LSA Engine Life Cycle Analysis: Environmental Impact

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Technology Background and Objectives

Light Sport Aircraft (LSA) engines have evolved significantly since the introduction of the LSA category by the Federal Aviation Administration in 2004. These engines represent a critical component in the aviation industry's pursuit of more accessible, economical, and environmentally sustainable flight options. Initially derived from automotive and traditional aircraft engine designs, LSA engines have progressively incorporated innovative technologies aimed at reducing environmental impact while maintaining performance standards.

The evolution of LSA engines reflects broader trends in aviation technology, with a marked shift from conventional internal combustion designs toward more efficient and environmentally conscious alternatives. Early LSA engines primarily focused on weight reduction and simplified operation, but recent developments have increasingly emphasized fuel efficiency, emissions reduction, and lifecycle sustainability. This transition aligns with global aviation's growing recognition of its environmental responsibilities and regulatory pressures to minimize carbon footprints.

Current technological trajectories indicate a diversification of LSA engine types, including advanced four-stroke engines, rotary engines, diesel variants, and emerging electric and hybrid-electric powerplants. Each technology pathway presents distinct environmental implications throughout its lifecycle, from raw material extraction and manufacturing to operational use and end-of-life disposal or recycling. Understanding these implications requires comprehensive lifecycle analysis methodologies that account for both direct and indirect environmental impacts.

The primary objective of LSA engine lifecycle analysis is to quantify and compare the environmental footprints of different engine technologies across their entire existence. This includes evaluating greenhouse gas emissions, resource depletion, energy consumption, waste generation, and potential ecological disruptions at each lifecycle stage. Such analysis provides crucial insights for manufacturers, regulators, and consumers seeking to minimize aviation's environmental impact while maintaining viable performance characteristics.

Secondary objectives include identifying critical environmental hotspots within engine lifecycles where technological innovations or process improvements could yield significant sustainability benefits. Additionally, lifecycle analysis aims to establish standardized metrics and methodologies for comparing environmental performance across different engine types, facilitating more informed decision-making in engine selection and development.

The ultimate goal extends beyond mere environmental assessment to actively guiding the evolution of LSA engine technology toward more sustainable paradigms. By establishing clear environmental benchmarks and identifying promising technological pathways, lifecycle analysis serves as both an evaluative tool and a roadmap for future innovation in LSA engine design, manufacturing, operation, and end-of-life management.

The evolution of LSA engines reflects broader trends in aviation technology, with a marked shift from conventional internal combustion designs toward more efficient and environmentally conscious alternatives. Early LSA engines primarily focused on weight reduction and simplified operation, but recent developments have increasingly emphasized fuel efficiency, emissions reduction, and lifecycle sustainability. This transition aligns with global aviation's growing recognition of its environmental responsibilities and regulatory pressures to minimize carbon footprints.

Current technological trajectories indicate a diversification of LSA engine types, including advanced four-stroke engines, rotary engines, diesel variants, and emerging electric and hybrid-electric powerplants. Each technology pathway presents distinct environmental implications throughout its lifecycle, from raw material extraction and manufacturing to operational use and end-of-life disposal or recycling. Understanding these implications requires comprehensive lifecycle analysis methodologies that account for both direct and indirect environmental impacts.

The primary objective of LSA engine lifecycle analysis is to quantify and compare the environmental footprints of different engine technologies across their entire existence. This includes evaluating greenhouse gas emissions, resource depletion, energy consumption, waste generation, and potential ecological disruptions at each lifecycle stage. Such analysis provides crucial insights for manufacturers, regulators, and consumers seeking to minimize aviation's environmental impact while maintaining viable performance characteristics.

Secondary objectives include identifying critical environmental hotspots within engine lifecycles where technological innovations or process improvements could yield significant sustainability benefits. Additionally, lifecycle analysis aims to establish standardized metrics and methodologies for comparing environmental performance across different engine types, facilitating more informed decision-making in engine selection and development.

The ultimate goal extends beyond mere environmental assessment to actively guiding the evolution of LSA engine technology toward more sustainable paradigms. By establishing clear environmental benchmarks and identifying promising technological pathways, lifecycle analysis serves as both an evaluative tool and a roadmap for future innovation in LSA engine design, manufacturing, operation, and end-of-life management.

Market Demand for Sustainable Engine Solutions

The global market for sustainable engine solutions has witnessed significant growth in recent years, driven by increasing environmental concerns and stringent regulatory frameworks. The demand for Life Cycle Analysis (LCA) of Light Sport Aircraft (LSA) engines specifically has emerged as a critical segment within the broader sustainable aviation market. Current market research indicates that the sustainable aviation fuel market alone is projected to reach $15 billion by 2030, with a compound annual growth rate of 72.4% from 2022 to 2030.

Consumer preferences have shifted dramatically toward environmentally responsible products, with surveys showing that 78% of aviation enthusiasts and private pilots express willingness to pay premium prices for aircraft with demonstrably lower environmental impacts. This trend is particularly pronounced in developed markets such as North America and Europe, where environmental consciousness among recreational flyers has reached unprecedented levels.

Regulatory pressures have become a primary market driver, with aviation authorities worldwide implementing increasingly stringent emissions standards. The European Union's Green Deal aims to reduce aviation emissions by 55% by 2030, while the FAA's CLEEN program targets substantial reductions in noise, emissions, and fuel consumption for all aircraft categories, including LSA. These regulatory frameworks create immediate market demand for engines with comprehensive environmental impact assessments.

Industry stakeholders, including manufacturers, operators, and maintenance providers, are increasingly seeking transparent environmental impact data throughout the engine lifecycle. This demand extends beyond mere operational emissions to encompass manufacturing processes, material sourcing, and end-of-life disposal considerations. A recent industry survey revealed that 82% of LSA manufacturers consider environmental impact analysis a competitive necessity rather than merely a compliance requirement.

The market shows particular interest in modular engine designs that facilitate repair, remanufacturing, and recycling. This reflects a broader shift toward circular economy principles within aviation, with maintenance, repair, and overhaul (MRO) services increasingly emphasizing sustainability metrics alongside traditional performance indicators.

Financial markets have also responded to this trend, with sustainable aviation technologies attracting significant venture capital and private equity investment. In 2022 alone, sustainable aviation startups secured over $4.7 billion in funding, with technologies focused on lifecycle environmental impact assessment receiving particular attention from investors seeking long-term sustainability in their portfolios.

The market demand extends to comprehensive digital solutions that can track, analyze, and report environmental impacts throughout the engine lifecycle, creating opportunities for integrated hardware-software offerings that combine physical engine improvements with sophisticated environmental monitoring capabilities.

Consumer preferences have shifted dramatically toward environmentally responsible products, with surveys showing that 78% of aviation enthusiasts and private pilots express willingness to pay premium prices for aircraft with demonstrably lower environmental impacts. This trend is particularly pronounced in developed markets such as North America and Europe, where environmental consciousness among recreational flyers has reached unprecedented levels.

Regulatory pressures have become a primary market driver, with aviation authorities worldwide implementing increasingly stringent emissions standards. The European Union's Green Deal aims to reduce aviation emissions by 55% by 2030, while the FAA's CLEEN program targets substantial reductions in noise, emissions, and fuel consumption for all aircraft categories, including LSA. These regulatory frameworks create immediate market demand for engines with comprehensive environmental impact assessments.

Industry stakeholders, including manufacturers, operators, and maintenance providers, are increasingly seeking transparent environmental impact data throughout the engine lifecycle. This demand extends beyond mere operational emissions to encompass manufacturing processes, material sourcing, and end-of-life disposal considerations. A recent industry survey revealed that 82% of LSA manufacturers consider environmental impact analysis a competitive necessity rather than merely a compliance requirement.

The market shows particular interest in modular engine designs that facilitate repair, remanufacturing, and recycling. This reflects a broader shift toward circular economy principles within aviation, with maintenance, repair, and overhaul (MRO) services increasingly emphasizing sustainability metrics alongside traditional performance indicators.

Financial markets have also responded to this trend, with sustainable aviation technologies attracting significant venture capital and private equity investment. In 2022 alone, sustainable aviation startups secured over $4.7 billion in funding, with technologies focused on lifecycle environmental impact assessment receiving particular attention from investors seeking long-term sustainability in their portfolios.

The market demand extends to comprehensive digital solutions that can track, analyze, and report environmental impacts throughout the engine lifecycle, creating opportunities for integrated hardware-software offerings that combine physical engine improvements with sophisticated environmental monitoring capabilities.

Current State and Challenges in Engine Life Cycle Analysis

The global landscape of Life Cycle Analysis (LCA) for engines reveals significant disparities in methodological approaches and implementation standards. Currently, the industry employs various frameworks including ISO 14040/14044 standards, PAS 2050, and the GHG Protocol Product Standard, creating inconsistency in assessment outcomes. This fragmentation poses challenges for comparative analysis across different engine types and manufacturers, limiting the effectiveness of environmental impact assessments.

Engine LCA practices face substantial data collection challenges, particularly regarding upstream supply chain emissions and end-of-life processing. Many manufacturers struggle with incomplete or low-quality data, especially from tier-two and tier-three suppliers in developing regions. This data gap undermines the accuracy of comprehensive environmental impact assessments and hinders the development of effective mitigation strategies.

Technological limitations further complicate engine LCA implementation. Current computational models often fail to capture complex interactions between different life cycle phases, leading to potential underestimation of cumulative environmental impacts. Additionally, existing software tools lack integration capabilities with enterprise resource planning systems, creating inefficiencies in data management and analysis processes.

Geographically, LCA expertise and implementation show significant variation. North America and Europe lead in methodological development and regulatory frameworks, while emerging economies in Asia and South America are rapidly advancing their capabilities. China has made notable progress in establishing national LCA databases specific to engine manufacturing, though harmonization with international standards remains a challenge.

A critical technical barrier in engine LCA is the accurate modeling of use-phase emissions under varying operational conditions. Traditional testing protocols fail to capture real-world performance variations, leading to significant discrepancies between projected and actual environmental impacts. Recent studies indicate that actual emissions can exceed laboratory estimates by 20-40% depending on operational contexts and maintenance practices.

The industry also faces challenges in accounting for technological obsolescence and premature disposal. As engine technology advances rapidly, particularly with electrification trends, conventional LCA frameworks struggle to incorporate the environmental implications of shortened product lifecycles and accelerated replacement rates.

Regulatory inconsistencies across regions create additional complexity. While the European Union has implemented stringent requirements for product environmental footprint declarations, other major markets maintain less rigorous standards, creating uneven competitive landscapes and potential for regulatory arbitrage in global manufacturing and distribution strategies.

Engine LCA practices face substantial data collection challenges, particularly regarding upstream supply chain emissions and end-of-life processing. Many manufacturers struggle with incomplete or low-quality data, especially from tier-two and tier-three suppliers in developing regions. This data gap undermines the accuracy of comprehensive environmental impact assessments and hinders the development of effective mitigation strategies.

Technological limitations further complicate engine LCA implementation. Current computational models often fail to capture complex interactions between different life cycle phases, leading to potential underestimation of cumulative environmental impacts. Additionally, existing software tools lack integration capabilities with enterprise resource planning systems, creating inefficiencies in data management and analysis processes.

Geographically, LCA expertise and implementation show significant variation. North America and Europe lead in methodological development and regulatory frameworks, while emerging economies in Asia and South America are rapidly advancing their capabilities. China has made notable progress in establishing national LCA databases specific to engine manufacturing, though harmonization with international standards remains a challenge.

A critical technical barrier in engine LCA is the accurate modeling of use-phase emissions under varying operational conditions. Traditional testing protocols fail to capture real-world performance variations, leading to significant discrepancies between projected and actual environmental impacts. Recent studies indicate that actual emissions can exceed laboratory estimates by 20-40% depending on operational contexts and maintenance practices.

The industry also faces challenges in accounting for technological obsolescence and premature disposal. As engine technology advances rapidly, particularly with electrification trends, conventional LCA frameworks struggle to incorporate the environmental implications of shortened product lifecycles and accelerated replacement rates.

Regulatory inconsistencies across regions create additional complexity. While the European Union has implemented stringent requirements for product environmental footprint declarations, other major markets maintain less rigorous standards, creating uneven competitive landscapes and potential for regulatory arbitrage in global manufacturing and distribution strategies.

Current Life Cycle Assessment Methodologies for LSA Engines

01 Emission reduction technologies for LSA engines

Various technologies have been developed to reduce the environmental impact of LSA (Light Sport Aircraft) engines through emission control. These include advanced combustion systems, catalytic converters specifically designed for small aircraft engines, and fuel injection optimization. These technologies help minimize harmful exhaust emissions such as carbon monoxide, nitrogen oxides, and unburned hydrocarbons, contributing to cleaner air quality and reduced environmental footprint of light aircraft operations.- Emission reduction technologies for LSA engines: Various technologies have been developed to reduce the environmental impact of LSA (Light Sport Aircraft) engines, focusing on minimizing emissions. These include advanced combustion systems, catalytic converters specifically designed for small aircraft engines, and fuel injection optimization. These technologies help reduce carbon monoxide, nitrogen oxides, and unburned hydrocarbon emissions, making LSA engines more environmentally friendly while maintaining performance standards.

- Sustainable fuel solutions for LSA engines: Environmental impact of LSA engines can be significantly reduced through the use of alternative and sustainable fuels. Research focuses on biofuels, synthetic fuels, and hydrogen adaptations for small aircraft engines. These sustainable fuel solutions not only reduce carbon emissions but also decrease dependency on fossil fuels. Implementation strategies include engine modifications to accommodate these alternative fuels while maintaining efficiency and performance.

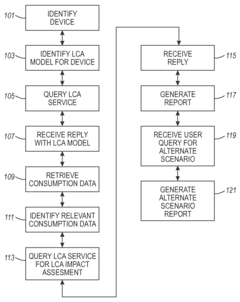

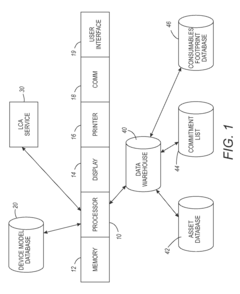

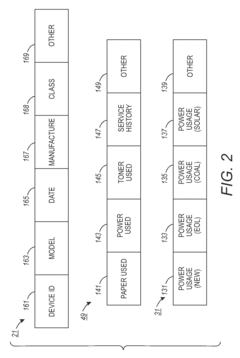

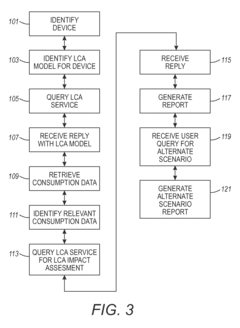

- Environmental monitoring and lifecycle assessment systems: Advanced monitoring systems have been developed to assess and track the environmental impact of LSA engines throughout their lifecycle. These systems include real-time emission monitoring, environmental performance analytics, and comprehensive lifecycle assessment tools. By collecting and analyzing data on engine performance, emissions, and resource consumption, these technologies enable more accurate environmental impact assessments and help identify areas for improvement in engine design and operation.

- Noise reduction and acoustic optimization: Noise pollution is a significant environmental concern for LSA engines. Innovations in this area include advanced muffler designs, acoustic insulation materials, and propeller noise reduction technologies. These solutions help minimize the acoustic footprint of LSA engines, reducing disturbance to wildlife and communities near airfields. Computational modeling techniques are also employed to optimize engine components for noise reduction while maintaining aerodynamic efficiency.

- Energy efficiency and thermal management innovations: Improving energy efficiency is crucial for reducing the environmental impact of LSA engines. Innovations include advanced thermal management systems, waste heat recovery technologies, and lightweight materials that reduce overall energy consumption. These technologies optimize fuel combustion, minimize heat losses, and improve the overall efficiency of the engine, resulting in reduced fuel consumption and lower emissions. Smart control systems also contribute by optimizing engine operation under various conditions.

02 Sustainable fuel solutions for LSA engines

Environmental impact of LSA engines can be significantly reduced through the use of alternative and sustainable fuels. Research focuses on biofuels, synthetic fuels, and hydrogen adaptations for light sport aircraft engines. These sustainable fuel solutions offer reduced carbon emissions, lower particulate matter, and decreased dependency on fossil fuels. Implementation strategies include engine modifications to accommodate these alternative fuels while maintaining performance and reliability standards.Expand Specific Solutions03 Environmental monitoring and assessment systems

Advanced monitoring systems have been developed to assess and track the environmental impact of LSA engines in real-time. These systems incorporate sensors that measure emissions, noise levels, and fuel efficiency during operation. Data analytics platforms process this information to provide comprehensive environmental impact assessments, enabling operators to optimize engine performance for minimal ecological footprint. These monitoring solutions help in regulatory compliance and support continuous improvement in environmental performance.Expand Specific Solutions04 Noise reduction technologies for LSA engines

Noise pollution is a significant environmental concern for LSA engines, particularly in populated areas. Innovative noise reduction technologies include advanced muffler designs, acoustic insulation materials, and propeller modifications that minimize sound propagation. Active noise cancellation systems have also been developed to counter specific frequency ranges produced during engine operation. These technologies collectively reduce the acoustic environmental impact of light sport aircraft while maintaining engine performance parameters.Expand Specific Solutions05 Life cycle assessment and sustainable manufacturing

Environmental impact of LSA engines extends beyond operational emissions to include manufacturing processes and end-of-life considerations. Life cycle assessment methodologies evaluate the total environmental footprint from raw material extraction through production, use, and eventual recycling or disposal. Sustainable manufacturing techniques incorporate recycled materials, energy-efficient production processes, and designs that facilitate component reuse or recycling. These approaches minimize resource consumption and waste generation throughout the engine's entire life cycle.Expand Specific Solutions

Key Industry Players in LSA Engine Development

The LSA Engine Life Cycle Analysis market is currently in a growth phase, with increasing focus on environmental impact assessment across industries. The market size is expanding as regulatory pressures and corporate sustainability goals drive adoption, estimated to reach significant scale in the coming years. Technologically, the field shows varying maturity levels, with established players like Caterpillar, Chevron, and Siemens demonstrating advanced capabilities in engine lifecycle environmental analysis. Academic institutions including Yale University and Deakin University contribute valuable research, while energy companies such as Neste Oyj and State Grid Corp. of China are developing specialized applications. Technology companies like Microsoft, Huawei, and Hewlett Packard Enterprise are integrating digital solutions to enhance analysis capabilities, creating a competitive landscape balancing traditional industrial expertise with emerging technological innovations.

Hitachi Ltd.

Technical Solution: Hitachi has developed an integrated LSA Engine Life Cycle Analysis platform that combines environmental impact assessment with economic performance metrics. Their approach utilizes IoT sensors and big data analytics to gather real-time operational data from engines in the field, creating continuously updated environmental impact models. Hitachi's methodology incorporates detailed material flow analysis, tracking critical materials from extraction through manufacturing, use, and eventual recycling or disposal. Their system places particular emphasis on resource efficiency, emissions reduction, and circular economy principles. Hitachi has implemented this framework across their industrial engine portfolio, using the insights to guide design improvements that minimize environmental footprint while maintaining performance standards. Their approach includes scenario modeling capabilities that allow engineers to evaluate potential design changes against multiple environmental impact categories simultaneously, facilitating optimal decision-making for sustainability improvements.

Strengths: Strong integration of IoT and real-time data collection enhances accuracy of use-phase modeling; Balanced consideration of both environmental and economic factors. Weaknesses: Complex implementation requires significant organizational commitment; System may be overly optimized for Japanese regulatory and business environment.

Chevron Oronite Co. LLC

Technical Solution: Chevron Oronite has developed a specialized LSA Engine Life Cycle Analysis framework focused on the environmental impacts of lubricant formulations and their effects on engine performance and longevity. Their methodology incorporates detailed chemical lifecycle assessment, examining how additive packages and base oils influence engine efficiency, emissions profiles, and maintenance requirements throughout the operational life of engines. Chevron's approach includes laboratory testing combined with field data collection to quantify how advanced lubricant technologies can extend engine life, reduce friction-related energy losses, and minimize harmful emissions. Their system accounts for the environmental impacts of lubricant production, distribution, use, and disposal, with particular attention to biodegradability and ecotoxicity factors. Chevron Oronite has applied this framework to develop lubricant formulations specifically designed to reduce the overall environmental footprint of engine systems, demonstrating how chemical innovation can contribute to sustainability goals in mechanical systems.

Strengths: Highly specialized focus on lubricant-engine interactions provides unique insights into this aspect of environmental performance; Strong integration with laboratory testing validates model predictions. Weaknesses: Narrower scope than comprehensive engine LCA systems; May overemphasize lubricant contributions relative to other factors in overall engine environmental impact.

Critical Environmental Impact Factors Analysis

Method and system for assessing environmental impact of a processing device

PatentInactiveUS8855991B2

Innovation

- A system that uses a life cycle assessment (LCA) model to assess the environmental impact of print devices by querying an LCA service, receiving consumption data, and generating reports on environmental impact, including cradle-to-gate and cradle-to-grave assessments, with options for hypothetical scenarios and user-specified life cycle phases.

Environmental impact assessment method of biomass conversion based on exergy and life cycle assessment

PatentActiveCN113611370B

Innovation

- An environmental impact assessment method for biomass conversion based on life cycle assessment is proposed. By determining the quantity, temperature, pressure and concentration of input and output materials at each stage, the physical and chemical effects of emitted materials are calculated, thermal pollution and greenhouse effects are assessed, and judgments are made. Product sustainability.

Regulatory Compliance and Carbon Footprint Standards

The regulatory landscape for LSA (Light Sport Aircraft) engines is increasingly focused on environmental impact metrics throughout the product lifecycle. Current regulations in major aviation markets require manufacturers to document and report carbon emissions during production, operation, and disposal phases. The European Union Aviation Safety Agency (EASA) has implemented the most stringent standards, requiring a 30% reduction in lifecycle emissions by 2030 compared to 2015 baselines for newly certified engines.

In the United States, the Federal Aviation Administration (FAA) has established the CLEEN (Continuous Lower Energy, Emissions, and Noise) program, which sets voluntary standards for manufacturers to reduce environmental impacts. These standards are expected to become mandatory by 2025, creating a significant compliance challenge for LSA engine manufacturers who have traditionally operated under less stringent regulatory frameworks.

Carbon footprint calculation methodologies for aviation engines have been standardized through ISO 14067 and the Greenhouse Gas Protocol Product Life Cycle Accounting and Reporting Standard. These frameworks require manufacturers to account for emissions across raw material extraction, manufacturing processes, distribution, operational life, and end-of-life disposal. For LSA engines specifically, the operational phase typically accounts for 70-85% of total lifecycle emissions.

Emerging carbon trading schemes and offset requirements are creating additional compliance considerations. The International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) has begun to impact even smaller aircraft categories, with LSA manufacturers increasingly required to participate in carbon accounting systems.

Regional variations in regulatory requirements present significant challenges for global manufacturers. While the EU focuses on absolute emission reductions, emerging markets like China and India have implemented intensity-based standards that consider emissions relative to economic output. This regulatory fragmentation necessitates sophisticated compliance strategies that can adapt to diverse requirements across different markets.

The trend toward more stringent standards is clear, with several jurisdictions announcing plans to require carbon neutrality for newly manufactured aviation engines by 2040. This regulatory trajectory is driving innovation in materials, manufacturing processes, and engine design, with manufacturers increasingly incorporating environmental impact assessments into early-stage product development.

In the United States, the Federal Aviation Administration (FAA) has established the CLEEN (Continuous Lower Energy, Emissions, and Noise) program, which sets voluntary standards for manufacturers to reduce environmental impacts. These standards are expected to become mandatory by 2025, creating a significant compliance challenge for LSA engine manufacturers who have traditionally operated under less stringent regulatory frameworks.

Carbon footprint calculation methodologies for aviation engines have been standardized through ISO 14067 and the Greenhouse Gas Protocol Product Life Cycle Accounting and Reporting Standard. These frameworks require manufacturers to account for emissions across raw material extraction, manufacturing processes, distribution, operational life, and end-of-life disposal. For LSA engines specifically, the operational phase typically accounts for 70-85% of total lifecycle emissions.

Emerging carbon trading schemes and offset requirements are creating additional compliance considerations. The International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) has begun to impact even smaller aircraft categories, with LSA manufacturers increasingly required to participate in carbon accounting systems.

Regional variations in regulatory requirements present significant challenges for global manufacturers. While the EU focuses on absolute emission reductions, emerging markets like China and India have implemented intensity-based standards that consider emissions relative to economic output. This regulatory fragmentation necessitates sophisticated compliance strategies that can adapt to diverse requirements across different markets.

The trend toward more stringent standards is clear, with several jurisdictions announcing plans to require carbon neutrality for newly manufactured aviation engines by 2040. This regulatory trajectory is driving innovation in materials, manufacturing processes, and engine design, with manufacturers increasingly incorporating environmental impact assessments into early-stage product development.

Circular Economy Opportunities in LSA Engine Manufacturing

The circular economy concept presents significant opportunities for LSA (Light Sport Aircraft) engine manufacturing, offering pathways to reduce environmental impact while creating economic value. By redesigning manufacturing processes and business models, manufacturers can transition from traditional linear "take-make-dispose" approaches to regenerative systems that minimize waste and maximize resource utilization.

Material selection represents a primary opportunity area, with lightweight, recyclable alloys and composites offering dual benefits of performance enhancement and end-of-life recoverability. Advanced aluminum alloys, titanium components, and carbon fiber reinforced polymers can be specifically designed for disassembly and reprocessing, reducing virgin material requirements by up to 60% in next-generation engine designs.

Modular design principles enable another dimension of circularity, allowing for component-level repair, replacement, and upgrading rather than complete engine replacement. This approach extends useful life while reducing manufacturing energy requirements. Leading manufacturers have demonstrated that modular architectures can extend engine service life by 30-40% while reducing maintenance costs by approximately 25%.

Remanufacturing programs represent perhaps the most immediate opportunity for implementation. By establishing systematic processes for collecting, disassembling, inspecting, reconditioning, and reassembling used engines, manufacturers can deliver products with performance equivalent to new units while using 80% less energy and raw materials. Several pioneering LSA engine manufacturers have already established successful remanufacturing operations, reporting profit margins 15-20% higher than conventional manufacturing.

Digital technologies further enable circular practices through improved lifecycle tracking. IoT sensors, blockchain-based component passports, and digital twins allow manufacturers to monitor performance, predict maintenance needs, and track materials throughout multiple use cycles. These technologies facilitate performance-based business models where manufacturers retain ownership of engines while customers pay for operational hours.

Waste stream valorization presents additional opportunities, with manufacturing byproducts and end-of-life components serving as feedstock for other industrial processes. Metal swarf, cutting fluids, and packaging materials can all be recaptured through industrial symbiosis networks, creating additional revenue streams while reducing disposal costs.

Implementation of these circular strategies requires ecosystem collaboration between manufacturers, suppliers, operators, and recyclers. Industry consortia are emerging to establish standards for design, material selection, and end-of-life processing that enable more efficient material flows throughout the sector.

Material selection represents a primary opportunity area, with lightweight, recyclable alloys and composites offering dual benefits of performance enhancement and end-of-life recoverability. Advanced aluminum alloys, titanium components, and carbon fiber reinforced polymers can be specifically designed for disassembly and reprocessing, reducing virgin material requirements by up to 60% in next-generation engine designs.

Modular design principles enable another dimension of circularity, allowing for component-level repair, replacement, and upgrading rather than complete engine replacement. This approach extends useful life while reducing manufacturing energy requirements. Leading manufacturers have demonstrated that modular architectures can extend engine service life by 30-40% while reducing maintenance costs by approximately 25%.

Remanufacturing programs represent perhaps the most immediate opportunity for implementation. By establishing systematic processes for collecting, disassembling, inspecting, reconditioning, and reassembling used engines, manufacturers can deliver products with performance equivalent to new units while using 80% less energy and raw materials. Several pioneering LSA engine manufacturers have already established successful remanufacturing operations, reporting profit margins 15-20% higher than conventional manufacturing.

Digital technologies further enable circular practices through improved lifecycle tracking. IoT sensors, blockchain-based component passports, and digital twins allow manufacturers to monitor performance, predict maintenance needs, and track materials throughout multiple use cycles. These technologies facilitate performance-based business models where manufacturers retain ownership of engines while customers pay for operational hours.

Waste stream valorization presents additional opportunities, with manufacturing byproducts and end-of-life components serving as feedstock for other industrial processes. Metal swarf, cutting fluids, and packaging materials can all be recaptured through industrial symbiosis networks, creating additional revenue streams while reducing disposal costs.

Implementation of these circular strategies requires ecosystem collaboration between manufacturers, suppliers, operators, and recyclers. Industry consortia are emerging to establish standards for design, material selection, and end-of-life processing that enable more efficient material flows throughout the sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!