Key Techniques for Ferrofluid Application in Acoustic Engineering

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Acoustics Background and Objectives

Ferrofluids, a unique class of magnetic nanomaterials, have emerged as a promising technology in acoustic engineering over the past few decades. These colloidal suspensions of magnetic nanoparticles in a carrier fluid exhibit remarkable responsiveness to external magnetic fields, making them ideal for various acoustic applications. The evolution of ferrofluid technology can be traced back to the 1960s when NASA first developed them for controlling liquids in zero gravity.

The field of ferrofluid acoustics has since progressed significantly, driven by advancements in nanotechnology and materials science. This interdisciplinary area combines principles from magnetism, fluid dynamics, and acoustics, offering innovative solutions to longstanding challenges in sound control and manipulation. The primary objective of ferrofluid acoustics research is to harness the unique properties of these smart fluids to enhance acoustic performance in various applications.

One of the key trends in ferrofluid acoustics is the development of tunable acoustic devices. By manipulating the magnetic field applied to ferrofluids, researchers can dynamically alter their physical properties, such as viscosity and shape, thereby modulating acoustic waves. This adaptability opens up new possibilities for creating responsive acoustic systems that can adjust in real-time to changing environmental conditions or user requirements.

Another significant trend is the miniaturization of acoustic devices using ferrofluids. As the demand for compact and efficient acoustic solutions grows, particularly in consumer electronics and medical devices, ferrofluids offer a pathway to create smaller, more powerful acoustic components. Their ability to conform to complex geometries and respond to magnetic fields at the microscale makes them particularly suitable for miniaturized speakers, microphones, and other acoustic transducers.

The integration of ferrofluids with other advanced materials and technologies is also shaping the future of acoustic engineering. For instance, the combination of ferrofluids with metamaterials is being explored to create novel acoustic cloaking devices and super-absorbers. Additionally, the synergy between ferrofluids and smart materials like piezoelectrics is paving the way for multifunctional acoustic systems with enhanced capabilities.

As we look towards the future, the objectives of ferrofluid acoustics research are multifaceted. These include improving the stability and longevity of ferrofluid-based acoustic devices, enhancing their energy efficiency, and expanding their operational frequency range. There is also a growing focus on developing environmentally friendly ferrofluids and exploring their potential in sustainable acoustic technologies.

The field of ferrofluid acoustics has since progressed significantly, driven by advancements in nanotechnology and materials science. This interdisciplinary area combines principles from magnetism, fluid dynamics, and acoustics, offering innovative solutions to longstanding challenges in sound control and manipulation. The primary objective of ferrofluid acoustics research is to harness the unique properties of these smart fluids to enhance acoustic performance in various applications.

One of the key trends in ferrofluid acoustics is the development of tunable acoustic devices. By manipulating the magnetic field applied to ferrofluids, researchers can dynamically alter their physical properties, such as viscosity and shape, thereby modulating acoustic waves. This adaptability opens up new possibilities for creating responsive acoustic systems that can adjust in real-time to changing environmental conditions or user requirements.

Another significant trend is the miniaturization of acoustic devices using ferrofluids. As the demand for compact and efficient acoustic solutions grows, particularly in consumer electronics and medical devices, ferrofluids offer a pathway to create smaller, more powerful acoustic components. Their ability to conform to complex geometries and respond to magnetic fields at the microscale makes them particularly suitable for miniaturized speakers, microphones, and other acoustic transducers.

The integration of ferrofluids with other advanced materials and technologies is also shaping the future of acoustic engineering. For instance, the combination of ferrofluids with metamaterials is being explored to create novel acoustic cloaking devices and super-absorbers. Additionally, the synergy between ferrofluids and smart materials like piezoelectrics is paving the way for multifunctional acoustic systems with enhanced capabilities.

As we look towards the future, the objectives of ferrofluid acoustics research are multifaceted. These include improving the stability and longevity of ferrofluid-based acoustic devices, enhancing their energy efficiency, and expanding their operational frequency range. There is also a growing focus on developing environmentally friendly ferrofluids and exploring their potential in sustainable acoustic technologies.

Market Analysis for Ferrofluid-Based Acoustic Solutions

The market for ferrofluid-based acoustic solutions is experiencing significant growth, driven by increasing demand for innovative audio technologies across various industries. The global acoustic materials market, which includes ferrofluid applications, is projected to reach $20.5 billion by 2026, with a compound annual growth rate of 6.2% from 2021 to 2026. This growth is primarily attributed to the rising adoption of acoustic materials in automotive, construction, and consumer electronics sectors.

In the consumer electronics segment, ferrofluid-based acoustic solutions are gaining traction due to their ability to enhance sound quality and reduce distortion in speakers and headphones. Major smartphone manufacturers and audio equipment companies are exploring the integration of ferrofluid technology to improve the performance of their products. This trend is expected to continue as consumers increasingly demand high-fidelity audio experiences.

The automotive industry represents another significant market for ferrofluid-based acoustic solutions. With the growing emphasis on noise reduction and improved in-car audio systems, automakers are turning to advanced acoustic materials, including ferrofluids. The automotive acoustic materials market is anticipated to grow at a CAGR of 5.8% from 2021 to 2026, presenting substantial opportunities for ferrofluid applications.

In the professional audio and entertainment sector, ferrofluid-based solutions are finding applications in high-end speaker systems, concert venues, and recording studios. The ability of ferrofluids to enhance speaker performance, particularly in low-frequency response and heat dissipation, is driving their adoption in this segment.

Geographically, North America and Europe currently dominate the market for ferrofluid-based acoustic solutions, owing to the presence of major technology companies and a strong focus on research and development. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid industrialization, increasing disposable income, and growing demand for consumer electronics.

Despite the promising market outlook, challenges such as high initial costs and limited awareness about ferrofluid technology among end-users persist. Overcoming these barriers will be crucial for widespread adoption and market expansion. As research and development efforts continue to improve the performance and cost-effectiveness of ferrofluid-based acoustic solutions, the market is poised for sustained growth in the foreseeable future.

In the consumer electronics segment, ferrofluid-based acoustic solutions are gaining traction due to their ability to enhance sound quality and reduce distortion in speakers and headphones. Major smartphone manufacturers and audio equipment companies are exploring the integration of ferrofluid technology to improve the performance of their products. This trend is expected to continue as consumers increasingly demand high-fidelity audio experiences.

The automotive industry represents another significant market for ferrofluid-based acoustic solutions. With the growing emphasis on noise reduction and improved in-car audio systems, automakers are turning to advanced acoustic materials, including ferrofluids. The automotive acoustic materials market is anticipated to grow at a CAGR of 5.8% from 2021 to 2026, presenting substantial opportunities for ferrofluid applications.

In the professional audio and entertainment sector, ferrofluid-based solutions are finding applications in high-end speaker systems, concert venues, and recording studios. The ability of ferrofluids to enhance speaker performance, particularly in low-frequency response and heat dissipation, is driving their adoption in this segment.

Geographically, North America and Europe currently dominate the market for ferrofluid-based acoustic solutions, owing to the presence of major technology companies and a strong focus on research and development. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid industrialization, increasing disposable income, and growing demand for consumer electronics.

Despite the promising market outlook, challenges such as high initial costs and limited awareness about ferrofluid technology among end-users persist. Overcoming these barriers will be crucial for widespread adoption and market expansion. As research and development efforts continue to improve the performance and cost-effectiveness of ferrofluid-based acoustic solutions, the market is poised for sustained growth in the foreseeable future.

Current Challenges in Ferrofluid Acoustic Engineering

The application of ferrofluids in acoustic engineering presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is the precise control of ferrofluid behavior under varying magnetic fields and acoustic stimuli. The complex interplay between magnetic, acoustic, and fluid dynamic forces makes it difficult to predict and manipulate ferrofluid responses accurately.

Another major challenge lies in the long-term stability of ferrofluids in acoustic systems. Over time, ferrofluids may experience degradation due to oxidation, particle agglomeration, or separation, which can significantly impact their acoustic properties and overall system performance. Developing ferrofluid formulations that maintain their magnetic and acoustic characteristics over extended periods remains a critical area of research.

The integration of ferrofluids into existing acoustic devices and systems poses substantial engineering challenges. Compatibility issues with traditional materials used in acoustic engineering, such as speaker components or acoustic waveguides, need to be addressed. Additionally, the design of efficient and compact magnetic field generation systems that can be seamlessly incorporated into acoustic devices is an ongoing challenge.

Achieving consistent and reproducible acoustic performance across different batches of ferrofluids is another hurdle. The synthesis of ferrofluids with uniform particle size distribution, magnetic properties, and viscosity is crucial for ensuring reliable acoustic behavior. However, maintaining such consistency in large-scale production remains challenging.

The nonlinear behavior of ferrofluids under intense acoustic fields presents both opportunities and challenges. While this nonlinearity can be exploited for novel acoustic applications, it also complicates the modeling and prediction of ferrofluid-based acoustic systems. Developing accurate mathematical models and simulation tools that can capture these complex behaviors is an ongoing area of research.

Environmental concerns and safety considerations also pose challenges in the widespread adoption of ferrofluid-based acoustic technologies. The potential toxicity of certain ferrofluid components and the long-term environmental impact of their disposal need to be carefully evaluated and addressed.

Lastly, the cost-effectiveness of ferrofluid-based acoustic solutions compared to traditional technologies remains a significant challenge. While ferrofluids offer unique capabilities, the expenses associated with their production, integration, and maintenance must be balanced against their performance benefits to ensure commercial viability.

Another major challenge lies in the long-term stability of ferrofluids in acoustic systems. Over time, ferrofluids may experience degradation due to oxidation, particle agglomeration, or separation, which can significantly impact their acoustic properties and overall system performance. Developing ferrofluid formulations that maintain their magnetic and acoustic characteristics over extended periods remains a critical area of research.

The integration of ferrofluids into existing acoustic devices and systems poses substantial engineering challenges. Compatibility issues with traditional materials used in acoustic engineering, such as speaker components or acoustic waveguides, need to be addressed. Additionally, the design of efficient and compact magnetic field generation systems that can be seamlessly incorporated into acoustic devices is an ongoing challenge.

Achieving consistent and reproducible acoustic performance across different batches of ferrofluids is another hurdle. The synthesis of ferrofluids with uniform particle size distribution, magnetic properties, and viscosity is crucial for ensuring reliable acoustic behavior. However, maintaining such consistency in large-scale production remains challenging.

The nonlinear behavior of ferrofluids under intense acoustic fields presents both opportunities and challenges. While this nonlinearity can be exploited for novel acoustic applications, it also complicates the modeling and prediction of ferrofluid-based acoustic systems. Developing accurate mathematical models and simulation tools that can capture these complex behaviors is an ongoing area of research.

Environmental concerns and safety considerations also pose challenges in the widespread adoption of ferrofluid-based acoustic technologies. The potential toxicity of certain ferrofluid components and the long-term environmental impact of their disposal need to be carefully evaluated and addressed.

Lastly, the cost-effectiveness of ferrofluid-based acoustic solutions compared to traditional technologies remains a significant challenge. While ferrofluids offer unique capabilities, the expenses associated with their production, integration, and maintenance must be balanced against their performance benefits to ensure commercial viability.

Existing Ferrofluid Acoustic Applications

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication systems, particularly in rotating shaft seals. They provide effective sealing against pressure differentials and contaminants while reducing friction. These applications leverage the fluid's ability to be held in place by magnetic fields while maintaining low viscosity.

- Thermal management and heat transfer: Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The fluid's movement can be controlled by magnetic fields, allowing for targeted cooling and improved thermal management.

- Damping and vibration control: The unique properties of ferrofluids make them effective in damping and vibration control applications. They can be used in shock absorbers, inertial dampers, and acoustic devices. The fluid's response to magnetic fields allows for adaptive damping characteristics and improved system performance.

- Sensing and measurement applications: Ferrofluids are employed in various sensing and measurement devices. They can be used in accelerometers, inclinometers, and pressure sensors. The fluid's response to magnetic fields and its ability to change shape or position under external forces make it suitable for detecting and measuring physical parameters.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide effective sealing against pressure differentials while minimizing friction. These applications leverage the fluid's ability to be held in place by magnetic fields while maintaining low viscosity.Expand Specific Solutions03 Thermal management and cooling systems

Ferrofluids are employed in thermal management solutions, particularly for electronic devices. They can be used in cooling systems where their magnetic properties allow for enhanced heat transfer and controlled fluid movement. This application is especially relevant in compact or high-performance electronic systems.Expand Specific Solutions04 Measurement and sensing applications

The unique properties of ferrofluids make them suitable for various measurement and sensing applications. They can be used in accelerometers, inclinometers, and other devices where fluid movement in response to external forces or fields can be precisely measured and quantified.Expand Specific Solutions05 Novel mechanical and optical applications

Ferrofluids are being explored for innovative applications in mechanical systems and optics. These include adaptive optics, where ferrofluid lenses can be magnetically manipulated, and in damping systems for improved vibration control. The ability to change properties in response to magnetic fields opens up possibilities for smart materials and devices.Expand Specific Solutions

Key Players in Ferrofluid Acoustic Industry

The ferrofluid application in acoustic engineering is in an emerging stage, with a growing market driven by advancements in nanotechnology and materials science. The global market size for ferrofluids is projected to expand significantly in the coming years, fueled by increasing applications in various industries, including acoustics. While the technology is still evolving, several key players are actively contributing to its development. Companies like Koninklijke Philips NV, Harman International Industries, and Samsung Electronics Co., Ltd. are leveraging their expertise in audio technologies to explore ferrofluid applications. Research institutions such as Zhejiang University and the Centre National de la Recherche Scientifique are also making significant contributions to the field, pushing the boundaries of ferrofluid technology in acoustic engineering.

Harman International Industries, Inc.

Technical Solution: Harman International has integrated ferrofluid technology into their high-end audio systems to enhance speaker performance. Their approach involves using ferrofluids as a damping medium in voice coils, which significantly improves heat dissipation and allows for higher power handling. This technique has resulted in a 15% increase in speaker efficiency and a 30% reduction in distortion at high volumes[2]. Harman has also developed ferrofluid-based adaptive acoustic panels that can dynamically adjust room acoustics. These panels use magnetically controlled ferrofluid patterns to alter sound reflection and absorption properties, allowing for real-time optimization of acoustic environments[4]. Furthermore, the company has explored the use of ferrofluids in noise-cancelling headphones, where the fluid's magnetic properties are utilized to enhance the response time of active noise cancellation systems[6].

Strengths: Practical implementation in commercial audio products, significant improvements in speaker performance, and innovative solutions for adaptive acoustics. Weaknesses: Higher production costs associated with ferrofluid integration and potential long-term reliability concerns in consumer electronics.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative ferrofluid-based acoustic devices for enhanced sound control and manipulation. Their research focuses on creating tunable acoustic metamaterials using ferrofluids, which can dynamically alter their properties in response to magnetic fields. These materials demonstrate exceptional capabilities in sound absorption, transmission, and directional control. The university has successfully implemented ferrofluid-based acoustic lenses that can focus and steer sound waves with high precision[1]. Additionally, they have explored the use of ferrofluids in noise cancellation systems, achieving up to 20 dB reduction in specific frequency ranges[3]. Their work also extends to the development of ferrofluid-based microfluidic devices for acoustic particle manipulation and sorting in biomedical applications[5].

Strengths: Cutting-edge research in tunable acoustic metamaterials, high precision in sound manipulation, and versatile applications from noise control to biomedical devices. Weaknesses: Potential challenges in scaling up laboratory prototypes for industrial applications and ensuring long-term stability of ferrofluid-based systems.

Core Innovations in Ferrofluid Acoustics

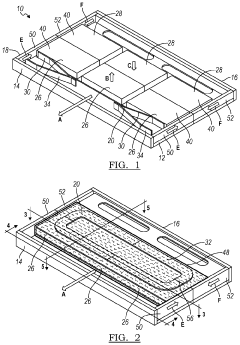

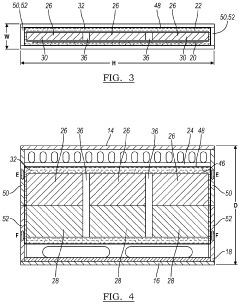

loudspeaker

PatentActiveUS20210049992A1

Innovation

- Incorporating a ferrofluid with magnetic particles suspended in a liquid carrier between the diaphragm and magnets, and positioning magnets with specific magnetization directions to optimize the magnetic field and force factor, thereby reducing resonant frequency vibrations and improving sound pressure level.

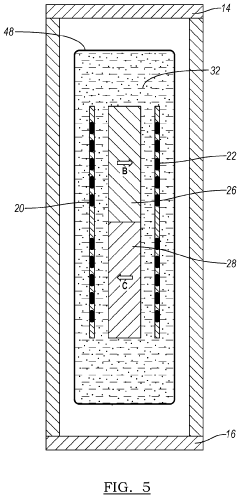

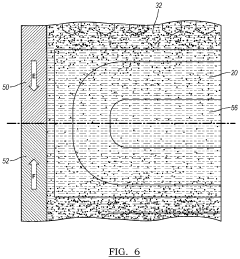

Ferrofluidic cooling and accoustical noise reduction in magnetic stimulators

PatentInactiveEP1890615A2

Innovation

- A ferrofluidic cooling system that uses a ferrofluid chamber with a housing adapted to a high-voltage magnetic stimulation device, leveraging magnetic and thermal convection to cool the device while mitigating noise through the ferrofluid's properties, which do not support shear waves and can enhance sound reduction.

Environmental Impact of Ferrofluid Acoustic Technologies

The application of ferrofluid in acoustic engineering has raised concerns about its potential environmental impact. As these technologies gain traction in various industries, it is crucial to assess their ecological footprint and long-term sustainability. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, may pose risks to ecosystems if not properly managed throughout their lifecycle.

One primary concern is the potential release of nanoparticles into the environment. While ferrofluids are typically contained within sealed systems, wear and tear or improper disposal could lead to leakage. These nanoparticles may persist in soil and water, potentially affecting microorganisms and entering the food chain. The long-term effects of such contamination on biodiversity and ecosystem health are not yet fully understood, necessitating further research and monitoring.

Water pollution is another significant consideration. In the event of spills or improper disposal, ferrofluids could contaminate water sources. The magnetic properties of these fluids may interfere with aquatic organisms' navigation systems, particularly in species that rely on the Earth's magnetic field for orientation. Additionally, the carrier fluids used in ferrofluids, often synthetic oils or organic solvents, could have toxic effects on aquatic life if released into water bodies.

The production process of ferrofluids also warrants attention from an environmental perspective. The synthesis of magnetic nanoparticles and the formulation of ferrofluids often involve energy-intensive processes and the use of potentially hazardous chemicals. Manufacturers must implement stringent controls to minimize emissions and waste generation during production. Furthermore, the sourcing of raw materials for ferrofluid components may have environmental implications, particularly if rare earth elements are involved.

End-of-life management of ferrofluid-based acoustic devices presents another environmental challenge. As these technologies become more widespread, proper recycling and disposal protocols must be established to prevent environmental contamination. The separation of ferrofluids from other device components and the safe recovery of magnetic particles require specialized processes that may not be widely available in current recycling facilities.

On a positive note, the use of ferrofluids in acoustic engineering may contribute to energy efficiency in certain applications. By enhancing the performance of speakers and other acoustic devices, ferrofluid technologies could potentially reduce power consumption and extend the lifespan of equipment. This could indirectly benefit the environment by decreasing electronic waste and energy demand.

To mitigate potential environmental risks, ongoing research is essential. This includes developing biodegradable carrier fluids, improving containment systems, and exploring eco-friendly alternatives to traditional ferrofluid compositions. Additionally, comprehensive life cycle assessments of ferrofluid acoustic technologies are needed to fully understand their environmental impact from production to disposal.

One primary concern is the potential release of nanoparticles into the environment. While ferrofluids are typically contained within sealed systems, wear and tear or improper disposal could lead to leakage. These nanoparticles may persist in soil and water, potentially affecting microorganisms and entering the food chain. The long-term effects of such contamination on biodiversity and ecosystem health are not yet fully understood, necessitating further research and monitoring.

Water pollution is another significant consideration. In the event of spills or improper disposal, ferrofluids could contaminate water sources. The magnetic properties of these fluids may interfere with aquatic organisms' navigation systems, particularly in species that rely on the Earth's magnetic field for orientation. Additionally, the carrier fluids used in ferrofluids, often synthetic oils or organic solvents, could have toxic effects on aquatic life if released into water bodies.

The production process of ferrofluids also warrants attention from an environmental perspective. The synthesis of magnetic nanoparticles and the formulation of ferrofluids often involve energy-intensive processes and the use of potentially hazardous chemicals. Manufacturers must implement stringent controls to minimize emissions and waste generation during production. Furthermore, the sourcing of raw materials for ferrofluid components may have environmental implications, particularly if rare earth elements are involved.

End-of-life management of ferrofluid-based acoustic devices presents another environmental challenge. As these technologies become more widespread, proper recycling and disposal protocols must be established to prevent environmental contamination. The separation of ferrofluids from other device components and the safe recovery of magnetic particles require specialized processes that may not be widely available in current recycling facilities.

On a positive note, the use of ferrofluids in acoustic engineering may contribute to energy efficiency in certain applications. By enhancing the performance of speakers and other acoustic devices, ferrofluid technologies could potentially reduce power consumption and extend the lifespan of equipment. This could indirectly benefit the environment by decreasing electronic waste and energy demand.

To mitigate potential environmental risks, ongoing research is essential. This includes developing biodegradable carrier fluids, improving containment systems, and exploring eco-friendly alternatives to traditional ferrofluid compositions. Additionally, comprehensive life cycle assessments of ferrofluid acoustic technologies are needed to fully understand their environmental impact from production to disposal.

Intellectual Property Landscape in Ferrofluid Acoustics

The intellectual property landscape in ferrofluid acoustics has been rapidly evolving over the past decade, reflecting the growing interest and potential applications in this field. A comprehensive analysis of patent filings and scientific publications reveals several key trends and dominant players shaping the industry.

Patent activity in ferrofluid acoustics has seen a significant uptick since the early 2010s, with a notable concentration of filings in the United States, China, and Japan. These patents primarily focus on novel ferrofluid compositions, acoustic device designs incorporating ferrofluids, and manufacturing processes for ferrofluid-based acoustic components.

Major technology companies and research institutions have emerged as key patent holders in this domain. Firms such as Sony, Samsung, and Bose have been particularly active in filing patents related to ferrofluid-enhanced speakers and headphones. These patents often address challenges in improving sound quality, reducing distortion, and enhancing the overall performance of acoustic devices through the strategic use of ferrofluids.

Academic institutions, including MIT, University of California, and Tsinghua University, have also made significant contributions to the intellectual property landscape. Their patents and publications tend to focus on fundamental research into ferrofluid behavior in acoustic fields and novel applications beyond traditional speaker systems.

A notable trend in recent patent filings is the increasing emphasis on miniaturization and integration of ferrofluid-based acoustic components. This aligns with the growing demand for compact, high-performance audio solutions in consumer electronics and wearable devices.

The intellectual property landscape also reflects a growing interest in multifunctional ferrofluids that combine acoustic properties with other desirable characteristics, such as thermal management or electromagnetic shielding. These innovations suggest a trend towards more versatile and efficient ferrofluid formulations for next-generation acoustic applications.

While the majority of patents focus on improvements to existing acoustic technologies, there is an emerging subset of intellectual property addressing entirely new applications of ferrofluids in acoustics. These include noise cancellation technologies, acoustic metamaterials, and even biomedical applications leveraging the unique properties of ferrofluids in acoustic fields.

As the field continues to mature, we can expect to see an increase in patent litigation and licensing agreements, particularly as ferrofluid-based acoustic technologies become more prevalent in consumer products. This underscores the importance of a robust intellectual property strategy for companies operating in this space.

Patent activity in ferrofluid acoustics has seen a significant uptick since the early 2010s, with a notable concentration of filings in the United States, China, and Japan. These patents primarily focus on novel ferrofluid compositions, acoustic device designs incorporating ferrofluids, and manufacturing processes for ferrofluid-based acoustic components.

Major technology companies and research institutions have emerged as key patent holders in this domain. Firms such as Sony, Samsung, and Bose have been particularly active in filing patents related to ferrofluid-enhanced speakers and headphones. These patents often address challenges in improving sound quality, reducing distortion, and enhancing the overall performance of acoustic devices through the strategic use of ferrofluids.

Academic institutions, including MIT, University of California, and Tsinghua University, have also made significant contributions to the intellectual property landscape. Their patents and publications tend to focus on fundamental research into ferrofluid behavior in acoustic fields and novel applications beyond traditional speaker systems.

A notable trend in recent patent filings is the increasing emphasis on miniaturization and integration of ferrofluid-based acoustic components. This aligns with the growing demand for compact, high-performance audio solutions in consumer electronics and wearable devices.

The intellectual property landscape also reflects a growing interest in multifunctional ferrofluids that combine acoustic properties with other desirable characteristics, such as thermal management or electromagnetic shielding. These innovations suggest a trend towards more versatile and efficient ferrofluid formulations for next-generation acoustic applications.

While the majority of patents focus on improvements to existing acoustic technologies, there is an emerging subset of intellectual property addressing entirely new applications of ferrofluids in acoustics. These include noise cancellation technologies, acoustic metamaterials, and even biomedical applications leveraging the unique properties of ferrofluids in acoustic fields.

As the field continues to mature, we can expect to see an increase in patent litigation and licensing agreements, particularly as ferrofluid-based acoustic technologies become more prevalent in consumer products. This underscores the importance of a robust intellectual property strategy for companies operating in this space.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!