and reducing waste through closed-loop recycling of materials.

Environmental Regulations Impact

The isocyanate industry has been significantly impacted by environmental regulations stemming from green chemistry movements. These regulations have been implemented at various levels, including local, national, and international, with the aim of reducing the environmental and health risks associated with isocyanate production and use.

One of the primary areas of focus has been the reduction of volatile organic compound (VOC) emissions. Many countries have introduced strict limits on VOC emissions from industrial processes, including those involving isocyanates. This has led to the development and adoption of new technologies and processes within the industry to minimize emissions and improve air quality.

Additionally, regulations have been put in place to address the potential health hazards associated with isocyanate exposure. Occupational safety and health agencies have established stringent guidelines for worker protection, including the use of personal protective equipment and the implementation of engineering controls to reduce exposure risks.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union has had a substantial impact on the isocyanate industry. Under REACH, manufacturers and importers are required to assess and manage the risks associated with the chemicals they produce or import, including isocyanates. This has led to increased transparency and accountability within the industry.

Environmental regulations have also driven innovation in the development of alternative, more environmentally friendly products. Many companies have invested in research and development to create isocyanate-free or low-isocyanate formulations that meet regulatory requirements while maintaining performance standards.

The disposal and management of isocyanate waste have come under increased scrutiny. Regulations now mandate proper handling, storage, and disposal practices to prevent environmental contamination. This has led to the implementation of more sophisticated waste management systems and the development of recycling and recovery technologies within the industry.

Furthermore, regulations have encouraged the adoption of life cycle assessment (LCA) approaches in the isocyanate industry. Companies are now required to consider the environmental impact of their products throughout their entire life cycle, from raw material extraction to end-of-life disposal. This holistic approach has led to more sustainable practices and product designs.

In response to these regulations, the isocyanate industry has had to adapt its business models and operational practices. Many companies have invested in cleaner production technologies, improved monitoring systems, and enhanced safety protocols. While these changes have often resulted in increased costs, they have also driven efficiency improvements and fostered innovation within the industry.

One of the primary areas of focus has been the reduction of volatile organic compound (VOC) emissions. Many countries have introduced strict limits on VOC emissions from industrial processes, including those involving isocyanates. This has led to the development and adoption of new technologies and processes within the industry to minimize emissions and improve air quality.

Additionally, regulations have been put in place to address the potential health hazards associated with isocyanate exposure. Occupational safety and health agencies have established stringent guidelines for worker protection, including the use of personal protective equipment and the implementation of engineering controls to reduce exposure risks.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union has had a substantial impact on the isocyanate industry. Under REACH, manufacturers and importers are required to assess and manage the risks associated with the chemicals they produce or import, including isocyanates. This has led to increased transparency and accountability within the industry.

Environmental regulations have also driven innovation in the development of alternative, more environmentally friendly products. Many companies have invested in research and development to create isocyanate-free or low-isocyanate formulations that meet regulatory requirements while maintaining performance standards.

The disposal and management of isocyanate waste have come under increased scrutiny. Regulations now mandate proper handling, storage, and disposal practices to prevent environmental contamination. This has led to the implementation of more sophisticated waste management systems and the development of recycling and recovery technologies within the industry.

Furthermore, regulations have encouraged the adoption of life cycle assessment (LCA) approaches in the isocyanate industry. Companies are now required to consider the environmental impact of their products throughout their entire life cycle, from raw material extraction to end-of-life disposal. This holistic approach has led to more sustainable practices and product designs.

In response to these regulations, the isocyanate industry has had to adapt its business models and operational practices. Many companies have invested in cleaner production technologies, improved monitoring systems, and enhanced safety protocols. While these changes have often resulted in increased costs, they have also driven efficiency improvements and fostered innovation within the industry.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in evaluating the environmental impact of isocyanate production and use in response to green chemistry movements. This comprehensive approach examines the entire lifecycle of isocyanate products, from raw material extraction to disposal or recycling.

In the context of isocyanates, LCA typically begins with the production of raw materials, such as toluene and aniline. These processes often involve energy-intensive petrochemical operations, contributing significantly to the overall environmental footprint. The next stage focuses on the synthesis of isocyanates, which requires careful handling of hazardous chemicals and energy-intensive reactions.

The use phase of isocyanate-based products, such as polyurethanes, is generally considered less impactful from an environmental perspective. However, the durability and insulation properties of these materials can lead to energy savings in applications like building insulation or automotive components, potentially offsetting some of the production-related impacts.

End-of-life considerations for isocyanate-based products present both challenges and opportunities. While some polyurethane products can be recycled or repurposed, others may end up in landfills or incineration facilities. The decomposition of these materials can release harmful substances, necessitating proper waste management strategies.

In response to green chemistry movements, the isocyanate industry has been exploring alternative production methods and raw materials. Bio-based isocyanates derived from renewable resources are gaining attention, potentially reducing the reliance on fossil fuels. Additionally, efforts to improve energy efficiency in production processes and develop safer handling procedures are ongoing.

LCA studies have revealed that the most significant environmental impacts of isocyanates often occur during the production phase. This insight has driven research into catalysts that can reduce energy requirements and improve reaction selectivity. Furthermore, the industry is investigating ways to minimize the use of toxic precursors and solvents, aligning with green chemistry principles.

Water-based systems and non-isocyanate polyurethanes (NIPUs) are emerging as potential alternatives, driven by LCA findings and regulatory pressures. These technologies aim to address concerns about volatile organic compound (VOC) emissions and worker exposure to hazardous chemicals during application and curing processes.

By employing LCA methodologies, the isocyanate industry can identify hotspots in the product lifecycle and prioritize areas for improvement. This data-driven approach enables companies to make informed decisions about process modifications, material substitutions, and product design changes that can reduce overall environmental impact while meeting performance requirements.

In the context of isocyanates, LCA typically begins with the production of raw materials, such as toluene and aniline. These processes often involve energy-intensive petrochemical operations, contributing significantly to the overall environmental footprint. The next stage focuses on the synthesis of isocyanates, which requires careful handling of hazardous chemicals and energy-intensive reactions.

The use phase of isocyanate-based products, such as polyurethanes, is generally considered less impactful from an environmental perspective. However, the durability and insulation properties of these materials can lead to energy savings in applications like building insulation or automotive components, potentially offsetting some of the production-related impacts.

End-of-life considerations for isocyanate-based products present both challenges and opportunities. While some polyurethane products can be recycled or repurposed, others may end up in landfills or incineration facilities. The decomposition of these materials can release harmful substances, necessitating proper waste management strategies.

In response to green chemistry movements, the isocyanate industry has been exploring alternative production methods and raw materials. Bio-based isocyanates derived from renewable resources are gaining attention, potentially reducing the reliance on fossil fuels. Additionally, efforts to improve energy efficiency in production processes and develop safer handling procedures are ongoing.

LCA studies have revealed that the most significant environmental impacts of isocyanates often occur during the production phase. This insight has driven research into catalysts that can reduce energy requirements and improve reaction selectivity. Furthermore, the industry is investigating ways to minimize the use of toxic precursors and solvents, aligning with green chemistry principles.

Water-based systems and non-isocyanate polyurethanes (NIPUs) are emerging as potential alternatives, driven by LCA findings and regulatory pressures. These technologies aim to address concerns about volatile organic compound (VOC) emissions and worker exposure to hazardous chemicals during application and curing processes.

By employing LCA methodologies, the isocyanate industry can identify hotspots in the product lifecycle and prioritize areas for improvement. This data-driven approach enables companies to make informed decisions about process modifications, material substitutions, and product design changes that can reduce overall environmental impact while meeting performance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!