Key Ferrofluid Applications in Dynamic Semiconductor Solutions

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluids, first developed in the 1960s by NASA, have undergone significant technological evolution over the past six decades. Initially conceived for fuel control in zero-gravity environments, these magnetic nanofluids have found their way into various industrial applications, including semiconductor manufacturing.

The evolution of ferrofluid technology in semiconductor solutions can be traced through several key phases. In the 1970s and 1980s, researchers began exploring the potential of ferrofluids for heat dissipation in electronic components. This led to the development of ferrofluid-based cooling systems for high-power semiconductors, marking the first significant application in the industry.

The 1990s saw a shift towards precision engineering applications. Ferrofluids were integrated into dynamic sealing systems for rotating shafts in semiconductor manufacturing equipment. This innovation significantly reduced contamination risks and improved the overall reliability of production processes.

The early 2000s brought about a revolution in ferrofluid formulation. Advanced synthesis techniques allowed for the creation of ferrofluids with enhanced stability and magnetic properties. These improvements enabled their use in more demanding semiconductor applications, such as magnetically-assisted polishing of silicon wafers.

From 2010 onwards, the focus shifted towards nanoscale applications. Researchers began exploring the use of ferrofluids in nanofluidic devices for lab-on-chip applications in semiconductor testing. This period also saw the emergence of ferrofluid-based actuators for precise positioning in semiconductor lithography equipment.

Recent years have witnessed the integration of ferrofluids with smart materials and IoT technologies. Adaptive cooling systems using ferrofluids and real-time monitoring capabilities have been developed, addressing the thermal management challenges in advanced semiconductor devices.

Looking ahead, the evolution of ferrofluid technology in semiconductor solutions is likely to continue along several trajectories. One promising direction is the development of multifunctional ferrofluids that can simultaneously perform cooling, sealing, and actuation tasks. Another area of focus is the creation of environmentally friendly ferrofluids with reduced environmental impact and improved recyclability.

As semiconductor devices continue to shrink and become more complex, the role of ferrofluids in manufacturing and thermal management is expected to grow. Future developments may include ferrofluid-based self-healing materials for semiconductor packaging and advanced magnetic field-guided assembly techniques for nanoelectronics.

The evolution of ferrofluid technology in semiconductor solutions can be traced through several key phases. In the 1970s and 1980s, researchers began exploring the potential of ferrofluids for heat dissipation in electronic components. This led to the development of ferrofluid-based cooling systems for high-power semiconductors, marking the first significant application in the industry.

The 1990s saw a shift towards precision engineering applications. Ferrofluids were integrated into dynamic sealing systems for rotating shafts in semiconductor manufacturing equipment. This innovation significantly reduced contamination risks and improved the overall reliability of production processes.

The early 2000s brought about a revolution in ferrofluid formulation. Advanced synthesis techniques allowed for the creation of ferrofluids with enhanced stability and magnetic properties. These improvements enabled their use in more demanding semiconductor applications, such as magnetically-assisted polishing of silicon wafers.

From 2010 onwards, the focus shifted towards nanoscale applications. Researchers began exploring the use of ferrofluids in nanofluidic devices for lab-on-chip applications in semiconductor testing. This period also saw the emergence of ferrofluid-based actuators for precise positioning in semiconductor lithography equipment.

Recent years have witnessed the integration of ferrofluids with smart materials and IoT technologies. Adaptive cooling systems using ferrofluids and real-time monitoring capabilities have been developed, addressing the thermal management challenges in advanced semiconductor devices.

Looking ahead, the evolution of ferrofluid technology in semiconductor solutions is likely to continue along several trajectories. One promising direction is the development of multifunctional ferrofluids that can simultaneously perform cooling, sealing, and actuation tasks. Another area of focus is the creation of environmentally friendly ferrofluids with reduced environmental impact and improved recyclability.

As semiconductor devices continue to shrink and become more complex, the role of ferrofluids in manufacturing and thermal management is expected to grow. Future developments may include ferrofluid-based self-healing materials for semiconductor packaging and advanced magnetic field-guided assembly techniques for nanoelectronics.

Semiconductor Market Needs

The semiconductor industry is experiencing a surge in demand for innovative solutions to address the challenges of miniaturization, power efficiency, and thermal management. As chip designs become more complex and densely packed, traditional cooling methods are reaching their limits. This has created a significant market need for advanced thermal management solutions, particularly in high-performance computing, data centers, and mobile devices.

Ferrofluids, with their unique magnetic and thermal properties, are emerging as a promising technology to meet these semiconductor market needs. The ability of ferrofluids to respond dynamically to magnetic fields and efficiently transfer heat makes them ideal candidates for next-generation cooling systems in semiconductor applications.

One of the primary market drivers is the increasing power density in semiconductor devices. As transistor counts continue to rise and chip sizes shrink, the amount of heat generated per unit area has escalated dramatically. This trend has led to a growing demand for more effective cooling solutions that can maintain optimal operating temperatures without compromising performance or reliability.

Another key market need is the requirement for flexible and adaptable thermal management systems. The semiconductor industry is constantly evolving, with new chip architectures and packaging technologies being introduced regularly. Ferrofluid-based solutions offer the potential for dynamic, reconfigurable cooling systems that can adapt to changing thermal loads and device geometries.

Energy efficiency is also a critical concern in the semiconductor market. Data centers, in particular, are under pressure to reduce their energy consumption and carbon footprint. Ferrofluid-based cooling systems have the potential to improve overall system efficiency by providing more effective heat dissipation, potentially reducing the need for energy-intensive air conditioning and allowing for higher clock speeds and improved performance.

The market is also seeking solutions that can address the challenges of 3D chip stacking and heterogeneous integration. These advanced packaging technologies create complex thermal management issues that traditional cooling methods struggle to address. Ferrofluids, with their ability to conform to irregular shapes and penetrate small spaces, could provide effective cooling for these intricate structures.

Reliability and longevity of semiconductor devices are paramount concerns for manufacturers and end-users alike. The market demands cooling solutions that not only improve performance but also extend the lifespan of electronic components. Ferrofluid-based systems have the potential to offer more uniform temperature distribution, reducing thermal stress and potentially improving device reliability.

Ferrofluids, with their unique magnetic and thermal properties, are emerging as a promising technology to meet these semiconductor market needs. The ability of ferrofluids to respond dynamically to magnetic fields and efficiently transfer heat makes them ideal candidates for next-generation cooling systems in semiconductor applications.

One of the primary market drivers is the increasing power density in semiconductor devices. As transistor counts continue to rise and chip sizes shrink, the amount of heat generated per unit area has escalated dramatically. This trend has led to a growing demand for more effective cooling solutions that can maintain optimal operating temperatures without compromising performance or reliability.

Another key market need is the requirement for flexible and adaptable thermal management systems. The semiconductor industry is constantly evolving, with new chip architectures and packaging technologies being introduced regularly. Ferrofluid-based solutions offer the potential for dynamic, reconfigurable cooling systems that can adapt to changing thermal loads and device geometries.

Energy efficiency is also a critical concern in the semiconductor market. Data centers, in particular, are under pressure to reduce their energy consumption and carbon footprint. Ferrofluid-based cooling systems have the potential to improve overall system efficiency by providing more effective heat dissipation, potentially reducing the need for energy-intensive air conditioning and allowing for higher clock speeds and improved performance.

The market is also seeking solutions that can address the challenges of 3D chip stacking and heterogeneous integration. These advanced packaging technologies create complex thermal management issues that traditional cooling methods struggle to address. Ferrofluids, with their ability to conform to irregular shapes and penetrate small spaces, could provide effective cooling for these intricate structures.

Reliability and longevity of semiconductor devices are paramount concerns for manufacturers and end-users alike. The market demands cooling solutions that not only improve performance but also extend the lifespan of electronic components. Ferrofluid-based systems have the potential to offer more uniform temperature distribution, reducing thermal stress and potentially improving device reliability.

Ferrofluid Challenges

Despite the promising applications of ferrofluids in semiconductor solutions, several significant challenges hinder their widespread adoption and optimal performance. One of the primary obstacles is the long-term stability of ferrofluids. Over time, these magnetic nanofluids tend to agglomerate, leading to sedimentation and a loss of their unique properties. This instability can compromise the reliability and efficiency of semiconductor devices that rely on ferrofluid functionality.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields and environmental conditions. The complex interplay between magnetic forces, surface tensions, and fluid dynamics makes it difficult to predict and manipulate ferrofluid responses accurately. This unpredictability can result in inconsistent performance in semiconductor applications, particularly in scenarios requiring high precision and repeatability.

The thermal management of ferrofluids presents another significant hurdle. While ferrofluids offer excellent heat transfer capabilities, their magnetic properties can be affected by temperature fluctuations. This sensitivity to temperature changes can lead to performance variations in semiconductor cooling systems, potentially impacting the overall efficiency and reliability of electronic devices.

Compatibility issues between ferrofluids and semiconductor materials pose additional challenges. The chemical composition of ferrofluids must be carefully tailored to prevent corrosion or degradation of semiconductor components. Furthermore, ensuring that ferrofluids do not interfere with the electrical properties of semiconductors is crucial for maintaining device integrity and functionality.

The scalability of ferrofluid-based solutions in semiconductor manufacturing processes remains a significant concern. Integrating ferrofluid technologies into existing production lines while maintaining cost-effectiveness and high throughput is a complex task. The need for specialized equipment and handling procedures can increase manufacturing complexity and costs.

Lastly, the environmental and health implications of ferrofluids in semiconductor applications require careful consideration. The potential release of nanoparticles during manufacturing or device operation raises concerns about long-term environmental impacts and worker safety. Developing eco-friendly ferrofluid formulations and implementing robust containment measures are essential steps in addressing these challenges.

Overcoming these multifaceted challenges requires interdisciplinary research efforts, combining expertise in materials science, fluid dynamics, magnetism, and semiconductor engineering. As the demand for advanced semiconductor solutions continues to grow, addressing these ferrofluid challenges will be crucial in unlocking the full potential of this innovative technology in the semiconductor industry.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields and environmental conditions. The complex interplay between magnetic forces, surface tensions, and fluid dynamics makes it difficult to predict and manipulate ferrofluid responses accurately. This unpredictability can result in inconsistent performance in semiconductor applications, particularly in scenarios requiring high precision and repeatability.

The thermal management of ferrofluids presents another significant hurdle. While ferrofluids offer excellent heat transfer capabilities, their magnetic properties can be affected by temperature fluctuations. This sensitivity to temperature changes can lead to performance variations in semiconductor cooling systems, potentially impacting the overall efficiency and reliability of electronic devices.

Compatibility issues between ferrofluids and semiconductor materials pose additional challenges. The chemical composition of ferrofluids must be carefully tailored to prevent corrosion or degradation of semiconductor components. Furthermore, ensuring that ferrofluids do not interfere with the electrical properties of semiconductors is crucial for maintaining device integrity and functionality.

The scalability of ferrofluid-based solutions in semiconductor manufacturing processes remains a significant concern. Integrating ferrofluid technologies into existing production lines while maintaining cost-effectiveness and high throughput is a complex task. The need for specialized equipment and handling procedures can increase manufacturing complexity and costs.

Lastly, the environmental and health implications of ferrofluids in semiconductor applications require careful consideration. The potential release of nanoparticles during manufacturing or device operation raises concerns about long-term environmental impacts and worker safety. Developing eco-friendly ferrofluid formulations and implementing robust containment measures are essential steps in addressing these challenges.

Overcoming these multifaceted challenges requires interdisciplinary research efforts, combining expertise in materials science, fluid dynamics, magnetism, and semiconductor engineering. As the demand for advanced semiconductor solutions continues to grow, addressing these ferrofluid challenges will be crucial in unlocking the full potential of this innovative technology in the semiconductor industry.

Current Ferrofluid Apps

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide a unique combination of liquid properties with magnetic responsiveness, allowing for improved sealing performance and reduced friction in various mechanical systems.

- Thermal management and cooling systems: Ferrofluids have applications in thermal management and cooling systems, particularly in electronic devices. Their ability to be manipulated by magnetic fields allows for targeted heat transfer and improved cooling efficiency in compact spaces, such as computer components and power electronics.

- Magnetic field sensing and measurement: Ferrofluids are utilized in various sensing and measurement applications involving magnetic fields. Their unique response to magnetic fields enables the development of sensitive instruments for detecting and measuring magnetic field strength and direction, with applications in scientific research and industrial processes.

- Medical and biomedical applications: Ferrofluids have emerging applications in the medical and biomedical fields. They are being explored for targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). The ability to control ferrofluids with external magnetic fields offers potential for minimally invasive medical procedures.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. Their unique properties allow them to form liquid O-rings that can be controlled by magnetic fields, providing effective sealing in dynamic systems and reducing friction in various mechanical components.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids have excellent heat transfer properties and are used in thermal management systems. They can be employed in cooling systems for electronic devices, transformers, and other heat-generating equipment. The magnetic properties of ferrofluids allow for enhanced heat dissipation and improved thermal conductivity in various applications.Expand Specific Solutions04 Magnetic field sensing and measurement

Ferrofluids are utilized in various sensing and measurement applications related to magnetic fields. They can be used in devices for detecting and measuring magnetic field strength, orientation, and gradients. These applications include magnetic field sensors, compasses, and scientific instruments for studying magnetic phenomena.Expand Specific Solutions05 Damping and vibration control

Ferrofluids exhibit unique damping properties that make them useful in vibration control applications. They can be employed in shock absorbers, vibration isolators, and other damping systems. The magnetic properties of ferrofluids allow for adaptive damping characteristics that can be controlled by external magnetic fields.Expand Specific Solutions

Key Industry Players

The field of key ferrofluid applications in dynamic semiconductor solutions is in a nascent stage of development, with significant potential for growth. The market size is relatively small but expanding rapidly as researchers and companies explore novel uses for ferrofluids in semiconductor manufacturing and device design. Technologically, the field is still evolving, with varying levels of maturity across different applications. Companies like Yale University, CSIC, and Midatech Ltd. are at the forefront of research, while established semiconductor players such as Kyocera Corp., TDK Corp., and IBM are exploring integration possibilities. The competitive landscape is diverse, with academic institutions, specialized materials companies, and major tech firms all vying to advance the technology and capture emerging market opportunities.

University of Maryland

Technical Solution: The University of Maryland has been at the forefront of ferrofluid research for semiconductor applications. Their work includes developing novel ferrofluid-based microfluidic devices for lab-on-a-chip applications in semiconductor testing and analysis[7]. The university's researchers have created ferrofluid-actuated valves and pumps that can precisely control fluid flow at the microscale, enabling more efficient and compact semiconductor processing and testing equipment. Additionally, they have explored the use of ferrofluids in creating adaptive heat spreaders for dynamic thermal management in high-performance computing systems[8]. This technology allows for real-time adjustment of thermal conductivity, potentially solving hotspot issues in complex semiconductor architectures.

Strengths: Cutting-edge research in microfluidics and thermal management, with potential for significant impact on semiconductor manufacturing and testing processes. Weaknesses: As an academic institution, may face challenges in commercialization and large-scale implementation of developed technologies.

Sony Semiconductor Solutions Corp.

Technical Solution: Sony has been investigating the application of ferrofluids in advanced imaging sensors and display technologies. Their research includes the development of ferrofluid-based adaptive lenses for semiconductor image sensors, allowing for rapid and precise focus adjustments without mechanical parts[5]. This technology could significantly enhance the performance of cameras in smartphones and other compact devices. Additionally, Sony has explored the use of ferrofluids in creating tunable optical filters for display applications, potentially improving color accuracy and contrast in next-generation screens[6]. The company has also filed patents related to using ferrofluids for thermal management in high-performance image processing units, addressing heat dissipation challenges in compact camera modules.

Strengths: Innovative applications in imaging and display technologies, leveraging Sony's expertise in consumer electronics. Potential for miniaturization and improved performance in camera and display systems. Weaknesses: May face challenges in mass production and integration with existing semiconductor manufacturing processes.

Core Ferrofluid Patents

Label-Free Cellular Manipulation and Sorting Via Biocompatible Ferrofluids

PatentActiveUS20180128729A1

Innovation

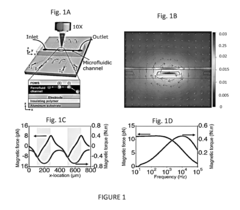

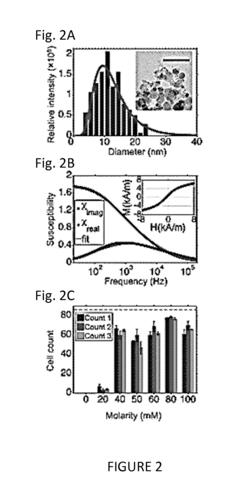

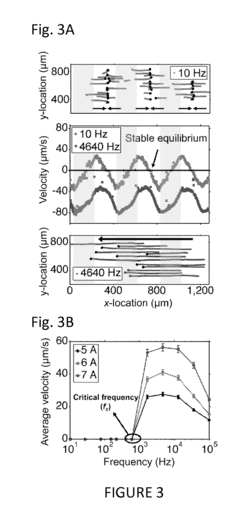

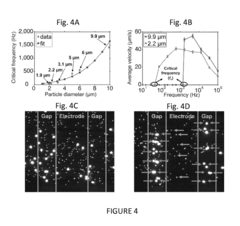

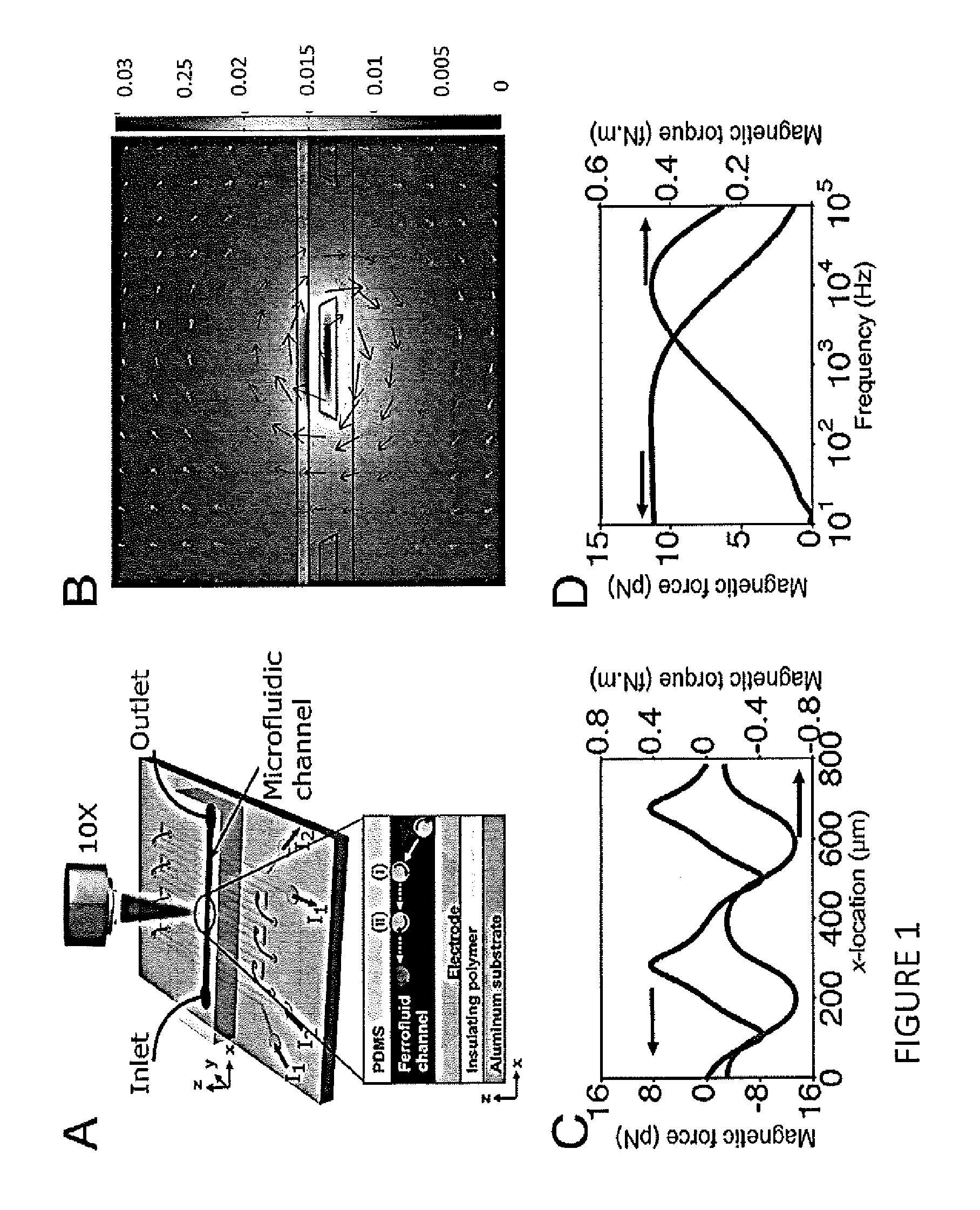

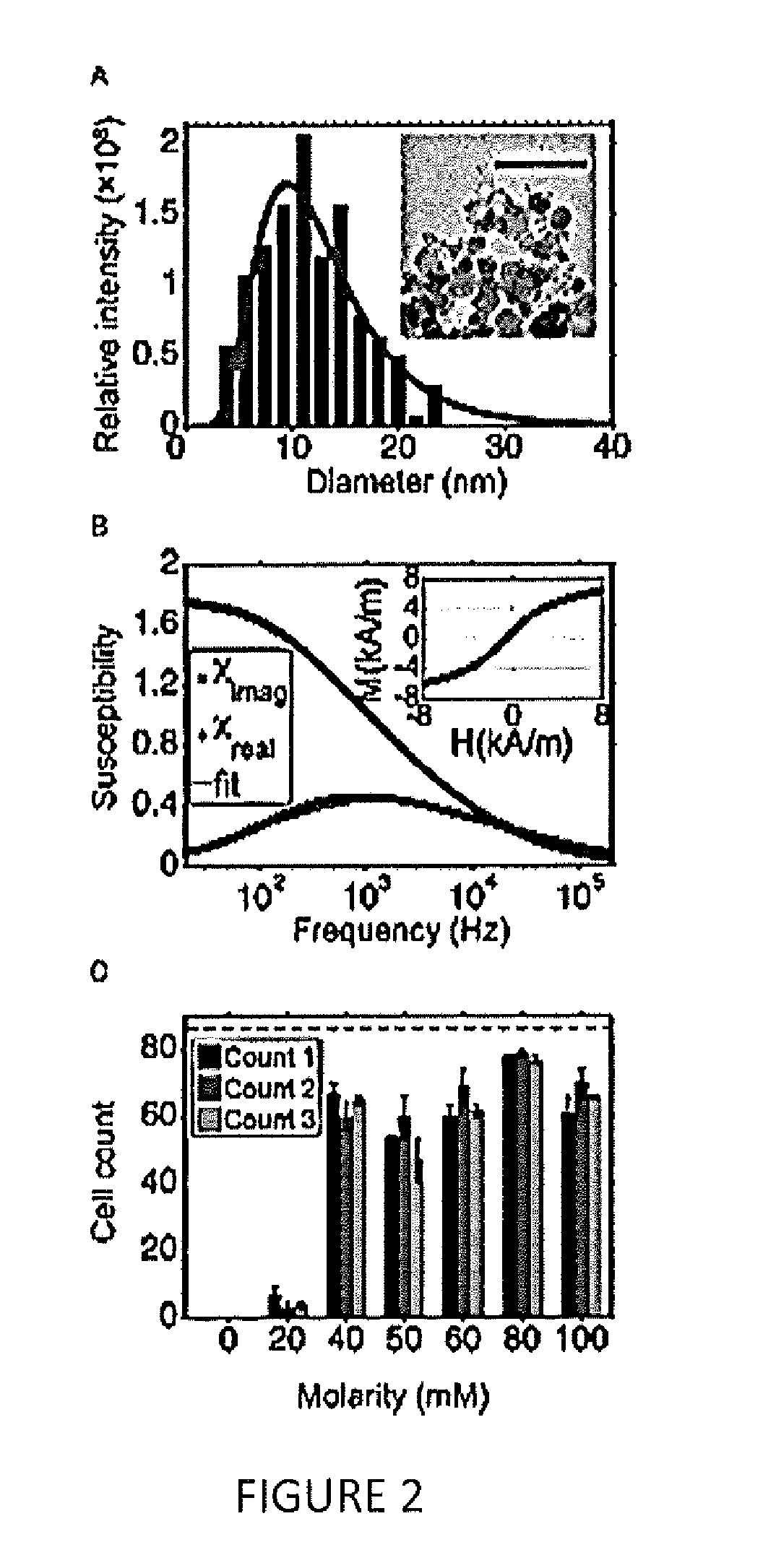

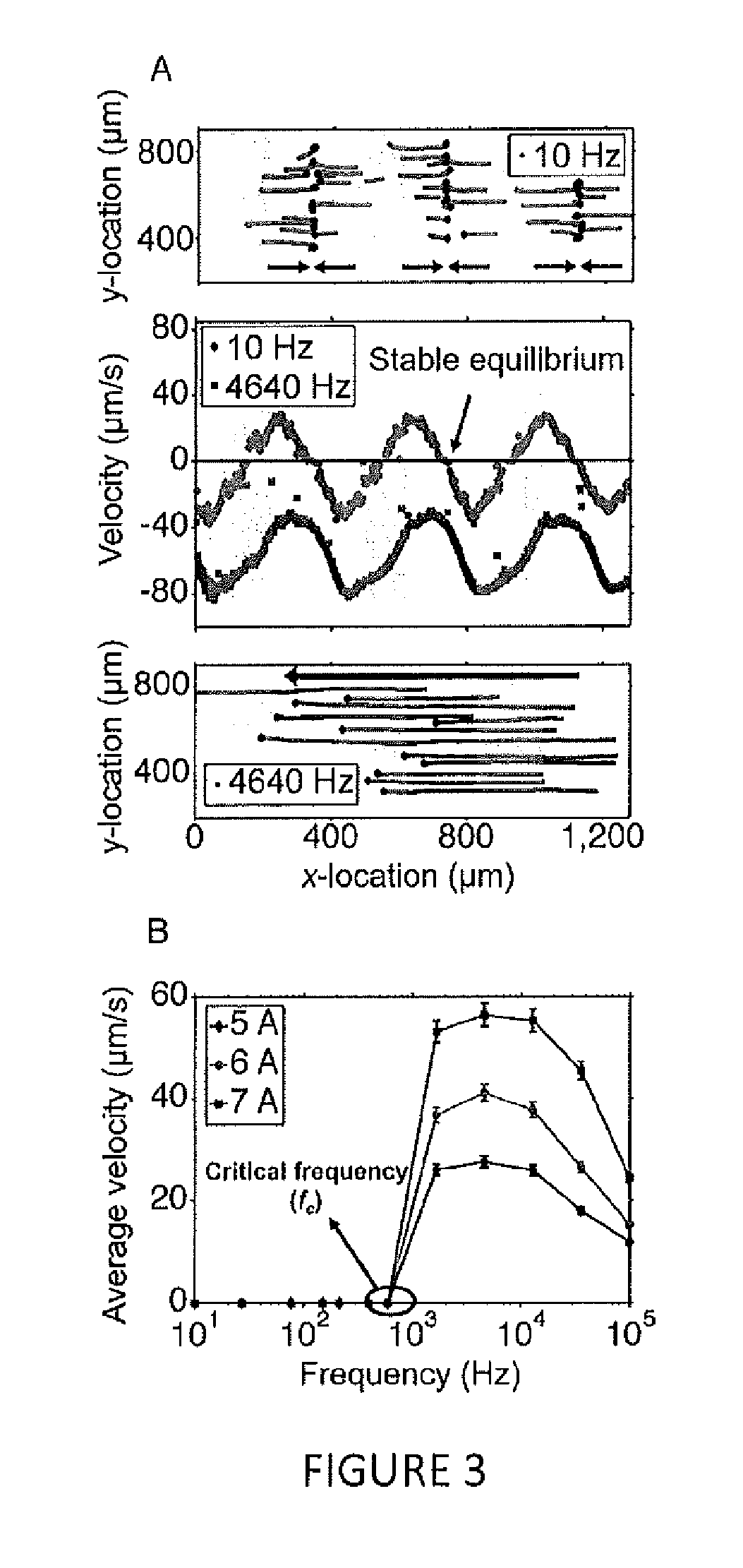

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Label-free cellular manipulation and sorting via biocompatible ferrofluids

PatentActiveUS20120237997A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Thermal Management

Thermal management is a critical aspect of semiconductor solutions, and ferrofluids offer innovative approaches to address heat dissipation challenges. In the context of dynamic semiconductor applications, ferrofluids present unique properties that can be leveraged for efficient thermal control.

Ferrofluids, being magnetic nanofluids, exhibit enhanced thermal conductivity compared to conventional coolants. This characteristic makes them particularly suitable for targeted heat removal in semiconductor devices. When subjected to magnetic fields, ferrofluids can be precisely controlled and directed to hotspots within the semiconductor architecture, allowing for localized cooling and temperature regulation.

One key application of ferrofluids in thermal management is in the development of adaptive cooling systems. These systems can dynamically adjust their cooling capacity based on the real-time thermal demands of the semiconductor components. By manipulating the ferrofluid's flow and distribution using external magnetic fields, it becomes possible to create responsive cooling solutions that optimize energy efficiency while maintaining optimal operating temperatures.

Ferrofluid-based heat pipes represent another promising application in semiconductor thermal management. These advanced heat transfer devices utilize the magnetic properties of ferrofluids to enhance capillary action and fluid circulation. The result is a more efficient heat transport mechanism that can effectively dissipate heat from high-power density areas within semiconductor packages.

Moreover, ferrofluids can be integrated into microfluidic cooling channels within semiconductor devices. This approach allows for the creation of intricate cooling networks that can navigate complex three-dimensional structures, addressing thermal challenges in advanced packaging designs such as 3D-stacked chips and system-in-package solutions.

The use of ferrofluids in thermal interface materials (TIMs) is another area of interest. By incorporating ferrofluid particles into conventional TIMs, it is possible to create adaptive interfaces that can be magnetically actuated to improve thermal contact and reduce thermal resistance between heat-generating components and heat sinks.

As semiconductor devices continue to shrink in size while increasing in complexity and power density, the need for innovative thermal management solutions becomes more pressing. Ferrofluids offer a unique set of properties that can be harnessed to address these challenges, potentially enabling the development of more efficient and reliable semiconductor solutions for next-generation applications.

Ferrofluids, being magnetic nanofluids, exhibit enhanced thermal conductivity compared to conventional coolants. This characteristic makes them particularly suitable for targeted heat removal in semiconductor devices. When subjected to magnetic fields, ferrofluids can be precisely controlled and directed to hotspots within the semiconductor architecture, allowing for localized cooling and temperature regulation.

One key application of ferrofluids in thermal management is in the development of adaptive cooling systems. These systems can dynamically adjust their cooling capacity based on the real-time thermal demands of the semiconductor components. By manipulating the ferrofluid's flow and distribution using external magnetic fields, it becomes possible to create responsive cooling solutions that optimize energy efficiency while maintaining optimal operating temperatures.

Ferrofluid-based heat pipes represent another promising application in semiconductor thermal management. These advanced heat transfer devices utilize the magnetic properties of ferrofluids to enhance capillary action and fluid circulation. The result is a more efficient heat transport mechanism that can effectively dissipate heat from high-power density areas within semiconductor packages.

Moreover, ferrofluids can be integrated into microfluidic cooling channels within semiconductor devices. This approach allows for the creation of intricate cooling networks that can navigate complex three-dimensional structures, addressing thermal challenges in advanced packaging designs such as 3D-stacked chips and system-in-package solutions.

The use of ferrofluids in thermal interface materials (TIMs) is another area of interest. By incorporating ferrofluid particles into conventional TIMs, it is possible to create adaptive interfaces that can be magnetically actuated to improve thermal contact and reduce thermal resistance between heat-generating components and heat sinks.

As semiconductor devices continue to shrink in size while increasing in complexity and power density, the need for innovative thermal management solutions becomes more pressing. Ferrofluids offer a unique set of properties that can be harnessed to address these challenges, potentially enabling the development of more efficient and reliable semiconductor solutions for next-generation applications.

Environmental Impact

The application of ferrofluids in dynamic semiconductor solutions presents both opportunities and challenges from an environmental perspective. While these innovative materials offer potential improvements in efficiency and performance, their environmental impact must be carefully considered and managed throughout their lifecycle.

Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have unique properties that make them valuable in semiconductor manufacturing and cooling systems. However, the production and disposal of these materials raise environmental concerns. The synthesis of ferrofluids often involves the use of toxic chemicals and energy-intensive processes, contributing to greenhouse gas emissions and potential pollution if not properly controlled.

In semiconductor applications, ferrofluids can enhance heat transfer and improve overall system efficiency, potentially reducing energy consumption and associated environmental impacts. This positive effect may offset some of the environmental costs associated with their production. Additionally, the use of ferrofluids in dynamic sealing and damping applications can extend the lifespan of semiconductor equipment, reducing waste and resource consumption in the long term.

However, the disposal of ferrofluids at the end of their useful life presents significant environmental challenges. The nanoparticles in ferrofluids can persist in the environment and may have unforeseen ecological effects if released. Proper recycling and disposal methods must be developed and implemented to prevent contamination of soil and water resources.

The potential for ferrofluid leakage during use in semiconductor applications also raises concerns about workplace safety and environmental contamination. Stringent containment measures and monitoring protocols are necessary to mitigate these risks. Furthermore, the long-term effects of exposure to ferrofluid nanoparticles on human health and ecosystems are not yet fully understood, necessitating ongoing research and risk assessment.

As the semiconductor industry continues to explore and expand the use of ferrofluids, it is crucial to adopt a lifecycle approach to environmental management. This includes optimizing production processes to minimize resource consumption and emissions, implementing robust containment and handling procedures during use, and developing effective recycling and disposal methods. Collaboration between industry, researchers, and regulatory bodies is essential to establish best practices and standards for the environmentally responsible use of ferrofluids in semiconductor applications.

Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have unique properties that make them valuable in semiconductor manufacturing and cooling systems. However, the production and disposal of these materials raise environmental concerns. The synthesis of ferrofluids often involves the use of toxic chemicals and energy-intensive processes, contributing to greenhouse gas emissions and potential pollution if not properly controlled.

In semiconductor applications, ferrofluids can enhance heat transfer and improve overall system efficiency, potentially reducing energy consumption and associated environmental impacts. This positive effect may offset some of the environmental costs associated with their production. Additionally, the use of ferrofluids in dynamic sealing and damping applications can extend the lifespan of semiconductor equipment, reducing waste and resource consumption in the long term.

However, the disposal of ferrofluids at the end of their useful life presents significant environmental challenges. The nanoparticles in ferrofluids can persist in the environment and may have unforeseen ecological effects if released. Proper recycling and disposal methods must be developed and implemented to prevent contamination of soil and water resources.

The potential for ferrofluid leakage during use in semiconductor applications also raises concerns about workplace safety and environmental contamination. Stringent containment measures and monitoring protocols are necessary to mitigate these risks. Furthermore, the long-term effects of exposure to ferrofluid nanoparticles on human health and ecosystems are not yet fully understood, necessitating ongoing research and risk assessment.

As the semiconductor industry continues to explore and expand the use of ferrofluids, it is crucial to adopt a lifecycle approach to environmental management. This includes optimizing production processes to minimize resource consumption and emissions, implementing robust containment and handling procedures during use, and developing effective recycling and disposal methods. Collaboration between industry, researchers, and regulatory bodies is essential to establish best practices and standards for the environmentally responsible use of ferrofluids in semiconductor applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!