Isocyanate Innovation: Decoding Recent Technological Advances

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution

Isocyanates have undergone significant evolution since their initial discovery in the mid-19th century. The journey began with the synthesis of the first isocyanate compound by Wurtz in 1848, marking the inception of a revolutionary class of chemicals. However, it wasn't until the 1930s that the true potential of isocyanates was realized, primarily through the groundbreaking work of Otto Bayer and his team at I.G. Farben.

The 1940s and 1950s witnessed a surge in isocyanate research and development, driven by the growing demand for versatile materials in various industries. This period saw the emergence of polyurethanes, a class of polymers derived from the reaction between isocyanates and polyols. The versatility of polyurethanes quickly led to their adoption in numerous applications, from flexible foams in furniture to rigid insulation materials in construction.

The 1960s and 1970s marked a period of rapid technological advancement in isocyanate production. New synthesis methods were developed, improving efficiency and reducing costs. This era also saw the introduction of modified isocyanates, such as blocked isocyanates, which offered enhanced stability and controlled reactivity, expanding their use in coatings and adhesives.

Environmental and health concerns came to the forefront in the 1980s and 1990s, prompting research into safer isocyanate alternatives and improved handling techniques. This period witnessed the development of water-based polyurethane systems and low-VOC formulations, addressing growing regulatory pressures and market demands for more sustainable products.

The turn of the millennium brought about a new focus on nanotechnology and smart materials. Isocyanate chemistry played a crucial role in developing self-healing polymers and shape-memory materials, opening up new possibilities in advanced engineering applications. Concurrently, bio-based isocyanates emerged as a promising avenue for reducing reliance on petroleum-derived raw materials.

Recent years have seen a shift towards more sustainable and environmentally friendly isocyanate technologies. Research efforts have intensified in areas such as non-isocyanate polyurethanes (NIPUs) and isocyanate-free chemistries, driven by stringent regulations and increasing consumer awareness. Additionally, advancements in catalysis and process technologies have led to more efficient and selective isocyanate production methods, reducing energy consumption and waste generation.

The evolution of isocyanates continues to be shaped by global challenges and emerging technologies. Current trends include the development of ultra-low monomer (ULM) isocyanates for improved safety, the exploration of novel curing mechanisms for enhanced performance, and the integration of isocyanate chemistry with other cutting-edge fields such as 3D printing and smart coatings.

The 1940s and 1950s witnessed a surge in isocyanate research and development, driven by the growing demand for versatile materials in various industries. This period saw the emergence of polyurethanes, a class of polymers derived from the reaction between isocyanates and polyols. The versatility of polyurethanes quickly led to their adoption in numerous applications, from flexible foams in furniture to rigid insulation materials in construction.

The 1960s and 1970s marked a period of rapid technological advancement in isocyanate production. New synthesis methods were developed, improving efficiency and reducing costs. This era also saw the introduction of modified isocyanates, such as blocked isocyanates, which offered enhanced stability and controlled reactivity, expanding their use in coatings and adhesives.

Environmental and health concerns came to the forefront in the 1980s and 1990s, prompting research into safer isocyanate alternatives and improved handling techniques. This period witnessed the development of water-based polyurethane systems and low-VOC formulations, addressing growing regulatory pressures and market demands for more sustainable products.

The turn of the millennium brought about a new focus on nanotechnology and smart materials. Isocyanate chemistry played a crucial role in developing self-healing polymers and shape-memory materials, opening up new possibilities in advanced engineering applications. Concurrently, bio-based isocyanates emerged as a promising avenue for reducing reliance on petroleum-derived raw materials.

Recent years have seen a shift towards more sustainable and environmentally friendly isocyanate technologies. Research efforts have intensified in areas such as non-isocyanate polyurethanes (NIPUs) and isocyanate-free chemistries, driven by stringent regulations and increasing consumer awareness. Additionally, advancements in catalysis and process technologies have led to more efficient and selective isocyanate production methods, reducing energy consumption and waste generation.

The evolution of isocyanates continues to be shaped by global challenges and emerging technologies. Current trends include the development of ultra-low monomer (ULM) isocyanates for improved safety, the exploration of novel curing mechanisms for enhanced performance, and the integration of isocyanate chemistry with other cutting-edge fields such as 3D printing and smart coatings.

Market Demand Analysis

The isocyanate market has experienced significant growth in recent years, driven by increasing demand across various industries. The global isocyanate market size was valued at approximately $35 billion in 2020 and is projected to reach $60 billion by 2027, growing at a CAGR of around 7% during the forecast period. This robust growth is primarily attributed to the expanding applications of isocyanates in the production of polyurethanes, which are widely used in construction, automotive, furniture, and electronics industries.

In the construction sector, isocyanates play a crucial role in the manufacturing of insulation materials, sealants, and adhesives. The growing emphasis on energy-efficient buildings and sustainable construction practices has led to increased demand for polyurethane-based insulation products. This trend is particularly evident in developing economies, where rapid urbanization and infrastructure development are driving the need for advanced construction materials.

The automotive industry represents another significant market for isocyanates, with applications in the production of lightweight components, seat cushions, and coatings. As automakers strive to improve fuel efficiency and reduce vehicle weight, the demand for polyurethane-based materials is expected to rise. Additionally, the growing electric vehicle market presents new opportunities for isocyanate-based products in battery encapsulation and thermal management systems.

The furniture industry has also contributed to the increasing demand for isocyanates, particularly in the production of flexible and rigid foams for mattresses, sofas, and other upholstered products. The rising disposable income in emerging markets and changing consumer preferences towards comfortable and durable furniture are driving this segment's growth.

In the electronics sector, isocyanates are used in the production of protective coatings, adhesives, and encapsulants for various electronic components. The rapid expansion of the electronics industry, coupled with the increasing adoption of smart devices and wearable technology, is expected to fuel the demand for isocyanate-based materials in this sector.

Despite the positive market outlook, there are growing concerns regarding the environmental and health impacts of traditional isocyanates. This has led to increased research and development efforts focused on developing eco-friendly alternatives and improving the safety profile of isocyanate-based products. As a result, there is a rising demand for bio-based isocyanates and low-VOC formulations, which present both challenges and opportunities for market players.

In the construction sector, isocyanates play a crucial role in the manufacturing of insulation materials, sealants, and adhesives. The growing emphasis on energy-efficient buildings and sustainable construction practices has led to increased demand for polyurethane-based insulation products. This trend is particularly evident in developing economies, where rapid urbanization and infrastructure development are driving the need for advanced construction materials.

The automotive industry represents another significant market for isocyanates, with applications in the production of lightweight components, seat cushions, and coatings. As automakers strive to improve fuel efficiency and reduce vehicle weight, the demand for polyurethane-based materials is expected to rise. Additionally, the growing electric vehicle market presents new opportunities for isocyanate-based products in battery encapsulation and thermal management systems.

The furniture industry has also contributed to the increasing demand for isocyanates, particularly in the production of flexible and rigid foams for mattresses, sofas, and other upholstered products. The rising disposable income in emerging markets and changing consumer preferences towards comfortable and durable furniture are driving this segment's growth.

In the electronics sector, isocyanates are used in the production of protective coatings, adhesives, and encapsulants for various electronic components. The rapid expansion of the electronics industry, coupled with the increasing adoption of smart devices and wearable technology, is expected to fuel the demand for isocyanate-based materials in this sector.

Despite the positive market outlook, there are growing concerns regarding the environmental and health impacts of traditional isocyanates. This has led to increased research and development efforts focused on developing eco-friendly alternatives and improving the safety profile of isocyanate-based products. As a result, there is a rising demand for bio-based isocyanates and low-VOC formulations, which present both challenges and opportunities for market players.

Technical Challenges

The isocyanate industry faces several significant technical challenges that are shaping its current landscape and future development. One of the primary concerns is the toxicity of isocyanates, particularly during the manufacturing process and in end-use applications. This has led to increased regulatory scrutiny and a push for safer alternatives, driving research into less hazardous production methods and formulations.

Another major challenge is the environmental impact of isocyanate production. Traditional manufacturing processes often involve the use of phosgene, a highly toxic gas, which raises environmental and safety concerns. The industry is under pressure to develop greener synthesis routes that reduce or eliminate the need for phosgene, while maintaining product quality and economic viability.

The volatility of raw material prices, particularly for key feedstocks like toluene and propylene, presents an ongoing challenge for isocyanate manufacturers. This price instability affects production costs and can lead to fluctuations in product pricing, impacting the entire value chain. Developing more efficient production processes and exploring alternative feedstocks are crucial areas of focus to address this issue.

Energy efficiency in isocyanate production remains a significant technical hurdle. The synthesis of isocyanates is energy-intensive, contributing to high production costs and carbon footprints. Improving reactor designs, optimizing reaction conditions, and exploring novel catalysts are key areas of research aimed at enhancing energy efficiency and reducing overall production costs.

The demand for high-performance and specialized isocyanates in emerging applications, such as advanced coatings, adhesives, and composite materials, is driving the need for innovation in molecular design and synthesis. Developing isocyanates with tailored properties, improved reactivity, and enhanced compatibility with various substrates presents ongoing technical challenges for researchers and manufacturers.

Lastly, the industry faces challenges in recycling and end-of-life management of isocyanate-based products, particularly polyurethanes. Developing efficient recycling technologies and designing products for easier disassembly and reuse are critical areas requiring technical innovation to improve the sustainability profile of isocyanate-derived materials.

Addressing these technical challenges requires a multifaceted approach, combining advances in chemistry, process engineering, and materials science. Collaborative efforts between industry, academia, and regulatory bodies are essential to drive innovation and overcome these hurdles, ensuring the continued growth and sustainability of the isocyanate sector.

Another major challenge is the environmental impact of isocyanate production. Traditional manufacturing processes often involve the use of phosgene, a highly toxic gas, which raises environmental and safety concerns. The industry is under pressure to develop greener synthesis routes that reduce or eliminate the need for phosgene, while maintaining product quality and economic viability.

The volatility of raw material prices, particularly for key feedstocks like toluene and propylene, presents an ongoing challenge for isocyanate manufacturers. This price instability affects production costs and can lead to fluctuations in product pricing, impacting the entire value chain. Developing more efficient production processes and exploring alternative feedstocks are crucial areas of focus to address this issue.

Energy efficiency in isocyanate production remains a significant technical hurdle. The synthesis of isocyanates is energy-intensive, contributing to high production costs and carbon footprints. Improving reactor designs, optimizing reaction conditions, and exploring novel catalysts are key areas of research aimed at enhancing energy efficiency and reducing overall production costs.

The demand for high-performance and specialized isocyanates in emerging applications, such as advanced coatings, adhesives, and composite materials, is driving the need for innovation in molecular design and synthesis. Developing isocyanates with tailored properties, improved reactivity, and enhanced compatibility with various substrates presents ongoing technical challenges for researchers and manufacturers.

Lastly, the industry faces challenges in recycling and end-of-life management of isocyanate-based products, particularly polyurethanes. Developing efficient recycling technologies and designing products for easier disassembly and reuse are critical areas requiring technical innovation to improve the sustainability profile of isocyanate-derived materials.

Addressing these technical challenges requires a multifaceted approach, combining advances in chemistry, process engineering, and materials science. Collaborative efforts between industry, academia, and regulatory bodies are essential to drive innovation and overcome these hurdles, ensuring the continued growth and sustainability of the isocyanate sector.

Current Solutions

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in isocyanate manufacturing.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in isocyanate manufacturing.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents discuss various applications, including foam production, coatings, adhesives, and elastomers, as well as novel polymer formulations incorporating isocyanates.

- Isocyanate-based catalysts and reaction modifiers: Several patents focus on the use of isocyanates as catalysts or reaction modifiers in various chemical processes. This includes their role in polymerization reactions, cross-linking agents, and as components in complex catalyst systems.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, patents address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer formulations for industrial use.

- Isocyanate derivatives and modified compounds: Research into isocyanate derivatives and modified compounds is presented, including blocked isocyanates, isocyanate-terminated prepolymers, and novel isocyanate-containing molecules with enhanced properties or specific functionalities.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The search results cover various applications, including coatings, adhesives, foams, and elastomers, highlighting the versatility of isocyanates in material science.Expand Specific Solutions03 Isocyanate-based catalysts and reaction modifiers

Several patents discuss the use of isocyanates as catalysts or reaction modifiers in various chemical processes. These applications leverage the unique reactivity of isocyanate groups to enhance or control specific reactions.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, several patents address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer formulations for industrial use.Expand Specific Solutions05 Novel isocyanate compounds and derivatives

The search results reveal patents describing new isocyanate compounds and their derivatives. These novel structures may offer improved properties or functionalities for specific applications in various industries.Expand Specific Solutions

Key Industry Players

The isocyanate innovation landscape is characterized by a mature market with steady growth, driven by increasing demand in various industries. The global market size for isocyanates is substantial, with key players like Wanhua Chemical Group, BASF, and Covestro dominating the field. These companies, along with others such as Dow Global Technologies and Mitsui Chemicals, are at the forefront of technological advancements. The technology maturity is high, with ongoing research focused on improving efficiency, sustainability, and developing novel applications. Recent innovations include eco-friendly formulations, enhanced performance characteristics, and exploration of bio-based alternatives, indicating a shift towards more sustainable solutions in this well-established chemical sector.

Wanhua Chemical Group Co., Ltd.

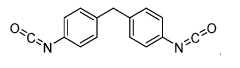

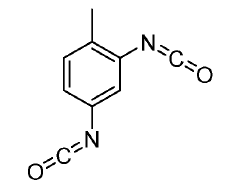

Technical Solution: Wanhua Chemical has made significant strides in isocyanate innovation, particularly in the development of methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI). Their advanced production processes have led to improved product purity and reduced environmental impact. Wanhua has implemented a proprietary gas-phase phosgenation technology for MDI production, which has increased efficiency by up to 20% compared to traditional liquid-phase processes[1]. Additionally, they have developed a novel catalytic system for TDI synthesis that reduces energy consumption by approximately 15%[2]. Wanhua's continuous investment in R&D has resulted in the creation of specialized isocyanates for high-performance polyurethane applications, such as automotive lightweight materials and energy-efficient insulation.

Strengths: Industry-leading production capacity, advanced proprietary technologies, and a strong focus on sustainability. Weaknesses: Heavy reliance on petrochemical feedstocks and potential vulnerability to raw material price fluctuations.

BASF Corp.

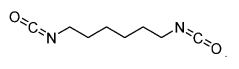

Technical Solution: BASF has been at the forefront of isocyanate innovation, focusing on sustainable production methods and novel applications. They have developed a groundbreaking process for the production of hexamethylene diisocyanate (HDI) using bio-based feedstocks, reducing the carbon footprint by up to 40% compared to conventional methods[3]. BASF's research has also led to the creation of aliphatic isocyanates with enhanced UV stability and weathering resistance, crucial for high-performance coatings. Their patented microencapsulation technology for isocyanates has enabled the development of one-component polyurethane systems with extended shelf life and improved handling safety[4]. Furthermore, BASF has made significant progress in water-based polyurethane dispersions, addressing the growing demand for low-VOC coatings in various industries.

Strengths: Extensive R&D capabilities, broad product portfolio, and strong focus on sustainable chemistry. Weaknesses: Complex global supply chain and potential regulatory challenges in different markets.

Breakthrough Patents

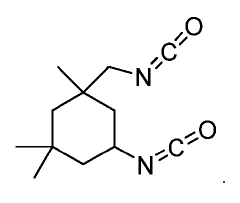

Blocked isocyanates and their use in coating compositions

PatentActiveEP1789466A1

Innovation

- A thermally dissociative blocked polyisocyanate composition containing isocyanurate moieties derived from bis(isocyanatomethyl)cyclohexane, specifically comprising a mixture of cis- and trans-1,3- and cis- and trans-1,4-isomers with at least 5 weight percent of the 1,4-isomer, reacted with a blocking agent and trimerization catalyst to achieve high reactivity and optimal isocyanate group distribution, enhancing the coating's properties.

Flow chemistry synthesis of isocyanates

PatentWO2021119606A1

Innovation

- A continuous flow process involving the mixing of acyl hydrazides with nitrous acid to form acyl azides, followed by heating in the presence of an organic solvent to produce isocyanates through Curtius rearrangement, offering a safer and more scalable method for isocyanate synthesis.

Environmental Impact

The environmental impact of isocyanate production and use has been a significant concern in recent years, prompting innovative approaches to mitigate negative effects. Traditional isocyanate manufacturing processes often involve the use of phosgene, a highly toxic substance, and release harmful emissions. However, recent technological advances have focused on developing more sustainable and environmentally friendly production methods.

One notable innovation is the development of non-phosgene routes for isocyanate synthesis. These alternative processes utilize less hazardous raw materials and reduce the overall environmental footprint of production. For instance, some companies have successfully implemented carbon dioxide-based technologies, which not only eliminate the need for phosgene but also contribute to carbon capture and utilization efforts.

Advancements in catalysis have also played a crucial role in improving the environmental profile of isocyanate production. Novel catalysts have been designed to increase reaction efficiency, reduce energy consumption, and minimize waste generation. These catalysts enable lower reaction temperatures and pressures, resulting in decreased greenhouse gas emissions and improved overall process sustainability.

Water-based and solvent-free isocyanate systems have gained traction as environmentally friendly alternatives to traditional solvent-based formulations. These innovations reduce volatile organic compound (VOC) emissions and improve air quality in both manufacturing and application settings. Additionally, the development of bio-based isocyanates derived from renewable resources has shown promise in reducing reliance on fossil fuels and decreasing the carbon footprint of isocyanate products.

Efforts to enhance the recyclability and biodegradability of isocyanate-based materials have also made significant strides. Researchers have developed novel chemical structures and formulations that facilitate easier end-of-life management, including improved recycling processes and controlled biodegradation. These advancements contribute to the circular economy and help address concerns related to plastic waste accumulation.

Furthermore, the implementation of advanced process control systems and real-time monitoring technologies has enabled more precise management of isocyanate production processes. This optimization leads to reduced energy consumption, improved resource efficiency, and minimized environmental impact through better control of emissions and waste streams.

One notable innovation is the development of non-phosgene routes for isocyanate synthesis. These alternative processes utilize less hazardous raw materials and reduce the overall environmental footprint of production. For instance, some companies have successfully implemented carbon dioxide-based technologies, which not only eliminate the need for phosgene but also contribute to carbon capture and utilization efforts.

Advancements in catalysis have also played a crucial role in improving the environmental profile of isocyanate production. Novel catalysts have been designed to increase reaction efficiency, reduce energy consumption, and minimize waste generation. These catalysts enable lower reaction temperatures and pressures, resulting in decreased greenhouse gas emissions and improved overall process sustainability.

Water-based and solvent-free isocyanate systems have gained traction as environmentally friendly alternatives to traditional solvent-based formulations. These innovations reduce volatile organic compound (VOC) emissions and improve air quality in both manufacturing and application settings. Additionally, the development of bio-based isocyanates derived from renewable resources has shown promise in reducing reliance on fossil fuels and decreasing the carbon footprint of isocyanate products.

Efforts to enhance the recyclability and biodegradability of isocyanate-based materials have also made significant strides. Researchers have developed novel chemical structures and formulations that facilitate easier end-of-life management, including improved recycling processes and controlled biodegradation. These advancements contribute to the circular economy and help address concerns related to plastic waste accumulation.

Furthermore, the implementation of advanced process control systems and real-time monitoring technologies has enabled more precise management of isocyanate production processes. This optimization leads to reduced energy consumption, improved resource efficiency, and minimized environmental impact through better control of emissions and waste streams.

Safety Regulations

The safety regulations surrounding isocyanates have become increasingly stringent in recent years, reflecting growing awareness of their potential health and environmental risks. Regulatory bodies worldwide have implemented comprehensive frameworks to govern the production, handling, and use of isocyanates across various industries.

In the United States, the Occupational Safety and Health Administration (OSHA) has established strict exposure limits for isocyanates in workplace environments. These regulations mandate the use of personal protective equipment, implementation of engineering controls, and regular monitoring of air quality in facilities where isocyanates are present. The Environmental Protection Agency (EPA) has also introduced measures to control emissions and manage waste associated with isocyanate production and use.

The European Union has taken a proactive stance through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This framework requires manufacturers and importers to assess and manage the risks associated with isocyanates, ensuring their safe use throughout the supply chain. Additionally, the EU has implemented specific restrictions on certain isocyanates in consumer products to minimize public exposure.

In Asia, countries like China and Japan have developed their own regulatory frameworks to address isocyanate safety. These regulations often align with international standards while considering local industrial contexts. For instance, China's Ministry of Ecology and Environment has introduced stricter emission standards for isocyanate-producing facilities, while Japan's Industrial Safety and Health Law mandates regular health check-ups for workers exposed to isocyanates.

Recent technological advances have played a crucial role in facilitating compliance with these safety regulations. Improved analytical techniques have enhanced the accuracy and sensitivity of isocyanate detection, enabling more effective monitoring of workplace and environmental exposure. Real-time monitoring systems and wearable sensors have been developed to provide immediate alerts in case of dangerous exposure levels, significantly improving worker safety.

Furthermore, innovations in production processes have led to the development of low-emission and low-volatility isocyanates, reducing the risk of exposure during handling and application. These advancements not only improve safety but also contribute to meeting increasingly stringent environmental regulations.

The ongoing evolution of safety regulations continues to drive innovation in the isocyanate industry. Manufacturers are investing in research and development to create safer alternatives and improve existing formulations. This regulatory landscape has also spurred the development of specialized training programs and certification systems to ensure proper handling and use of isocyanates across various sectors.

In the United States, the Occupational Safety and Health Administration (OSHA) has established strict exposure limits for isocyanates in workplace environments. These regulations mandate the use of personal protective equipment, implementation of engineering controls, and regular monitoring of air quality in facilities where isocyanates are present. The Environmental Protection Agency (EPA) has also introduced measures to control emissions and manage waste associated with isocyanate production and use.

The European Union has taken a proactive stance through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This framework requires manufacturers and importers to assess and manage the risks associated with isocyanates, ensuring their safe use throughout the supply chain. Additionally, the EU has implemented specific restrictions on certain isocyanates in consumer products to minimize public exposure.

In Asia, countries like China and Japan have developed their own regulatory frameworks to address isocyanate safety. These regulations often align with international standards while considering local industrial contexts. For instance, China's Ministry of Ecology and Environment has introduced stricter emission standards for isocyanate-producing facilities, while Japan's Industrial Safety and Health Law mandates regular health check-ups for workers exposed to isocyanates.

Recent technological advances have played a crucial role in facilitating compliance with these safety regulations. Improved analytical techniques have enhanced the accuracy and sensitivity of isocyanate detection, enabling more effective monitoring of workplace and environmental exposure. Real-time monitoring systems and wearable sensors have been developed to provide immediate alerts in case of dangerous exposure levels, significantly improving worker safety.

Furthermore, innovations in production processes have led to the development of low-emission and low-volatility isocyanates, reducing the risk of exposure during handling and application. These advancements not only improve safety but also contribute to meeting increasingly stringent environmental regulations.

The ongoing evolution of safety regulations continues to drive innovation in the isocyanate industry. Manufacturers are investing in research and development to create safer alternatives and improve existing formulations. This regulatory landscape has also spurred the development of specialized training programs and certification systems to ensure proper handling and use of isocyanates across various sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!