Isocyanate Research: Pioneering Next-Gen Materials

JUL 10, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution

Isocyanates have undergone a remarkable evolution since their discovery in the mid-19th century. Initially synthesized as chemical curiosities, these compounds quickly gained prominence due to their unique reactivity and versatility. The journey of isocyanates began with their first industrial production in the 1930s, primarily for the manufacture of polyurethanes.

The 1940s and 1950s marked a significant turning point in isocyanate technology. During this period, researchers discovered the potential of isocyanates in creating flexible and rigid foams, elastomers, and coatings. This breakthrough led to a surge in research and development activities, resulting in the rapid expansion of isocyanate applications across various industries.

The 1960s and 1970s witnessed further advancements in isocyanate chemistry. Scientists developed new synthesis methods and explored novel isocyanate derivatives, expanding the range of available compounds. This era also saw the emergence of more environmentally friendly and safer production processes, addressing growing concerns about the toxicity of certain isocyanates.

In the 1980s and 1990s, the focus shifted towards enhancing the performance and sustainability of isocyanate-based materials. Researchers developed low-emission formulations and improved the durability of polyurethane products. This period also saw the introduction of water-based polyurethane systems, reducing the reliance on volatile organic compounds.

The turn of the millennium brought about a renewed interest in bio-based isocyanates. As sustainability became a global priority, scientists began exploring renewable sources for isocyanate production. This led to the development of isocyanates derived from plant oils and other natural resources, opening up new possibilities for eco-friendly materials.

Recent years have seen a surge in research focused on smart and responsive isocyanate-based materials. These advanced materials can change their properties in response to external stimuli, such as temperature, light, or electrical fields. This innovation has paved the way for cutting-edge applications in fields like biomedicine, aerospace, and electronics.

The evolution of isocyanates continues to accelerate, driven by the demand for high-performance, sustainable materials. Current research efforts are focused on developing isocyanates with enhanced functionality, improved safety profiles, and reduced environmental impact. As we look to the future, the ongoing evolution of isocyanates promises to deliver groundbreaking solutions for next-generation materials across a wide spectrum of industries.

The 1940s and 1950s marked a significant turning point in isocyanate technology. During this period, researchers discovered the potential of isocyanates in creating flexible and rigid foams, elastomers, and coatings. This breakthrough led to a surge in research and development activities, resulting in the rapid expansion of isocyanate applications across various industries.

The 1960s and 1970s witnessed further advancements in isocyanate chemistry. Scientists developed new synthesis methods and explored novel isocyanate derivatives, expanding the range of available compounds. This era also saw the emergence of more environmentally friendly and safer production processes, addressing growing concerns about the toxicity of certain isocyanates.

In the 1980s and 1990s, the focus shifted towards enhancing the performance and sustainability of isocyanate-based materials. Researchers developed low-emission formulations and improved the durability of polyurethane products. This period also saw the introduction of water-based polyurethane systems, reducing the reliance on volatile organic compounds.

The turn of the millennium brought about a renewed interest in bio-based isocyanates. As sustainability became a global priority, scientists began exploring renewable sources for isocyanate production. This led to the development of isocyanates derived from plant oils and other natural resources, opening up new possibilities for eco-friendly materials.

Recent years have seen a surge in research focused on smart and responsive isocyanate-based materials. These advanced materials can change their properties in response to external stimuli, such as temperature, light, or electrical fields. This innovation has paved the way for cutting-edge applications in fields like biomedicine, aerospace, and electronics.

The evolution of isocyanates continues to accelerate, driven by the demand for high-performance, sustainable materials. Current research efforts are focused on developing isocyanates with enhanced functionality, improved safety profiles, and reduced environmental impact. As we look to the future, the ongoing evolution of isocyanates promises to deliver groundbreaking solutions for next-generation materials across a wide spectrum of industries.

Market Applications

Isocyanates have found widespread applications across various industries, driving innovation in material science and product development. The construction sector heavily relies on isocyanate-based polyurethanes for insulation, sealants, and adhesives, contributing to energy-efficient buildings and infrastructure. These materials offer excellent thermal insulation properties, moisture resistance, and durability, making them indispensable in modern construction practices.

In the automotive industry, isocyanates play a crucial role in manufacturing lightweight components, cushioning materials, and protective coatings. The use of polyurethane foams in car seats, headrests, and interior trim parts has significantly improved vehicle comfort and safety while reducing overall weight. Additionally, isocyanate-based coatings provide superior protection against corrosion and weathering, extending the lifespan of automotive parts.

The furniture and bedding industry has embraced isocyanate-based materials for their versatility and performance. Memory foam mattresses, which have gained immense popularity, rely on the unique properties of polyurethane foams derived from isocyanates. These materials offer excellent pressure distribution, comfort, and durability, revolutionizing the sleep industry.

In the electronics sector, isocyanates contribute to the development of advanced protective coatings and encapsulants. These materials safeguard sensitive electronic components from moisture, dust, and mechanical stress, ensuring the longevity and reliability of electronic devices. The miniaturization trend in electronics has further increased the demand for high-performance isocyanate-based materials that can provide effective protection in compact designs.

The footwear industry has also benefited from isocyanate technology, particularly in the production of athletic shoes. Polyurethane soles offer superior cushioning, flexibility, and wear resistance, enhancing the performance and comfort of sports footwear. The ability to fine-tune the properties of isocyanate-based materials allows manufacturers to create specialized shoes for different sports and activities.

In the medical field, isocyanates have found applications in the production of wound dressings, medical tubing, and prosthetics. The biocompatibility and customizable properties of certain isocyanate-based materials make them suitable for various medical devices and implants. Ongoing research in this area aims to develop even more advanced biomaterials for tissue engineering and regenerative medicine.

The packaging industry utilizes isocyanate-based adhesives and coatings to improve the performance of packaging materials. These applications enhance the barrier properties of packaging, extending the shelf life of food products and protecting goods during transportation and storage. The development of eco-friendly, bio-based isocyanates is also gaining traction in this sector, aligning with the growing demand for sustainable packaging solutions.

In the automotive industry, isocyanates play a crucial role in manufacturing lightweight components, cushioning materials, and protective coatings. The use of polyurethane foams in car seats, headrests, and interior trim parts has significantly improved vehicle comfort and safety while reducing overall weight. Additionally, isocyanate-based coatings provide superior protection against corrosion and weathering, extending the lifespan of automotive parts.

The furniture and bedding industry has embraced isocyanate-based materials for their versatility and performance. Memory foam mattresses, which have gained immense popularity, rely on the unique properties of polyurethane foams derived from isocyanates. These materials offer excellent pressure distribution, comfort, and durability, revolutionizing the sleep industry.

In the electronics sector, isocyanates contribute to the development of advanced protective coatings and encapsulants. These materials safeguard sensitive electronic components from moisture, dust, and mechanical stress, ensuring the longevity and reliability of electronic devices. The miniaturization trend in electronics has further increased the demand for high-performance isocyanate-based materials that can provide effective protection in compact designs.

The footwear industry has also benefited from isocyanate technology, particularly in the production of athletic shoes. Polyurethane soles offer superior cushioning, flexibility, and wear resistance, enhancing the performance and comfort of sports footwear. The ability to fine-tune the properties of isocyanate-based materials allows manufacturers to create specialized shoes for different sports and activities.

In the medical field, isocyanates have found applications in the production of wound dressings, medical tubing, and prosthetics. The biocompatibility and customizable properties of certain isocyanate-based materials make them suitable for various medical devices and implants. Ongoing research in this area aims to develop even more advanced biomaterials for tissue engineering and regenerative medicine.

The packaging industry utilizes isocyanate-based adhesives and coatings to improve the performance of packaging materials. These applications enhance the barrier properties of packaging, extending the shelf life of food products and protecting goods during transportation and storage. The development of eco-friendly, bio-based isocyanates is also gaining traction in this sector, aligning with the growing demand for sustainable packaging solutions.

Technical Challenges

Isocyanate research faces several significant technical challenges that hinder the development of next-generation materials. One of the primary obstacles is the high reactivity of isocyanates, which makes them difficult to handle and control during synthesis and processing. This reactivity can lead to unwanted side reactions, compromising the quality and consistency of the final products.

Another major challenge lies in the toxicity of isocyanates, particularly their potential to cause respiratory sensitization and occupational asthma. This safety concern necessitates stringent handling protocols and protective measures, which can increase production costs and complexity. Developing safer alternatives or methods to mitigate these health risks remains a critical area of focus for researchers.

The environmental impact of isocyanate production and use also presents significant challenges. Traditional manufacturing processes often involve the use of phosgene, a highly toxic gas, raising concerns about worker safety and environmental contamination. Finding greener, more sustainable synthesis routes is crucial for the long-term viability of isocyanate-based materials.

Achieving precise control over the molecular structure and properties of isocyanate-derived materials poses another technical hurdle. The complex chemistry involved in polyurethane formation, for instance, makes it challenging to consistently produce materials with desired characteristics such as flexibility, durability, and thermal stability across different batches and scales.

Furthermore, the development of bio-based isocyanates faces obstacles in terms of cost-effectiveness and performance parity with petroleum-derived counterparts. While renewable feedstocks offer potential environmental benefits, optimizing reaction pathways and improving yields to make these alternatives economically viable remains a significant challenge.

Lastly, the recyclability and end-of-life management of isocyanate-based materials present ongoing technical difficulties. Many current products, such as polyurethane foams, are challenging to recycle effectively, leading to waste accumulation. Developing innovative recycling technologies or designing materials with improved circularity is essential for addressing sustainability concerns in the isocyanate industry.

Another major challenge lies in the toxicity of isocyanates, particularly their potential to cause respiratory sensitization and occupational asthma. This safety concern necessitates stringent handling protocols and protective measures, which can increase production costs and complexity. Developing safer alternatives or methods to mitigate these health risks remains a critical area of focus for researchers.

The environmental impact of isocyanate production and use also presents significant challenges. Traditional manufacturing processes often involve the use of phosgene, a highly toxic gas, raising concerns about worker safety and environmental contamination. Finding greener, more sustainable synthesis routes is crucial for the long-term viability of isocyanate-based materials.

Achieving precise control over the molecular structure and properties of isocyanate-derived materials poses another technical hurdle. The complex chemistry involved in polyurethane formation, for instance, makes it challenging to consistently produce materials with desired characteristics such as flexibility, durability, and thermal stability across different batches and scales.

Furthermore, the development of bio-based isocyanates faces obstacles in terms of cost-effectiveness and performance parity with petroleum-derived counterparts. While renewable feedstocks offer potential environmental benefits, optimizing reaction pathways and improving yields to make these alternatives economically viable remains a significant challenge.

Lastly, the recyclability and end-of-life management of isocyanate-based materials present ongoing technical difficulties. Many current products, such as polyurethane foams, are challenging to recycle effectively, leading to waste accumulation. Developing innovative recycling technologies or designing materials with improved circularity is essential for addressing sustainability concerns in the isocyanate industry.

Current Solutions

01 Synthesis and production of isocyanates

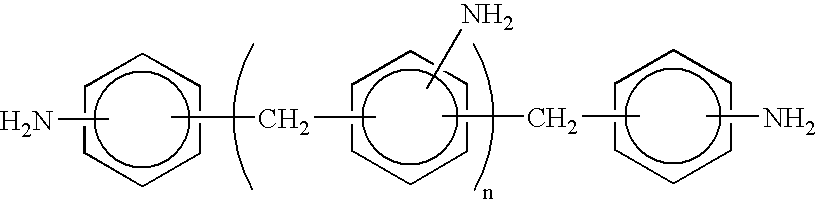

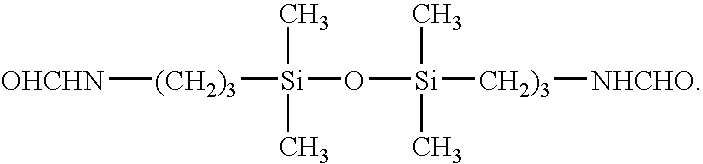

Various methods and processes for synthesizing and producing isocyanates are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in isocyanate manufacturing.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in isocyanate manufacturing.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents discuss various applications, including foam production, coatings, adhesives, and elastomers, as well as novel polymer formulations incorporating isocyanates.

- Isocyanate-based coating technologies: Several patents focus on coating technologies utilizing isocyanates. These include developments in paint formulations, protective coatings, and surface treatments that leverage the reactive properties of isocyanates to create durable and functional coatings.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, patents address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer alternatives or modified isocyanates with reduced health risks.

- Isocyanate-free alternatives and substitutes: Research into isocyanate-free alternatives and substitutes is presented in several patents. These innovations aim to develop new materials or processes that can replace isocyanates in various applications while maintaining similar performance characteristics.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents discuss various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.Expand Specific Solutions03 Isocyanate-based catalysts and reaction modifiers

Several patents focus on the development of isocyanate-based catalysts and reaction modifiers. These compounds are used to enhance various chemical processes, improve reaction kinetics, and modify the properties of resulting products.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, patents address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer formulations for various applications.Expand Specific Solutions05 Isocyanate-free alternatives and substitutes

Some patents explore alternatives to traditional isocyanates, aiming to develop more environmentally friendly or less hazardous options. This includes novel compounds, formulations, and processes that can replace isocyanates in certain applications while maintaining desired properties.Expand Specific Solutions

Industry Leaders

The isocyanate research field is currently in a growth phase, with increasing market demand driven by applications in polyurethanes and advanced materials. The global market size for isocyanates is projected to reach $40 billion by 2025, growing at a CAGR of 6%. Technologically, the field is moderately mature but still evolving, with companies like Covestro, BASF, and Dow leading innovation. These industry giants are focusing on developing more sustainable and high-performance isocyanates. Emerging players like Wanhua Chemical and Asahi Kasei are also making significant strides, particularly in Asia. The competitive landscape is characterized by ongoing R&D efforts to improve production efficiency, reduce environmental impact, and expand application areas.

Covestro Deutschland AG

Technical Solution: Covestro has developed innovative isocyanate-based materials for next-generation applications. Their research focuses on sustainable polyurethanes using bio-based and CO2-based raw materials[1]. They have pioneered the use of CO2 as a raw material for polyols in polyurethane production, reducing the reliance on fossil-based resources[2]. Covestro has also developed novel aliphatic isocyanates for high-performance coatings with improved durability and weather resistance[3]. Their cardyon® technology incorporates up to 20% CO2 into polyols, significantly reducing the carbon footprint of polyurethane products[4].

Strengths: Strong focus on sustainability and CO2 utilization, innovative bio-based solutions. Weaknesses: Potential higher costs associated with new technologies, market acceptance of novel materials.

Dow Global Technologies LLC

Technical Solution: Dow has made significant advancements in isocyanate research, particularly in the development of low-emission and high-performance polyurethane systems. Their VORALUX™ polyurethane technology offers improved comfort and durability for automotive seating applications[5]. Dow has also developed VORAMER™, a range of prepolymers based on novel isocyanate chemistry, providing enhanced processing and performance characteristics for various industrial applications[6]. Their research extends to moisture-curing polyurethane adhesives with improved bonding strength and environmental resistance[7]. Dow's isocyanate-free polyurethane dispersions represent a breakthrough in sustainable coating technologies[8].

Strengths: Broad range of applications, focus on low-emission technologies. Weaknesses: Potential regulatory challenges with traditional isocyanates, competition from alternative technologies.

Key Innovations

Blocked isocyanates and their use in coating compositions

PatentActiveEP1789466A1

Innovation

- A thermally dissociative blocked polyisocyanate composition containing isocyanurate moieties derived from bis(isocyanatomethyl)cyclohexane, specifically comprising a mixture of cis- and trans-1,3- and cis- and trans-1,4-isomers with at least 5 weight percent of the 1,4-isomer, reacted with a blocking agent and trimerization catalyst to achieve high reactivity and optimal isocyanate group distribution, enhancing the coating's properties.

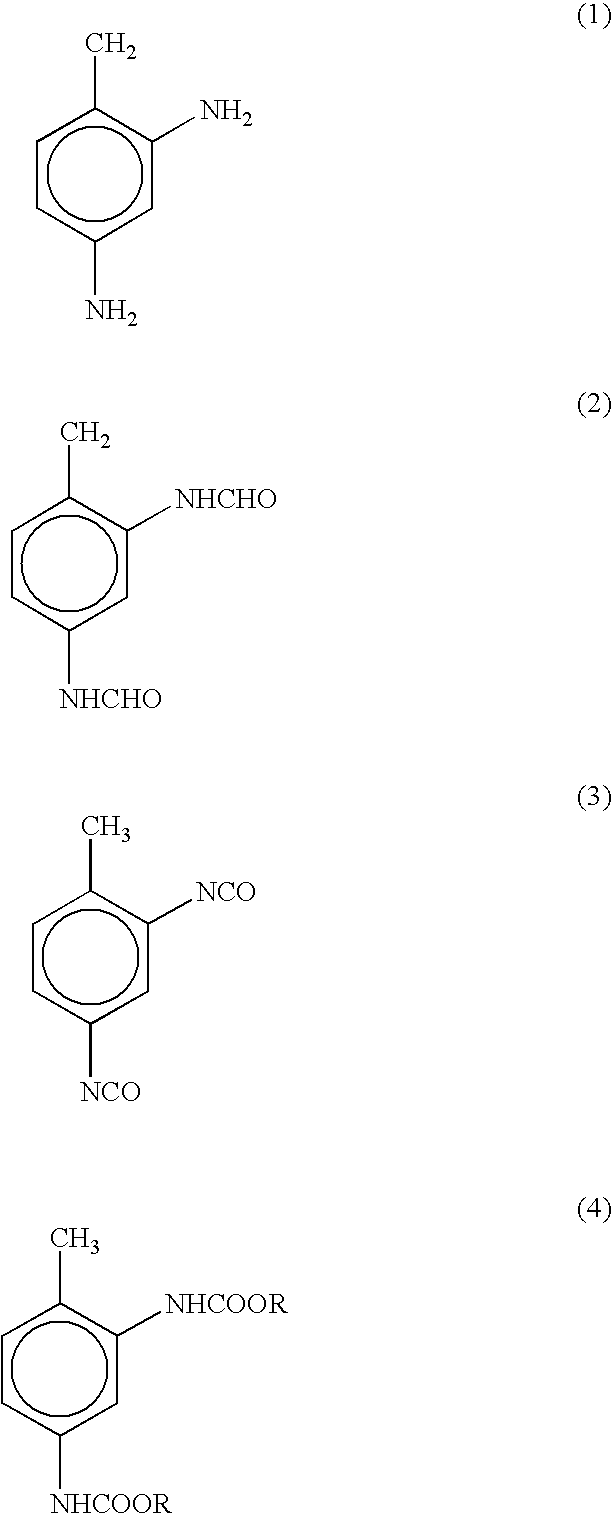

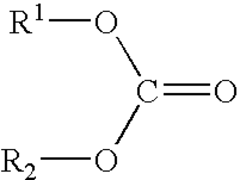

Non-phosgene route to the manufacture of organic isocyanates

PatentInactiveUS6781010B1

Innovation

- The synthesis of organic isocyanates through the reaction of formamides with diorganocarbonates, where the major byproducts can be thermolyzed to additional isocyanates or recycled to generate raw materials, resulting in a high-yield, efficient process with minimal waste.

Environmental Impact

Isocyanates, while pivotal in the development of next-generation materials, pose significant environmental challenges that demand careful consideration. The production and use of isocyanates have been associated with various environmental impacts, primarily due to their chemical properties and manufacturing processes.

One of the most pressing concerns is the potential for air pollution. During the production of isocyanates, volatile organic compounds (VOCs) and other hazardous air pollutants may be released. These emissions can contribute to smog formation, ozone depletion, and overall air quality degradation. Furthermore, the release of isocyanates into the atmosphere can lead to the formation of secondary pollutants through chemical reactions, exacerbating the environmental impact.

Water contamination is another critical issue associated with isocyanate production and use. Improper handling, storage, or disposal of isocyanates can result in their release into water bodies, potentially harming aquatic ecosystems. Isocyanates can react with water to form insoluble polyureas, which may accumulate in sediments and affect benthic organisms. Additionally, the breakdown products of isocyanates in water can include toxic compounds that pose risks to aquatic life and human health.

Soil contamination is a concern, particularly in areas surrounding isocyanate production facilities or where isocyanate-containing products are improperly disposed of. The persistence of isocyanates and their degradation products in soil can lead to long-term environmental impacts, affecting soil microorganisms and potentially entering the food chain through plant uptake.

The energy-intensive nature of isocyanate production contributes to its carbon footprint. The manufacturing process often relies on fossil fuels, leading to greenhouse gas emissions and contributing to climate change. As the demand for isocyanate-based materials grows, the cumulative environmental impact of their production becomes increasingly significant.

Waste management is a crucial aspect of mitigating the environmental impact of isocyanates. Proper disposal and recycling of isocyanate-containing products are essential to prevent environmental contamination. However, the complexity of many isocyanate-based materials can make recycling challenging, often resulting in these products ending up in landfills where they may slowly degrade and release harmful substances.

To address these environmental concerns, research efforts are focusing on developing more sustainable production methods and alternative materials. Green chemistry approaches aim to reduce the use of hazardous substances and minimize waste generation in isocyanate production. Additionally, bio-based isocyanates derived from renewable resources are being explored as potential environmentally friendly alternatives to traditional petroleum-based isocyanates.

One of the most pressing concerns is the potential for air pollution. During the production of isocyanates, volatile organic compounds (VOCs) and other hazardous air pollutants may be released. These emissions can contribute to smog formation, ozone depletion, and overall air quality degradation. Furthermore, the release of isocyanates into the atmosphere can lead to the formation of secondary pollutants through chemical reactions, exacerbating the environmental impact.

Water contamination is another critical issue associated with isocyanate production and use. Improper handling, storage, or disposal of isocyanates can result in their release into water bodies, potentially harming aquatic ecosystems. Isocyanates can react with water to form insoluble polyureas, which may accumulate in sediments and affect benthic organisms. Additionally, the breakdown products of isocyanates in water can include toxic compounds that pose risks to aquatic life and human health.

Soil contamination is a concern, particularly in areas surrounding isocyanate production facilities or where isocyanate-containing products are improperly disposed of. The persistence of isocyanates and their degradation products in soil can lead to long-term environmental impacts, affecting soil microorganisms and potentially entering the food chain through plant uptake.

The energy-intensive nature of isocyanate production contributes to its carbon footprint. The manufacturing process often relies on fossil fuels, leading to greenhouse gas emissions and contributing to climate change. As the demand for isocyanate-based materials grows, the cumulative environmental impact of their production becomes increasingly significant.

Waste management is a crucial aspect of mitigating the environmental impact of isocyanates. Proper disposal and recycling of isocyanate-containing products are essential to prevent environmental contamination. However, the complexity of many isocyanate-based materials can make recycling challenging, often resulting in these products ending up in landfills where they may slowly degrade and release harmful substances.

To address these environmental concerns, research efforts are focusing on developing more sustainable production methods and alternative materials. Green chemistry approaches aim to reduce the use of hazardous substances and minimize waste generation in isocyanate production. Additionally, bio-based isocyanates derived from renewable resources are being explored as potential environmentally friendly alternatives to traditional petroleum-based isocyanates.

Safety Regulations

Safety regulations play a crucial role in the research and development of isocyanates, given their potential health and environmental risks. The handling, storage, and use of isocyanates are subject to stringent guidelines and standards set by various regulatory bodies worldwide.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for isocyanate exposure in the workplace. These regulations mandate permissible exposure limits (PELs) and require employers to implement comprehensive hazard communication programs, including proper labeling, safety data sheets, and employee training.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which apply to isocyanates and their derivatives. Under REACH, manufacturers and importers must register substances and provide detailed safety information. Additionally, the EU has imposed restrictions on certain diisocyanates, requiring professional and industrial users to undergo specific training.

Japan's regulatory framework for isocyanates falls under the Industrial Safety and Health Act and the Chemical Substances Control Law. These regulations focus on workplace safety, proper handling procedures, and environmental protection measures.

Environmental regulations also play a significant role in isocyanate research and production. Many countries have implemented strict emission controls and waste management protocols to minimize the environmental impact of isocyanate-related activities. For instance, the U.S. Environmental Protection Agency (EPA) regulates isocyanates under the Clean Air Act and the Toxic Substances Control Act.

As research into next-generation materials involving isocyanates progresses, regulatory bodies are continually updating their guidelines to address emerging concerns. This includes the development of more sensitive analytical methods for detecting isocyanate exposure and the establishment of lower occupational exposure limits.

The global nature of isocyanate research and production has led to efforts towards international harmonization of safety standards. The United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to hazard communication, which many countries have adopted or are in the process of implementing.

Compliance with these evolving safety regulations presents both challenges and opportunities for researchers and manufacturers. While adherence to strict safety protocols may increase operational costs, it also drives innovation in safer handling techniques, exposure monitoring technologies, and the development of less hazardous alternatives.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for isocyanate exposure in the workplace. These regulations mandate permissible exposure limits (PELs) and require employers to implement comprehensive hazard communication programs, including proper labeling, safety data sheets, and employee training.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which apply to isocyanates and their derivatives. Under REACH, manufacturers and importers must register substances and provide detailed safety information. Additionally, the EU has imposed restrictions on certain diisocyanates, requiring professional and industrial users to undergo specific training.

Japan's regulatory framework for isocyanates falls under the Industrial Safety and Health Act and the Chemical Substances Control Law. These regulations focus on workplace safety, proper handling procedures, and environmental protection measures.

Environmental regulations also play a significant role in isocyanate research and production. Many countries have implemented strict emission controls and waste management protocols to minimize the environmental impact of isocyanate-related activities. For instance, the U.S. Environmental Protection Agency (EPA) regulates isocyanates under the Clean Air Act and the Toxic Substances Control Act.

As research into next-generation materials involving isocyanates progresses, regulatory bodies are continually updating their guidelines to address emerging concerns. This includes the development of more sensitive analytical methods for detecting isocyanate exposure and the establishment of lower occupational exposure limits.

The global nature of isocyanate research and production has led to efforts towards international harmonization of safety standards. The United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to hazard communication, which many countries have adopted or are in the process of implementing.

Compliance with these evolving safety regulations presents both challenges and opportunities for researchers and manufacturers. While adherence to strict safety protocols may increase operational costs, it also drives innovation in safer handling techniques, exposure monitoring technologies, and the development of less hazardous alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!