Isocyanate Synthesis Techniques for Improved Safety

Isocyanate Synthesis Background and Objectives

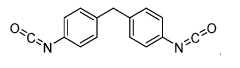

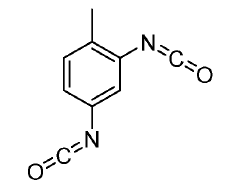

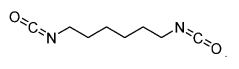

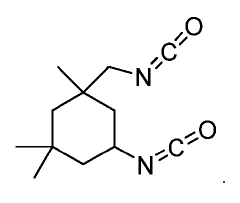

Isocyanates have been a cornerstone in the chemical industry since their discovery in the mid-19th century. These highly reactive compounds, characterized by the -N=C=O functional group, play a crucial role in the production of polyurethanes, a versatile class of polymers used in various applications ranging from foams and coatings to adhesives and elastomers. The synthesis of isocyanates has evolved significantly over the years, driven by the need for more efficient and safer production methods.

The primary objective in isocyanate synthesis has always been to develop techniques that maximize yield and purity while minimizing the associated risks. Traditionally, the most common method for producing isocyanates has been the phosgenation of primary amines. However, this process involves the use of highly toxic phosgene gas, presenting significant safety concerns and environmental challenges. As a result, the industry has been actively seeking alternative synthesis routes that can mitigate these risks without compromising product quality or production efficiency.

Recent technological advancements have led to the exploration of novel isocyanate synthesis techniques that prioritize safety. These include non-phosgene routes, such as the carbonylation of nitro compounds, the use of carbon dioxide as a carbonyl source, and the development of catalytic processes that operate under milder conditions. The goal is to reduce or eliminate the dependence on hazardous reagents while maintaining or improving the overall process economics.

The evolution of isocyanate synthesis techniques is closely tied to broader trends in green chemistry and sustainable manufacturing. There is a growing emphasis on developing processes that not only enhance safety but also reduce environmental impact, minimize waste generation, and improve energy efficiency. This aligns with global initiatives to create more sustainable chemical production methods and address concerns related to worker safety and environmental protection.

As the demand for polyurethane products continues to grow across various industries, including automotive, construction, and electronics, the need for safer and more efficient isocyanate synthesis methods becomes increasingly critical. The technological trajectory in this field is focused on innovation that can meet stringent safety standards while satisfying the escalating market demand. This involves a multidisciplinary approach, combining advances in catalysis, process engineering, and materials science to overcome the challenges associated with traditional synthesis methods.

The pursuit of improved safety in isocyanate synthesis is not only driven by regulatory pressures but also by the industry's commitment to responsible manufacturing practices. As such, the development of new synthesis techniques is expected to have far-reaching implications, potentially transforming the polyurethane value chain and opening up new possibilities for product innovation and market expansion.

Market Analysis for Safe Isocyanate Production

The global market for isocyanates has been experiencing steady growth, driven by increasing demand in various end-use industries such as automotive, construction, and furniture. However, the production of isocyanates has long been associated with significant safety concerns due to their highly reactive nature and potential health hazards. This has created a pressing need for safer synthesis techniques, opening up new opportunities in the market for innovative solutions.

The demand for safer isocyanate production methods is particularly strong in regions with stringent environmental and safety regulations, such as Europe and North America. These regions are likely to be early adopters of new, safer synthesis techniques. Emerging economies in Asia-Pacific, particularly China and India, are also showing increased interest in safer production methods as they seek to balance rapid industrial growth with improved worker safety and environmental protection.

Key market drivers for safe isocyanate production include regulatory pressures, growing awareness of occupational health risks, and the potential for cost savings through reduced safety measures and insurance premiums. Companies that can develop and implement safer synthesis techniques are likely to gain a competitive edge in the market, potentially capturing a larger market share and commanding premium prices for their products.

The market for safe isocyanate production technologies is expected to grow faster than the overall isocyanate market. This growth is fueled by the increasing adoption of green chemistry principles and the push towards sustainable manufacturing practices. Safer production methods not only address immediate safety concerns but also align with broader industry trends towards environmental responsibility and sustainable development.

Several major chemical companies are investing heavily in research and development of safer isocyanate synthesis techniques. These investments are driven by the potential for significant returns in terms of market share, brand reputation, and long-term sustainability. Collaborations between industry players and academic institutions are also becoming more common, accelerating the pace of innovation in this field.

The market for safer isocyanate production is not limited to new synthesis techniques alone. It also encompasses a range of ancillary products and services, including specialized equipment, safety monitoring systems, and consulting services for implementing safer production processes. This creates additional opportunities for companies operating in adjacent markets to enter the safe isocyanate production space.

Current Challenges in Isocyanate Synthesis Safety

The synthesis of isocyanates, while crucial for various industries, presents significant safety challenges that continue to concern manufacturers and researchers. One of the primary issues is the high reactivity of isocyanates, which can lead to uncontrolled reactions and potential hazards during production. This reactivity also makes isocyanates particularly sensitive to moisture, requiring stringent control of environmental conditions throughout the synthesis process.

Another major challenge is the toxicity of isocyanates and their precursors. Exposure to these compounds can cause severe respiratory issues, skin irritation, and other health problems. This necessitates robust safety protocols and personal protective equipment for workers, which can increase production costs and complexity. The potential for accidental releases or spills also poses environmental risks, requiring comprehensive containment and emergency response measures.

The use of phosgene as a key reagent in traditional isocyanate synthesis methods remains a significant safety concern. Phosgene is highly toxic and difficult to handle, presenting risks of acute poisoning and long-term health effects. While alternative methods have been developed, many still rely on phosgene or similarly hazardous intermediates, highlighting the need for safer synthetic routes.

Scale-up of isocyanate production from laboratory to industrial levels introduces additional safety challenges. Heat management becomes critical, as the exothermic nature of many isocyanate reactions can lead to thermal runaway if not properly controlled. This risk is compounded by the potential for side reactions and impurities, which can accumulate and create unexpected hazards in large-scale processes.

The transportation and storage of isocyanates also present ongoing safety challenges. These compounds require specialized containers and handling procedures to prevent exposure and maintain stability. Incidents during transport or storage can have severe consequences, necessitating rigorous risk assessment and mitigation strategies throughout the supply chain.

Regulatory compliance adds another layer of complexity to isocyanate synthesis safety. Evolving standards and increasing scrutiny from regulatory bodies require manufacturers to continually update their safety practices and documentation. This includes comprehensive hazard assessments, detailed safety data sheets, and regular audits of production facilities.

Addressing these challenges requires a multifaceted approach, combining innovative chemistry, advanced engineering controls, and comprehensive safety management systems. The development of inherently safer synthesis routes, improved catalysts, and novel reactor designs are active areas of research aimed at mitigating these risks. Additionally, the integration of real-time monitoring and advanced process control systems is becoming increasingly important for maintaining safety in isocyanate production.

Existing Safety Measures in Isocyanate Synthesis

01 Closed-loop synthesis systems

Implementing closed-loop synthesis systems for isocyanate production enhances safety by minimizing exposure risks. These systems incorporate advanced monitoring and control mechanisms to prevent leaks and contain hazardous materials throughout the synthesis process.- Closed-loop synthesis systems: Implementing closed-loop synthesis systems for isocyanate production enhances safety by minimizing exposure risks. These systems incorporate advanced monitoring and control mechanisms, reducing the potential for leaks or emissions. Automated processes and containment strategies further improve overall safety in isocyanate synthesis.

- Personal protective equipment (PPE) and safety protocols: Proper use of PPE and adherence to strict safety protocols are crucial in isocyanate synthesis. This includes specialized respirators, chemical-resistant suits, and gloves. Regular safety training, emergency response procedures, and proper ventilation systems are essential components of a comprehensive safety program for handling isocyanates.

- Alternative synthesis methods: Exploring alternative synthesis methods can improve safety in isocyanate production. These may include using less hazardous precursors, developing catalytic processes that operate under milder conditions, or employing novel reaction pathways that reduce the formation of toxic intermediates. Such approaches can significantly decrease the risks associated with traditional isocyanate synthesis techniques.

- Real-time monitoring and detection systems: Implementing advanced real-time monitoring and detection systems enhances safety in isocyanate synthesis. These systems can quickly identify leaks, abnormal process conditions, or the presence of hazardous vapors. Integration with automated shutdown procedures and alarm systems allows for rapid response to potential safety threats.

- Green chemistry approaches: Adopting green chemistry principles in isocyanate synthesis can improve safety and environmental impact. This includes using renewable feedstocks, designing processes with reduced energy consumption, and minimizing waste generation. These approaches often result in inherently safer synthesis techniques with lower toxicity and reduced environmental hazards.

02 Personal protective equipment (PPE)

Proper use of PPE is crucial for ensuring worker safety during isocyanate synthesis. This includes specialized respirators, chemical-resistant gloves, and protective clothing designed to prevent skin contact and inhalation of isocyanate vapors.Expand Specific Solutions03 Ventilation and exhaust systems

Effective ventilation and exhaust systems are essential for maintaining safe air quality in isocyanate synthesis facilities. These systems help remove toxic fumes and maintain proper air circulation, reducing the risk of exposure to harmful vapors.Expand Specific Solutions04 Safety monitoring and emergency response

Implementing comprehensive safety monitoring systems and emergency response protocols is crucial for isocyanate synthesis safety. This includes real-time detection of leaks, automated shutdown procedures, and well-trained emergency response teams.Expand Specific Solutions05 Alternative synthesis methods

Exploring alternative synthesis methods for isocyanates can improve overall safety. This includes developing new catalysts, using less hazardous precursors, or employing novel reaction pathways that reduce the risks associated with traditional isocyanate synthesis techniques.Expand Specific Solutions

Key Players in Isocyanate Manufacturing Industry

The isocyanate synthesis techniques for improved safety market is in a growth phase, driven by increasing demand for safer production methods in various industries. The global market size is estimated to be over $1 billion, with steady growth projected. Technologically, the field is advancing rapidly, with major players like Wanhua Chemical, BASF, and Asahi Kasei leading innovation. These companies are investing heavily in R&D to develop novel catalysts, process optimizations, and alternative synthesis routes that enhance safety while maintaining efficiency. Emerging players like Zhejiang University of Technology and the Institute of Process Engineering are also contributing significant research advancements, indicating a competitive and dynamic landscape focused on balancing safety, sustainability, and industrial scalability.

Wanhua Chemical Group Co., Ltd.

BASF Corp.

Innovative Approaches to Safer Isocyanate Production

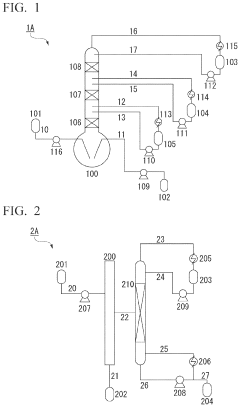

- A continuous flow process involving the mixing of acyl hydrazides with nitrous acid to form acyl azides, followed by heating in the presence of an organic solvent to produce isocyanates through Curtius rearrangement, offering a safer and more scalable method for isocyanate synthesis.

- A method involving the thermal decomposition of carbamates in the presence of specific compounds, where low-boiling-point decomposition products are continuously extracted in a gaseous state and high-boiling-point components are separately collected, suppressing side reactions and enabling continuous isocyanate production.

Environmental Impact of Isocyanate Production

The environmental impact of isocyanate production is a critical concern in the chemical industry, particularly given the increasing focus on sustainability and environmental protection. Isocyanate synthesis, while essential for various industrial applications, poses significant environmental challenges that require careful consideration and mitigation strategies.

One of the primary environmental concerns associated with isocyanate production is the emission of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). These emissions can contribute to air pollution, smog formation, and potential health risks for workers and surrounding communities. The release of unreacted raw materials, such as phosgene and toluene diisocyanate (TDI), can have severe ecological consequences if not properly controlled.

Water pollution is another significant environmental issue in isocyanate manufacturing. Wastewater from production processes may contain toxic substances, including unreacted isocyanates, amines, and other organic compounds. If not adequately treated, these contaminants can harm aquatic ecosystems and potentially enter the food chain, posing risks to human health and wildlife.

The energy-intensive nature of isocyanate synthesis contributes to greenhouse gas emissions and climate change. The high temperatures and pressures required for reactions, as well as the energy needed for purification and separation processes, result in substantial carbon footprints for isocyanate production facilities.

Waste management is a crucial aspect of environmental impact mitigation in isocyanate manufacturing. The generation of hazardous waste, including spent catalysts, byproducts, and off-specification materials, requires specialized disposal methods to prevent soil and groundwater contamination. Improper handling or disposal of these wastes can lead to long-term environmental degradation and potential health hazards.

To address these environmental challenges, the industry has been developing and implementing various strategies. These include the adoption of cleaner production technologies, such as closed-loop systems and solvent recovery processes, which minimize emissions and reduce waste generation. Advanced air pollution control systems, like thermal oxidizers and scrubbers, are being employed to capture and treat VOCs and HAPs before release into the atmosphere.

Water treatment technologies have also been enhanced to effectively remove isocyanates and related compounds from wastewater streams. Membrane filtration, advanced oxidation processes, and biological treatment systems are being utilized to ensure that effluents meet stringent environmental standards.

Furthermore, there is a growing emphasis on green chemistry principles in isocyanate synthesis. Researchers are exploring alternative raw materials and reaction pathways that reduce the environmental footprint of production processes. This includes the development of bio-based isocyanates and the use of less hazardous precursors to minimize the overall environmental impact of the industry.

Regulatory Framework for Isocyanate Manufacturing

The regulatory framework for isocyanate manufacturing has evolved significantly in recent years, driven by increasing awareness of the potential health and environmental risks associated with these chemicals. Governments and regulatory bodies worldwide have implemented stringent guidelines to ensure the safe production, handling, and use of isocyanates.

In the United States, the Occupational Safety and Health Administration (OSHA) has established comprehensive standards for isocyanate exposure in the workplace. These regulations include permissible exposure limits (PELs), requirements for personal protective equipment (PPE), and mandatory health monitoring programs for workers. The Environmental Protection Agency (EPA) also plays a crucial role in regulating isocyanate manufacturing through the Toxic Substances Control Act (TSCA) and the Clean Air Act.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which requires manufacturers and importers to register and assess the risks of chemicals, including isocyanates. Additionally, the EU has specific directives addressing occupational exposure limits and safety measures for isocyanate handling.

In Asia, countries like China and Japan have also strengthened their regulatory frameworks. China's Ministry of Ecology and Environment has introduced stricter environmental protection laws, while Japan's Industrial Safety and Health Law sets forth detailed guidelines for isocyanate manufacturing and use.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), have further standardized the approach to isocyanate regulation across different countries. This system provides a unified classification and labeling system for hazardous chemicals, facilitating international trade and improving safety communication.

Regulatory bodies are increasingly focusing on promoting safer alternatives and green chemistry principles in isocyanate synthesis. This includes incentives for developing and adopting less hazardous production methods, as well as requirements for lifecycle assessments of isocyanate products.

Compliance with these regulations presents significant challenges for manufacturers, necessitating substantial investments in safety equipment, training programs, and environmental control technologies. However, these measures have led to notable improvements in worker safety and environmental protection within the isocyanate industry.

As research continues to reveal more about the long-term effects of isocyanate exposure, regulatory frameworks are expected to evolve further. Future regulations may focus on stricter emission controls, more comprehensive health monitoring, and increased emphasis on sustainable production methods. This ongoing regulatory development underscores the importance of continued innovation in isocyanate synthesis techniques to improve safety and environmental performance.